A process for extracting vanadium from high-silicon vanadium-containing molten iron converter

A high-silicon and molten iron technology, applied in the manufacture of converters, etc., can solve the problems of high vanadium content and high-grade vanadium slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

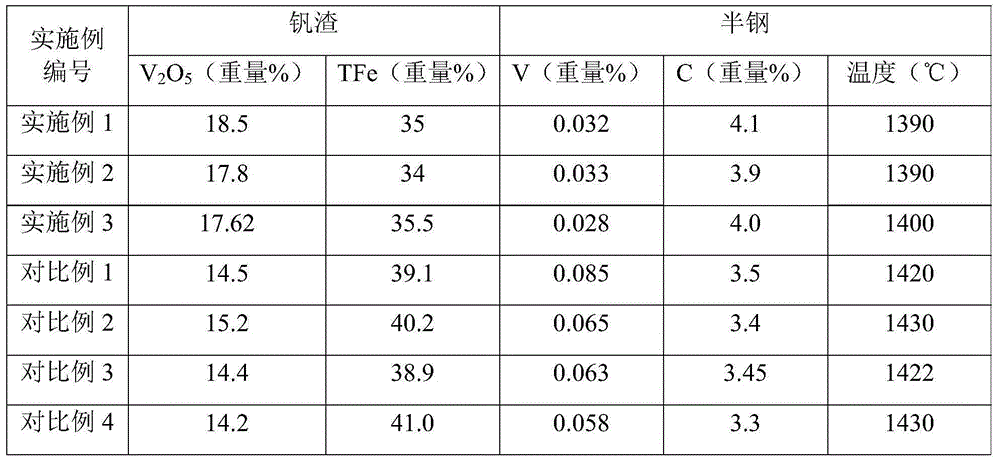

Embodiment 1

[0018] Load 140t of high-silicon vanadium-containing molten iron into the vanadium-extracting converter, and the high-silicon vanadium-containing molten iron into the furnace contains 4.55% by weight of C, 0.3% by weight of Si, 0.29% by weight of Mn, 0.26% by weight of Ti, and 0.25% by weight of V, 0.064% by weight of P, 0.005% by weight of S, and the balance being Fe. The temperature of the high-silicon vanadium-containing molten iron entering the furnace is 1280°C. Oxygen is blown into the converter through the oxygen lance (the position of the control lance is 1.7m) for blowing, the total amount of oxygen blowing is 9.6m 3 / t of high-silicon vanadium-containing molten iron, the temperature at the end of blowing is controlled at 1410°C (the blowing time is 5 minutes). When blowing 1min, add coolant (containing 40% by weight of Fe 2 o 3 , 50 wt% FeO, 10 wt% SiO 2 ), the addition amount is 35.7kg / t high-silicon vanadium-containing molten iron. C content and V content in s...

Embodiment 2

[0020] Load 140t of high-silicon vanadium-containing molten iron into the vanadium-extracting converter, and the high-silicon vanadium-containing molten iron into the furnace contains 4.45% by weight of C, 0.2% by weight of Si, 0.26% by weight of Mn, 0.27% by weight of Ti, and 0.28% by weight of V, 0.068% by weight of P, 0.006% by weight of S, and the rest being Fe. The temperature of the high-silicon vanadium-containing molten iron entering the furnace is 1270°C. Oxygen is blown into the converter through the oxygen lance (the control lance position is 1.75m) for blowing, the total amount of oxygen blowing is 8.6m 3 / t of high-silicon vanadium-containing molten iron, the temperature at the end of blowing is controlled at 1390°C (the blowing time is 4.5min). When blowing 1min, add coolant (containing 45% by weight of Fe 2 o 3 , 40 wt% FeO, 15 wt% SiO 2 ), the addition amount is 32.1kg / t high-silicon vanadium-containing molten iron. C content and V content in semi-steel ob...

Embodiment 3

[0022] Load 140t of high-silicon vanadium-containing molten iron into the vanadium-extracting converter, and the high-silicon vanadium-containing molten iron into the furnace contains 4.45% by weight of C, 0.25% by weight of Si, 0.30% by weight of Mn, 0.28% by weight of Ti, and 0.29% by weight of V, 0.069% by weight of P, 0.005% by weight of S, and the rest being Fe. The temperature of the high-silicon vanadium-containing molten iron entering the furnace is 1275°C. Oxygen is blown into the converter through the oxygen lance (the control lance position is 1.65m) for blowing, the total amount of oxygen blowing is 9.1m 3 / t of high-silicon vanadium-containing molten iron, the temperature at the end of blowing is controlled at 1400°C (the blowing time is 4.8min). When blowing 1min, add coolant (containing 40% by weight of Fe 2 o 3 , 40 wt% FeO, 20 wt% SiO 2 ), the addition amount is 33.9kg / t high-silicon vanadium-containing molten iron. C content and V content in semi-steel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com