Patents

Literature

117results about How to "Not easy to sinter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength lamellar Al-based metal ceramic composite material and preparation method thereof

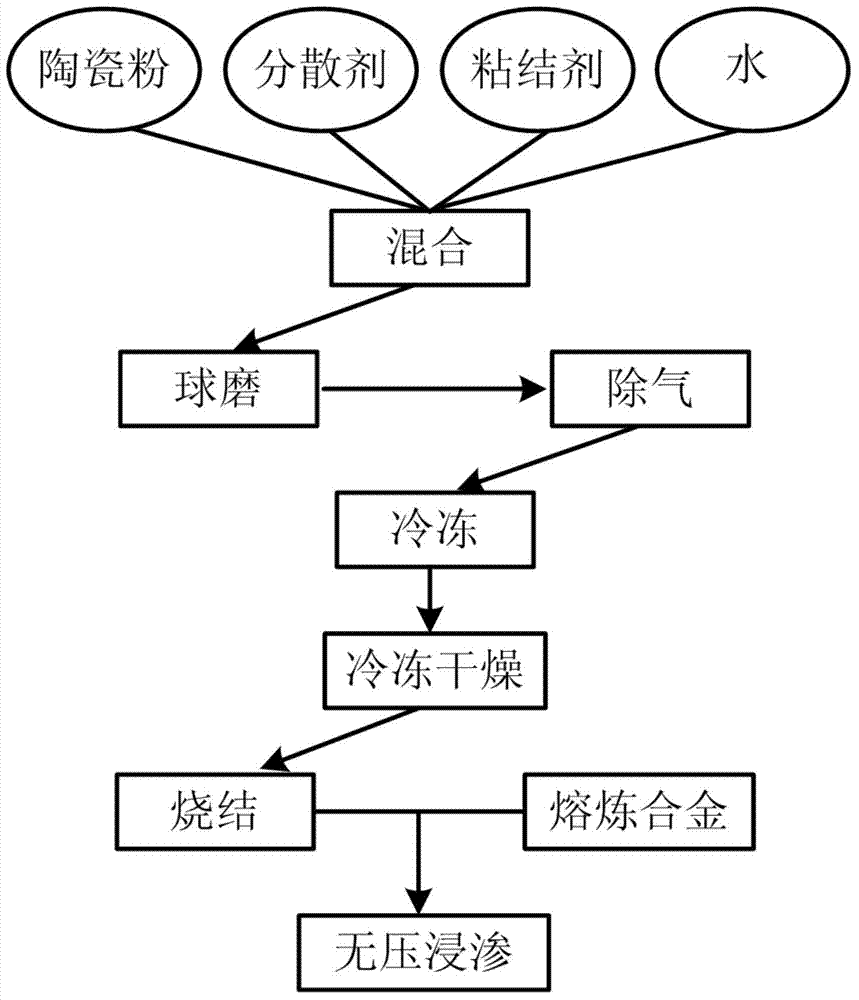

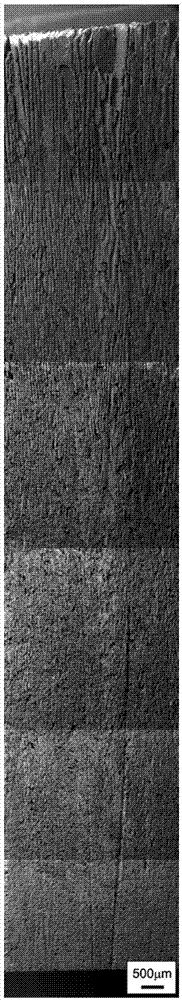

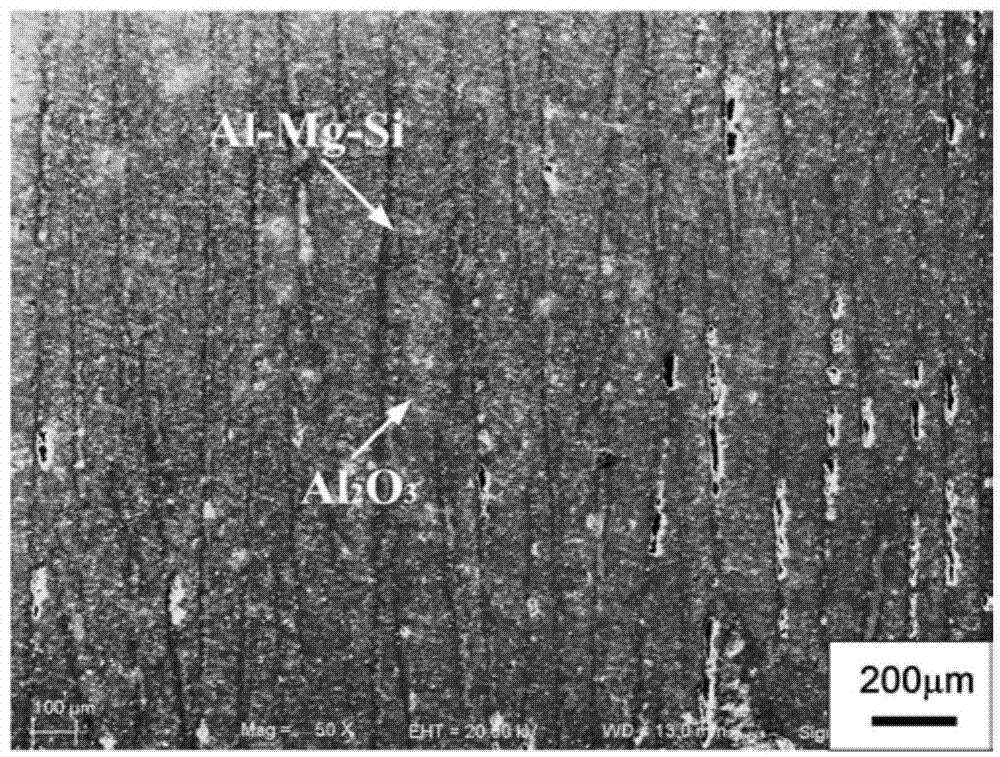

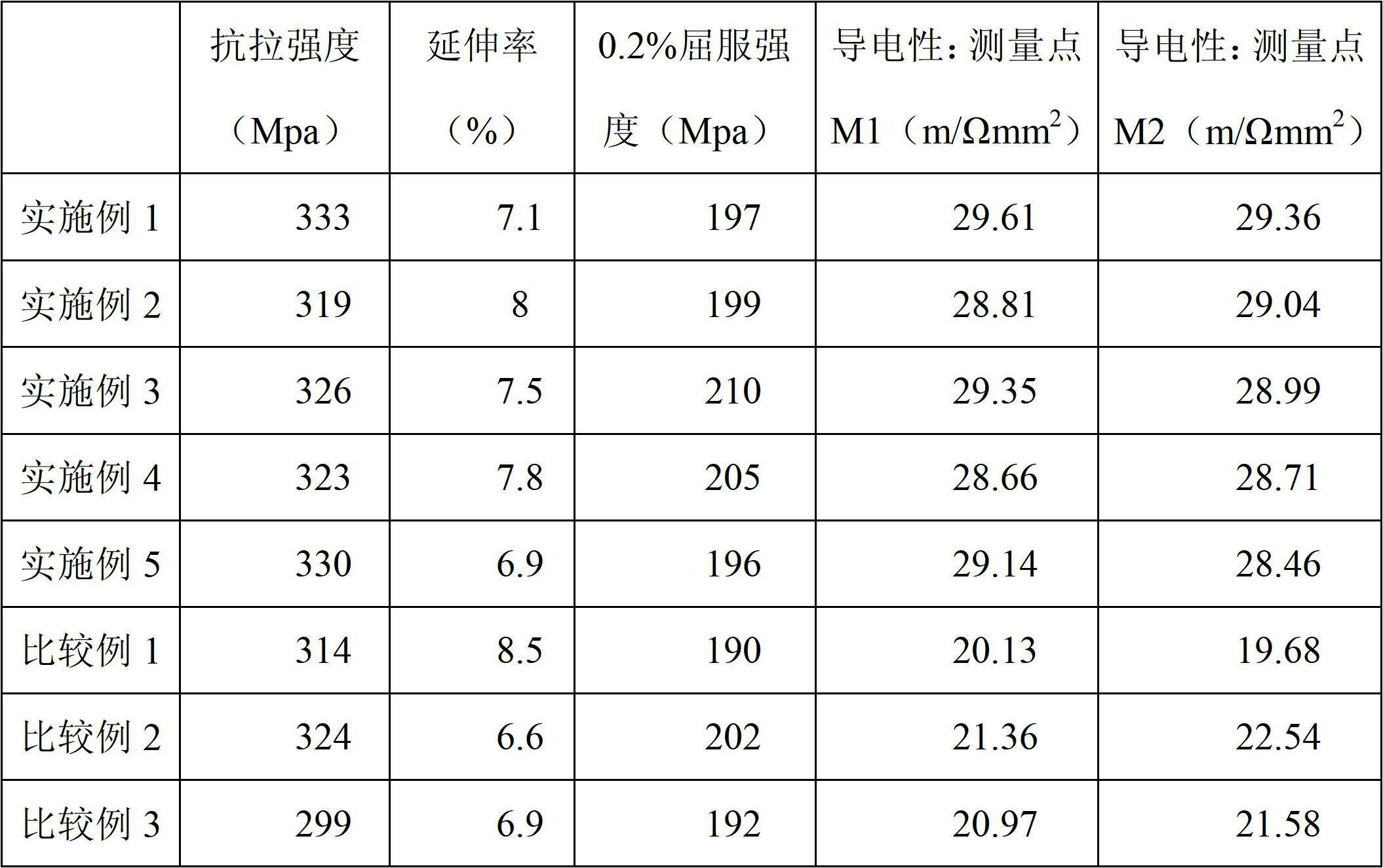

InactiveCN103895285ANot easy to sinterEasy to manufactureCeramicwareMetal layered productsWater basedMass ratio

The invention discloses a high-strength lamellar Al-based metal ceramic composite material and a preparation method thereof, aiming at solving the problems of high preparation cost, complex operation, single type of reinforcement ceramic and low strength. The high-strength lamellar Al-based metal ceramic composite material, i.e., high-strength lamellar structure Al-Si-Mg / (Al2O3, SiC, TiC) composite material comprises ceramic powder and Al-Si-Mg alloy. The volume fraction of ceramic powder is 20%-40vol%; the volume fraction of Al-Si-Mg alloy is 80%-60vol%; the mass ratio of aluminum in the Al-Si-Mg alloy is 75-84wt%; the mass ratio of silicon is 10-15wt%; the mass ratio of magnesium is 6-10wt%. The preparation method of the high-strength lamellar Al-based metal ceramic composite material comprises the following steps: preparation of water-based ceramic slurry; directional solidification; freezing and drying; sintering of blanks; smelting of alloy; and non-pressure infiltration.

Owner:JILIN UNIV

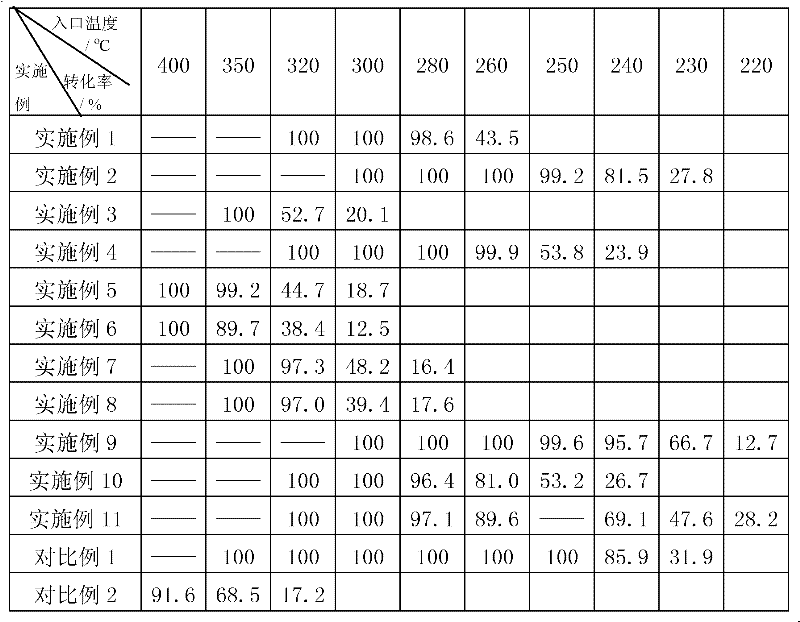

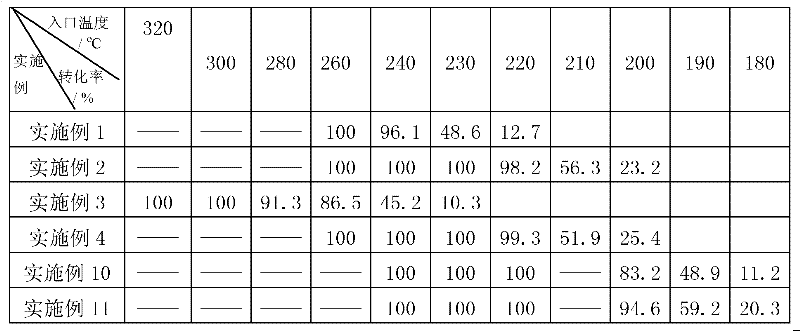

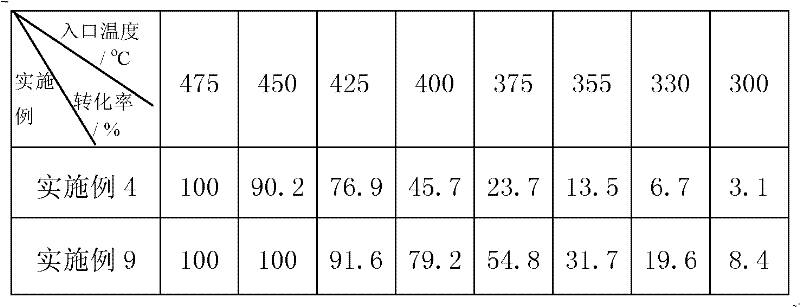

TiO2 supported manganese-cerium composite oxide catalyst and preparation method thereof

InactiveCN101352680AHigh catalytic activityUniform particlesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDispersityAdditive ingredient

The invention discloses a manganese-cerium complex oxide catalyst loaded by TiO2, which takes nanometer titanium dioxide as a carrier and the manganese-cerium complex oxide loaded on the carrier as an active ingredient. The mole ratio of each ingredient is that Ti: Mn: Ce is equal to 1: (0.05 to 1): (0.05 to 1). The invention also discloses a preparation method of the catalyst, which adopts sol-gel preparation technology to promote the dispersity and strength of the two ingredients of manganese and cerium on a TiO2 carrier. Furthermore, the catalyst prepared by adopting the preparation method has the advantages of high catalytic activity and uniform particles; active substances is good in dispersity and is hard to sinter; when used in low-temperature SCR reaction, the catalyst can greatly lower the operation temperature and the operation cost of the SCR since the catalyst has a very high removal rate of NO at the temperature about 120 DEG C.

Owner:ZHEJIANG UNIV

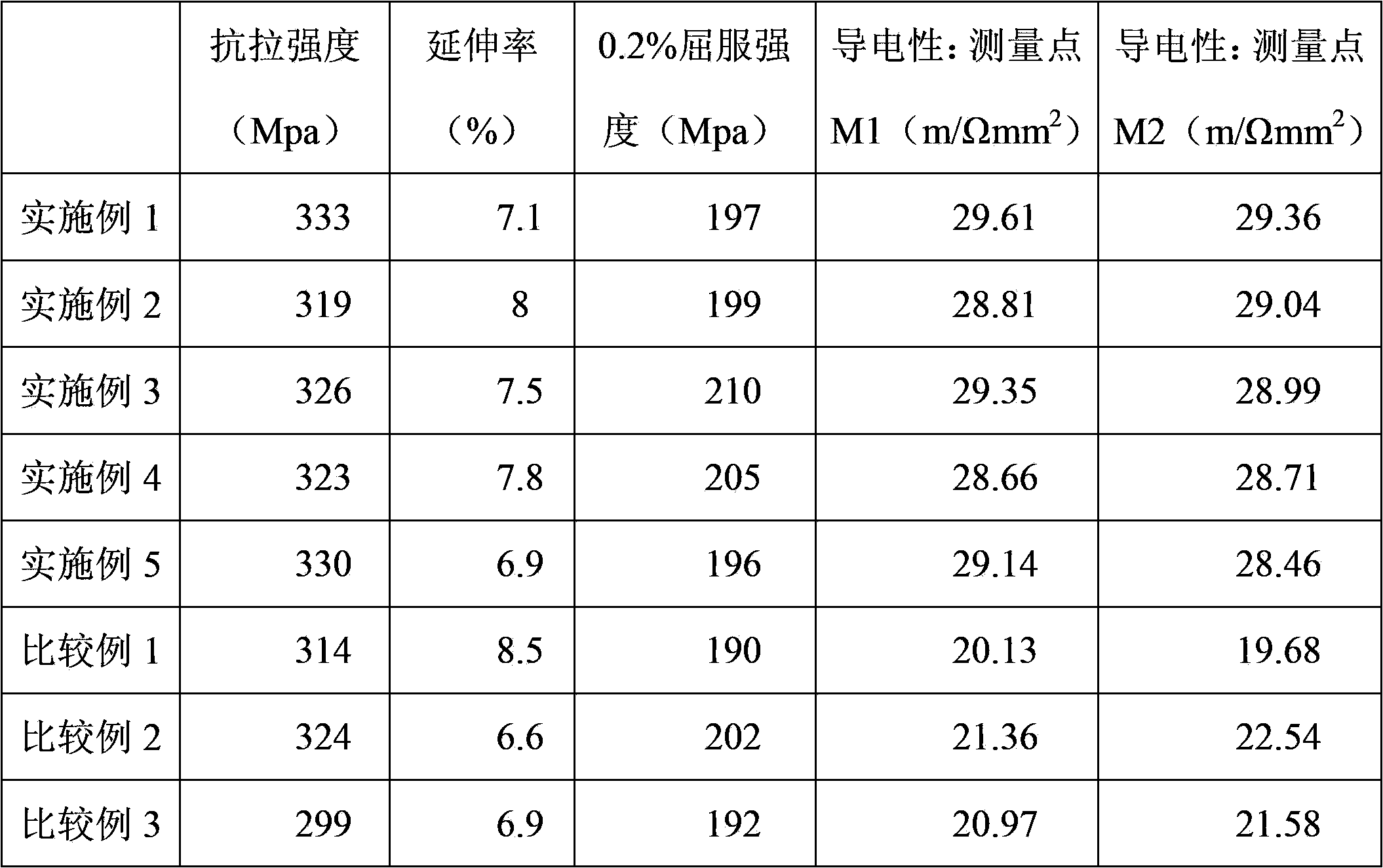

Aluminum alloy for compression casting and casting of aluminum alloy

The invention provides aluminum alloy for compression casting and a high-toughness aluminum alloy casting formed of the alloy through compression casting. The aluminum alloy has the advantages of superior yield strength and extensibility, low probability of sintering and superior thermal conductivity. The aluminum alloy is characterized by comprising the following components in percentage by weight: 5.5-11.0 percent of Si, 0.3-0.7 percent of Mg, 0.05-0.3 percent of Cu, 0.2-0.8 percent of Fe, 0.2-0.5 percent of Mn, 0.05-0.3 percent of Ti, 0.05-0.1 percent of Cr, 0.05-0.3 percent of V and the balance of Al and inevitable impurities. The aluminum alloy for compression casting and the casting of the aluminum alloy provided by the invention have the advantages of high yield strength and extensibility, superior thermal conductivity and low probability of sintering.

Owner:东莞市闻誉实业有限公司

Catalyzer for industrial production of 1,6-hexamethylene glycol and method of preparing the same

InactiveCN101138726AGood thermal stability and dispersibilityUniform precipitationOrganic compound preparationHydroxy compound preparationCopper nitrateZinc nitrate hexahydrate

A catalyst used for industrial production of 1, 6-hexanediol and a preparation method for the catalyst and relate to a catalyst used for hydrogenated production of 1, 6-hexanediol with 1, 6 dimethylene adipate, and a preparation method for the catalyst. The catalyst basically comprises copper oxide, zinc oxide and aluminum oxide. The copper oxide takes up 25 to 60 percent of the total catalyst weight, the zinc oxide takes up 25 to 60 percent of the total catalyst weight, and the aluminum oxide takes up 10 to 30 percent. The preparation method comprises preparation of a copper nitrate and zinc nitrate mixed solution, preparation of a aluminum hydroxide suspension, deposition, filtering, washing, drying, granule making, calcination, mixing with an extender, tablet pressing and molding. Thus, the catalyst used for industrial production of 1, 6-hexanediol is produced, and make the conversion rate of the raw material of 1, 6 dimethylene adipate larger than 99 percent and the hexanediol selectivity larger than 96 percent.

Owner:PETROCHINA CO LTD

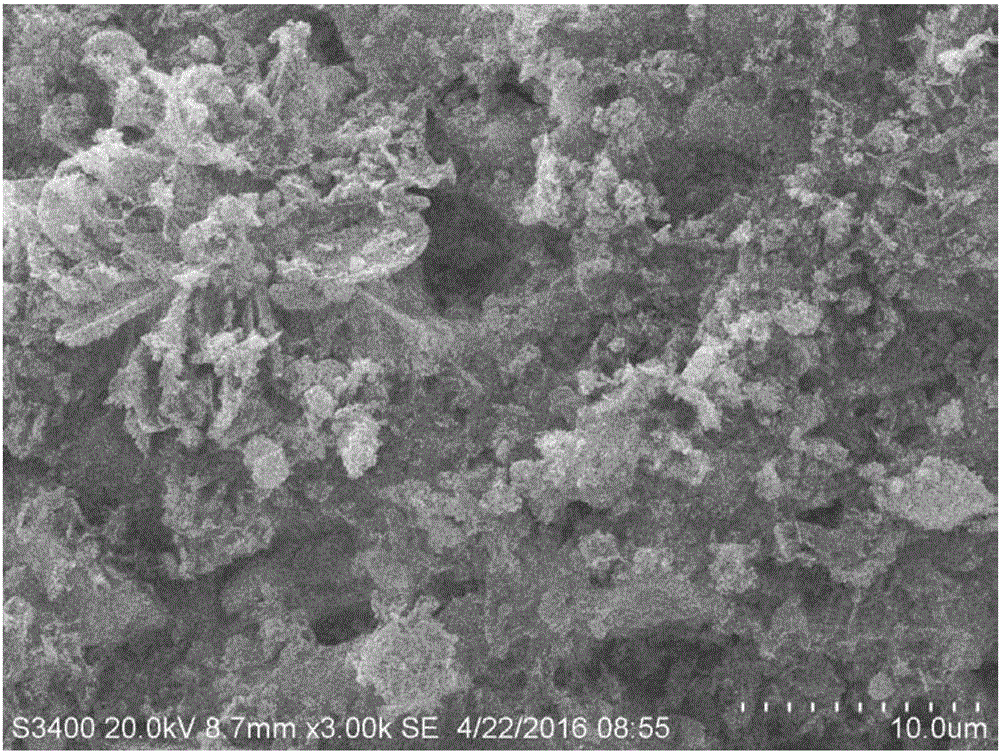

Molecular sieve coating load manganese based composite oxide integrated catalyst and preparation method thereof

InactiveCN102407154AStrong combinationNot easy to fall offMolecular sieve catalystsDispersed particle separationComposite oxideMolecular sieve

The invention provides a molecular sieve coating load manganese based composite oxide integrated catalyst with easy material acquisition, low preparation cost and firm combination of active constituents and carrier of catalyst, and a preparation method thereof for the defects that the noble metal catalyst has few noble metal resources, high price and high preparation cost. The catalyst provided by the invention is a cellular catalytic combustion catalyst, which comprises a molecular sieve coating, a manganese based composite oxide and a cellular carrier. The catalyst provided by the invention is prepared by the following steps of: uniformly mixing a precursor with the manganese based composite oxide, the molecular sieve and the water to obtain a grout with manganese based composite oxide precursor; soaking the cellular carrier into the grout with manganese based composite oxide precursor; and drying and baking to obtain the molecular sieve coating load manganese based composite oxide integrated catalyst.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

Montmorillonite/ZSM-5 molecular sieve composite material and preparation thereof

ActiveCN101239325ASimple processImprove thermal stabilityMolecular sieve catalystsSorbentHeat stability

The present invention provides a montmorillonite / ZSM-5 molecular sieve composite material and its preparing method. The montmorillonite / beta molecular sieve composite material is prepared by evenly mixing montmorillonite with ZSM-5 molecular sieve gelatin, then processing home position crystallization, and via filtering, washing and drying. The composite material have structure characteristics of the montmorillonite and the molecular sieve at the same time, the montmorillonite and the molecular sieve are alternative. The synthetic montmorillonite / ZSM-5 molecular sieve have characteristics of small crystal grain molecular sieve by controlling the synthetic course and the conditions. The preparing method is simple, the easily separating, the molecular sieve composite material has better water-heat stability. The composite material are mainly used for all kinds of catalysts and absorption agents, especially the preparing of hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

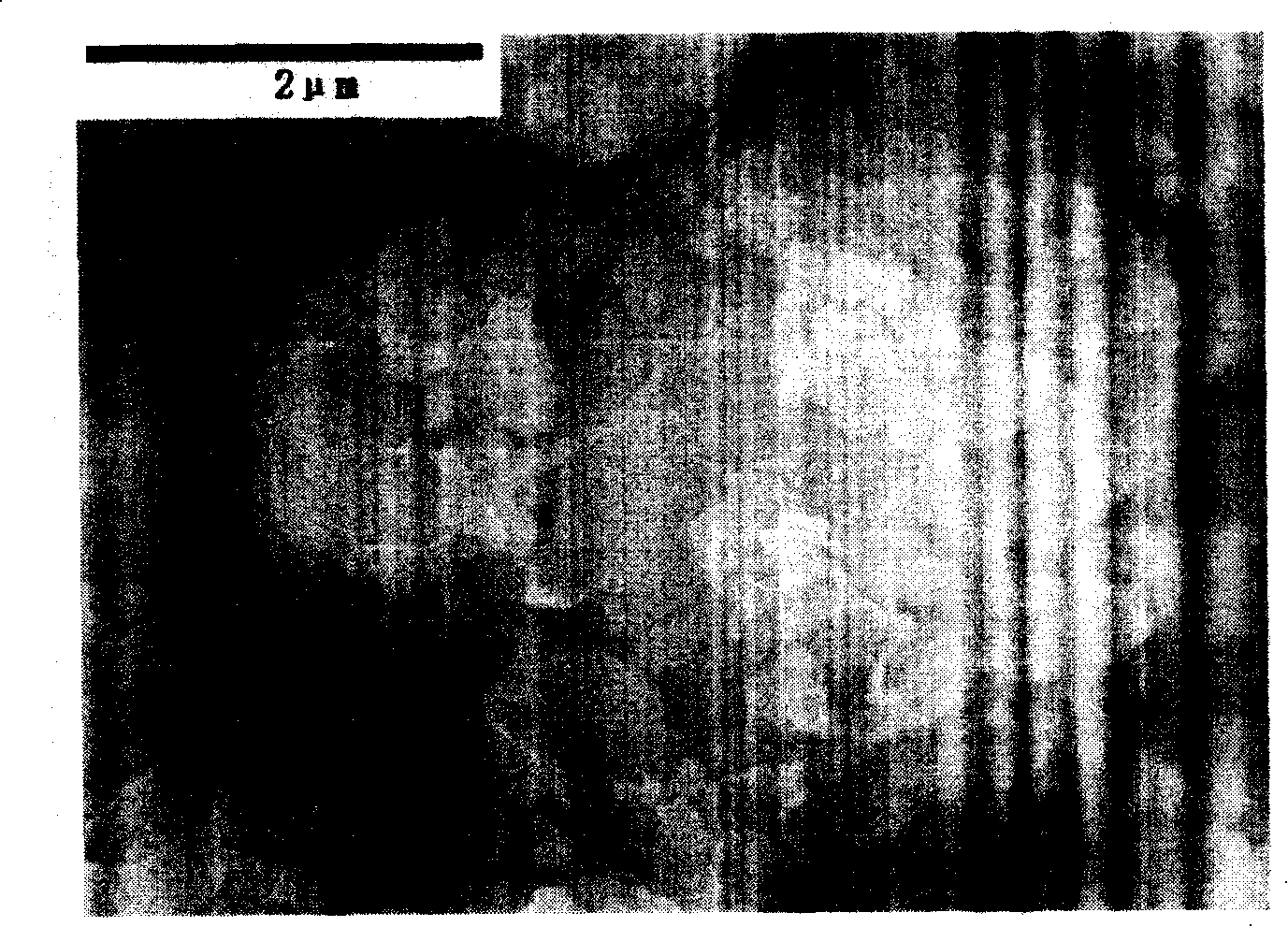

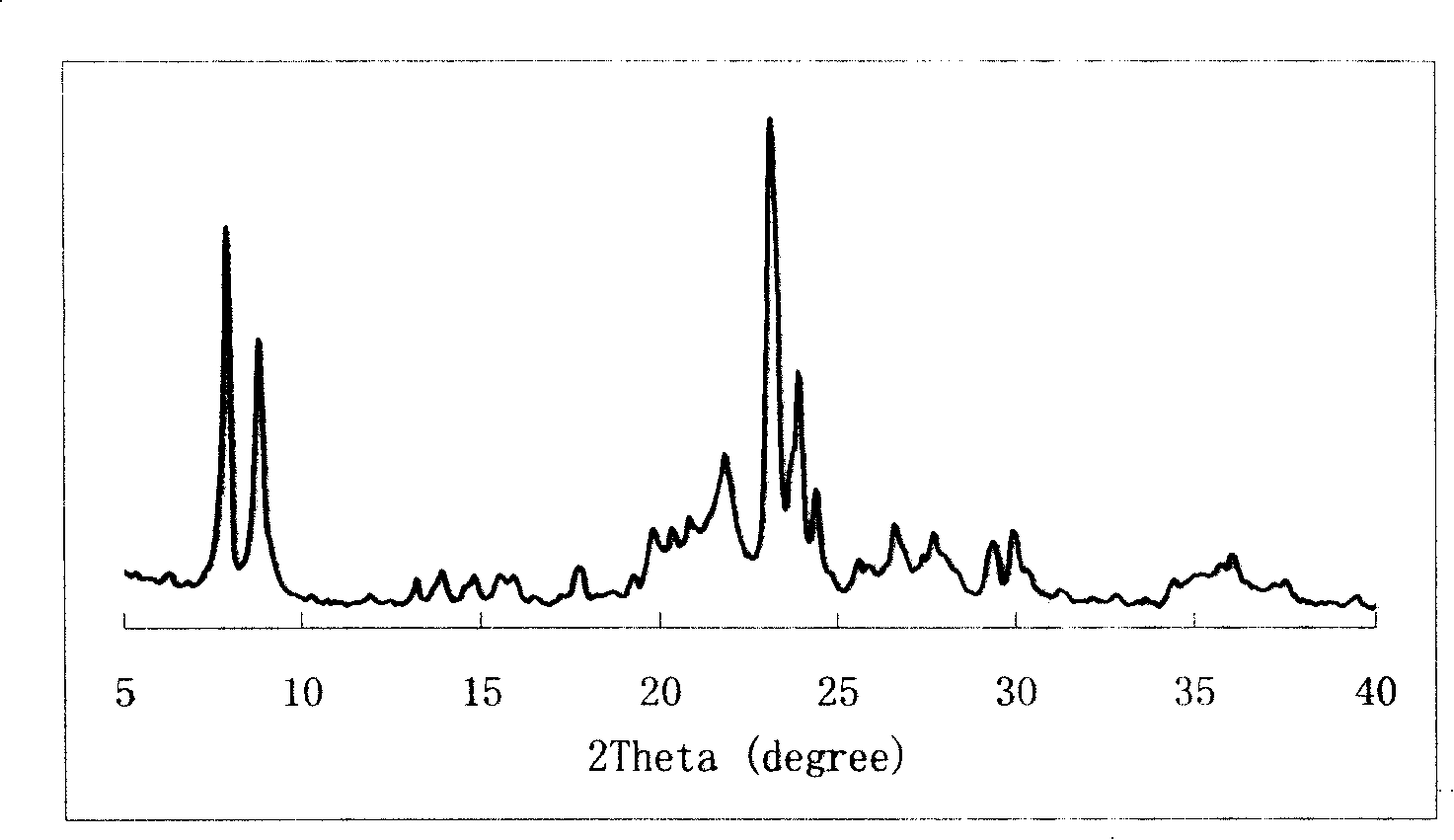

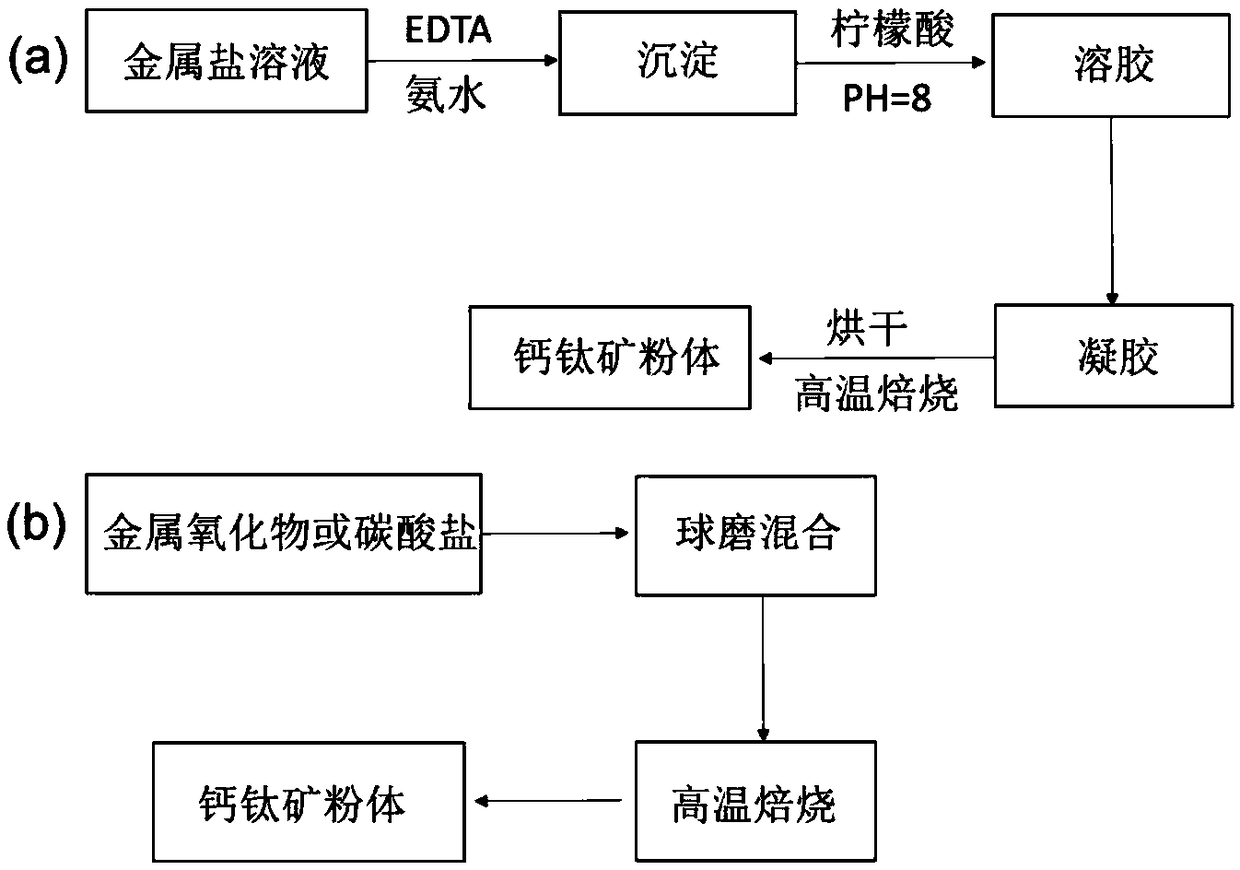

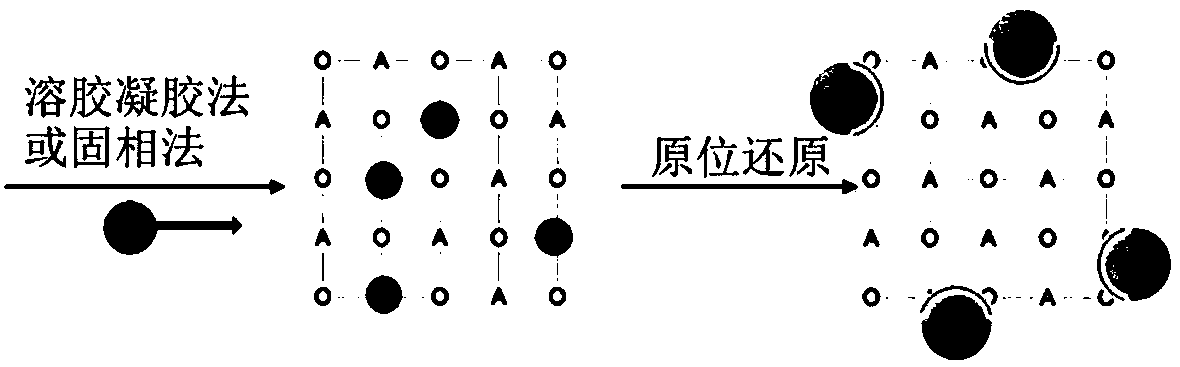

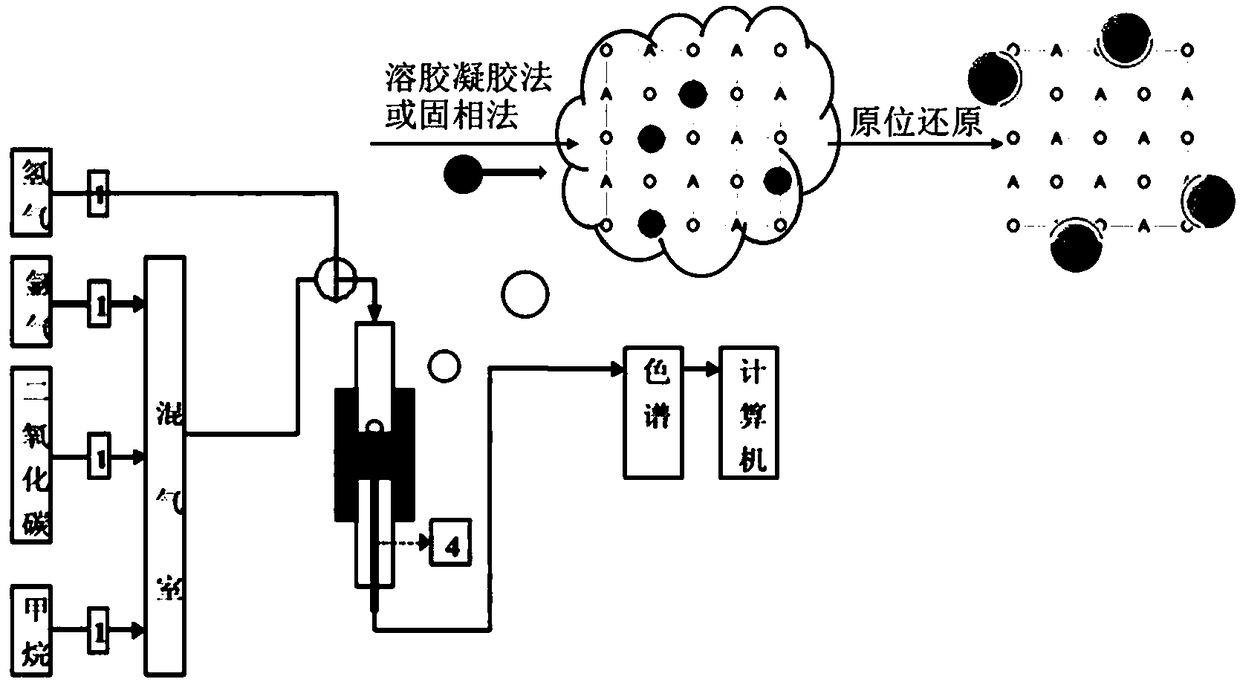

Perovskite catalyst, preparation method thereof and in-situ testing method of perovskite catalyst

InactiveCN108654592AHighly dispersed and stable dispersedImprove anti-coking performanceChemical analysis using catalysisHydrogenRare-earth elementAlkaline earth metal

The invention discloses a novel solid catalyst material for methane carbon dioxide reforming reaction, a corresponding widely-applicable preparation method and a simply and easily operated testing andreacting process. According to the perovskite catalyst, a substrate is a perovskite material which includes in-situ precipitated B-site doped metal nano-particles and an A site short of positive ions. The in-situ precipitated B-site high-activity metal nano-particles for catalyzing cover the surface of the substrate, the A site is any one of a rare earth element and an alkali-earth metal element,and a B-site substrate is doped transition metal with various valence states. The perovskite catalyst can provide good catalytic performances, and carbon deposit and catalyst deactivation caused by carbon deposit in reforming reaction are avoided. The in-situ precipitated-in-situ reaction preparation and testing method has the advantages of simplicity in operation, practicability, high efficiencyand novelty. The method has a good application prospect in a preparation and testing process of the catalyst.

Owner:HUAZHONG UNIV OF SCI & TECH

Catalyst for removing flue gas NOx under low temperature and preparation and application

ActiveCN101259408AConducive to loadNot easy to sinterCatalyst carriersDispersed particle separationFiberOxalate

The invention relates to a catalyst used for removing flue gas NOx at low temperature. The weight percentage of each component is: 90.0 to 99.0 percent of active carbon fiber and 0.1 to 10.0 percent of V2O5. The active carbon fiber is dipped into a mixed solution prepared by oxalic acid and ammonium metavanadate which contains V2O5 and has a concentration of 0.000088735 to 0.0088735g / ml, then is stood for 2 to 5h under the room temperature, dried for 2 to 12h under a temperature of 40 to 60 DEG C, dried for 2 to 6h under a temperature of 100 to 120 DEG C, then is calcined for 2 to 8h in an argon atmosphere at 400 to 500 DEG C and is calcined for 2 to 5h in air of 200 to 260 DEG C to obtain the catalyst. The invention is simple to be operated, has excellent poisoning capacities of H2O resistance and SO2 resistance and improves the activity of selectively catalyzing and reducing the NOx.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

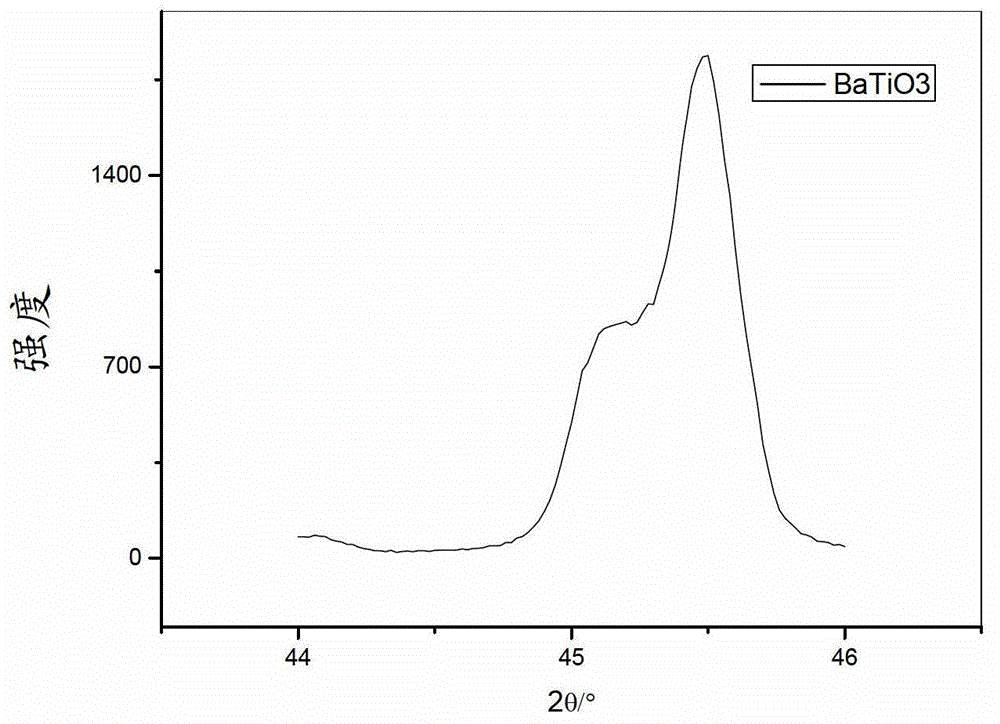

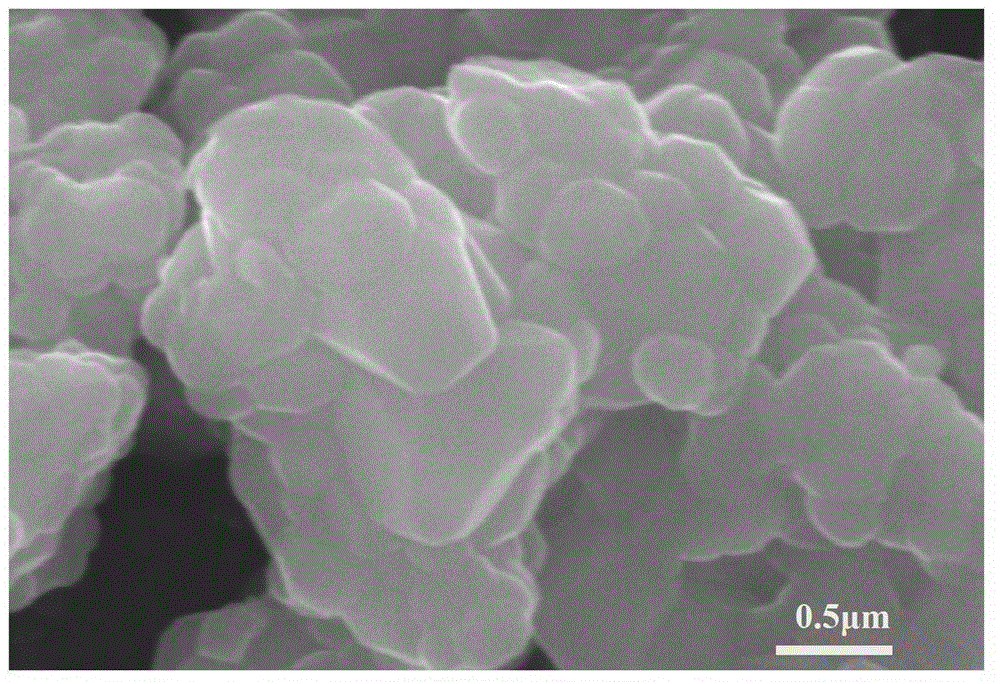

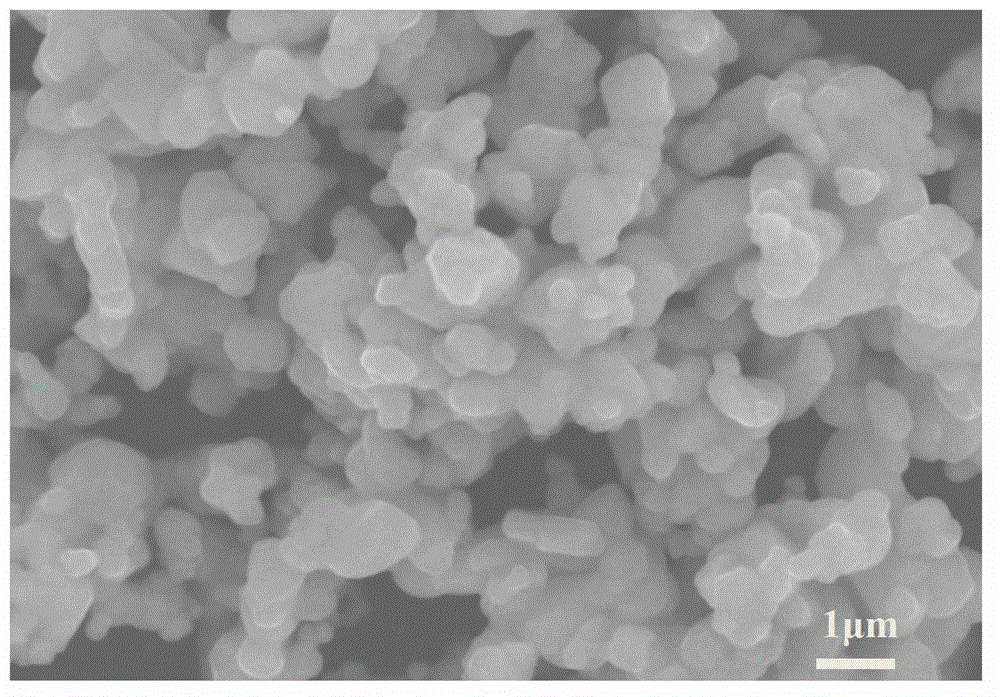

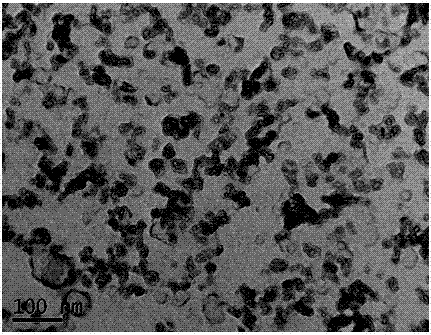

Preparation method for tetragonal phase nano barium titanate

InactiveCN102976400ASmall average particle sizeNarrow particle size distributionMaterial nanotechnologyTitanium compoundsComplex ionsOxalate precipitation

The invention provides a preparation method for tetragonal phase nano barium titanate. The preparation method comprises the steps as follows: i), preparing water solutions of barium chloride and oxalic acid respectively, and mixing alcoholic solution of butyl titanate and oxalic acid solution uniformly to obtain titanium oxyoxalate complex ion solution; ii), adding titanium oxyoxalate complex ion solution obtained in the step i) into a supergravity reactor as a circulating flowing phase to control the supergravity level; and meanwhile, dropping barium chloride solution to obtain white barium titanyl oxalate precipitation suspension as a precursor of barium titanate, and keeping the pH value of the whole system at 2.5-3.5 during reaction; and iii),ageing the precipitation suspension obtained in the step ii), leaching, washing and drying to obtain white barium titanyl oxalate power. The preparation method provided by the invention has the advantages that tetragonal phase nano barium titanate can be prepared; and the particle size of the prepared power can be controlled to be within the range of 30-90 nm; the average particle size is small, and the particle size is narrow in distribution; and the degree of crystallinity is high, and the crystal formation is intact.

Owner:XIANGTAN UNIV

Preparation method of high-activity crystal seed by hydrolysis of titanium sulfate solution

The invention discloses a preparation method of high-activity crystal seed by hydrolysis of a titanium sulfate solution and belongs to the technical field of production of titanium dioxide by a sulfuric acid method. The preparation method comprises the following steps of (A) taking and putting a hydrolytic titanium sulfate solution into a preheating groove to be preheated to 50-65 DEG C, wherein the concentration of TiO2 in the hydrolytic titanium sulfate solution is 195-205g / L, the concentration of Ti<3+> is 1.0-3.0g / L (calculated by TiO2), the concentration ratio F between effective acid andtotal TiO2 is 1.70-1.85, the concentration ratio between Fe and TiO2 is 0.26-0.31, the solid content is less than 30mg / L, and the stability is greater than or equal to 500; (B) preheating alkaline liquid to 50-65 DEG C, and controlling the concentration of the preheated alkaline liquid to 8.0-8.5%; (C) within 1-4 minutes, adding the hydrolytic titanium sulfate solution into the alkaline liquid, and after the reaction is finished, controlling the temperature of the crystal seed titanium sulfate solution to be 40-60 DEG C; (D) diluting and controlling the concentration of TiO2 in the crystal seed titanium sulfate solution to be 30-160g / L. The crystal seed prepared by the method is high in activity, less in added amount in water crystallization and high in hydrolysis rate, and the obtained hydrated titanium dioxide is uniform in particle size distribution.

Owner:HEBEI MILSON TITANIUM DIOXIDE

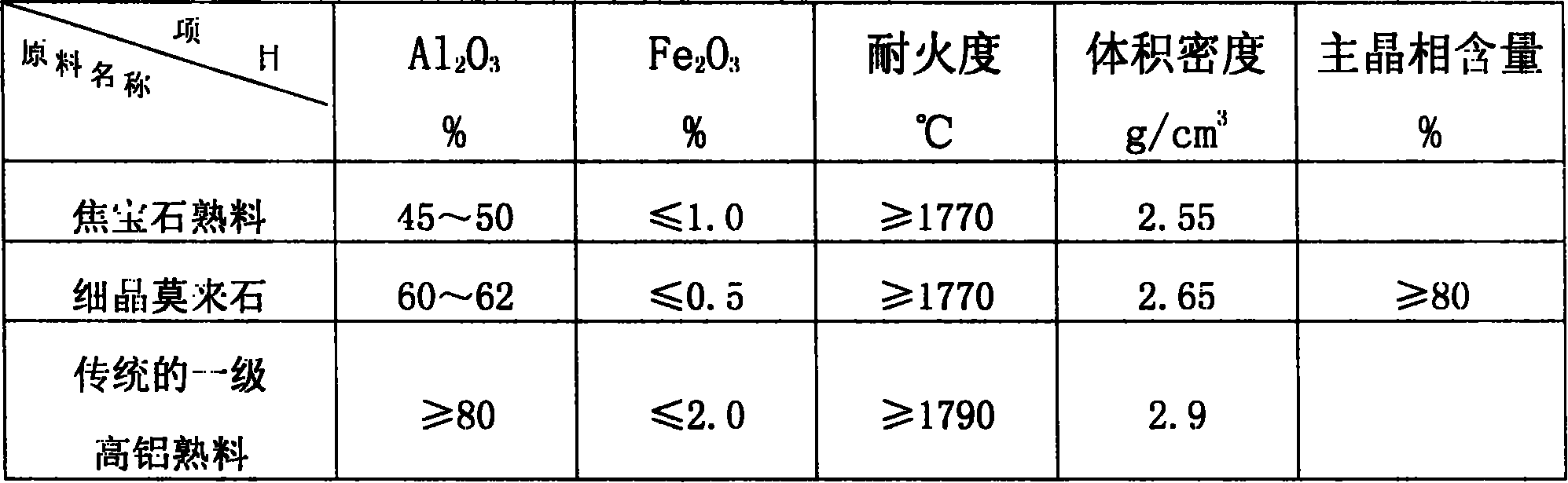

Flame-proof pouring material for hydroted alumina gas suspending roasting furnace furnace liner

The present invention provides a fire-resistant castable material of furnace lining for aluminum hydroxide gas suspension baking furnace. The fire-resistant castable material is a mixture of sintered coke sapphire chamotte and fine-grained mullite of good crystal structure in the sintering process, binder and composite additive according to different proportions; the lining of a main furnace body for aluminum hydroxide gas suspension baking furnace is prepared after furnace building, furnace baking and sintering. Wherein, the percentage of composition of raw materials is: 27 to 33 percent of coke sapphire chamotte less than 3mm, 25 to 30 percent of coke sapphire chamotte with a particle size between 3mm and 5mm, 8 to 15 percent of coke sapphire chamotte with a particle size between 5mm and 8mm, and 15 to 25 percent of fine-grained mullite powder with a particle size less than 0.074mm. The binder uses activated alumina of rho- Al2O3 of 5 to 8 percent; the composite additive uses high-dispersion oxidated alpha-Al2O3, superfine powder and silicon oxide SiO2; the contents of the superfine powder and the silicon oxide are respectively 2 to 5 percent; the particle size of the superfine powder is less than 5 Mu m; the content of sodium tripolyphosphate is 0.1 to 0.3 percent.

Owner:阮克胜

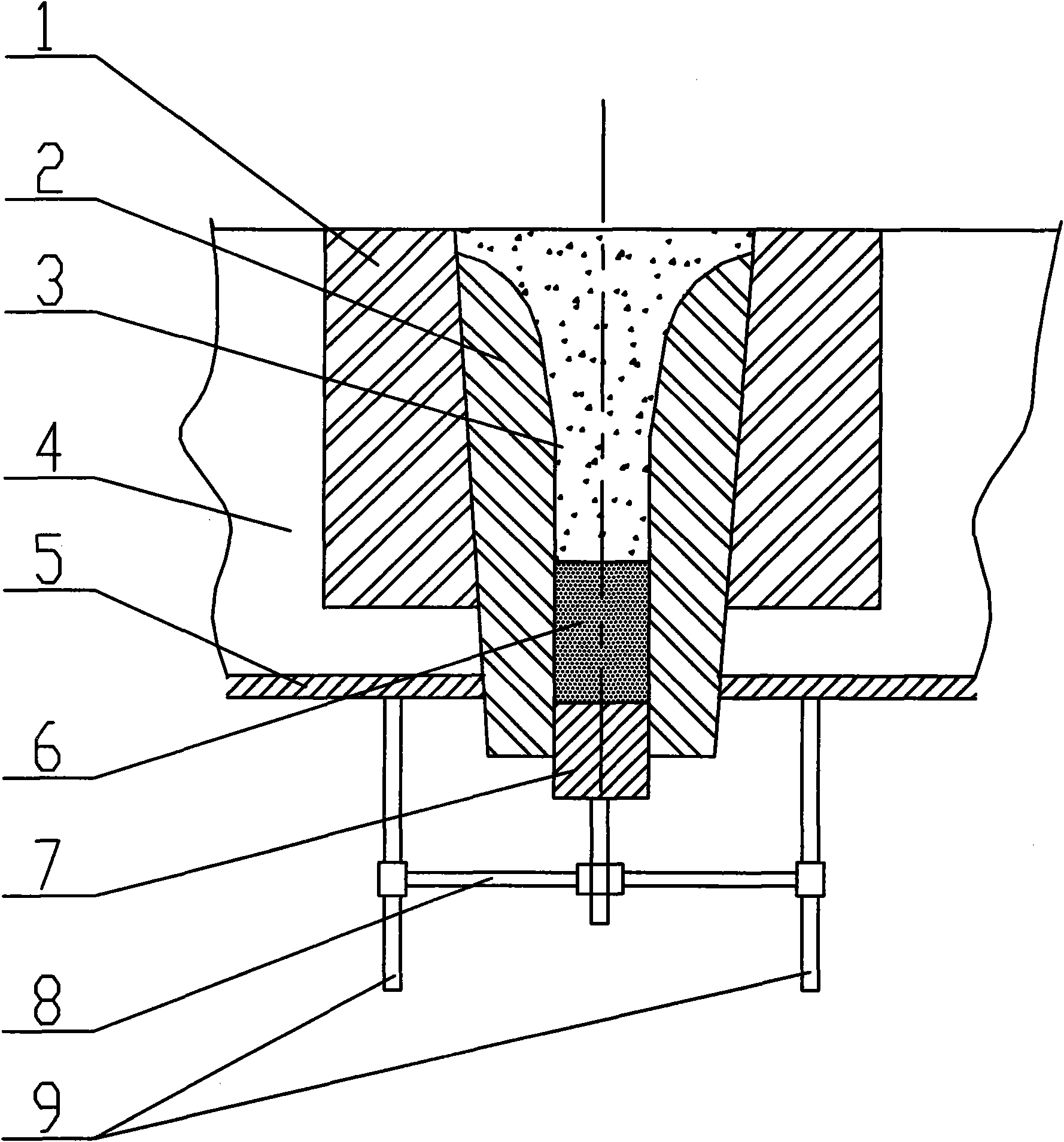

Nozzle structure at bottom of refining furnace and nozzle filling method

InactiveCN101579733AClose tightlyReduce the phenomenon of loose flow pouringMelt-holding vesselsBrickRefractory

The invention relates to a nozzle structure at the bottom of a refining furnace and a nozzle filling method. The nozzle structure at the bottom of the refining furnace comprises a seating brick, a nozzle brick, refractory lining, a refining furnace base, a plug, a rotatable bracket and a supporting frame, and is characterized in that: the nozzle brick is manufactured by adopting aluminum-carbon refractory material taking resin as bonding agent, and the chamfer angle of the upper mouth of an inner cavity of the nozzle brick is R58mm. The nozzle filling method comprises the following steps: in the situation that the lower mouth of the inner cavity of the nozzle brick is plugged and locked by the plug, cast-iron scrap is filled in the inner cavity of the nozzle brick to the height of 80-120mm and tamped, and then flow guiding sand is filled at the upper layer of the cast-iron scrap to the upper edge of the inner cavity of the nozzle brick and tamped so as to complete the plugging and filling of the nozzle, wherein the flow guiding sand adopts zirconium flow guiding sand. The invention has the advantages that: the aluminum-carbon refractory nozzle brick taking resin as bonding agent can meet the requirement of multi-box casting of the refining furnace, simultaneously the radian at the upper end of the inner cavity of the nozzle brick is changed from R90 to R58, the nozzle is tightly closed in the casting process, and the use of the zirconium flow guiding sand and the improvement of the filling method realize that multi-box casting molten steel of the refining furnace can automatically flow out along with the falling of the flow guiding sand, thus achieving the purpose of automatic casting.

Owner:INNER MONGOLIA FIRST MACHINERY GRP

Method for preparing TiO2/gamma-Al2O3 composite carrier

InactiveCN101234358AImprove thermal stabilityUniform compositionCatalyst carriersChemical compositionTitanium tetrachloride

The invention relates to a preparation method of TiO2 / Gamma-Al2O3 composite carrier. The weight percent of TiO2 in the chemical composition of the composite carrier is 15 percent, and the composite carrier has the precursors of titanium tetrachloride (TiCl4) and aluminum nitrate (Al(NO3)3 9H2O) as raw materials, and adopts concurrent co-precipitation method to prepare. The precipitation gets a TiO2 / Gamma-Al2O3 composite carrier with a 292.6m<2> / g specific surface area after drying for 24h under a temperature of 110 DEG C in oven and roasting for 2h under the temperature of 500 DEG C in muffle furnace. The preparation method of TiO2 / Gamma-Al2O3 composite carrier has the advantages of simple technology, convenient operation, and even components. Meanwhile, the composite carrier has the specific surface area which is bigger 50 to 100m<2> / g than ordinary titanium-aluminum bi-oxide, can play the role of the carrier of catalysts, and also is suitable to be used as the carrier of plasma-catalytic coordination de-NO catalyst.

Owner:ZHEJIANG UNIV

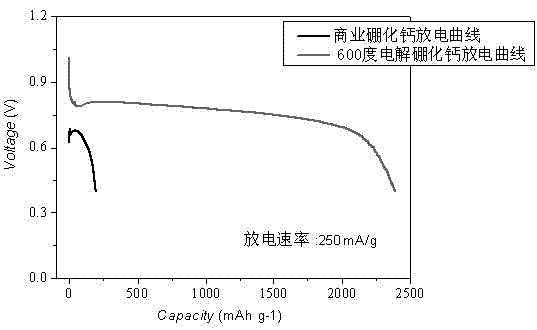

Preparation method and application of superfine calcium hexaboride

InactiveCN102242371AOvercome the shortcomings of high synthesis temperature, low yield and expensive raw materialsHigh melting pointElectrolysis componentsMetal boridesBorideElectrical conductor

The invention discloses a preparation method and application of superfine calcium hexaboride to a battery. The preparation method comprises the steps of: carrying out electrolysis in a fused-salt electrolytic cell at a temperature of 500-750 DEG C through taking a composition of porous calcium borate and a metal current collector as the cathode and taking an insoluble conductor material as the anode, wherein fused-salt electrolyte contains a haloid corresponding to a metal capable of chemically reducing the calcium borate, and the voltage applied through the electrolysis is enough to reduce the calcium borate but not enough to resolve the fused-salt electrolyte; and taking out a reduction product on the cathode from the electrolytic cell, washing by using water and acid removing impurities, drying and then obtaining CaB6 powder. The obtained superfine calcium hexaboride can be used for a cathode material of a high-specific energy alkaline cell. By means of the method, the defects of high synthesis temperature, low yield and more expensive raw material of conventional boride are overcome and continuous production can be carried out.

Owner:WUHAN UNIV

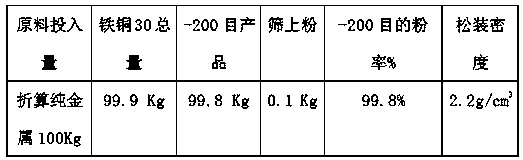

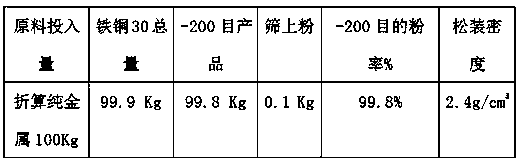

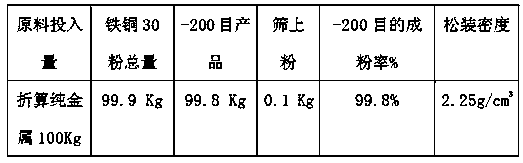

Production method for copper-iron diffusion powder

The invention belongs to the field of powder metallurgy manufacturing and discloses a production method for metal diffusion powder. The production method comprises the steps that cupric oxide powder with -300 meshes is selected, industrial machine oil is selected as binders, or mixed powder of reduced iron powder with -300 meshes and nickel powder with -300 meshes is selected; the cupric oxide powder and the industrial machine oil are mixed, the reduced iron powder or the mixed powder of the reduced iron powder and the nickel powder is loaded in a three-dimensional blender mixer, and then thecupric oxide powder is added into the three-dimensional blender mixer; material mixing is started, the mixed powder is added into an iron powder reducing furnace, a reducing atmosphere is added, temperature rise continues after reducing is finished, high temperature diffusion is started, a beater is utilized to scatter the powder discharged from the furnace, and then iron-copper diffusion powder or copper-iron-nickel diffusion powder with -200 meshes is screened out. The product produced by the method has the beneficial effects that ingredients are even, almost no segregation occurs, the apparent density of the product is low, and the formability is good, and has broad popularization value.

Owner:JINCHUAN GROUP LIMITED

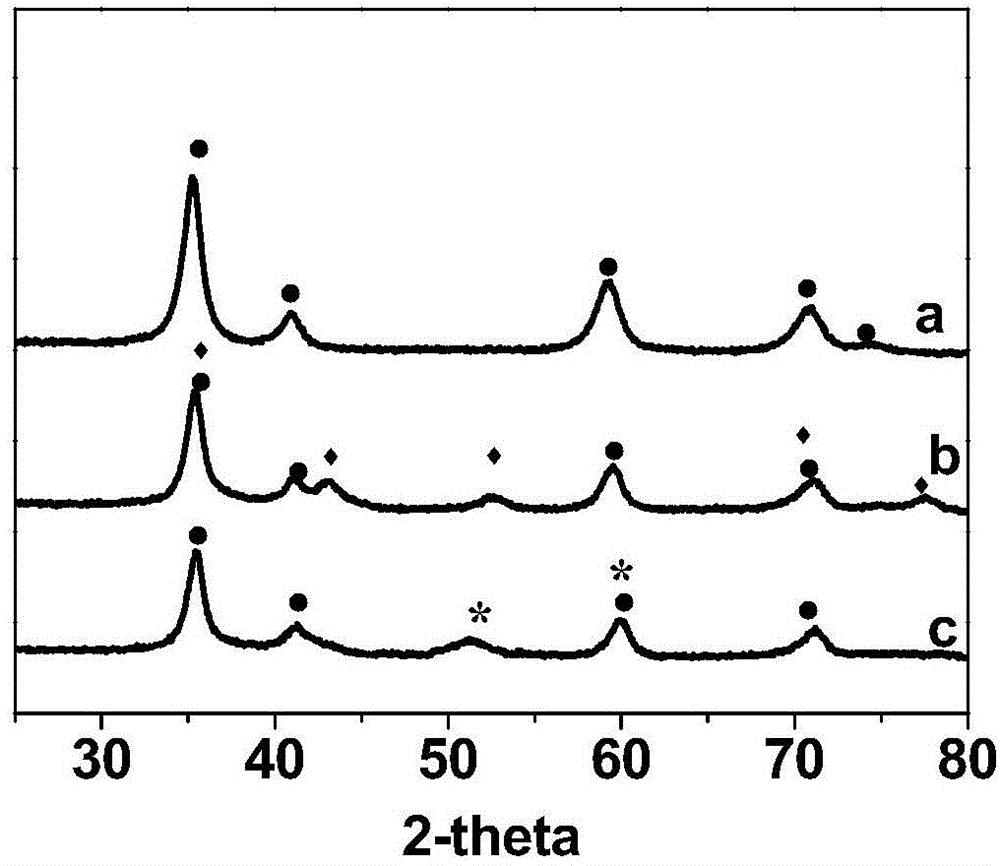

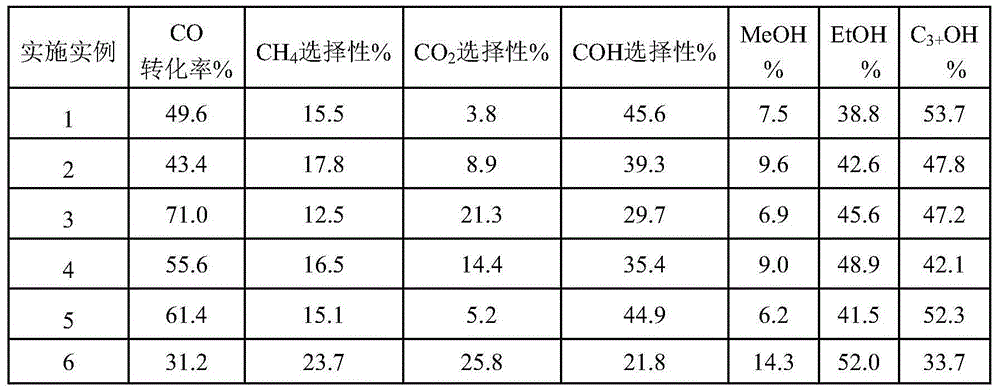

Preparation method and application of mixed oxide-doped nano copper-cobalt alloy catalyst

ActiveCN104645991AReduce contentGood dispersionOrganic compound preparationHydroxy compound preparationMixed oxideActive component

The invention relates to a preparation method and application of a mixed oxide-doped nano copper-cobalt alloy catalyst. According to the catalyst, CuCo serves as an active component and mixed oxide serves as a carrier, wherein Cu accounts for 5-25% in the catalyst in percentage by mass, Co accounts for 5-25% in the catalyst in percentage by mass, Al2O3 accounts for 13-25% in the catalyst in percentage by mass, and one of SiO2, ZrO2, CeO2 or TiO2 accounts for the balance. The mixed oxide-doped nano copper-cobalt alloy catalyst is obtained by calcinating and reducing a hydroxide-doped hydrotalcite-like precursor. Since silicon, zirconium, cerium and titanium ions cannot enter a hydrotalcite-like laminate, the dispersion of copper and cobalt on the surface is improved, the dispersion degree of active components is increased, and the formation of a hotspot in a reaction process of synthesizing low-carbon alcohol is relieved. The catalyst is relatively high in low-carbon alcohol selectivity and low-temperature activity, easy to operate, and low in cost and is applicable to industrial production.

Owner:TIANJIN UNIV

Catalytic purification composite material and preparation method and application thereof

ActiveCN106582701AShort maturation timeImprove catalytic degradation efficiencyOther chemical processesWater contaminantsPorous carbonImpurity

The invention provides a catalytic purification composite material and a preparation method and application thereof. Activated carbon loaded manganese sand particles are used as a basic framework of the material, and mixed metal oxides as active components are loaded on the outermost layer of the framework. The preparation method of the material comprises the following steps: pretreating manganese sand and removing impurities on the surface of the manganese sand; taking wooden activated carbon or shell activated carbon as an activated carbon precursor; roasting in an inert atmosphere; preparing a porous carbon structure which uses the manganese sand as a framework; and modifying the surface of the manganese sand-porous carbon structure by using the metal oxides to form the novel composite purification material with adsorption and electro-catalyst composite functions. When the catalytic purification composite material is used, the composite material effectively adsorbs and catches low-concentration organic matters in micro-polluted raw water at first, so that pollutants are adsorbed on the surface of the material, then the composite material with adsorption saturation is guided into an electrolytic bath for electrochemical oxidation, the pollutants on the surface of the composite material are desorbed and decomposed, and are thoroughly mineralized into carbon dioxide and water, and meanwhile, recycling of the composite material is realized.

Owner:南京朗科环保科技有限公司

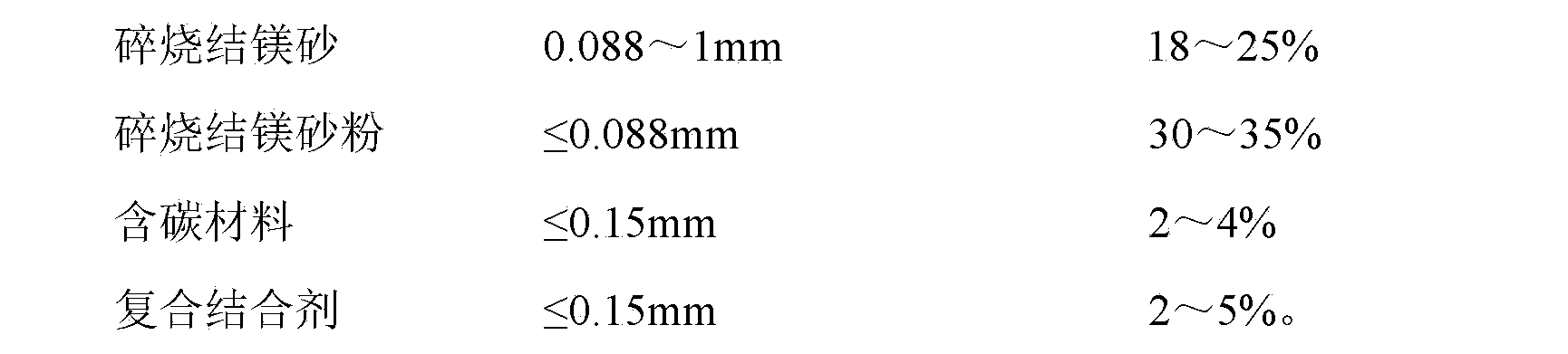

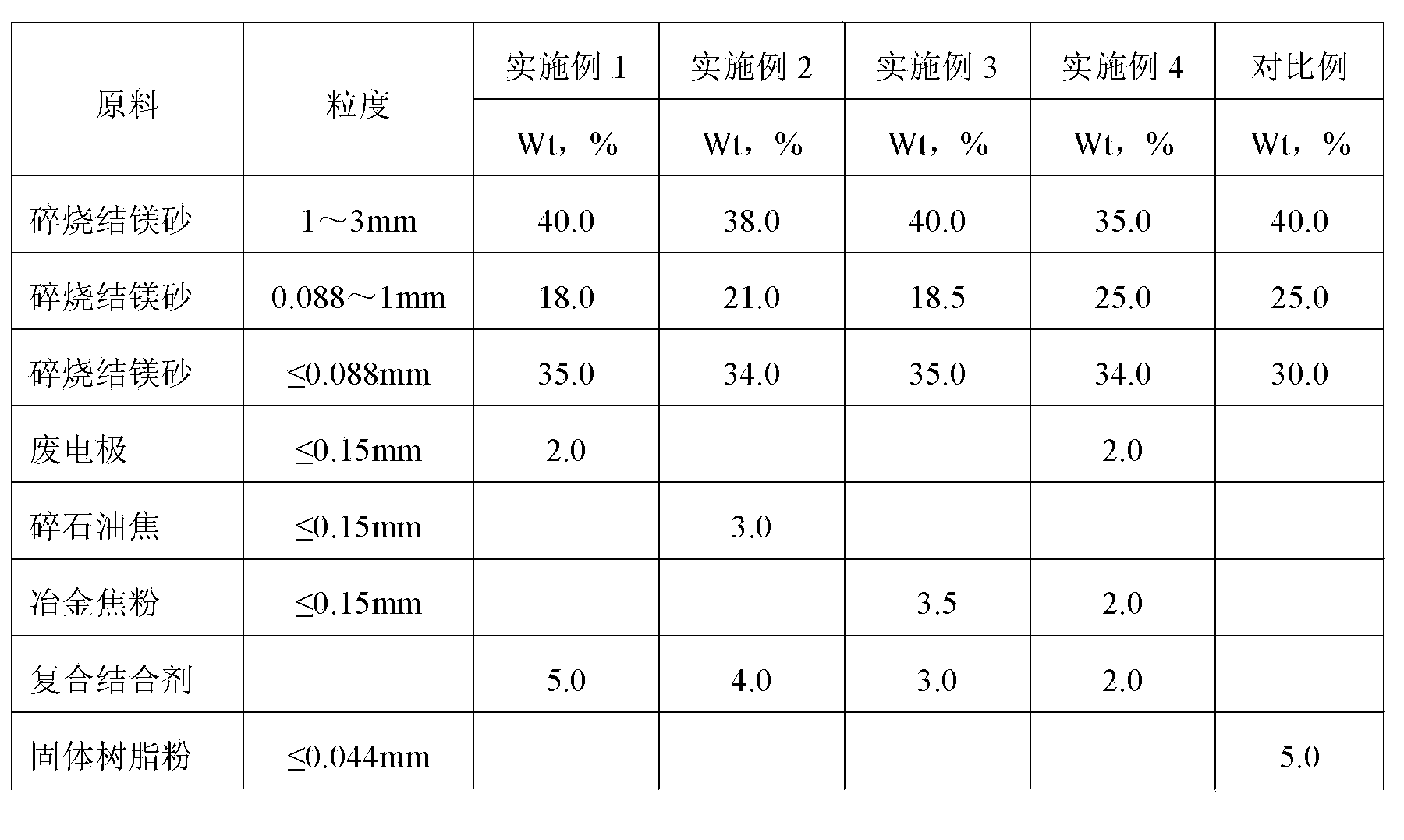

Non-sticking tundish dry material and production method thereof

The present invention discloses a non-sticking tundish dry material adopting broken sintered magnesia and a low cost carbon-containing material as main raw materials, and a production method thereof. The used technical scheme is that the non-sticking tundish dry material comprises, by weight, 35-40% of 1-3 mm broken sintered magnesia, 18-25% of 0.088-1 mm broken sintered magnesia, 30-35% of broken sintered magnesia with a particle size of less than or equal to 0.088 mm, and 2-4% of a carbon-containing material with a particle size of less than or equal to 0.15 mm, the amount of a composite binding agent is 2-5% of the total weight of the main material, and the composite binding agent comprises 20-40% by weight of dextrin and 60-80% by weight of solid resin powder. The preparation method comprises screening, grinding, material preparing, mixing, inspection, packaging, and other processes. According to the present invention, the used aggregate is the broken sintered magnesia, such that the prices is low; and the carbon-containing material is introduced so as to significantly improve sintering resistance of the magnesia dry material, and avoid difficult tundish disassembly caused by adhesion of the work lining on the permanent lining due to sintering after tundish off-line.

Owner:廊坊森德科技有限公司

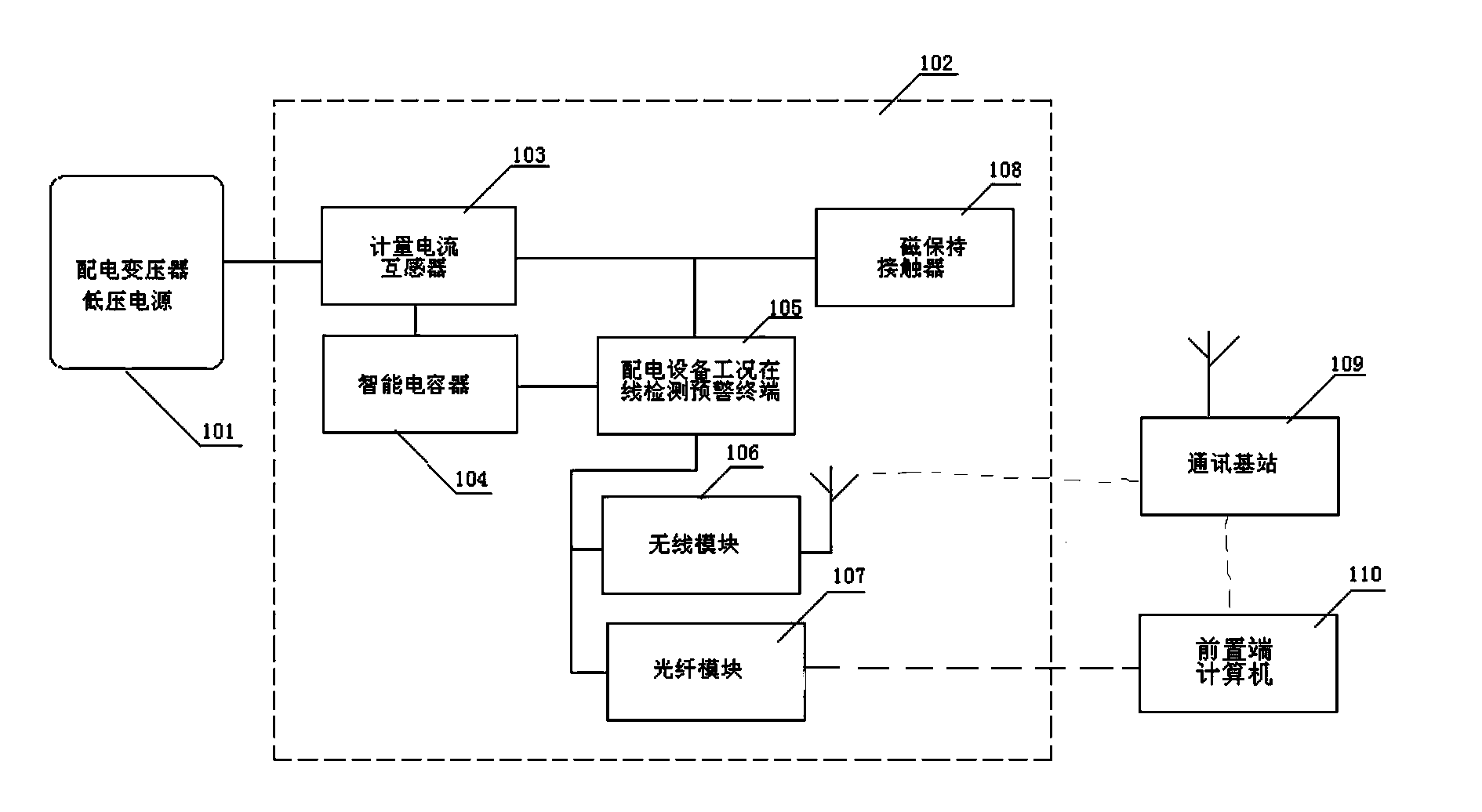

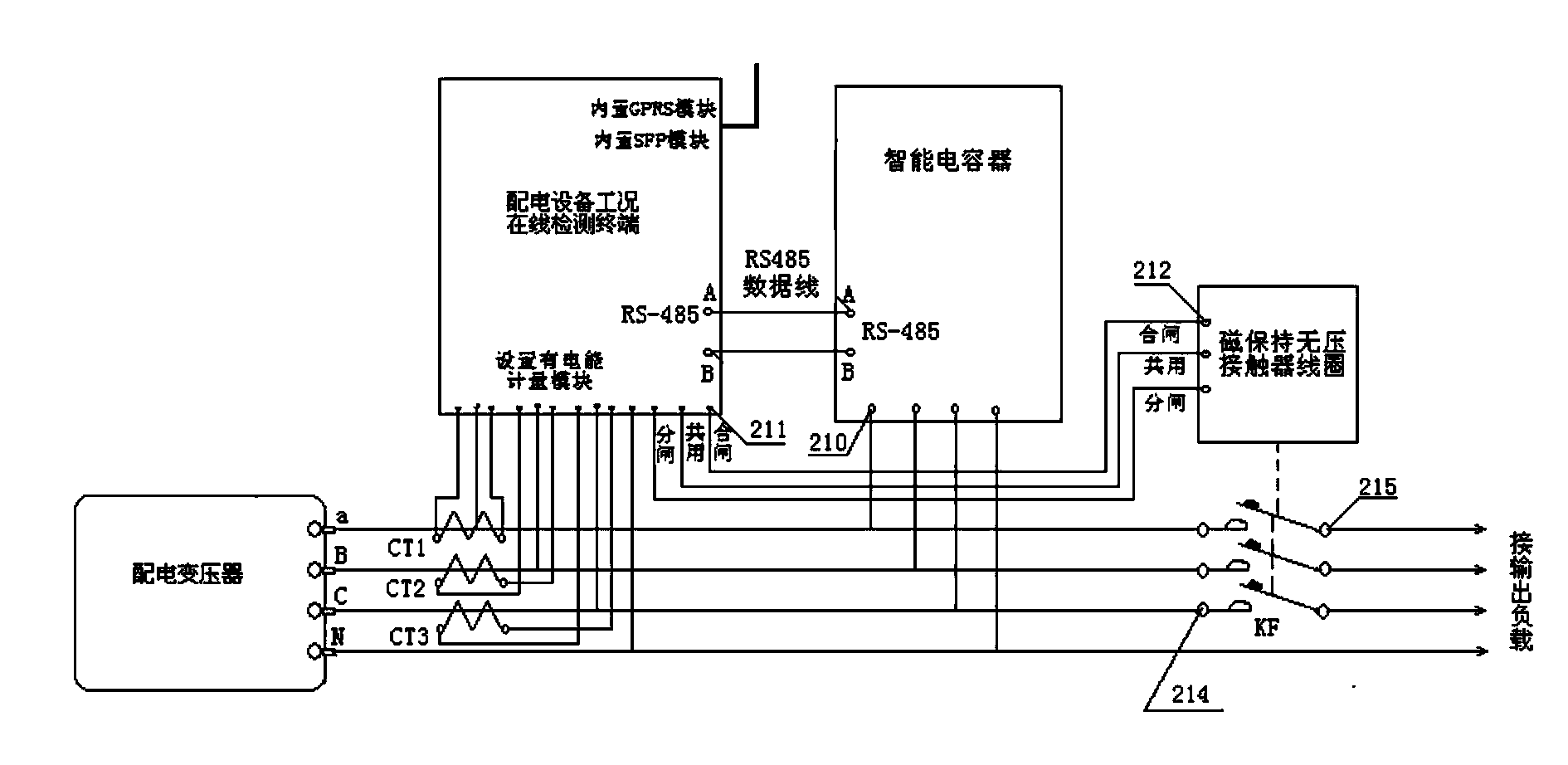

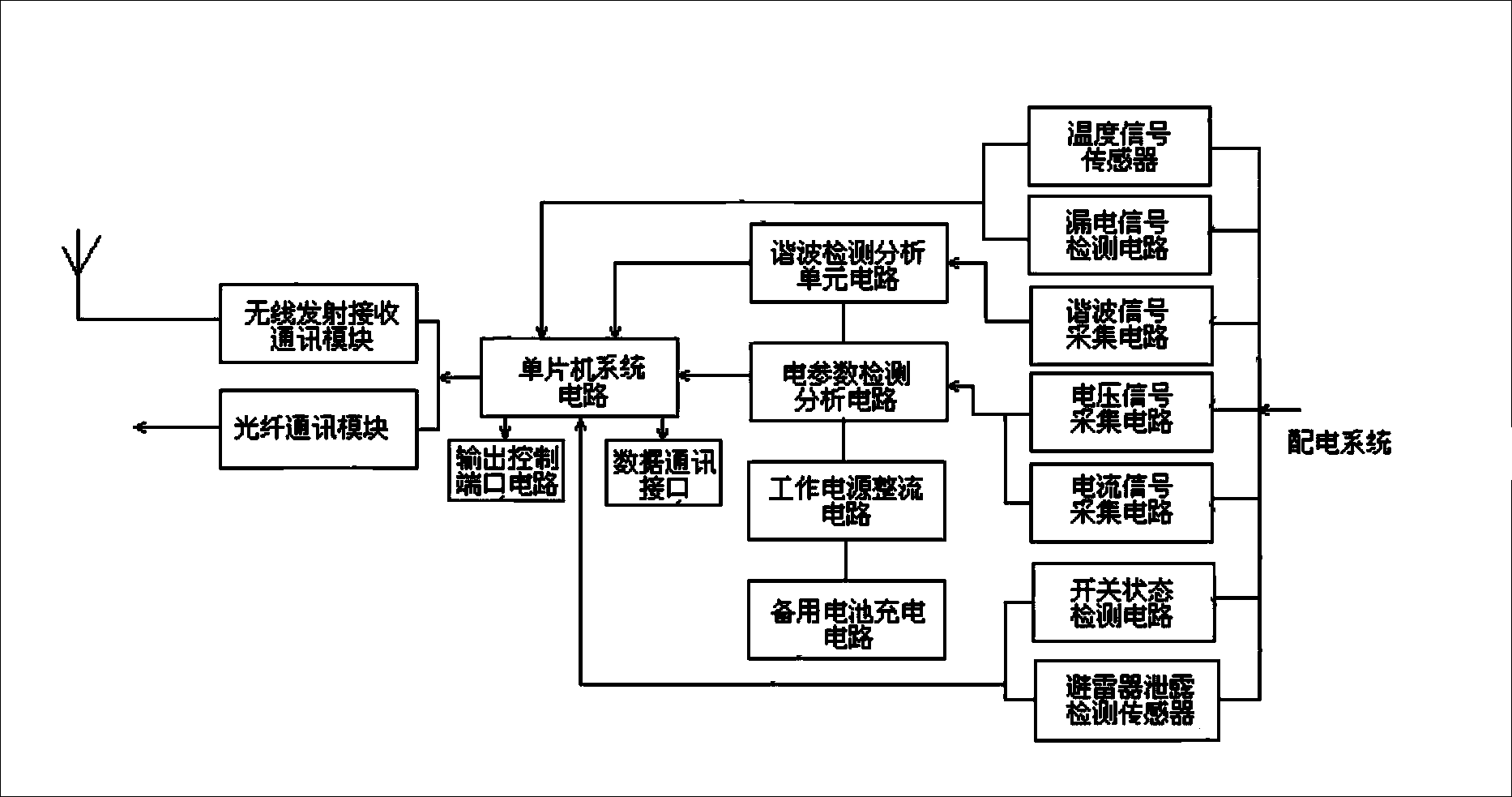

Intelligent integrated power distribution cabinet

InactiveCN103475105AVersatileHigh voltageCircuit arrangementsInformation technology support systemLow voltageSmart surveillance

The invention relates to an intelligent monitoring integrated power distribution cabinet which is applied to a power distribution system. According to the intelligent integrated power distribution cabinet, a current measuring mutual inductor, a power distribution equipment working condition on-line detecting terminal, an intelligent reactive power compensation capacitor and a magnet-holding non-voltage contactor are mounted on a metal outer shell control box according to a specified low-voltage apparatus mounting wiring standard, a wireless communication module is matched with the power distribution equipment working condition on-line detecting terminal to be arranged, and the power distribution equipment working condition on-line detecting terminal comprises an electric energy measuring module, a single chip microcomputer module, a power parameter collecting module and a harmonic signal detecting module. The power distribution cabinet is connected with a mobile communication base station and a front end computer through a wireless module and an optical fiber module, and uploading and receiving of power parameter data, early warning information and monitoring orders are achieved. The problems that a traditional power distribution system is high in operation loss, low in automatic degree, not reliable in power supply, poor in power supply quality and the like in operation are solved, and a good basis is laid for achieving intelligent monitoring management of the power distribution system.

Owner:HENAN KAIQI POWER IND

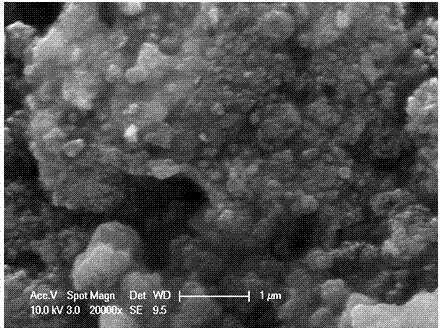

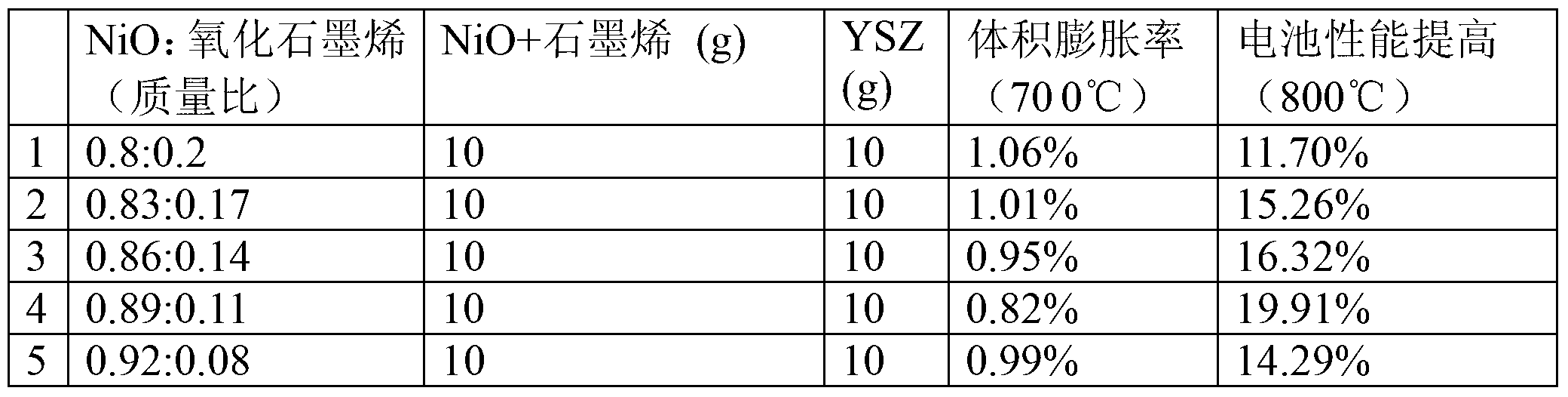

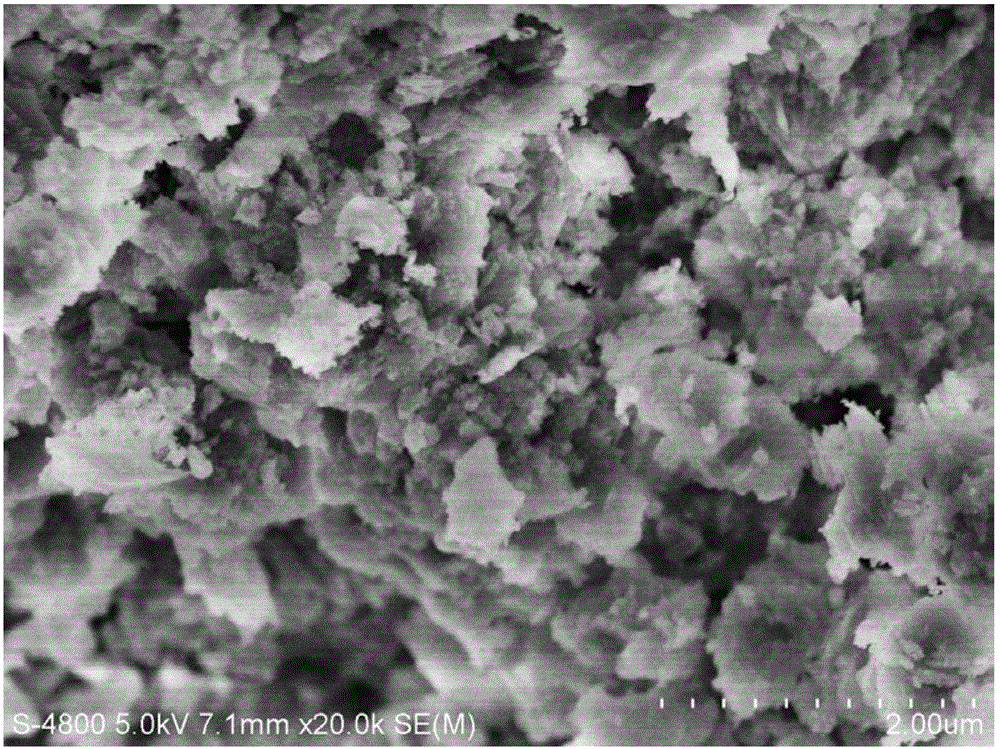

Graphene-modified nickel-base composite anode material of solid oxide fuel cell and preparation method thereof

ActiveCN103236550AImprove anti-cyclic redox performanceGood dispersionCell electrodesFuel cellsCvd graphene

The invention discloses a graphene-modified nickel-base composite anode material of a solid oxide fuel cell and a preparation method thereof. The modified nickel-base composite anode material is prepared by compounding metal salt, an oxide or hydroxide of metal, YSZ ((Yttria Stabilized Zirconia) and graphene oxide, and then a battery assembly is prepared by compounding the nickel-base composite anode material and an electrolyte material. Through testing the performance of the battery assembly, the performance of the battery assembly is greatly improved in comparison with a battery with an un-modified anode. The graphene oxide is added in a conventional nickel-base anode material for modifying the anode material, the reduced graphene is capable of stopping nickel particles from sintering and growing, and the surface appearance of the material is improved. The graphene-modified nickel-base composite anode material has the characteristics of uniformity in particle distribution, difficulty in sintering, high strength, small volume expansion ratio, stable structure and the like; and the cyclic oxidation-reduction resisting capability of the nickel-base anode material is improved. The application of the anode material has important significance to the promotion of the application of a nickel-base anode solid oxide fuel cell technology.

Owner:SHAANXI COAL & CHEM TECH INST

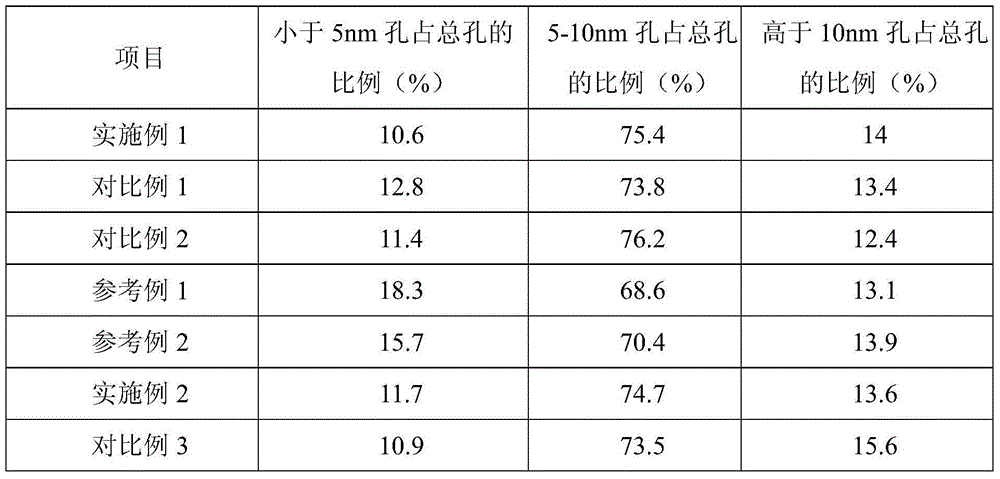

Acrylic acid catalyst regeneration method

InactiveCN103551161AStrong anti-coking abilityExtended service lifeOrganic compound preparationCarboxylic compound preparationPore distributionNitrogen atmosphere

The invention relates to an acrylic acid catalyst regeneration method. An acrylic acid catalyst has a concentrated pore distribution and a moderate total pore volume, the amount of medium-sized pores of about 5-10nm accounts for above 70% of the amount of total pores, and the medium-sized pores of about 5-10nm form short and thick tunnel structures, so the catalyst has the characteristics of strong carbon deposit resistance, difficult agglomeration and long service life. The two-step calcining regeneration method for regenerating an inactivated acrylic acid catalyst comprises the following steps: heating the inactivated acrylic acid catalyst to 280-320DEG C at a speed of 1-2DEG C / h, and carrying out constant temperature calcining for 1-10h; and heating to 330-370DEG C at a speed of 1-2DEG C / h, calcining in an oxidizing gas for 1-3d, heating to 380-410DEG C, and calcining in nitrogen atmosphere for 1-3d to obtain a regenerated acrylic acid catalyst having an equivalent activity with the fresh catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of catalyst for carbon dioxide hydrogenation methyl alcohol production

InactiveCN109772342AEasy to recycleHigh reusabilityOrganic compound preparationHydroxy compound preparationAlcohol productionMesoporous silica

The invention discloses a preparation method of a catalyst for carbon dioxide hydrogenation methyl alcohol production. The catalyst prepared through the method can sufficiently utilize the high specific surface area and the unique duct structure of mesoporous silicon dioxide, ultrahigh dispersion of active components is achieved, and generation of high-activity loci is promoted. The method comprises the following steps that 1, a polymer is weighed to be added into deionized water, stirring is performed to achieve complete dissolution; 2, concentrated hydrochloric acid, Cu(NO3)2 and Zn(NO3)2 solid powder are added, and heating and stirring are performed; 3, a silicon source is dropped in, and a precursor system solution is obtained; 4, sealing is performed for continuous stirring for 24-28h or longer, and the reaction solution is poured into a self-pressure reaction kettle for crystallization; 5, the crystallized solution is subjected to washing and suction filtering, and obtained filter cakes are dried; 6, the dried product is calcinated; 7, the calcinated product is placed into a tube furnace to be reduced in hydrogen airflow, and the catalyst for carbon dioxide hydrogenation methyl alcohol production is obtained.

Owner:NANJING UNIV OF TECH

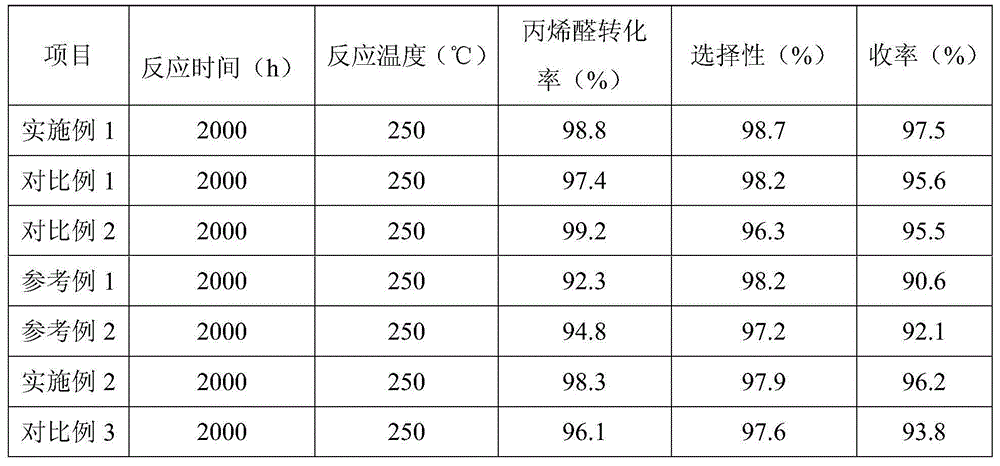

Preparation method of acrolein

ActiveCN102992977AReduce heat buildupInhibition formationOrganic compound preparationCarbonyl compound preparationFixed bedAcrolein

The invention relates to a preparation method of acrolein. According to the invention, a fixed-bed single-pipe reactor is adopted. A reaction raw material is preheated, and is delivered into a reactor. A Mo-Bi series multi-metal oxide catalyst is loaded in the reactor. The composition of the catalyst can be represented by the general formula (I): MoaBibFecCodCseCufSigAhBiOj (I). With the production method provided by the invention, single-pipe reactor local heat accumulation can be effectively reduced, hot spot formation can be inhibited, and catalyst sintering is prevented. The method has the characteristics of high reaction activity, high selectivity, and long service life. With the method, device long-period stable operation can be satisfied.

Owner:PETROCHINA CO LTD

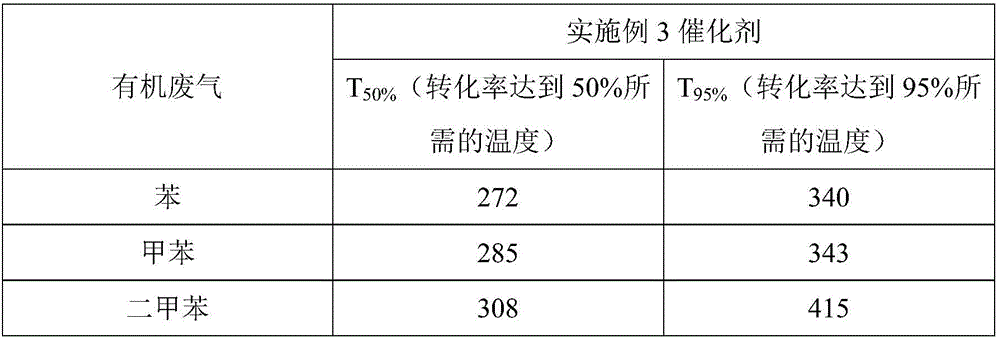

Sulfur-resistant catalytic combustion catalyst as well as preparation method and application

InactiveCN106732621ARaw materials are easy to getAnti-sulfur poisoningMolecular sieve catalystsHeterogenous catalyst chemical elementsMolecular sieveActive component

The invention discloses a sulfur-resistant catalytic combustion catalyst as well as a preparation method and an application. The catalyst takes a gamma-Al2O3 or 5A molecular sieve as a carrier and takes copper-cobalt solid solution oxide and cerium oxide or the copper-cobalt solid solution oxide as an active component, wherein the loading mass of the active component is 10%-20% of the mass of a carrier, the catalyst is prepared with an ultrasonic-equivalent volume impregnation method, and the prepared catalyst is applied to catalytic combustion to eliminate industrial volatile organic waste gas pollution. The catalyst has certain sulfur resistance in catalytic combustion for treating organic waste gas and has the advantages that the activity and stability are high, the preparation method is simple and the like.

Owner:NANJING UNIV OF TECH

Aluminum alloy for compression casting and casting of aluminum alloy

The invention provides aluminum alloy for compression casting and a high-toughness aluminum alloy casting formed of the alloy through compression casting. The aluminum alloy has the advantages of superior yield strength and extensibility, low probability of sintering and superior thermal conductivity. The aluminum alloy is characterized by comprising the following components in percentage by weight: 5.5-11.0 percent of Si, 0.3-0.7 percent of Mg, 0.05-0.3 percent of Cu, 0.2-0.8 percent of Fe, 0.2-0.5 percent of Mn, 0.05-0.3 percent of Ti, 0.05-0.1 percent of Cr, 0.05-0.3 percent of V and the balance of Al and inevitable impurities. The aluminum alloy for compression casting and the casting of the aluminum alloy provided by the invention have the advantages of high yield strength and extensibility, superior thermal conductivity and low probability of sintering.

Owner:东莞市闻誉实业有限公司

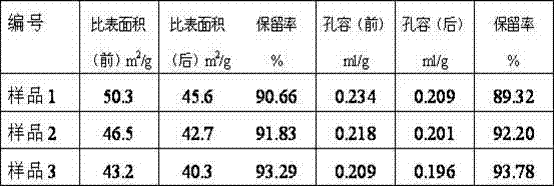

High-temperature-resistant catalyst carrier and preparation method thereof

InactiveCN102950030ASolution to short lifeNot easy to sinterCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementWater vapor

The invention discloses a high-temperature-resistant catalyst carrier and a preparation method thereof, belonging to the technical fields of high-temperature-resistant catalyst carrier materials and preparation thereof. The material of the high-temperature-resistant catalyst carrier is prepared by modifying three or more in a group consisting of Al2O3, ZrO2, TiO2, MgO and SiO2 via rare-earth compounds, wherein modifiers are the rare-earth oxides of rare-earth elements such as La, Ce, Nd and Sm, and have a content of 3-20%. The material of the carrier is extremely high in surface area stability, good in high-temperature resistance and high in specific surface area at a temperature above 600 DEG C and with the existence of high vapour; catalytic active constituents are loaded on the carriers, and during a high-temperature reaction, metal particles or metal oxide particles in the active constituents are not easy to sinter and stable in performance; and the catalyst has a long life. The carrier is simple in process and low in cost in preparation for a high-temperature reaction catalyst; and the prepared high-temperature carrier has a specific surface area of greater than 40 m<2> / g and a pore volume of greater than 0.2 ml / g, thus having a good application prospect.

Owner:大连瑞克科技股份有限公司

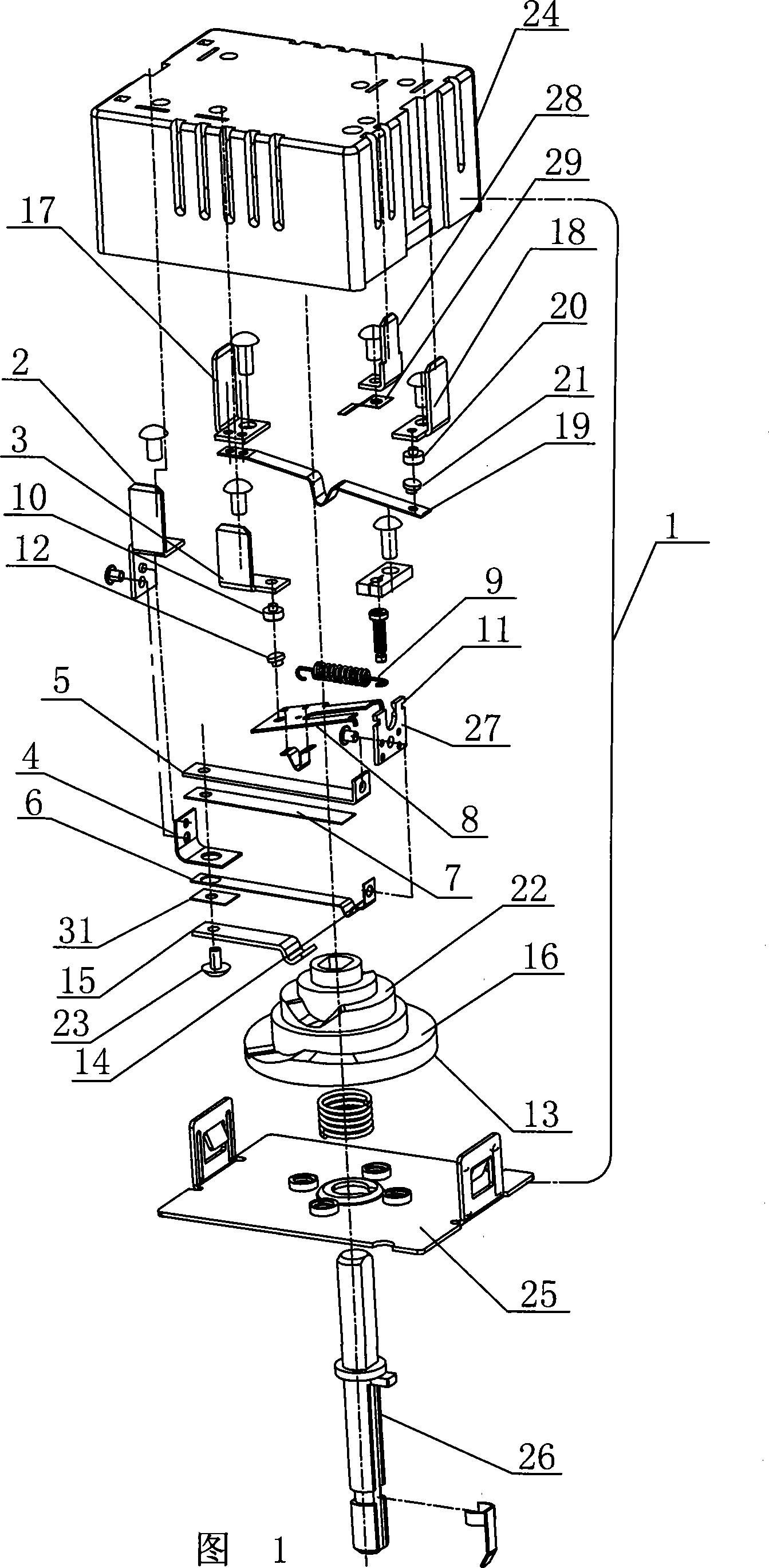

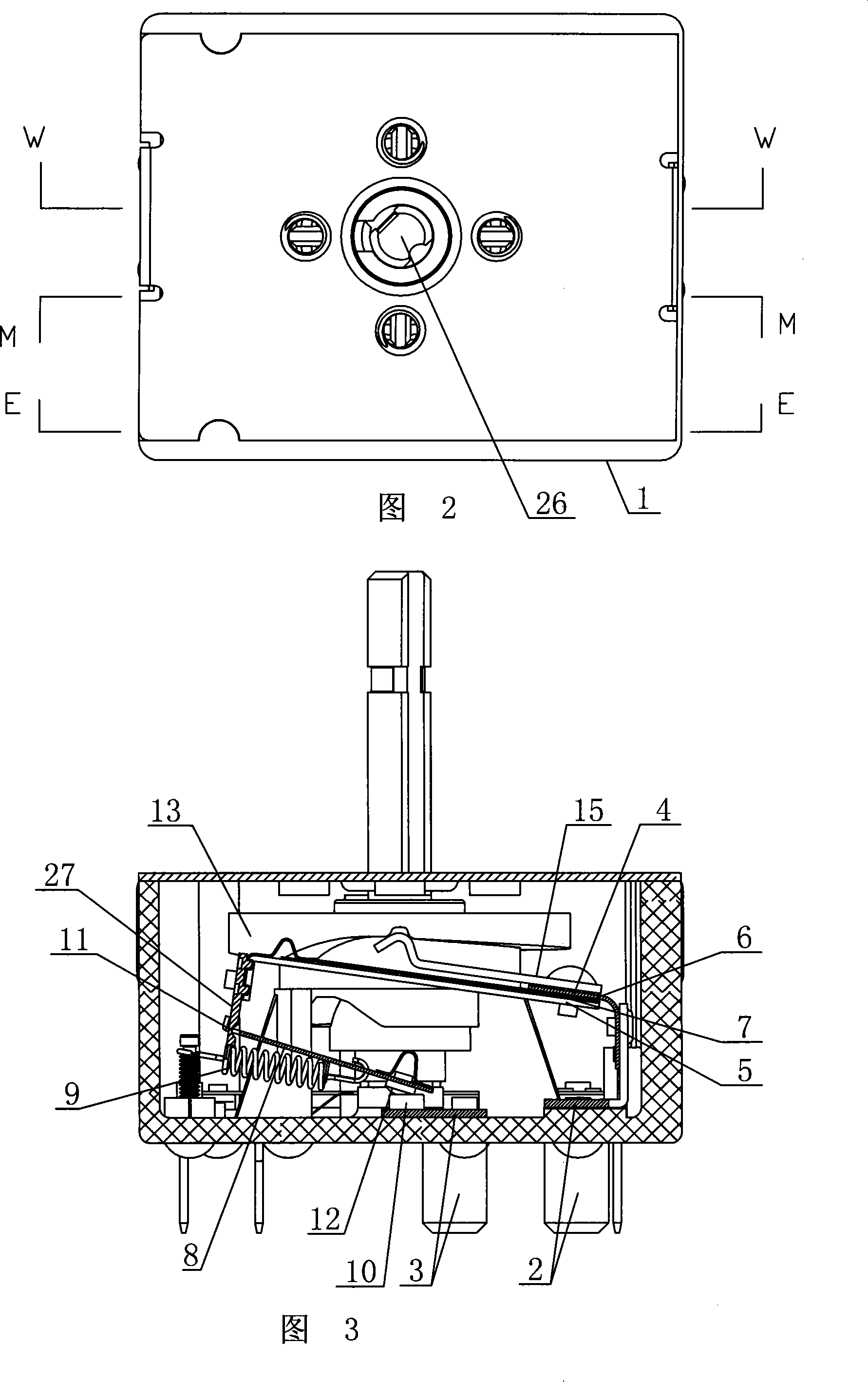

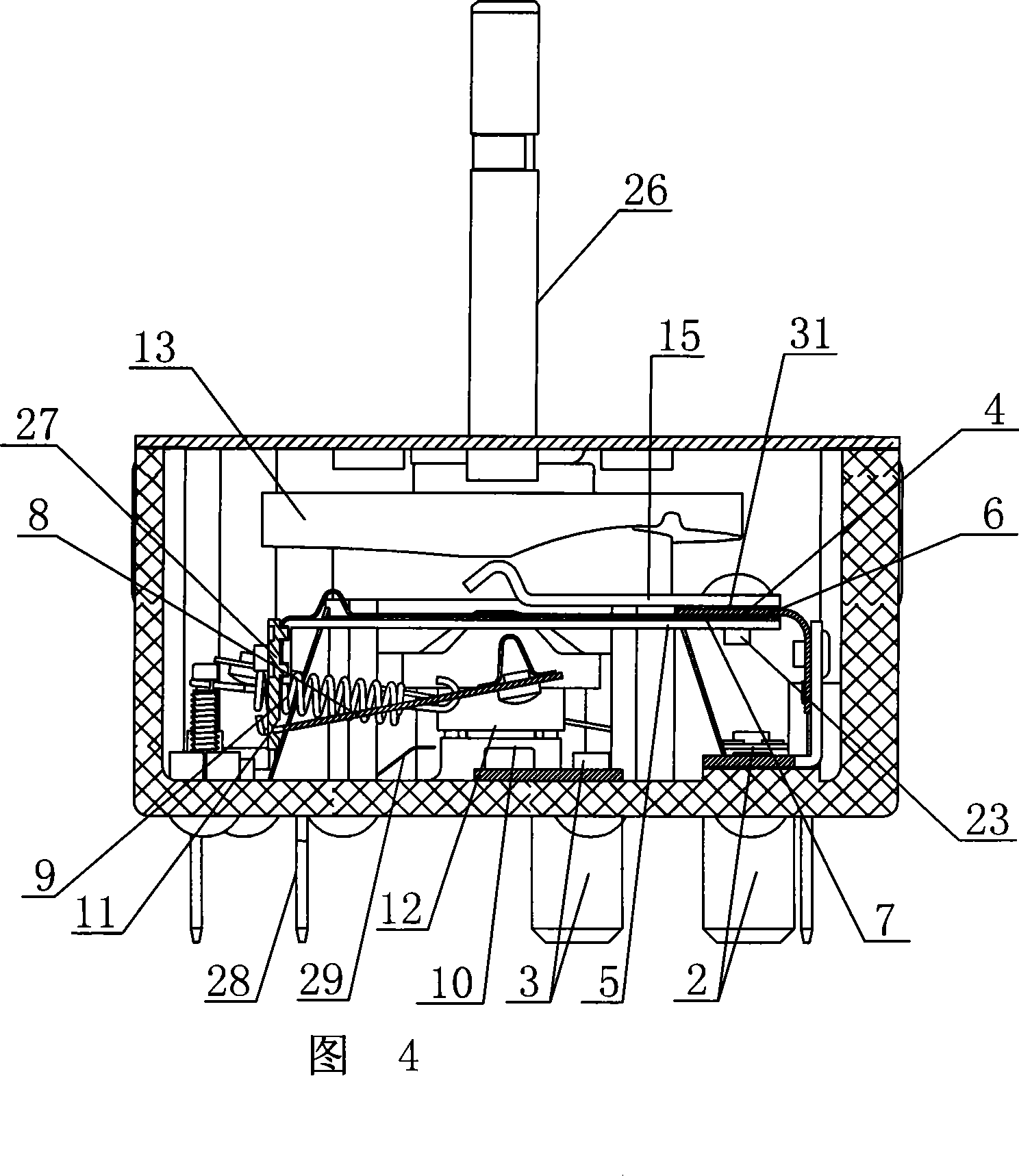

Temperature regulation switch

InactiveCN101197225ANot easy to sinterRapid disconnectionHeating/cooling contact switchesThermal switch detailsTemperature controlEngineering

The invention belongs to the temperature control technical field, which solves the problem that the on-off between contacts is gradual in the prior art, and caused to burn during connection and separation. A temperature adjusting switch is provided, wherein a shell 1 is provided with an elastic sheet 4 and a heat sensitive bimetal strip 5 is arranged on the springy end of the elastic sheet 4. An electric heater 6 is arranged on the heat sensitive bimetal strip 5, wherein the first end and the second end of the electric heater 6 are respectively connected between a first switch control end 2 and the heat sensitive bimetal strip 5 in serial manner. The tilting end of the heat sensitive bimetal strip 5 is hinged with one end of a tilting metal strip 8 to form a hinge point 11, while a swing contact 12 on the other end of the tilting metal strip 8 is arranged in the position of a contact point 10 of a second switch control end 3. The middle part of the tilting metal strip 8 is provided with a spring 9 which is fixed on the shell 1. The line formed at two ends of the spring 9 is in the range which the heat sensitive bimetal strip 5 is heated to deform and allow the hinge point 11 to swing. The shell 1 is provided with an adjusting cam 13 which can go against the elastic sheet 4.

Owner:东莞大朗金准电器厂

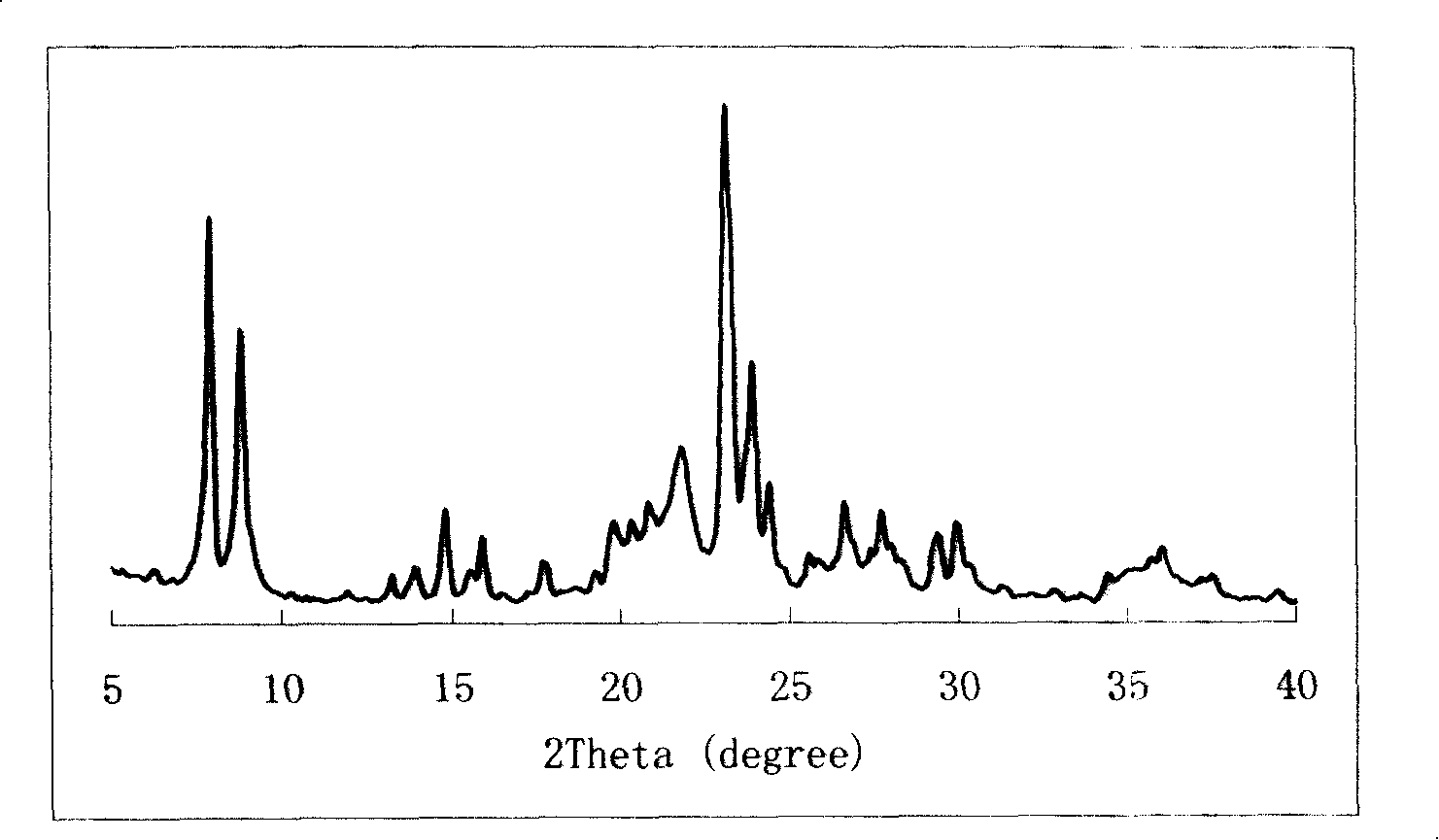

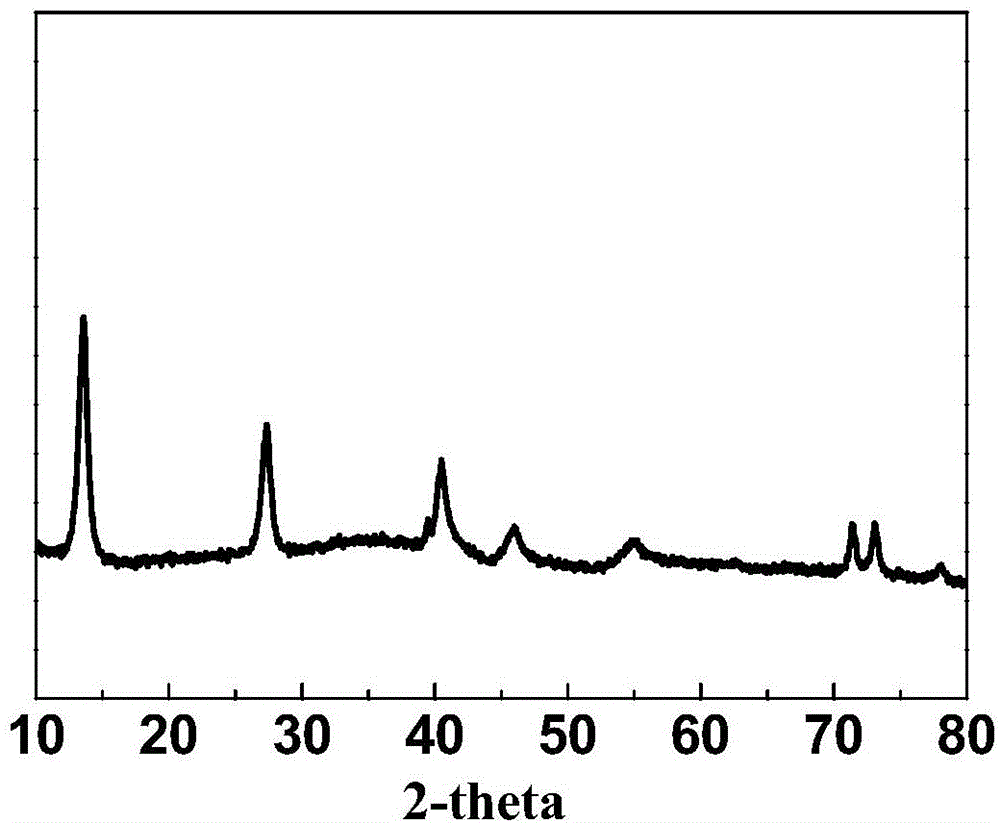

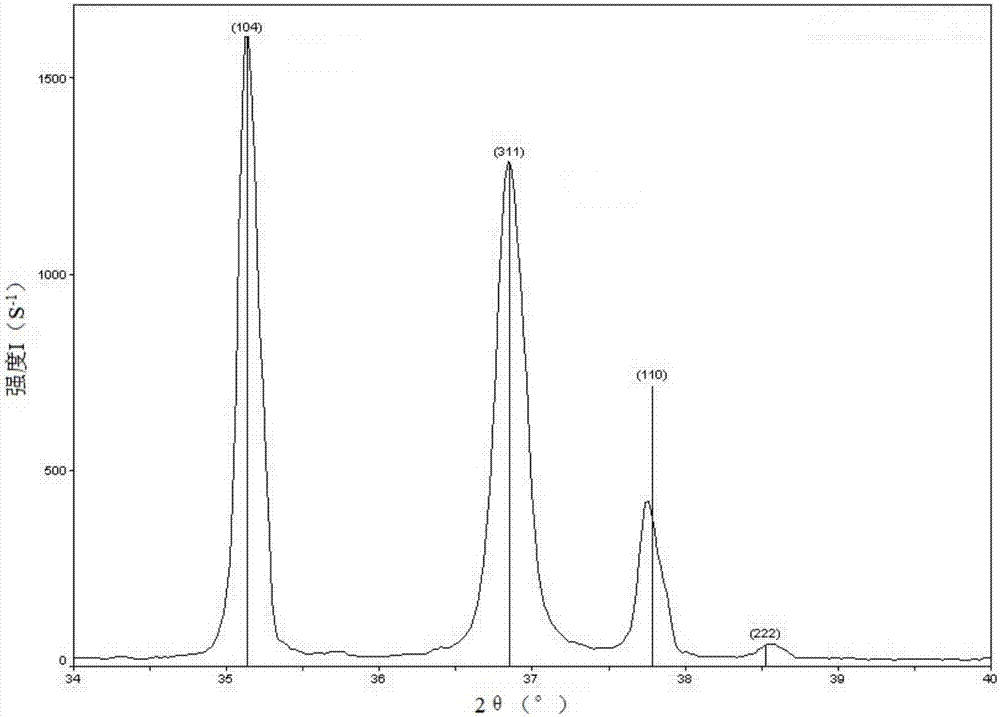

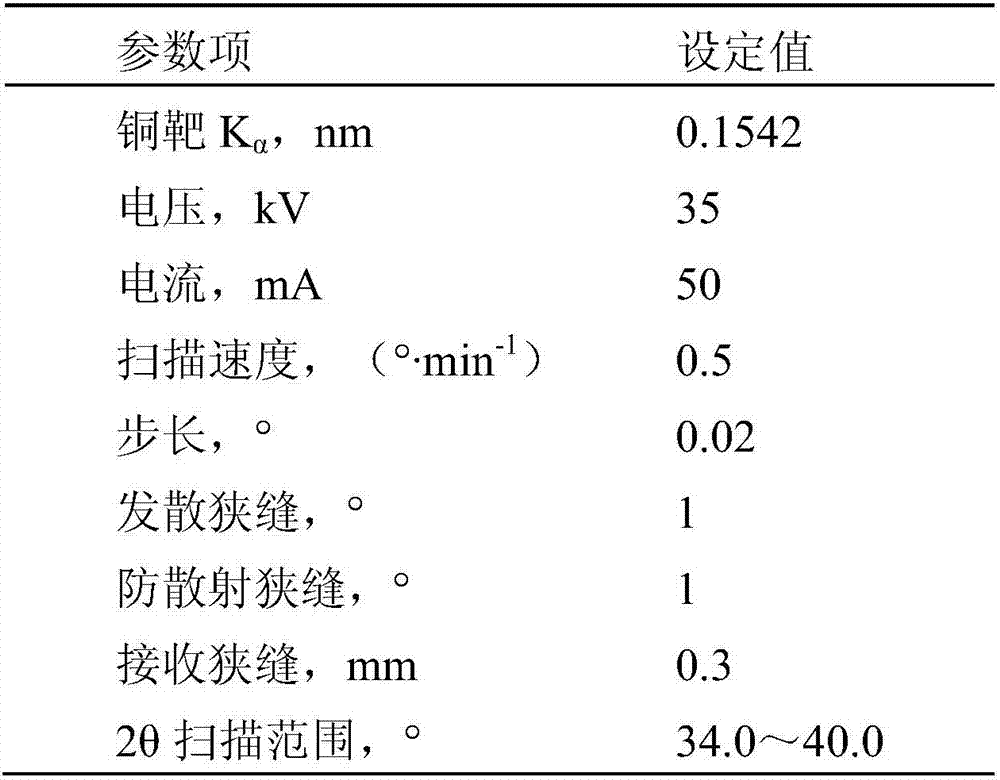

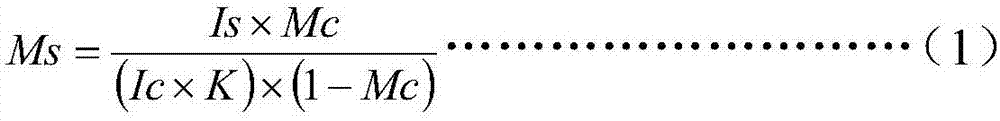

Powder X-ray diffraction method for determining magnesium aluminate spinel phase content in catalyst

ActiveCN107305191AImprove accuracyStable in natureMaterial analysis using radiation diffractionX-rayBiofuel

The invention provides a powder X-ray diffraction method for determining the magnesium aluminate spinel phase content in a catalyst. The method comprises the steps of grinding and sieving a to-be-detected biofuel hydrogenation catalyst sample to prepare a mixed sample of the to-be-detected biofuel hydrogenation catalyst sample and a corundum phase sample; simultaneously preparing a mixed standard sample of a magnesium aluminate spinel phase standard sample and a corundum phase standard sample; starting a powder X-ray diffractometer, verifying that the comprehensive stability of the diffractometer is smaller than or equal to 0.1% by using silicon powder after the diffractometer is stable to meet the determination requirements; and collecting copper target Kalpha X-ray diffraction data of the mixed standard sample and the mixed sample within a 2theta angle range of 34-40 degrees under the same working conditions of the X-ray diffractometer separately, processing programs of system software by using powder X-ray diffraction data to obtain peak intensity of a magnesium aluminate spinel phase (311) crystal surface and a corundum phase (104) crystal surface in each sample and determining the mean value, and calculating the magnesium aluminate spinel phase content in the to-be-detected biofuel hydrogenation catalyst sample by using a K-value method.

Owner:PETROCHINA CO LTD

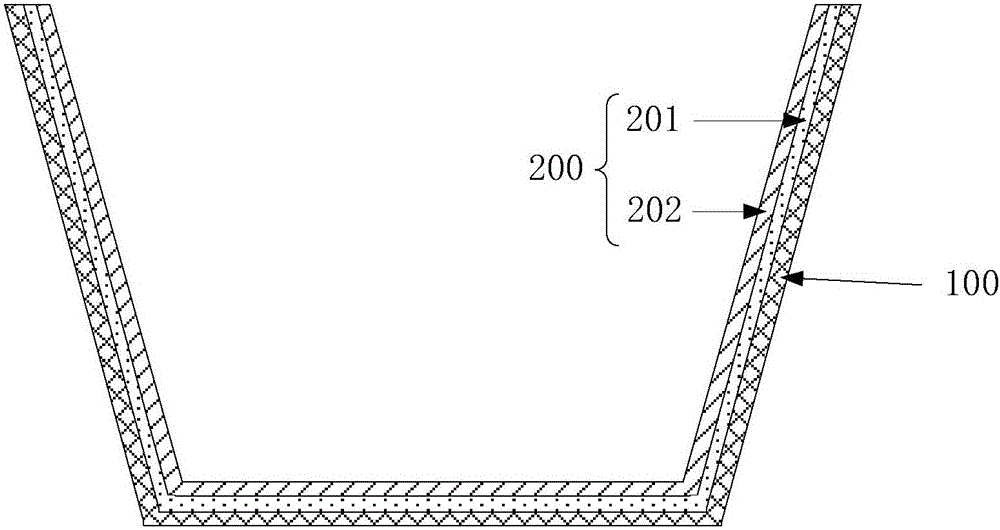

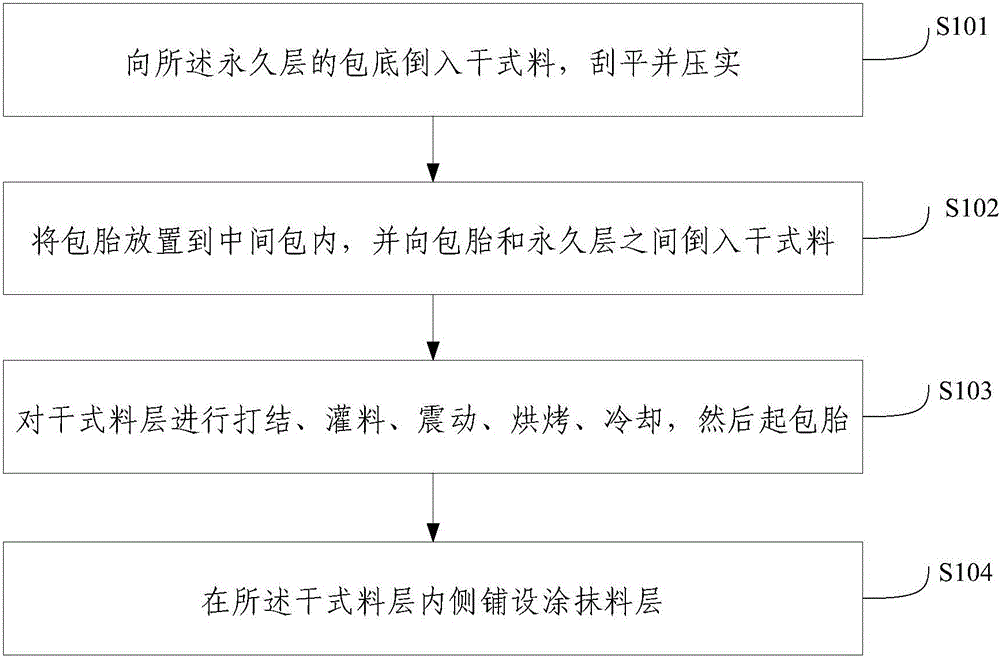

Tundish composite working lining, making method thereof and tundish

The invention provides a tundish composite working lining. The inner layer of the tundish composite working lining is a dry material layer, the outer layer of the composite working lining is a coated layer, and the dry material layer and the coated layer are closely connected and compounded into an integrated structure. The dry material layer and the coated layer are combined into the composite working lining, the advantages of the dry material layer and the coated layer are combined, and the composite working lining has the advantages of convenient construction, difficult sintering, easy tundish tilting and recarburization reduction, etc.

Owner:北京利尔高温材料股份有限公司

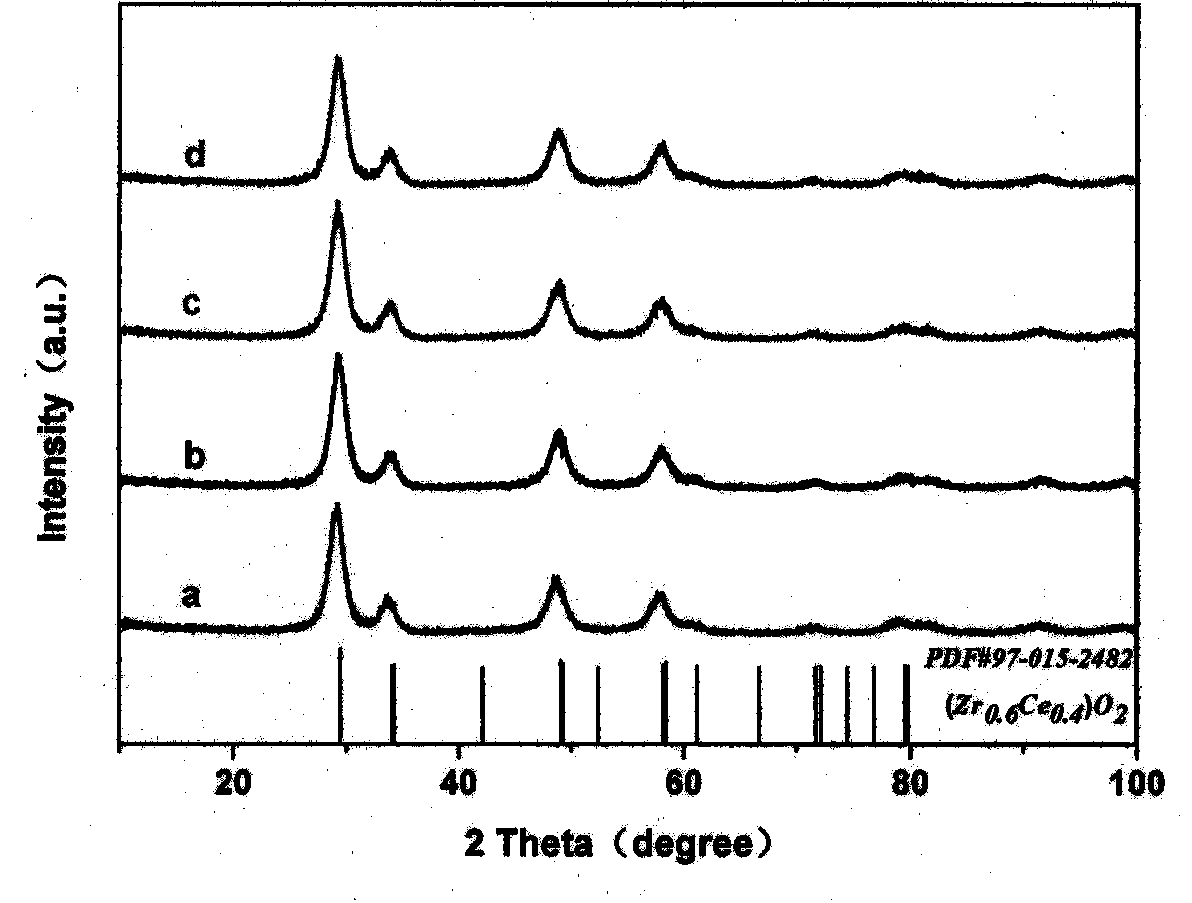

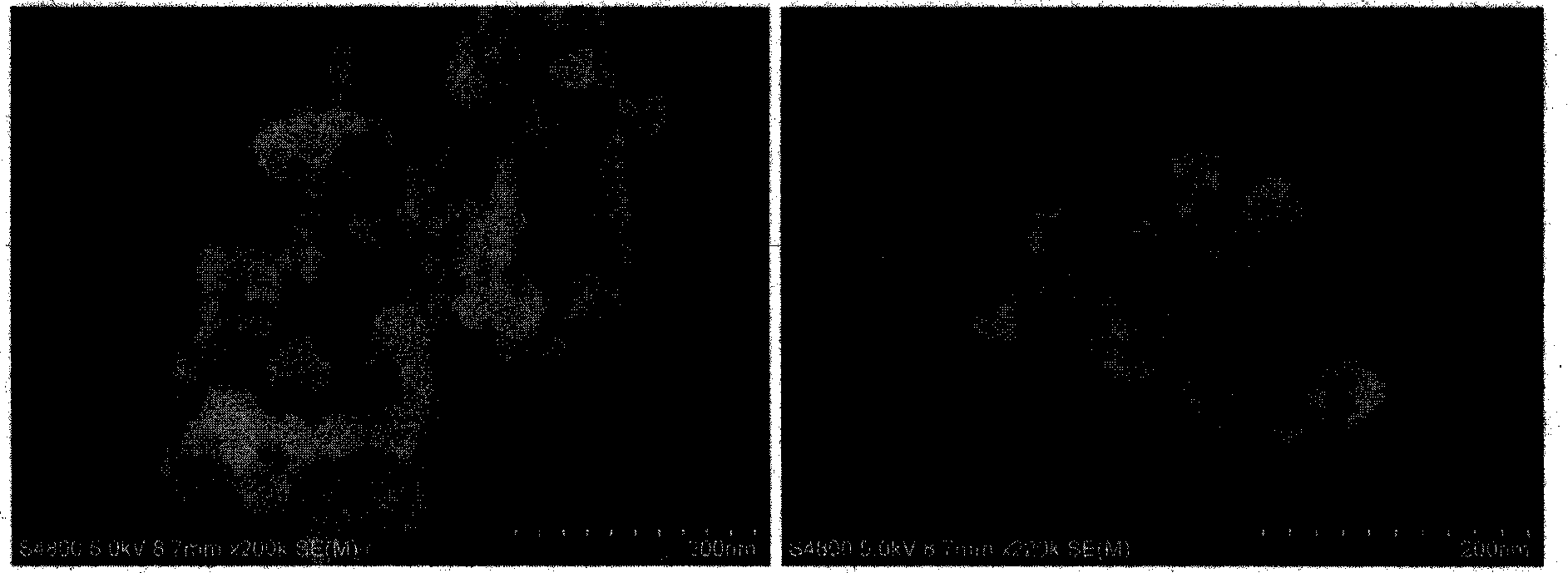

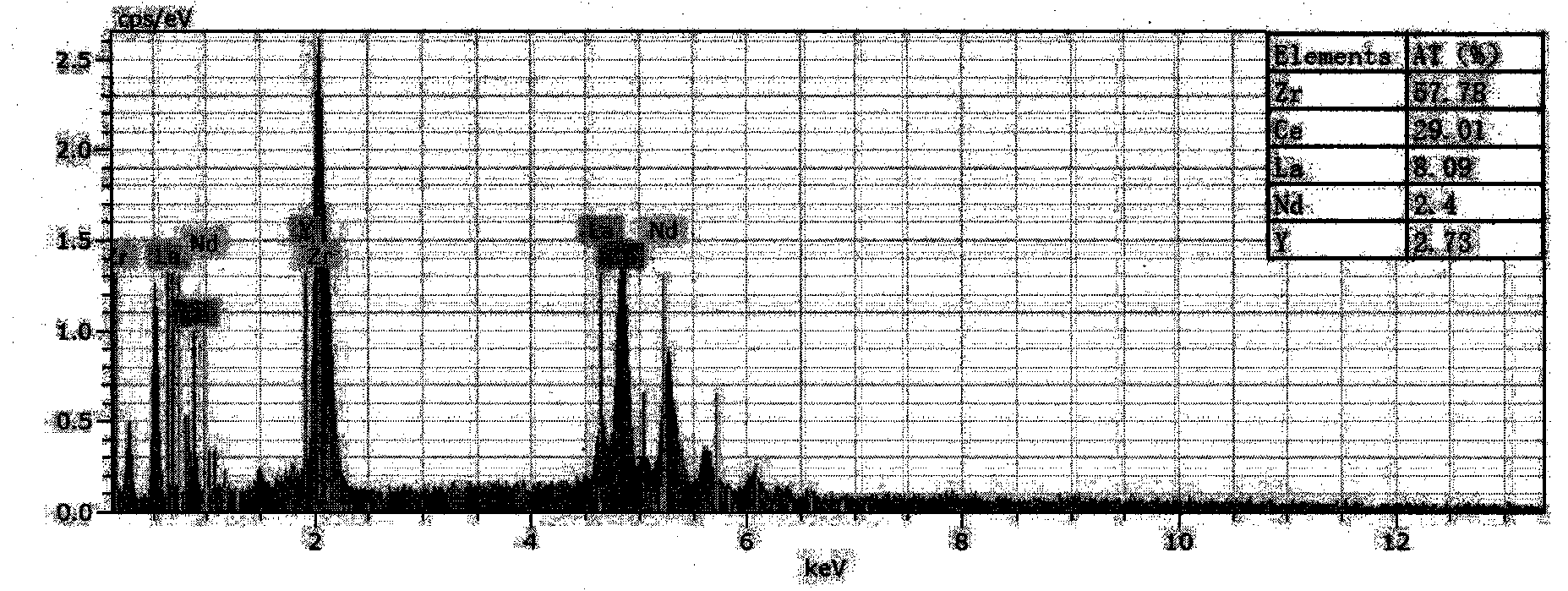

Preparation method of multi-element rare earth oxygen storage and release material in three-effect catalyst of automobile emission purification

InactiveCN104162420AThe reduction reaction is realizedWidening the air-fuel ratio windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumRare earth

The invention discloses a preparation method of a multi-element rare earth oxygen storage and release material in a three-effect catalyst of automobile emission purification. The preparation method comprises the following steps: with nitrate solutions of zirconium, cerium, lanthanum, neodymium and yttrium as a rare earth source and citric acid as a chelating agent, forming a chelate precursor through a sol-gel method, performing spray-drying on the obtained wet gel to obtain dry gel precursor powder, then rotating and calcining under a dynamic high-temperature furnace, and carrying out ball-milling through a superfine airflow to obtain a powder body of the multi-element rare earth oxygen storage and release material. According to the method for synthesizing the multi-element rare earth oxygen storage and release material, disclosed by the invention, the process is simple, no three industrial wastes are generated, no pollution is caused to the environment, convenience is brought for industrial production, and thus the method has an important significance for developing a new generation of high-performance automobile emission purification catalyst.

Owner:NEIMENGGU METALLURGICAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com