Graphene-modified nickel-base composite anode material of solid oxide fuel cell and preparation method thereof

A solid oxide and graphene modification technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as nickel catalyst sintering growth, battery performance degradation, battery structure damage, etc., to improve interface contact and improve electrode quality. Activity, effect of reducing polarization impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the solid oxide fuel cell nickel-based composite anode material modified by graphene of the present invention comprises the following steps:

[0039] 1) Preparation of nickel-based composite anode material:

[0040] Take the following three methods to composite nickel metal salt, oxide or hydroxide, YSZ and graphene oxide into a nickel-based composite anode material;

[0041] ①Compound NiO with graphene oxide, and then compound with YSZ:

[0042] Composite nickel metal salt, oxide or hydroxide and graphene oxide by means of impregnation, mechanical mixing and / or high-temperature solid-state reaction, and then compound the obtained NiO / graphene oxide composite with YSZ.

[0043] ②Compound NiO with YSZ, and then compound with graphene oxide:

[0044] Composite nickel metal salt, oxide or hydroxide and YSZ by means of impregnation, mechanical mixing and / or high-temperature solid-state reaction, and then composite the obtained NiO / YSZ composite wit...

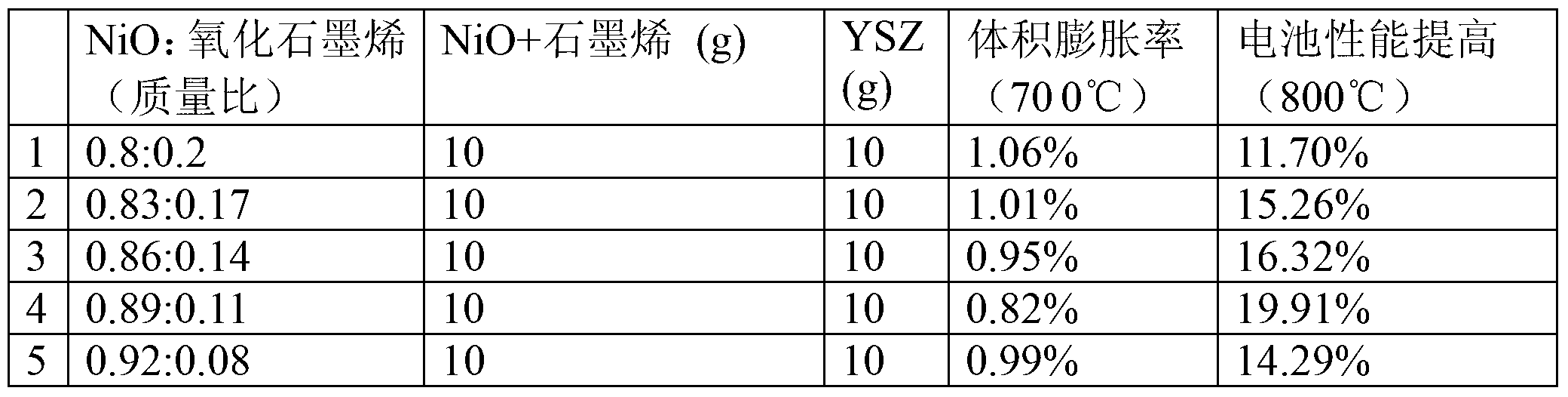

Embodiment 1

[0068] 1) Using the thermal decomposition method of nitrate to compound nickelate and graphene oxide and then compound with YSZ to prepare nickel-based composite anode material:

[0069] Weigh 2g graphene oxide and 32.173g Ni(NO 3 ) 2 ·6H 2 O, add 100ml of absolute ethanol, ultrasonically disperse for 2h, ball mill at 450r / min for 3.5h, and decompose at 700°C to obtain a mixture of 2g of graphene oxide and 8g of nickel oxide. Then mix with 6.668g of YSZ (the molar content of yttrium oxide in YSZ is 8%) (the mass ratio of graphene oxide to NiO is 0.25:1, and the mass ratio of (NiO+graphene oxide):YSZ is 60:40) , add 5g of organic binder (such as PVB and n-butanol (1:1 by weight) solvent, the amount is 30% of the total weight of the anode) to the powder, mix and grind thoroughly to obtain a nickel-based composite anode material.

[0070] 2) Determination of the volume expansion rate of graphene oxide modified composite anode materials:

[0071] Add an organic adhesive (such ...

Embodiment 2

[0076] 1) Using the method of thermal decomposition of nitrate, compound nickelate and YSZ and then compound with graphene oxide to prepare nickel-based composite anode material:

[0077] Take by weighing 34.182g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) and 15.3g of ScSZ (the molar content of scandium oxide in ScSZ is 0.05%) was added to 100ml of absolute ethanol, ultrasonically dispersed for 2h, ball milled at a speed of 450r / min for 3.5h, and decomposed at 1100°C to obtain 8.5g of NiO and 15.3 Composite of ScSZ of g. Mix this composite with 1.7g graphene oxide (the mass ratio of graphene oxide to NiO is 0.2:1, and the mass ratio of (NiO+graphene oxide): YSZ is 40:60) and grind them evenly. Add 8g of organic adhesive (such as PVB and n-butanol (1:1 by weight) solvent, the dosage is 30% of the total weight of the anode) and mix and grind thoroughly to obtain a nickel-based composite anode material.

[0078] 2) Determination of the volume expansion rate of graphene oxide modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com