Patents

Literature

117results about How to "Uniform structure distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

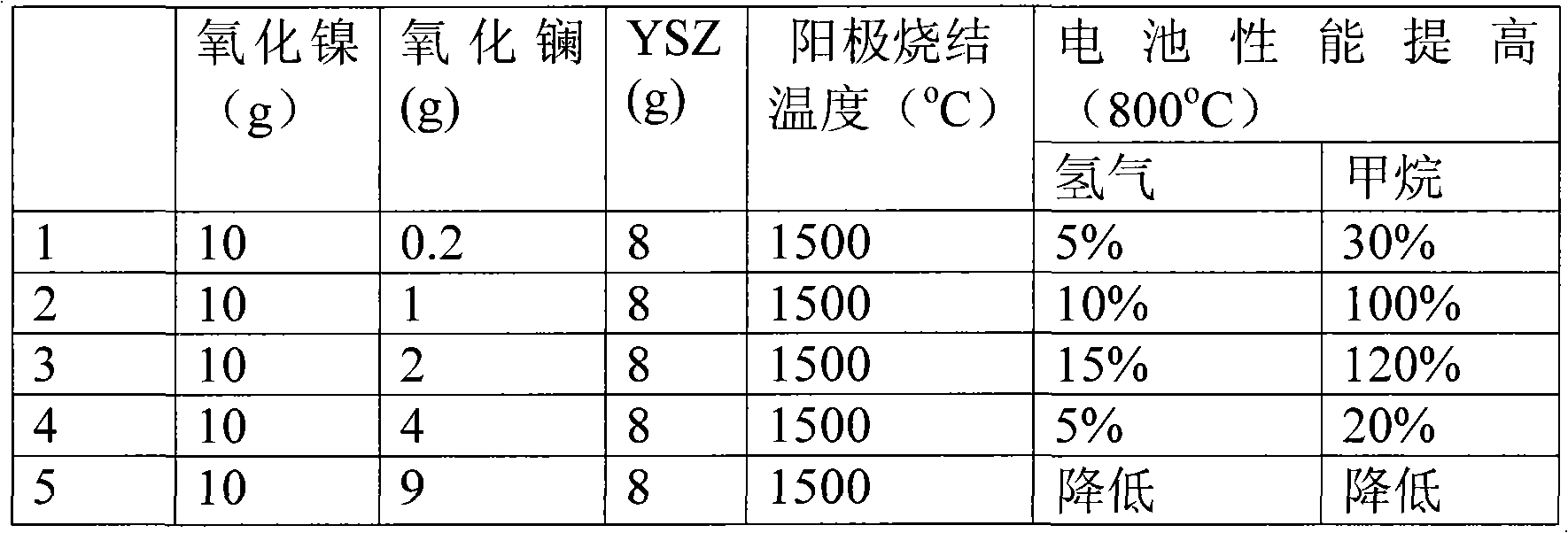

Compound anode of solid-oxide fuel battery and method for producing the same

InactiveCN101295792AGood electrode microstructureHigh activityCell electrodesSolid electrolyte fuel cellsFuel cellsRare earth

The invention relates to a solid oxide fuel cell, in particular to a composite anode of the solid oxide fuel cell and a preparation method thereof. According to weight percentage, the weight composition of the composite anode comprises 30 to 69.9 percent of NiO, 0.1 to 35 percent of rare earth materials and 30 to 69.9 percent of zirconia YSZ with stable yttrium oxide. The composite anode of the solid oxide fuel cell is compounded by adding the rare earth materials to the traditional anode of nickel oxide and zirconia with stable yttrium oxide, and the rare earth materials are added to the anode so as to improve the performance of the anode; the composite anode has the advantages of even distribution of electrode structure, tight interface contact between nickel and YSZ, low polarization impedance, high activity, etc., thus improving the output performance of the cell. The novel composite anode can be applied to flat type, tube type and flat tube type solid oxide fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

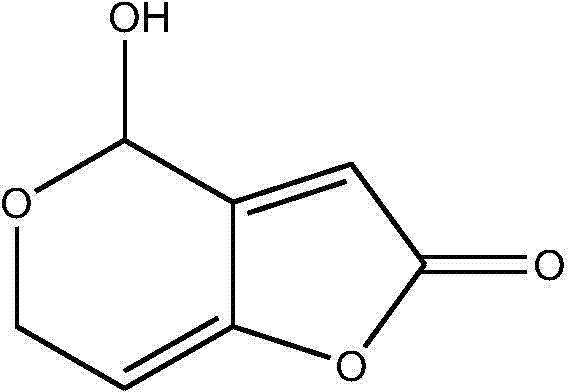

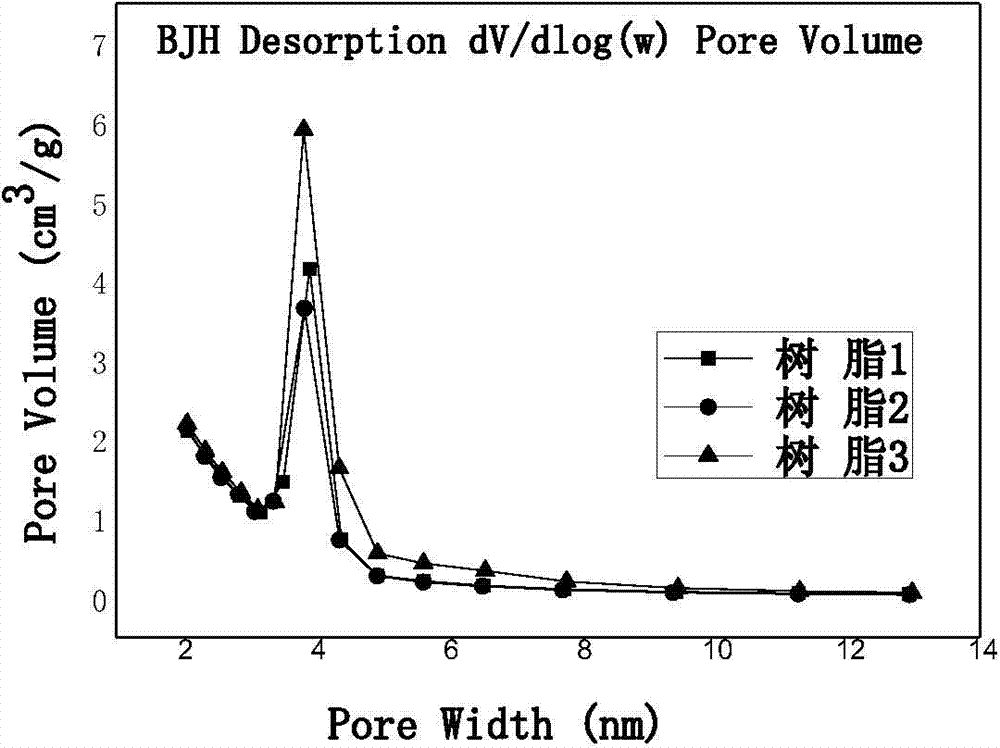

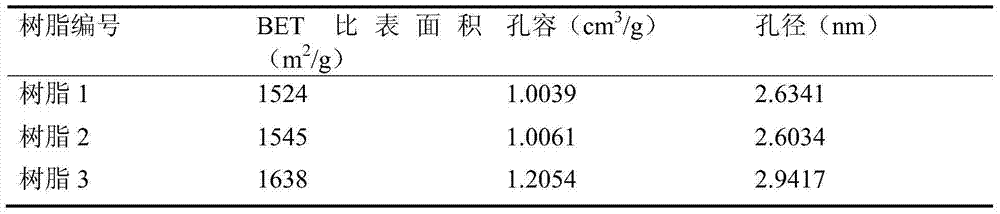

Ultrahigh cross-linked macro-porous adsorption resin applicable to removal of patulin

ActiveCN103772573ADense channelsUnique Pore Size DistributionIon-exchange process apparatusOther chemical processesCross-linkFunctional monomer

The invention provides ultrahigh cross-linked macro-porous adsorption resin which is obtained by taking a styrene monomer as a functional monomer, taking a multi-vinyl monomer as a cross-linking agent, suspending and polymerizing in the presence of a pore forming agent to obtain low-cross-linked macro-porous polystyrene white ball, reacting the obtained white ball with chloromethyl ether under the catalysis of lewis acid to obtain chloromethylation macro-porous polystyrene resin, and carrying out a Friedel-Crafts alkylation reaction on the obtained chloromethylation macro-porous polystyrene resin in the presence of a swelling agent by taking the lewis acid as a catalyst. Through adopting a novel cross-linking agent and pore forming agent system, the obtained resin has the advantages of high specific surface area and uniform pore diameter; the specific surface area is up to 1500-1800m<2> / g, the pore diameter distribution is uniform, a pore channel is dense and the average pore diameter is small; the pore diameter of the obtained macro-porous resin is rightly applicable to removal of patulin in juice and the removing efficiency is high; the resin can be used for pointedly removing the patulin which stably exists in the juice and the potential hazards on the human health, caused by the patulin in the juice, are solved; the ultrahigh cross-linked macro-porous adsorption resin has great social and economic benefits.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

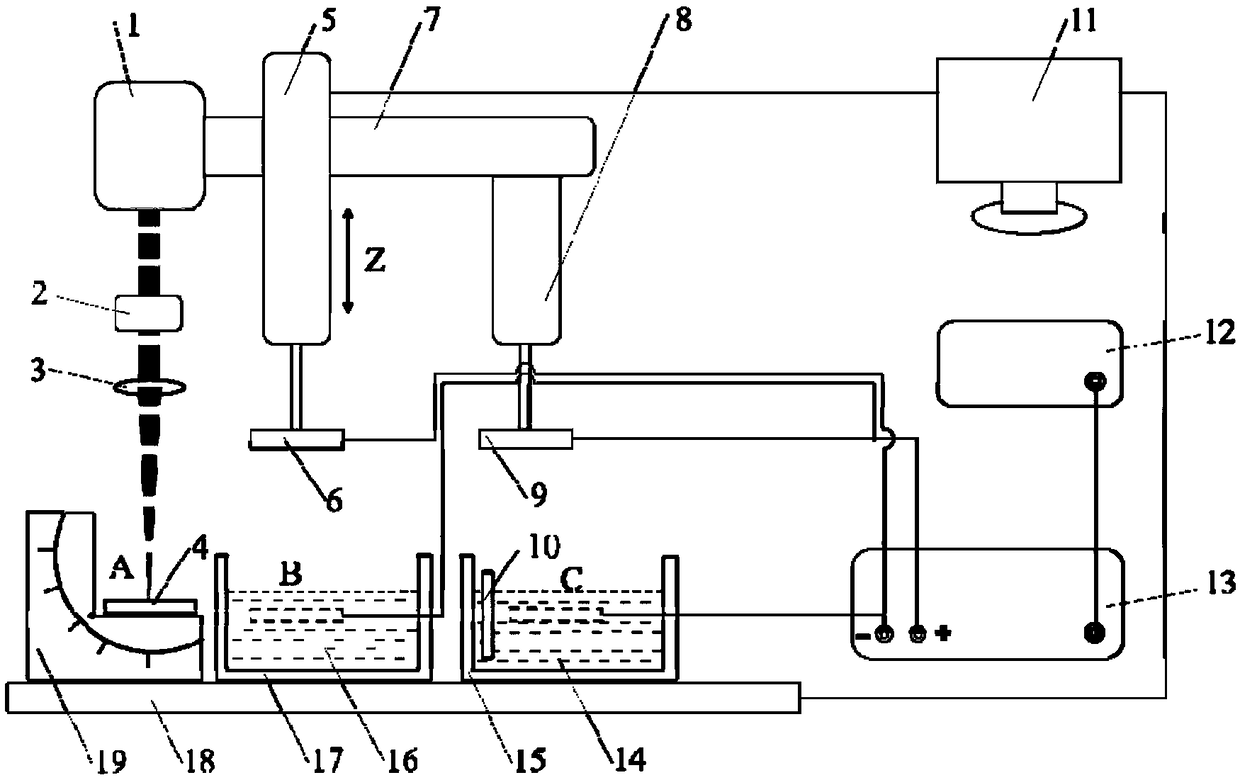

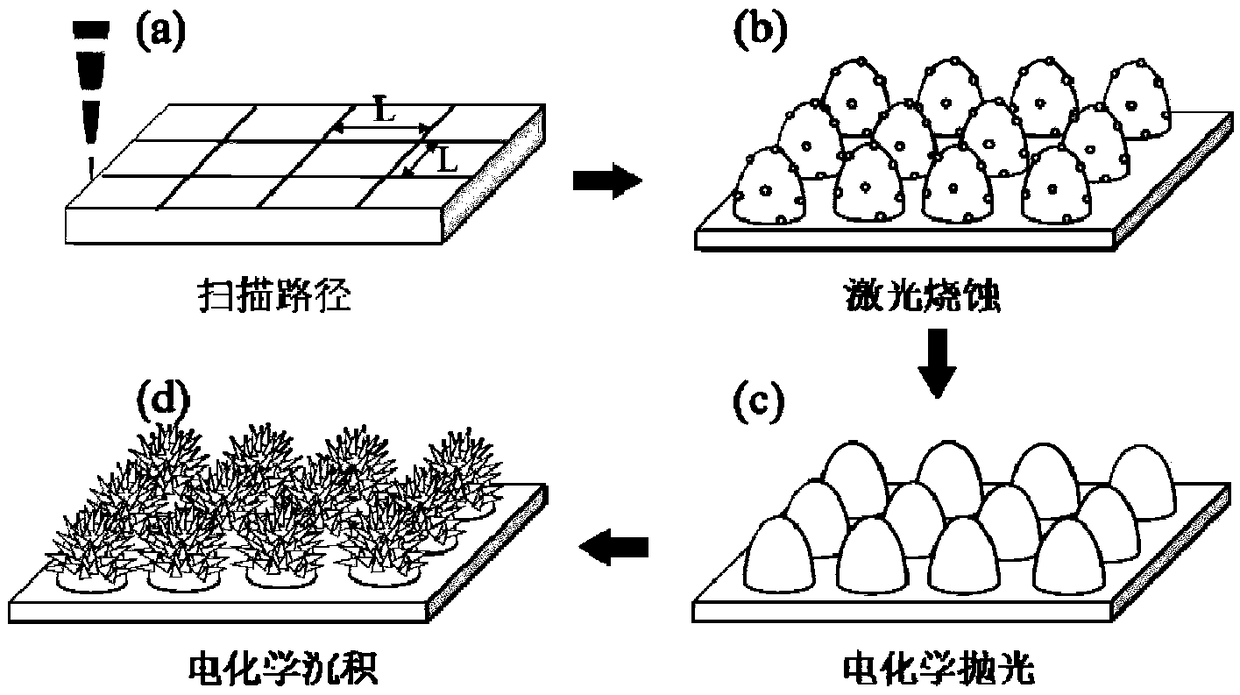

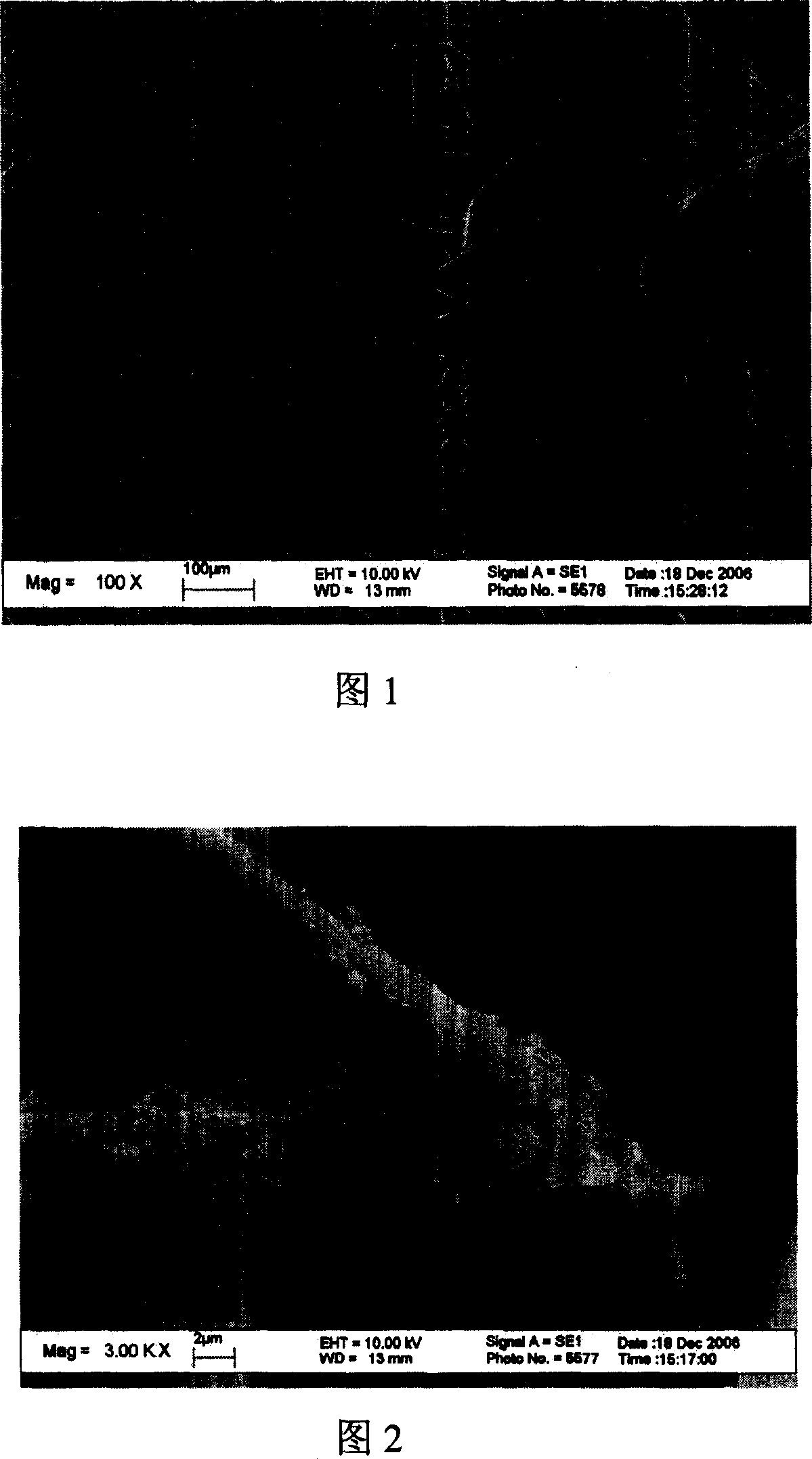

System and method for preparing bionic super-hydrophobic metal surface through laser-electrochemical deposition

ActiveCN109226973AImprove thermal stabilityImprove mechanical stabilityElectrochemical machining apparatusLaser beam welding apparatusMicro nanoSlag

The invention discloses a system and method for preparing a bionic super-hydrophobic metal surface through laser-electrochemical deposition and belongs to the field of preparation of bionic super-hydrophobic metal surfaces. The method comprises the following steps that 1, through a laser ablation texturization method, a micron array structure is constructed on a metal substrate; 2, through electrochemical polishing, nano particles and slag which adhere to the micron structure surface in the ablation process are removed; 3, through electrochemical deposition, densely-distributed nano pyramid structures cover the micron structure surface, and the micro-nano composite structure is prepared. Compared with the prior art, the method for preparing the bionic super-hydrophobic metal surface has the advantages that low-surface-energy substance modification is not needed, the prepared metal surface also has good hydrophobic stability at low temperature and can be applied to metal slopes, and theindustrial application field of the super-hydrophobic metal surface is enlarged.

Owner:JIANGSU UNIV

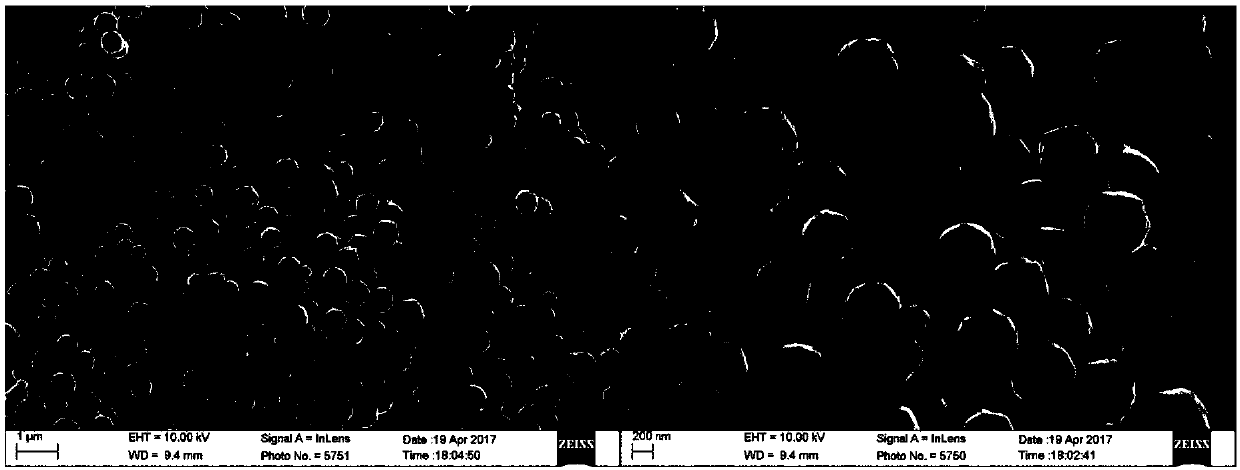

Superfine iron-copper alloy powder and preparation method thereof

The invention relates to superfine iron-copper alloy powder and a preparation method thereof. The superfine iron-copper alloy powder is prepared by using ferric oxalate powder at an industrial raw material stage and cupric oxide powder at an industrial raw material stage as raw materials through high-energy ball milling and hydrogen reduction and has a fisher particle size smaller than 1.0 microns and a oxygen content smaller than or equal to 0.5 percent by weight. The invention has the advantages that grains of the superfine iron-copper alloy powder are thinner, the physical and chemical properties are superior, and the manufacture cost is low.

Owner:惠州市新宏泰科技有限公司

Preparation method of self-hydrophobic silicon dioxide aerogel composite material

InactiveCN109437832ANot easy to cause crackingUniform structure distributionMaterials preparationSolvent

The invention discloses a preparation method of a self-hydrophobic silicon dioxide aerogel composite material. The method comprises the following steps of (1) sol preparation: preparing the sol from raw materials comprising silicon source precursors, hydrophobic modifiers, solvents, water and hydrolysis catalysts; (2) alcogel preparation by compounding sol and substrates; (3) aging of alcogel; (4)silicon dioxide aerogel composite material preparation by supercritical CO2 drying of aged alcogel; (5) aerogel composite material finished product correlation performance detection. The prepared self-hydrophobic silicon dioxide aerogel composite material has the excellent heat insulation performance, waterproof performance, fireproof and mechanical performance; the construction is convenient. The preparation method avoids a single hydrophobic modification step; the technical production steps are simplified; the operation is simple and easy; the process is controllable; the production continuity is realized.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

Polycarboxylate dispersing agent and preparation method thereof

PendingCN110054736AIn line with production principlesGood dispersionBiocideAnimal repellantsWastewaterEngineering

The invention discloses a polycarboxylate dispersing agent. The polycarboxylate dispersing agent comprises, by mass, 30-100 parts of monomers A, 30-100 parts of monomers B, 5-20 parts of initiators, 1-15 parts of chain transfer agents, 200 parts of deionized water and 6-15 parts of pH regulators. Linear polycarboxylate of the polycarboxylate dispersing agent is poisonless, and harmless to the human body. No waste water or waste residue is discharged during production of the polycarboxylate, discharged gases do not contain toxic components, and a green chemical production principle is followed.

Owner:SHANGHAI SHIDA POLYMER MATERIAL

Composite material of micro-fiber encapsulated active carbon or active carbon catalyst and preparation method thereof

InactiveCN101007270AUniform structure distributionEasy to manufacturePhysical/chemical process catalystsFiberVoid ratio

The invention discloses composite material of microfibrillar coating activated carbon or activated carbon catalysator and preparation method. The material includes micrometer ceramics or metal micro-fiber and micrometer activated carbon or activated carbon catalysator particles, the activated carbon or activated carbon catalysator particles are coated in the three-dimensional network structure uniformly. It mixes the adhesive agent, micro-fiber, activated carbon or activated carbon catalysator particle with the mass ratio of 1:1-3.5:7-10 and right amount of water to forming uniform slurry after high-speed agitation; then prepares precursor using wet paper-making art; the precursor is adglutinated and formed under 750-1400DEG C after dried fully. The material preparation art is simple and low in cost, the void ratio is high and can be adjusted within a wide range, mechanical strength is high, flexibility is good and molding is easy; it can replaces traditional activated carbon or activated carbon catalysator fixed-bed layer, enhance mass and heat transfer, reduce pressure drop and improve contact efficiency, its application prospects are bright.

Owner:SOUTH CHINA UNIV OF TECH

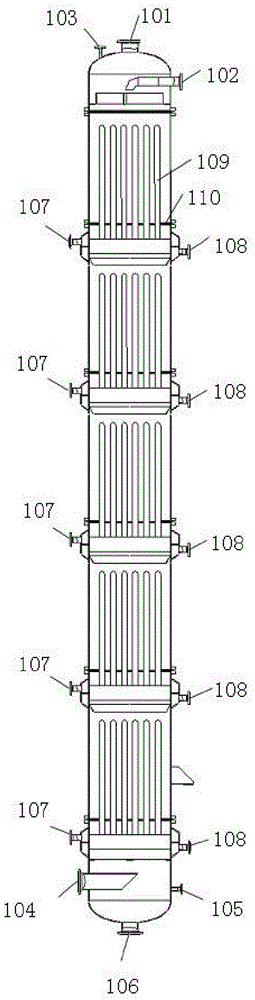

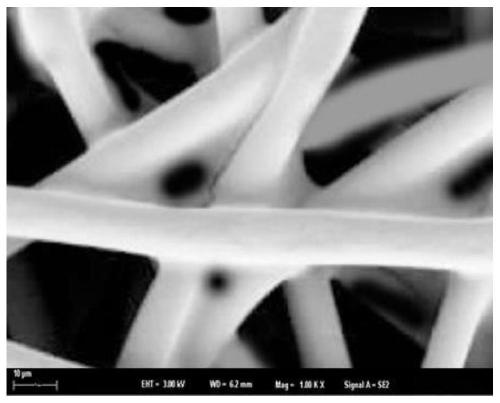

Paper sintering metal fiber load molecular sieve membrane and preparation method thereof

InactiveCN102512978AUniform structure distributionSimple preparation processSemi-permeable membranesMetal fiberMolecular sieve

The invention discloses a paper sintering metal fiber load molecular sieve membrane and a preparation method thereof. The paper sintering metal fiber load molecular sieve membrane has the thickness of 0.1-1.5mu m. The preparation method comprises the following steps of: pulping size prepared from an adhesive and a metal fiber at a mass ratio of (1-1):(1-3), drying, then sintering in a nitrogen or hydrogen atmosphere, preprocessing through an anode oxidization process, and synthesizing the molecular sieve membrane with an adjustable thickness on the surface of the metal fiber by adopting a secondary growth process. The preparation method is simple; the sintering metal fiber is of a three-dimensional net structure, and has the characteristics of high porosity, high mechanical strength, good flexibility and convenience for formation; the porosity can be regulated within a large range; and the synthesized molecular sieve membrane is thin and is good in continuity.

Owner:SOUTH CHINA UNIV OF TECH

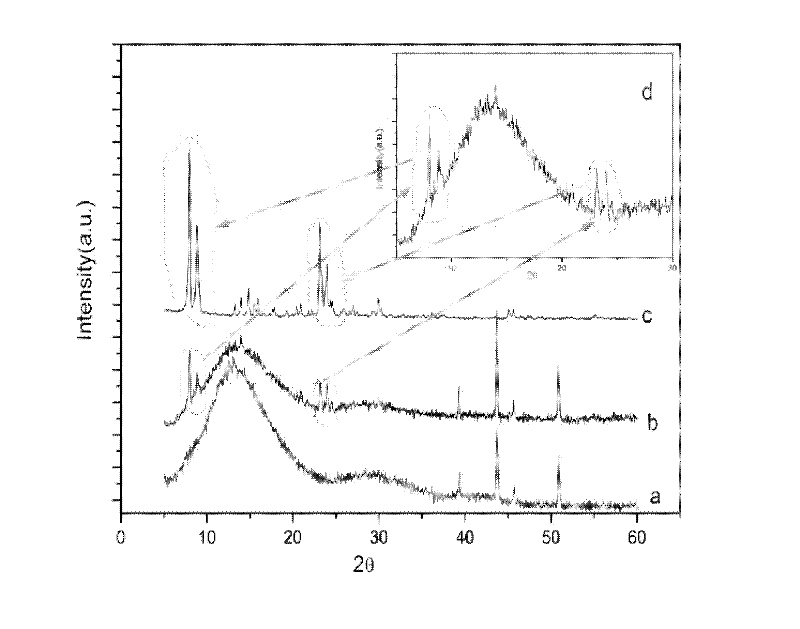

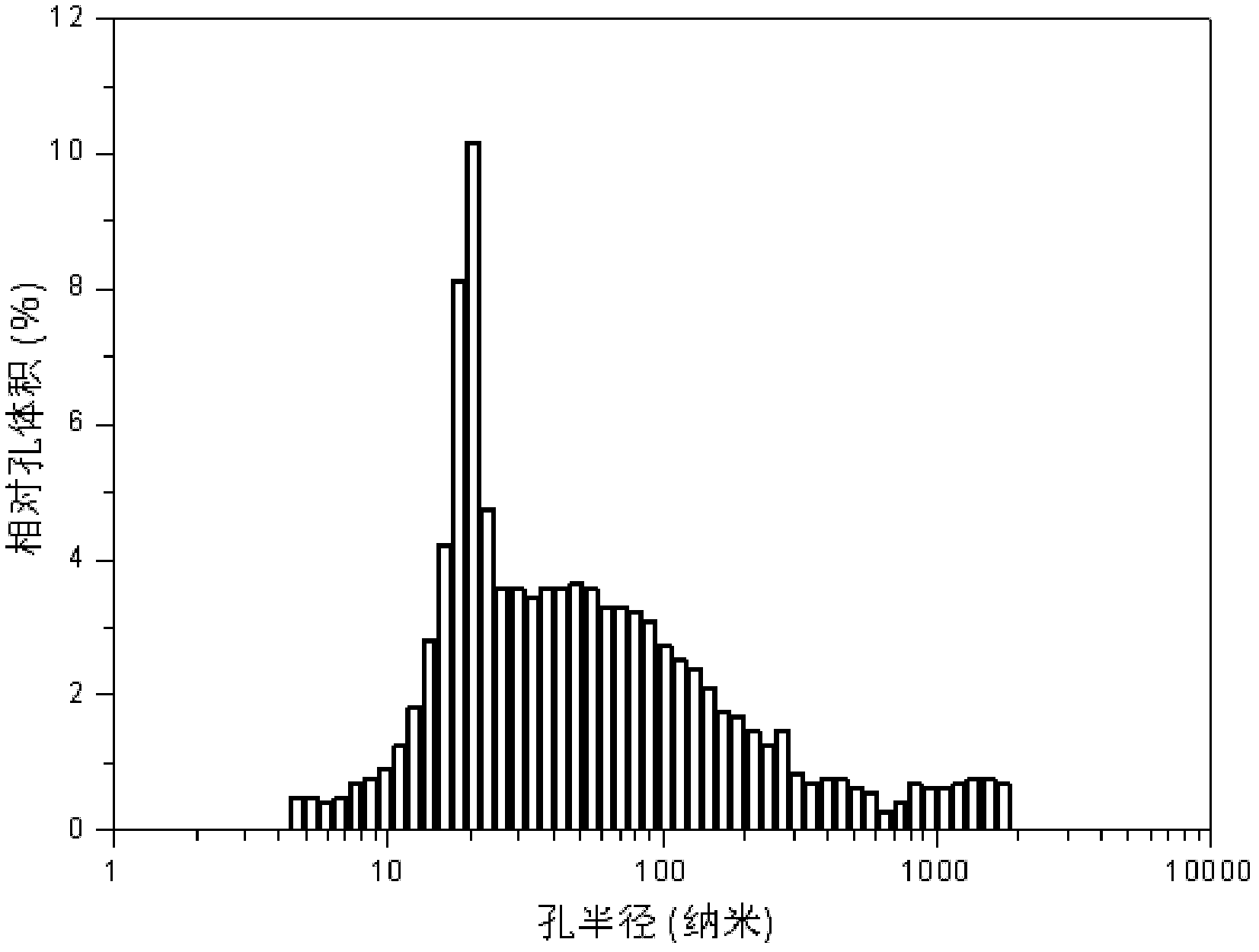

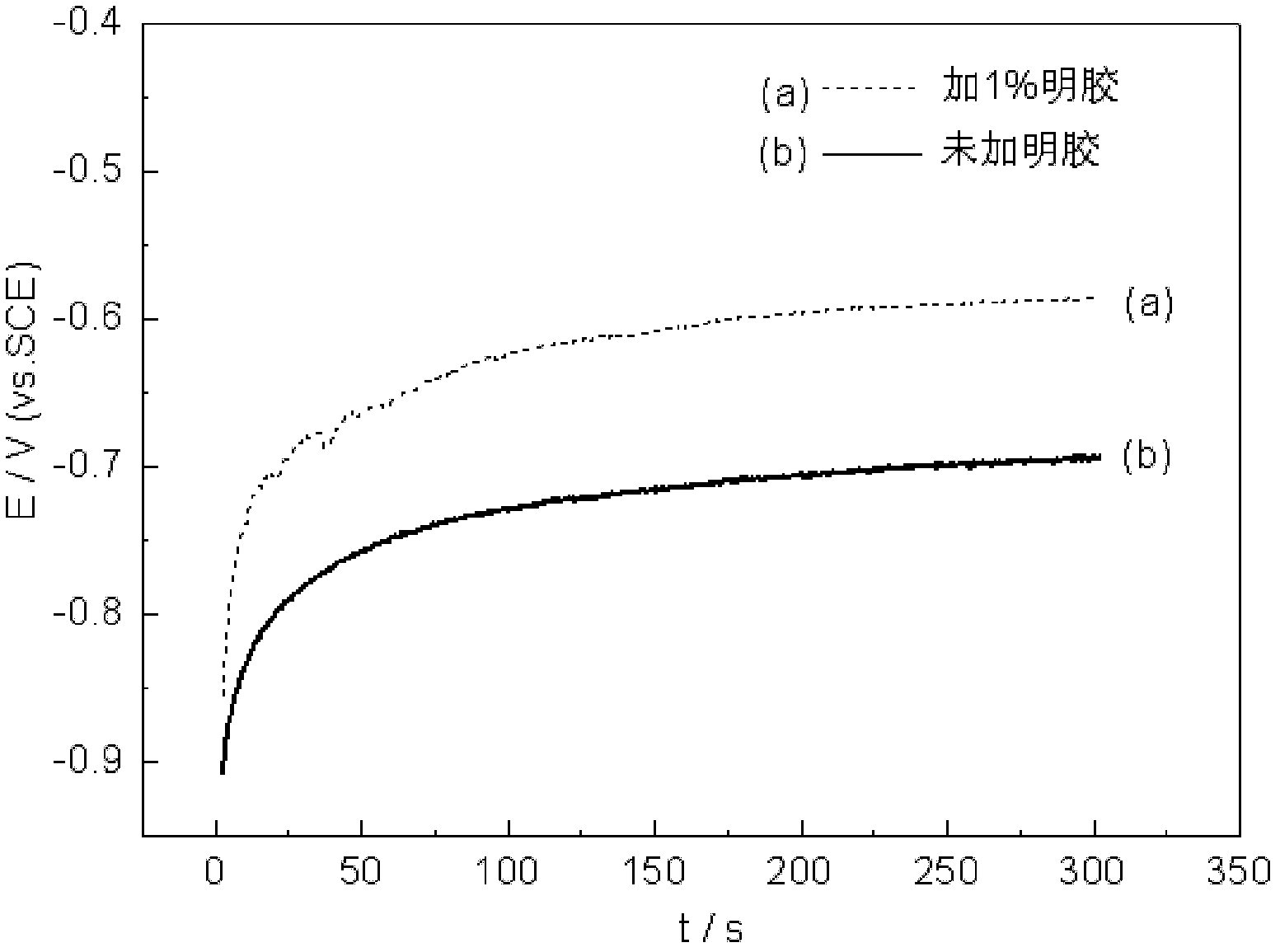

Gelatin hole forming method for gas diffusion electrodes

A gelatin hole forming method for gas diffusion electrodes belongs to the field of energy. The gelatin hole forming method includes steps of firstly coating Triton water solution with concentration of 4%, isopropanol, hydrophobic carbon black, 1% to 2% of gelatin water solution and 60% of PTFE (poly tetra fluoro ethylene) emulsion to foaming nickel so as to prepare a diffusion layer; coating 4% of Triton water solution, the isopropanol, 1% to 2% of gelatin water solution, 60% of PTFE emulsion, hydrophilic carbon black and silver / carbon catalyst onto the diffusion layer to form a catalyzing layer; heating gelatin to be carbonized and decomposed to form holes after one-hour heat treatment at the temperature ranging from 200 DEG C to 300 DEG C, and finally forming the electrodes in a hot pressing manner at the temperature of 360 DEG C. Electrode holes formed by the method are uniform in structural distribution and high in hole rate, the average radius of the electrode holes ranges from 20nm to 30nm, the electrodes are stable in structures and performance thereof is improved evidently.

Owner:BEIJING UNIV OF CHEM TECH +1

Preparation method of anti-high-temperature-oxidation crystal whisker modified Ti(C,N) base composite metal ceramic

The invention discloses a preparation method of anti-high-temperature-oxidation crystal whisker modified Ti(C,N) base composite metal ceramic, and belongs to the field of high-speed cutter materials. The preparation method of the crystal whisker modified Ti(C,N) base composite metal ceramic comprises the steps of raw material matching, ball milling and material mixing, material drying, vacuum hot pressed sintering and the like. The crystal whisker modified Ti(C,N) base composite metal ceramic comprises, by weight, 45-60% of Ti(C<0.5>N<0.5>), 10-25% f Al2O3 crystal whisker or ZrO2 crystal whisker, 8-15% of WC, 5-10% of Co, 5-10% of Mo2C and 5-10% of Ni. The Ti(C,N) base composite metal ceramic obtained through the preparation method has excellent compactness, high-strength toughness and high temperature oxidation resistance, and can serve as a (semi) precision-machined cutter material of a special steel material.

Owner:TAIZHOU UNIV

Conductive grapheme and organic silicon resin composite material

ActiveCN104231633AGood electrical conductivityExcellent heat and weather resistanceElectrically-conductive paintsSilicone resinWeather resistance

The invention relates to a conductive grapheme and organic silicon resin composite material, and belongs to the technical field of conductive materials. The conductive grapheme and organic silicon resin composite material provided by the invention is prepared by adding grapheme and methylphenyl silicon resin into a ball mill to grind and mixing to uniformity, wherein the weight ratio of the grapheme to the methylphenyl silicon resin is 1:20-500. According to the conductive grapheme and organic silicon resin composite material, the organic silicon resin becomes conductive from insulating, so that the composite material has good conductive performance of the grapheme and excellent weather fastness and heat resistance of the organic silicon resin; furthermore, the composite material adopts the specific organic silicon resin, namely the methylphenyl silicon resin, and a specific ratio, thus further improving the weather fastness and the heat resistance, being easy to solidify and capable of being used for preparing conductive paint, conductive film and other conductive materials. In addition, the conductive grapheme and organic silicon resin composite material is simple in preparation method and applicable to industrial production, and effectively saves energy consumption and reduces cost.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

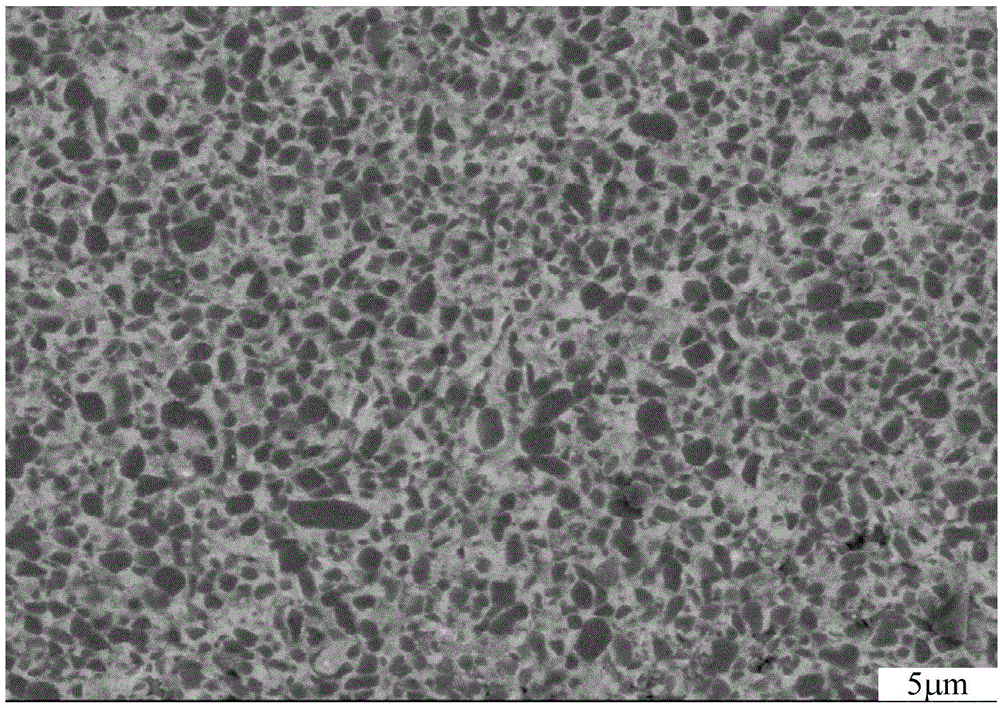

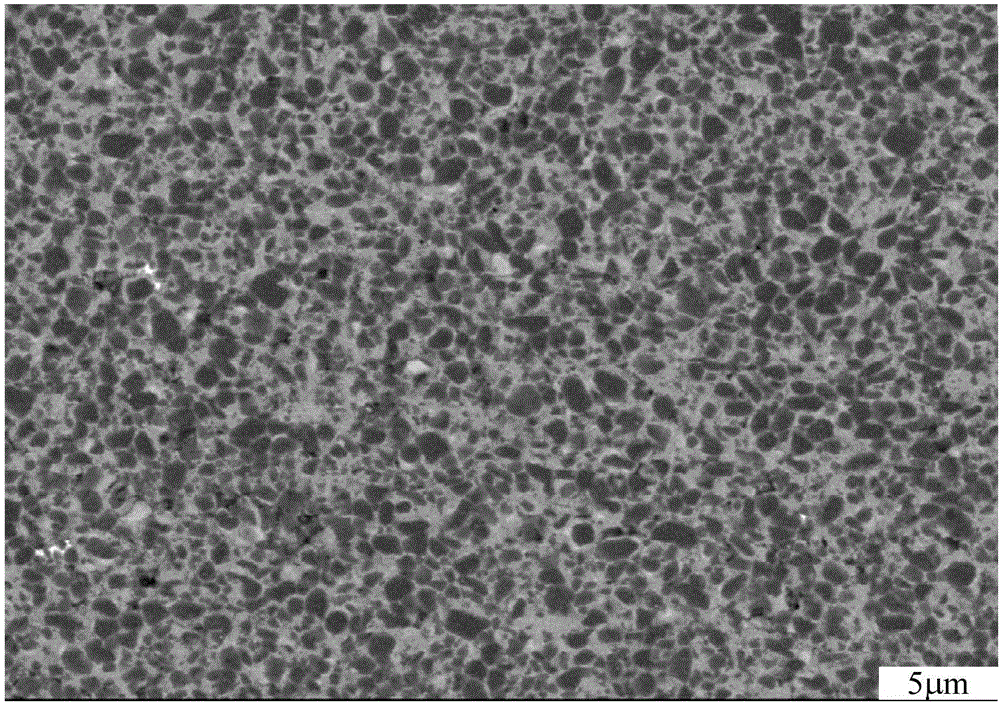

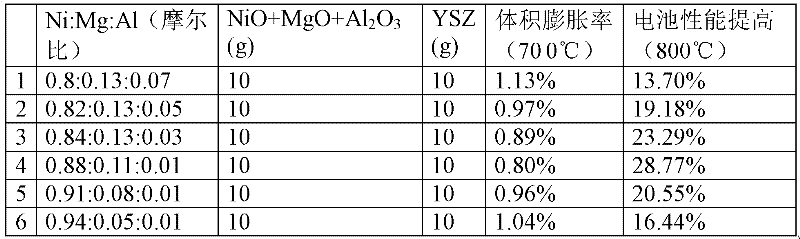

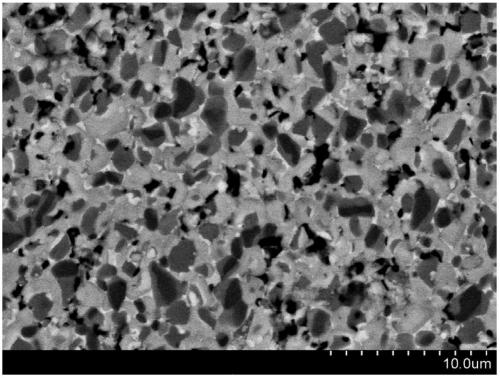

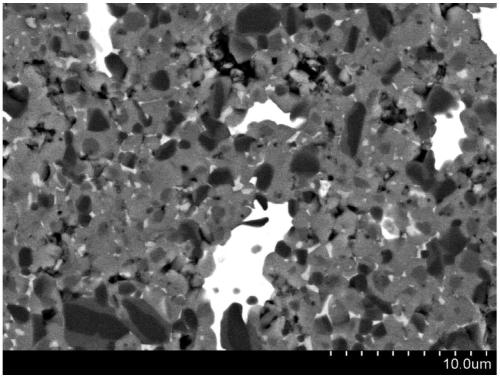

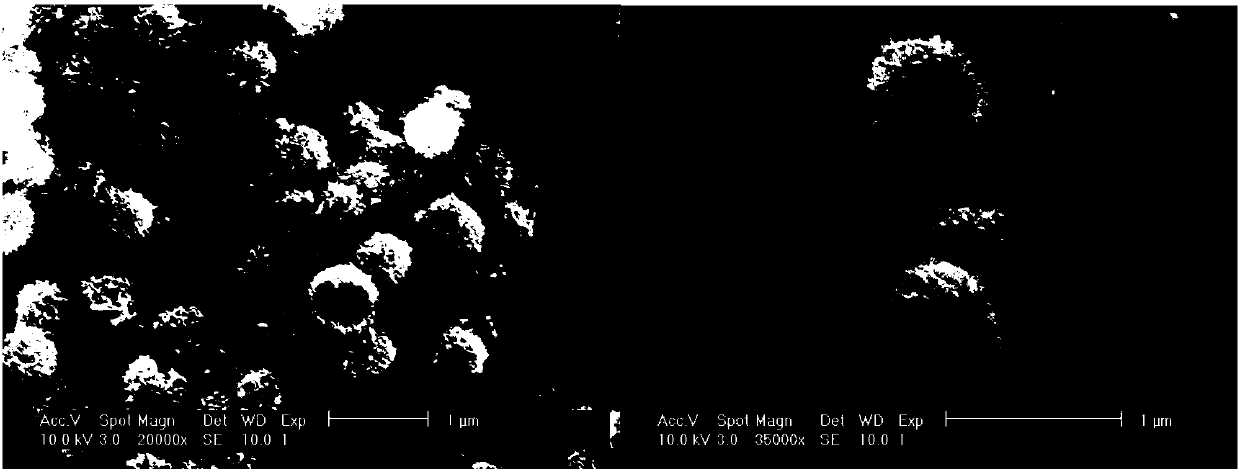

Nickel-based composite anode material of solid oxide fuel cell and application thereof

InactiveCN102651477AImprove dispersionHigh particle size and activityCell electrodesComposite oxideNickel oxides

The invention relates to a nickel-based composite anode material of a solid oxide fuel cell and an application thereof. The composition of the composite anode material can be expressed by Ni1-x-yMgxAlyO1 plus 0.5y, wherein x varies from 0.01 to 0.2 and y ranges from 0.001 to 0.2. The composite anode material is compounded with an electrolyte material to prepare an anode, and the weight percentage of magnesium oxide and aluminium oxide modified nickel-based composite oxide material is 30-70 percent. During practical application, the composite anode is put into use after reduction, the reduced anode contains the electrolyte material, metal micron-nickel and nano particles, magnesium oxide, aluminium oxide and a composite oxide formed by magnesium oxide, aluminium oxide and nickel oxide. The novel composite anode can be used for flat-plate-type, tubular, honeycomb-type and oblate-tube-type solid oxide fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Structured wave-absorbing material and preparation method thereof

InactiveCN102523730AUniform structure distributionSimple preparation processMagnetic/electric field screeningFiberMicron scale

The invention discloses a structured wave-absorbing material and a preparation method thereof. The structured wave-absorbing material contains fiber with a micron-scale diameter and absorbent particles, wherein the fiber forms a three-dimensional network structure with adjustable and controllable porosity; and the absorbent particles are evenly covered in the three-dimensional network structure. The preparation method comprises the following steps of; mixing adhesives, fiber and the absorbent particles with water, and stirring at high speed to form uniform serous fluid; utilizing a wet papermaking process to make a precursor; and after drying the precursor, high-temperature sintering to form the structured wave-absorbing material with the absorbent particles covered by the paper-type micro fiber. The prepared structured wave-absorbing material has the characteristics of thinner thickness, high porosity, good flexibility, convenience in molding, strong absorbing capacity for electromagnetic wave; and the preparation process is simple and is low in cost. The structured wave-absorbing material can be applied to military and civil fields, the density and the weight of the wave-absorbing material are greatly reduced, the thermostable performance is good, the wave-absorbing efficiency can be improved, and the application prospect is broad.

Owner:SOUTH CHINA UNIV OF TECH

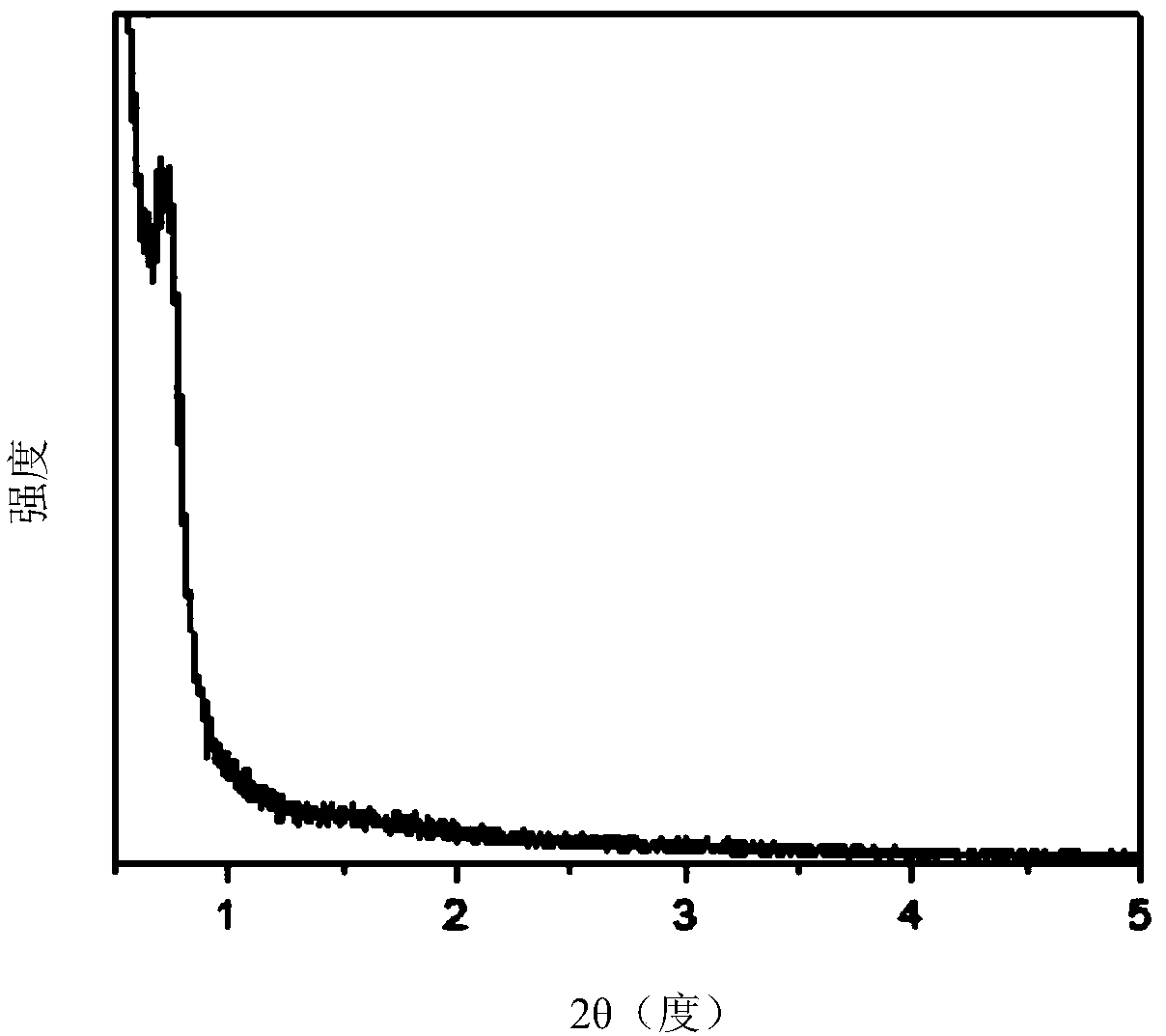

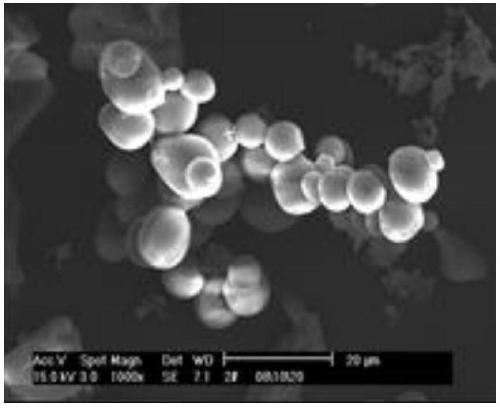

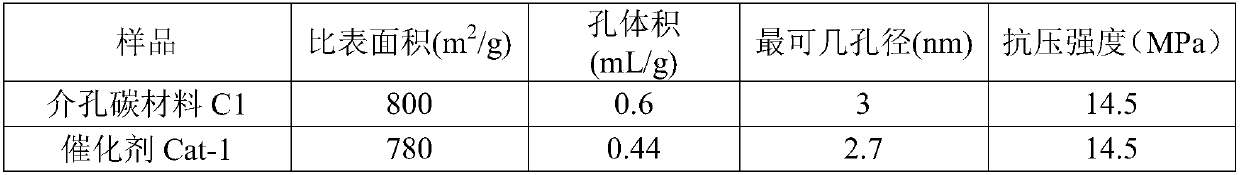

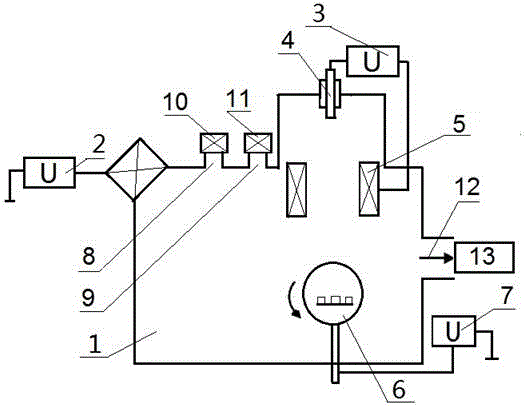

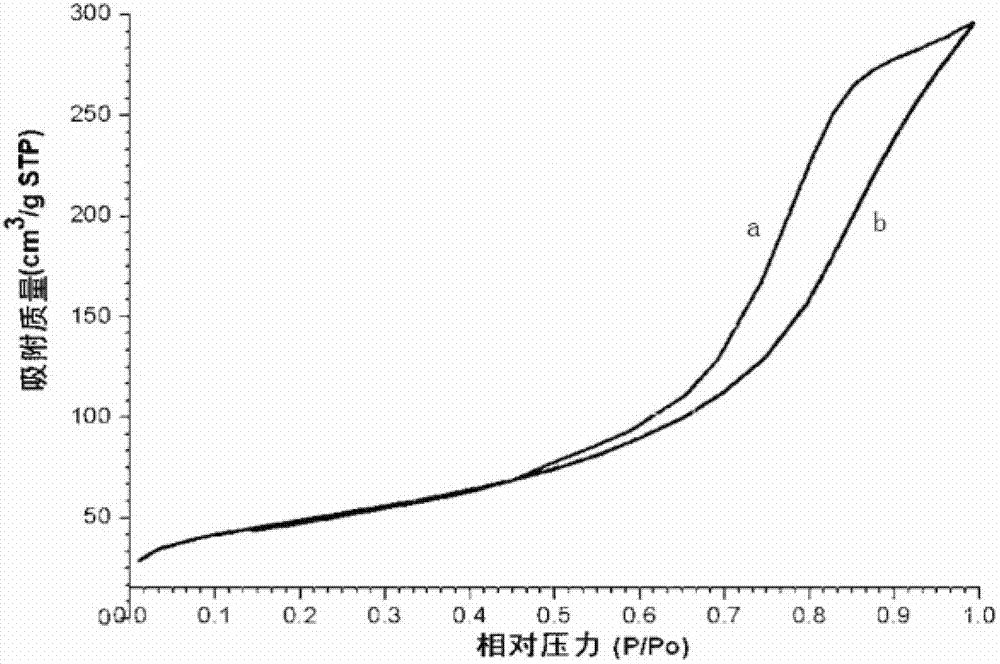

Propane dehydrogenation catalyst, preparation method thereof and method using propane dehydrogenation to prepare propylene

InactiveCN109745977AUniform structure distributionModerate pore sizeHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsMicrometerDehydrogenation

The invention relates to the field of catalysts and discloses a propane dehydrogenation catalyst, a preparation method thereof and a method using propane dehydrogenation to prepare propylene. The propane dehydrogenation catalyst comprises a carrier and a Pt component, a Sn component and a Na component which are loaded onto the carrier, wherein the carrier is spherical mesoporous silica, the spherical mesoporous silica has a cubic core structure, the compressive strength of the spherical mesoporous silica is 12-16MPa, the average particle size of the spherical mesoporous silica is 2-10 micrometers, the specific surface area of the spherical mesoporous silica is 700-900m<2> / g, the pore volume of the spherical mesoporous silica is 0.5-1mL / g, and the most probable pore diameter of the spherical mesoporous silica is 1-5 nanometers. When the propane dehydrogenation catalyst which is high in compressive strength is used in the reaction of propylene preparation using propane dehydrogenation, the propane dehydrogenation catalyst is good in catalytic performance, high in propane conversion rate, high in propylene selectivity and good in stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of water-soluble phenolic resin applied to preparation of copper-clad foil laminated board adhesive

InactiveCN102199264AUniform structure distributionImproved solder dip resistanceAldehyde/ketone condensation polymer adhesivesMetal layered productsAdhesiveReaction temperature

The invention relates to a preparation method of a water-soluble phenolic resin applied to preparation of a copper-clad foil laminated board adhesive. The preparation method is characterized in that phenol and formaldehyde are used as main raw materials, barium hydroxide is used as a catalyst, and the water-soluble phenolic resin is generated through synthesis reaction, wherein the reaction temperature is 90 DEG C-98 DEG C, the reaction time is 45-70 minutes, and normal pressure is maintained when in reaction. The feeding mass parts of various components of the water-soluble phenolic resin are as follows: 100 parts of the phenol, 100 parts of the formaldehyde and 2-4 parts of the barium hydroxide. By using the preparation method, the adhesive property and heat-resistant property between a copper foil and a papery substrate can be improved.

Owner:江阴市明康绝缘玻纤有限公司

Rare-earth-base denitrification catalyst powder and preparation method thereof

PendingCN106669659ASolution to short lifeUniform structure distributionHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystAmmonium paratungstate

The invention discloses a rare-earth-base denitrification catalyst powder and a preparation method thereof. The preparation method comprises the following steps: respectively preparing a metatitanic acid slurry, an ammonium paratungstate solution and a cerous nitrate-lanthanum nitrate mixed solution; transferring the ammonium paratungstate solution into the metatitanic acid slurry to obtain an intermediate mixed solution; transferring the cerous nitrate-lanthanum nitrate mixed solution into the intermediate mixed solution to obtain a metatitanic acid-ammonium paratungstate-cerous nitrate-lanthanum nitrate mixed slurry; regulating the pH value of the solution to the set range to obtain a mixed solution containing titanium, tungsten, cerium and lanthanum; drying; calcining; and grinding to obtain the catalyst powder. The invention aims to provide a rare-earth-base denitrification catalyst powder and a preparation method thereof. The rare-earth-base denitrification catalyst powder is nontoxic and harmless to the human and environment, and has the advantages of high-temperature aging resistance, long service life, wide temperature range and controllable product composition; and the preparation method has the advantages of simple facility request and simple operational process, and can easily implement large-scale industrial production.

Owner:湖北群有长物环保科技有限公司

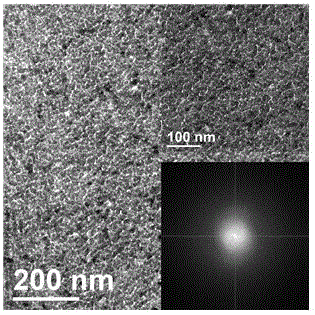

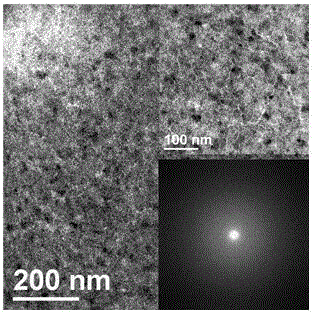

Device and method for preparing amorphous carbon and nitrogen thin films on surface of silicon

ActiveCN106011745AEvenly distributedThe relative content is controllableVacuum evaporation coatingSputtering coatingNitrogen gasVacuum chamber

The invention discloses a device and method for preparing amorphous carbon and nitrogen thin films on the surface of silicon. The device is a pulse cathode electric arc device assisted by an ion source. The preparation device includes the following steps that a silicon substrate which is chemically cleaned in advance is dried and placed on a rotating sample table; vacuumization is performed, argon gas is led into a vacuum chamber, and the surface of the silicon substrate is physically cleaned through an ion sputtering source; and high-purity graphite serves as a cathode target material of a pulse electric arc, the pulse discharging frequency is adjusted, nitrogen gas is led at the same time, the ion source is opened, and the atomization and ionization nitrogen-doped amorphous carbon and nitrogen thin films are prepared. By means of the device and method, the content of carbon / nitrogen atoms and carbon-nitrogen bonds / carbon-carbon bonds in the amorphous carbon and nitrogen thin films is adjustable, and the carbon and nitrogen bonding types and the graphite-like nitrogen / pyridine-like nitrogen structures are controllable.

Owner:BEIJING WUKE GUOHUA TECH CO LTD

TiB2 whisker high-temperature strengthening and toughening Ti (C, N)-based metal ceramic material preparation method

InactiveCN109439991AExcellent overall performanceExcellent high temperature strength and toughnessCermetHardness

The invention concretely relates to a TiB2 whisker high-temperature strengthening and toughening Ti (C, N)-based metal ceramic material preparation method which comprises the following steps of compounding reaction raw materials, wherein the reaction raw materials are prepared from the components in percentage: 50 to 65 percent of Ti (C, N), 15 to 30 percent of TiB2 whisker, 2 to 10 percent of WC,2 to 8 percent of Mo2C, 2 to 8 percent of TaC, 2 to 8 percent of NbC, 3 to 5 percent of Co, and 3 to 5 percent of Ni; and after compounding, compositely mixing the raw materials, pelletizing, drying,carrying out cold isostatic pressing molding, carrying out sectional type atmosphere hot pressing, rapidly cooling for reducing temperature, and sintering to obtain a TiB2 whisker high-temperature strengthening and toughening Ti (C, N)-based metal ceramic material. The Ti (C, N)-based composite metal ceramic prepared through the invention has a favorable combination property, and particularly hashigh high-temperature hardness and toughness during high-speed cutting, so that the TiB2 whisker high-temperature strengthening and toughening Ti (C, N)-based metal ceramic material is good for prolonging the service life of a cutter and can be used as a cutting tool material for high-speed cutting (semi) finish machining.

Owner:JIANGSU MARITIME INST

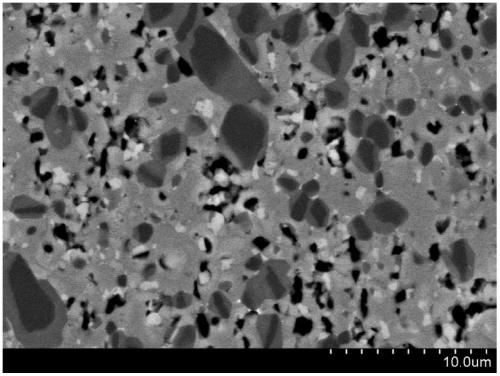

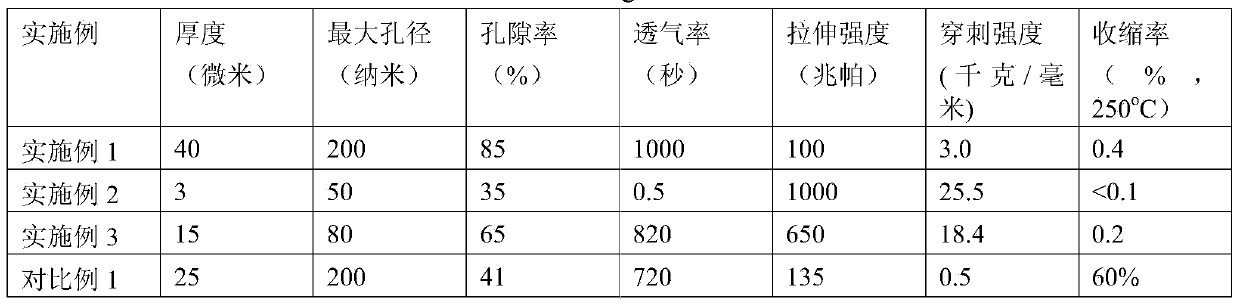

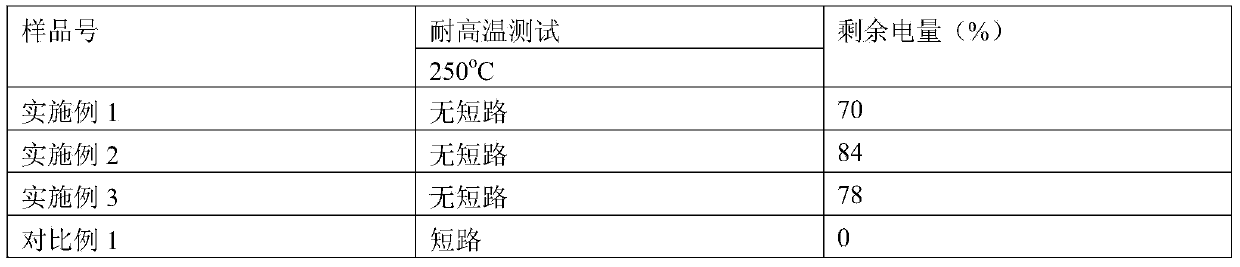

Poly(p-phenylenebenzobisoxazole) porous membrane, preparation method and application thereof

InactiveCN103746086AUniform structure distributionAperture adjustableCell seperators/membranes/diaphragms/spacersElectrolyte accumulators manufactureFiberLithium

The invention relates to a poly(p-phenylenebenzobisoxazole) porous membrane, a preparation method and an application thereof, and belongs to the technical field of lithium ion secondary batteries, wherein the membrane is composed of poly(phenylenebenzobisoxazole) (POB) fiber, the thickness of the membrane is 3-40 microns; pores on the surface and inside the membrane are distributed uniformly, the pore diameter is adjustable, the membrane has good air permeability, excellent resistance to high temperature and high tensile strength. The preparation method of the membrane is that a POB solution is subjected to vacuum defoamation treatment, solvent exchange after curtain coating and film forming, and freeze drying to obtain the membrane. The POB membrane provided by the invention can be used as the barrier film of a lithium ion secondary battery and has good performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

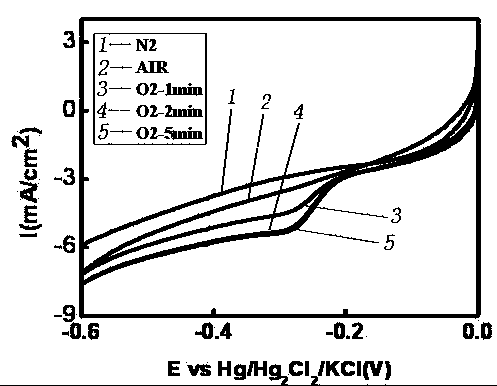

Novel preparation method of edge functionalized graphene catalyst

ActiveCN103785466AHigh catalytic activityUniform structure distributionOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystConductive polymer

The invention relates to a novel preparation method of an edge functionalized graphene catalyst. Mixed ball milling is carried out on graphite powder and conductive polymer monomer (such as pyrrole) at room temperature and normal pressure without adding any other chemical reagents, and ball milling is carried out continuously to obtain edge functionalized graphene nanosheet of the conductive polymer at the ball milling speed 25% lower than that reported previously and with ball milling time saved by 50%. The product is uniform in sheet, has the thickness being about 1.5 nanometers and the yield being 90% above, batch production of graphene can be effectively realized, the commercial cost is lowered, and the application universalness of graphene is popularized. The prepared product contains 6% of nitrogen atoms, provides effective active site for electrochemistry oxygen reduction, and can be directly used as an oxygen reduction catalyst with high performance. In the overall production process, toxic chemical reagent or high temperature and high pressure is not used. The preparation method is high in safety and environmental protection, simple in technological process and easy to operate.

Owner:WENZHOU MEDICAL UNIV

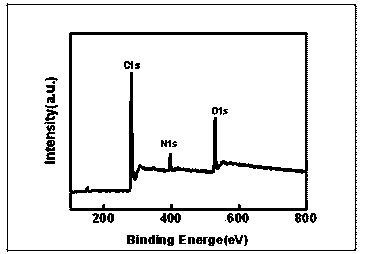

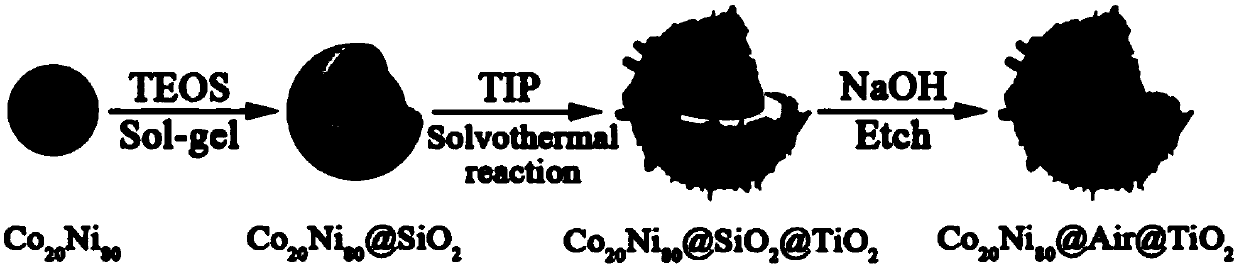

TiO2-coated CoNi nanoparticle of york-shell structure and preparation method of nanoparticle

ActiveCN107671280AUniform structure distributionImprove matchMaterial nanotechnologyTransportation and packagingMicrosphereAlloy

The invention discloses a TiO2-coated CoNi nanoparticle of a york-shell structure and a preparation method of the nanoparticle. The nanoparticle comprises a CoNi alloy particle nuclear structure, a shell layer structure and a hollow layer structure. The preparation method comprises the following steps: step 1, preparing raw materials for reaction; step 2, preparing the CoNi alloy particle nuclearstructure; step 3, injecting nitrogen into a reaction kettle, and then heating the reaction kettle by utilizing an oven; step 4, cooling, collecting solid phases, carrying out washing by utilizing ethanol, and carrying out vacuum drying; step 5, injecting nitrogen into a vacuum drying tank, and transferring a product into a solution acquired from the reaction among ethanol, distilled water and ammonium hydroxide; step 6, washing a reactant and drying the washed reactant; step 7, dissolving the above reactant in an isopropyl alcohol solvent; and step 8, adding powder acquired after the above reaction is finished into a sodium hydroxide solution. By adoption of the nanoparticle and the preparation method disclosed by the invention, the corrosion resistance and the microwave absorptivity of TiO2-coated CoNi are improved.

Owner:承德中宇众航新材料有限公司

Method for manufacturing porous preformed component of short fiber-reinforced metal matrix composite product

A method of producing porous prefabricated members of composite material containing short fibers and metal. It comprises: preparing sizing material, adding 0.8í½3 polyacrylamide, 4.2í½8 natural cellulose, 7í½ 12 water glass, 200í½500 water into a container, stirring until all components are dissolved, adding 100 wild-phase material, 40í½100 short fiber material, stirring and obtaining the sizingmaterial, standing for 1 hour; the wild-phase material selected from aluminum oxide, silicon oxide, silicon carbon, boron oxide; the short fiber material selected from aluminum silicate, or aluminum oxide, or silicon oxide, or carbon; 2) predehydrating;3) producing blanks; 3) baking: putting the dried blanks into a baking oven, sintering for 3hours at 200degree C, then heating to 1200degree C andsintering for 8hours, and obtaining prefabricated members.

Owner:张强

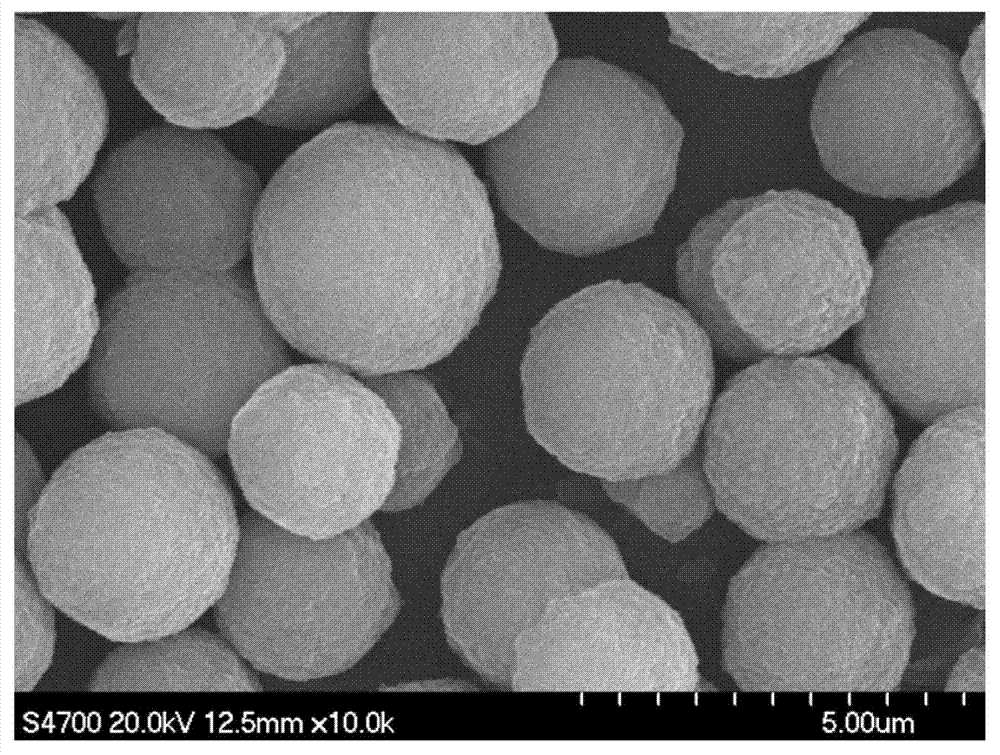

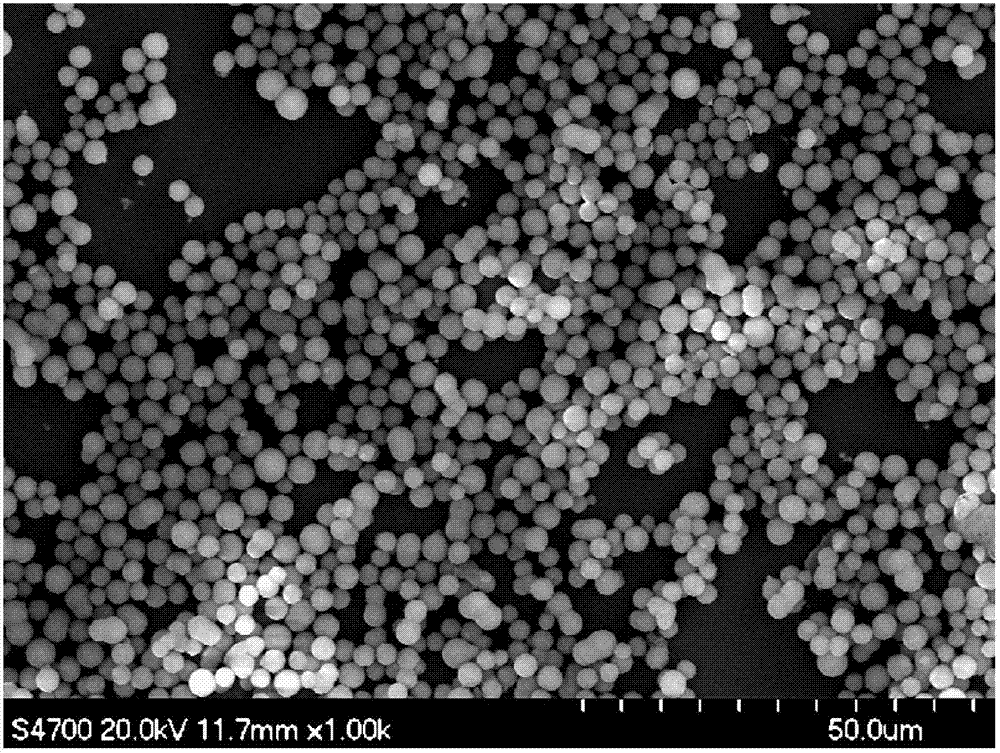

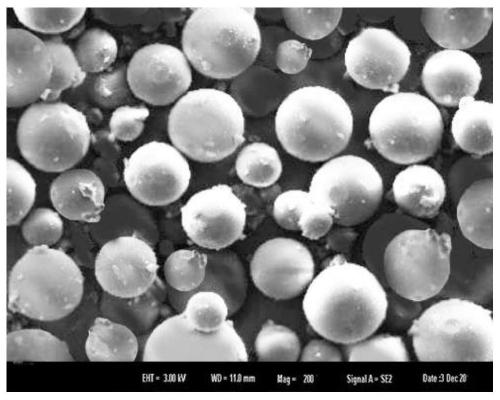

Method for preparing high-purity silica packing through sol-gel process

The invention discloses a method for preparing high-purity silica packing through a sol-gel process. The method is characterized in that monocrystalline silicon powder is taken as a silicon source, and under the catalysis of ammonia water, high-purity and monodispersed nanosilica hydrosol is firstly synthetized; and monodispersed microspheres are prepared through the sol-gel process, and the microspheres are subjected to thermal treatment, so that high-purity polyporous micron-size silica-based microspheres with the grain sizes of 2 to 10 um are finally obtained. According to the invention, the monocrystalline silicon powder is taken as the silicon source, and the ammonia water is taken as catalyst, so that such impurities as metal are prevented from mixing in, after the monodispersed microspheres are subjected to thermal treatment, the high-purity polyporous micron-size silica-based microspheres are obtained, have good monodispersity and uniformly-distributed surface pore structures, and can be used as silica packing directly without being processed in a grading manner.

Owner:BEIJING UNIV OF CHEM TECH

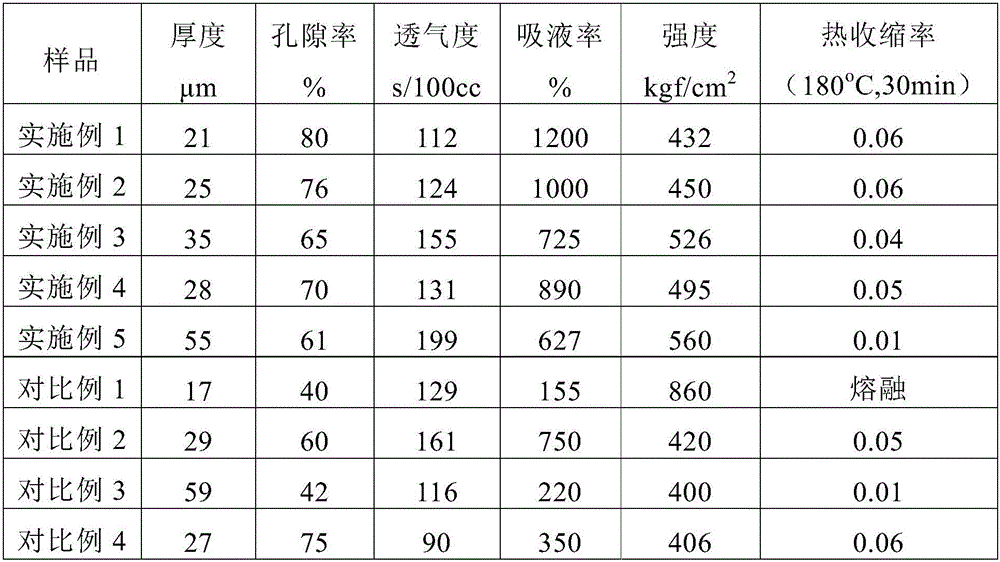

Lithium battery separator and preparation method and application thereof

InactiveCN107437630AUniform structure distributionGood electrolyte wetting propertiesSecondary cellsCell component detailsCelluloseSilicon dioxide

The invention discloses a lithium battery separator and a preparation method and application thereof. Cellulose and inorganic matter particles are contained in raw materials of the separator, wherein the inorganic matter particles are selected from more than one of silicon dioxide, aluminum oxide, boehmite, titanium oxide, zirconium oxide, tin oxide, magnesium oxide and silicon carbide.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

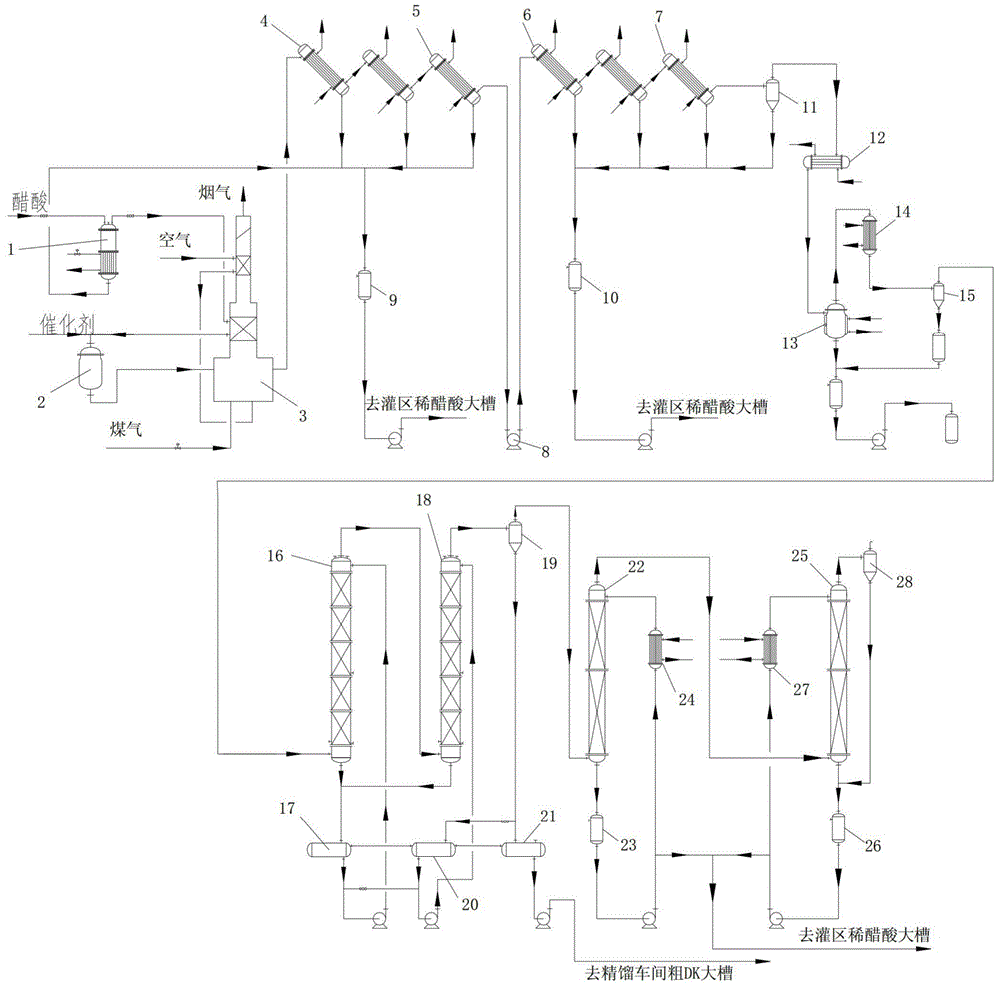

Diketene preparation device and diketene preparation method

ActiveCN104592172AEasy to condense and separateDowngradeOrganic chemistryAcetic acidAcetic anhydride

The invention relates to a diketene preparation device and a diketene preparation method. The diketene preparation device comprises an acetic acid evaporator, a mixer, a cracking furnace, a quenching condenser and an absorption tower. The outlets of the acetic acid evaporator and the mixer are connected with the cracking furnace; the cracking furnace is then connected with the multi-level quenching condenser; the quenching condenser is then connected with the absorption tower; one branch of the absorption tower is connected with a polymerization tank, and the other branch of the absorption tower is connected with a water absorption tower; and the outlet of the third-level quenching condenser is connected with the quenching condenser behind through a liquid ring pump. The diketene preparation device and diketene preparation method provided by the invention have the beneficial effects that when the cracked gas is pressurized, the impurities such as acetic acid, water and acetic anhydride in the cracked gas can be condensed out more sufficiently, and thus the quality of the cracked gas before entering the absorption tower is improved while the freezing level is lowered; and compared with the traditional technology in which the energy consumption accounts for 45% of the total cost of diketene, the device and method provided by the invention have the advantage that the energy consumption only accounts for 25% of the total cost of diketene through improvement.

Owner:QINGDAO UNIV OF SCI & TECH

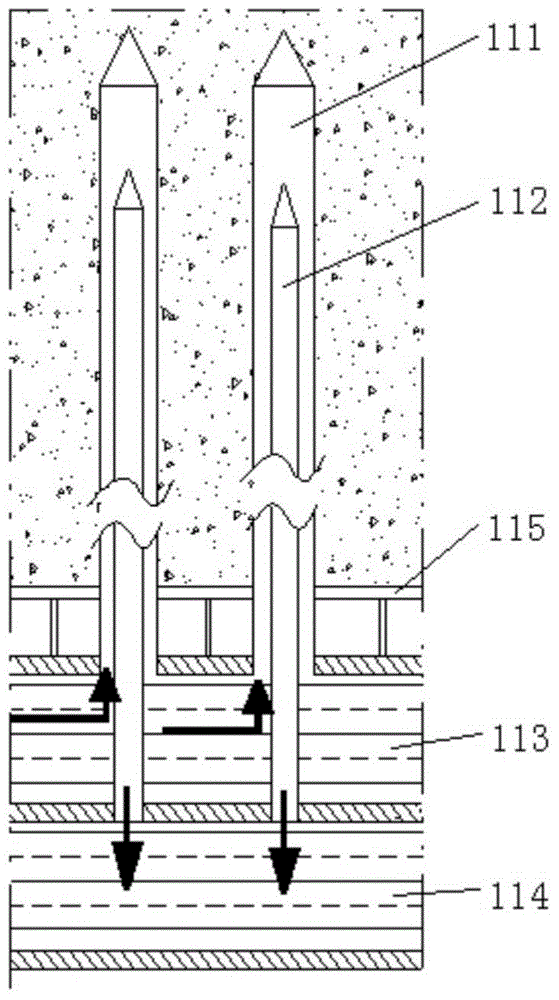

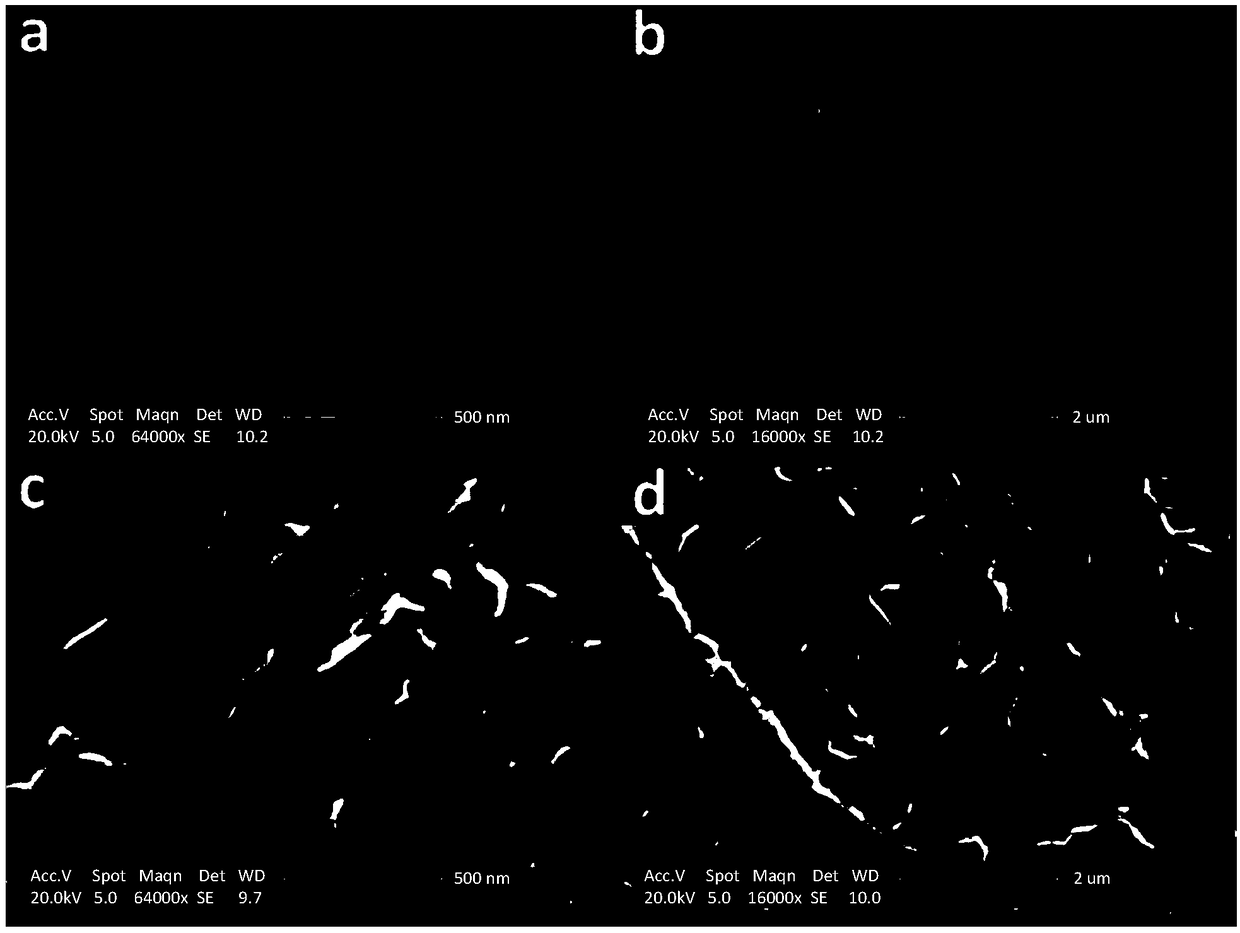

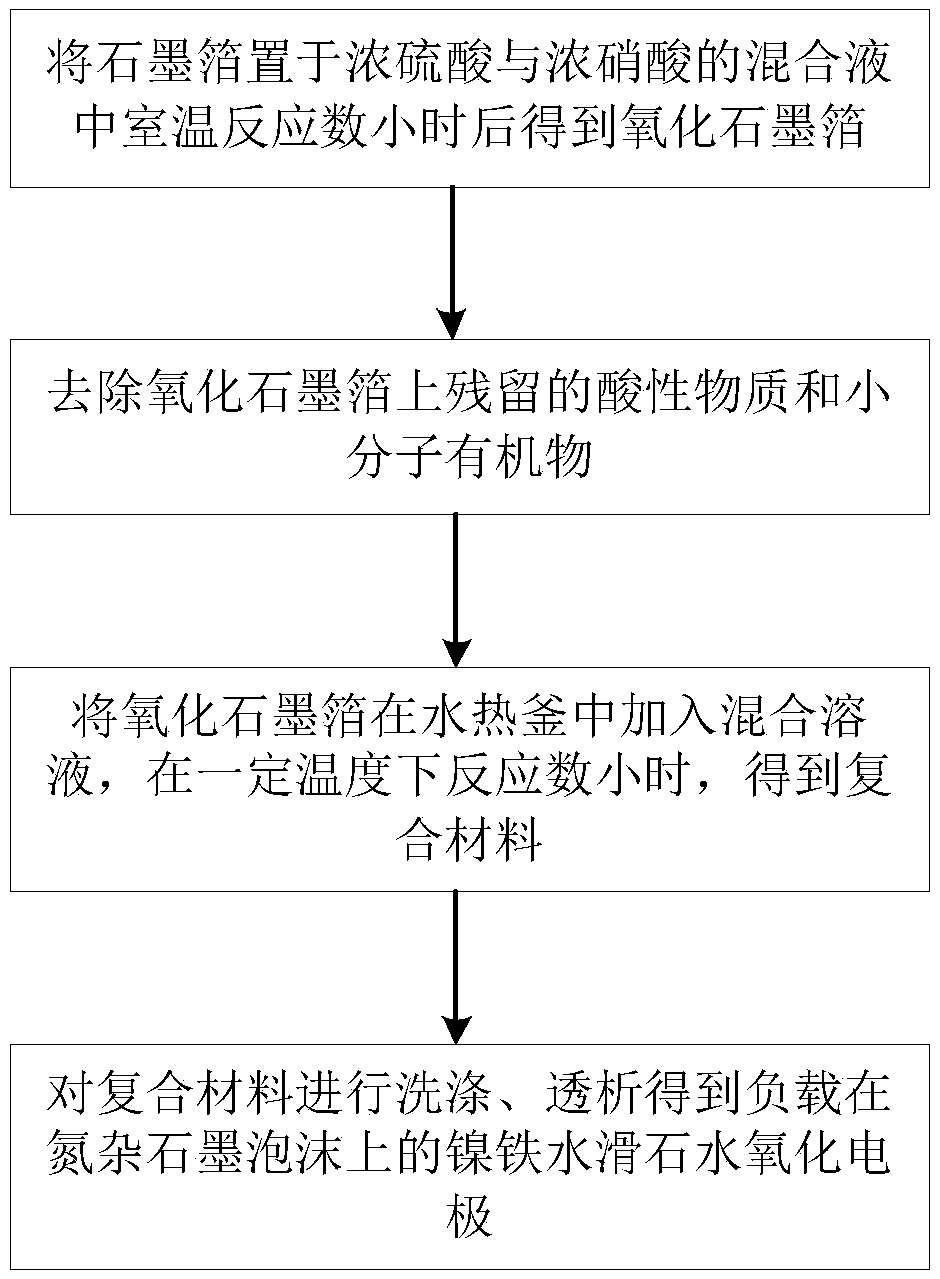

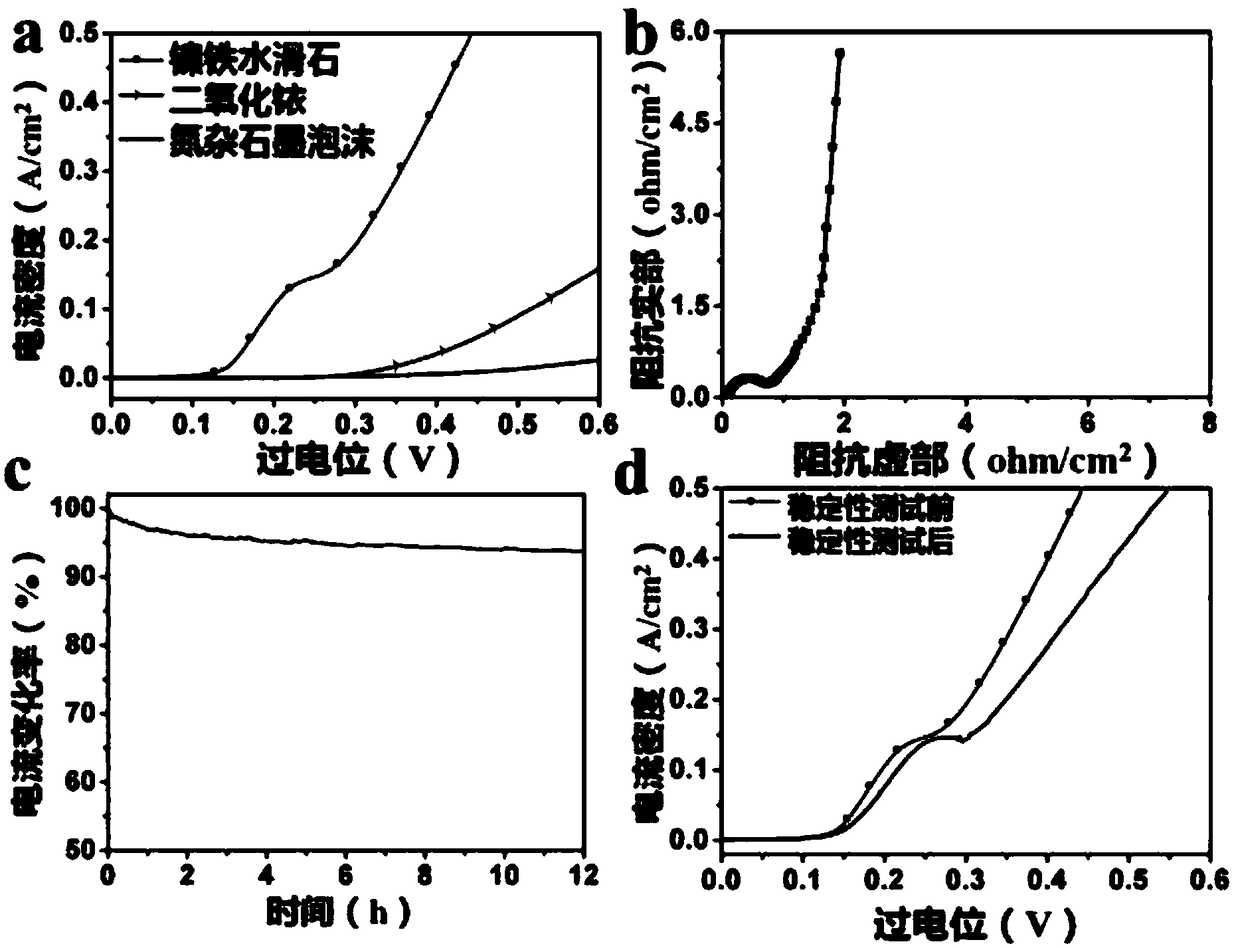

Preparation method of nickel-iron hydrotalcite water-oxidation electrode loaded on nitrogen-doped graphite foam

ActiveCN108660471AUniform structure distributionImprove stabilityElectrode shape/formsNickel saltAcid substances

The invention discloses a preparation method of a nickel-iron hydrotalcite water-oxidation electrode loaded on nitrogen-doped graphite foam. The method comprises the following steps that needed graphite foil is placed into a mixed solution, wherein the volume ratio of concentrated sulfuric acid to concentrated nitric acid in the mixed solution is 3:1, oxidizing is carried out at room temperature for 2-12 hours, obtained graphite oxide foil is taken out and is placed in deionized water, and dialysis is carried out to remove acidic substances and small-molecule organic matter remaining on the graphite oxide foil; and then the graphite oxide foil is placed in a hydrothermal kettle, a mixed solution of urea, soluble bivalent nickel salt and trivalent ferric salt is added into the kettle, furthermore, hydrothermal reaction is carried out under the condition of 120-180 DEG C for 6-12 hours, an obtained composite material is washed by using the deionized water, residual salt is removed through dialysis, and then the nickel-iron hydrotalcite water-oxidation electrode loaded on the nitrogen-doped graphite foam is obtained. According to the scheme, the purpose of obtaining the self-supporting electrode with the uniformly-dispersed hydrotalcite structure is achieved, and high practical value and popularization value are achieved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

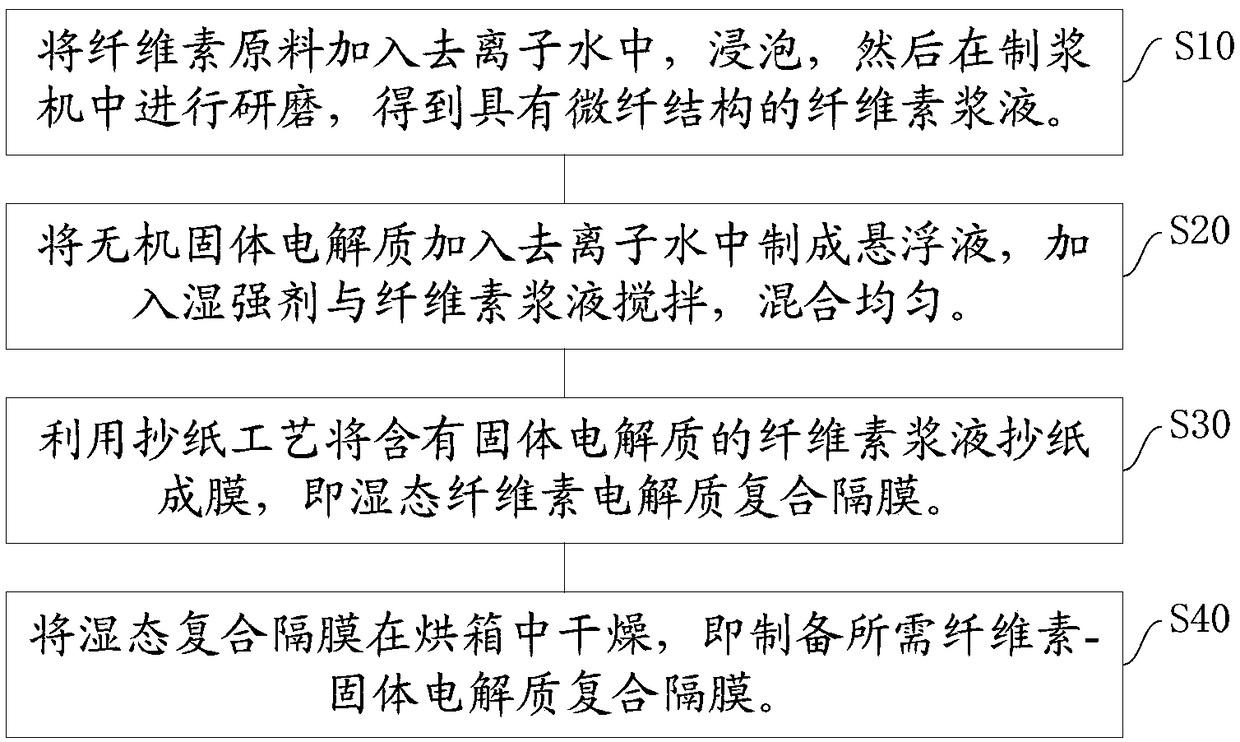

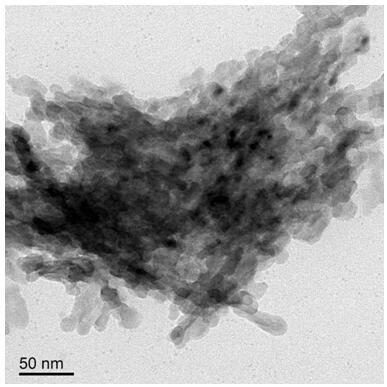

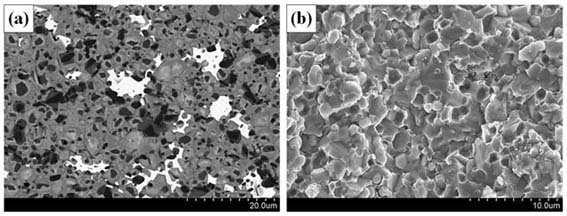

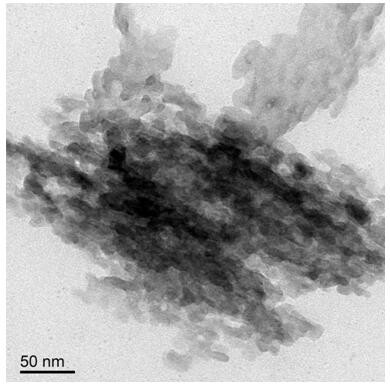

Inorganic solid electrolyte-cellulose composite diaphragm and preparation method thereof

InactiveCN108470875AEasy to manufactureUniform structure distributionCell component detailsPapermakingSlurry

The invention discloses an inorganic solid electrolyte-cellulose composite diaphragm and a preparation method thereof. The preparation method comprises the steps of S10, adding cellulose raw materialsinto deionized water to be immersed, and then performing grinding in a pulping machine to obtain a cellulose pulp solution with a micro-fiber structure; S20, adding an inorganic solid electrolyte into deionized water to prepare into a suspension liquid, then adding a wet strength agent and the cellulose pulp solution to be mixed uniformly; S30, performing papermaking and film forming on the cellulose pulp solution comprising the solid electrolyte by a papermaking process, namely, obtaining a wet cellulose electrolyte composite diaphragm; and S40, performing drying on the wet composite diaphragm in a drying oven to obtain the needed cellulose-solid electrolyte composite diaphragm. The prepared composite diaphragm is uniform in hole structural distribution, convenient to prepare, suitable for batch production, and high in heat resistance, high in wettability, high in ionic conductivity, high in breakdown resistance, and suitable for a lithium ion battery diaphragm; and meanwhile, the diaphragm is compounded with the inorganic solid electrolyte, so that an effect of the electrolyte can be played, and extra addition of an electrolyte solution is not needed.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

Method for in-situ integrated preparation of Ti (C, N)-based metal ceramic cutter material with high heat resistance

ActiveCN112743080AUniform structure distributionImprove performanceTurbinesOther manufacturing equipments/toolsHigh entropy alloysGrain structure

The invention discloses a method for in-situ integrated preparation of a Ti (C, N)-based metal ceramic cutter material with high heat resistance, and belongs to the technical field of novel metal ceramic materials. The method comprises the following steps that 1) nanocrystalline AlxCoCrFeNiTi high-entropy alloy binding phase powder is prepared; 2) reaction raw materials are subjected to proportioning and mixing, and a Ti (C, N)-TiB2-AlxCoCrFeNiTi metal ceramic mixture is prepared; 3) a cutter mixed green body is prepared; and 4) the cutter mixed green body is placed in an atmosphere sintering furnace to be fired into a cutter sample. The Ti (C, N)-based composite metal ceramic material prepared through the method has a Ti (C, N) and TiB2 double 'core-ring ' structure, is compact and uniform in grain structure distribution, can be used for efficient machining of high-strength and other difficult-to-cut materials, and achieves industrial application of cutters.

Owner:LIFENG PRECISION TOOLS (ZHEJIANG) CO LTD

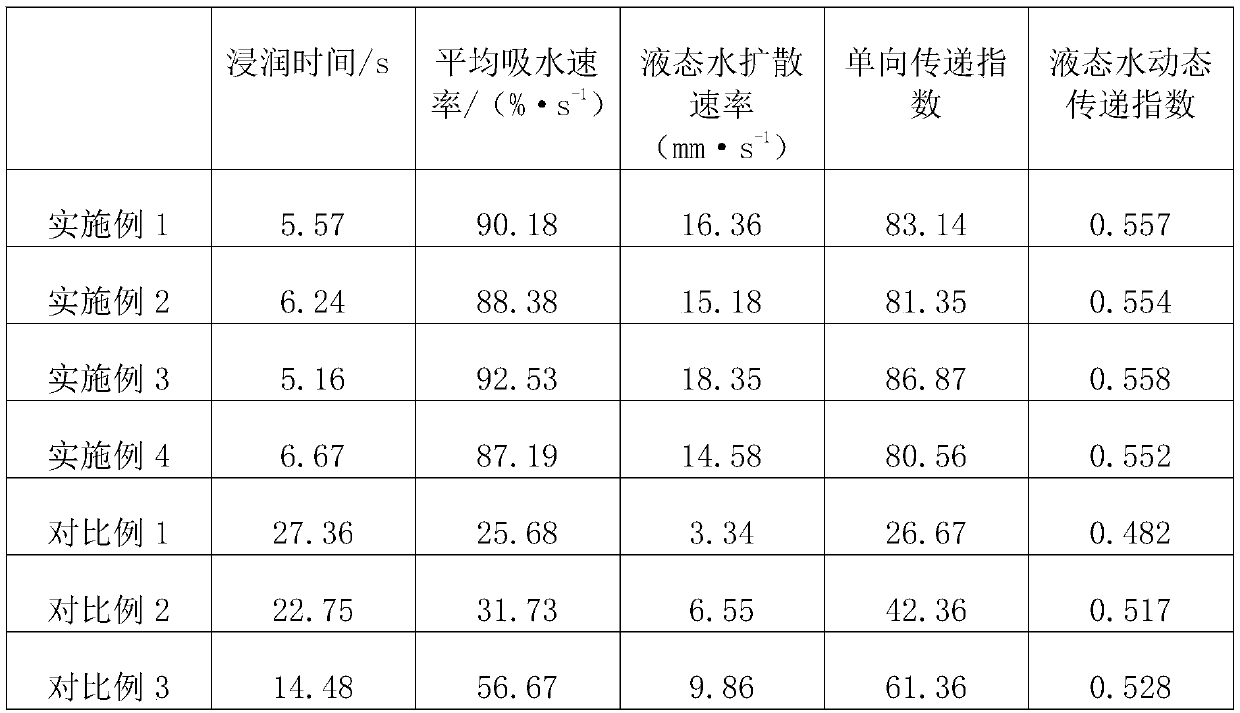

Finishing process of moisture-absorbing and sweat-wicking polyester non-woven fabrics

InactiveCN111549532AStrong Hydrophilic PerformanceGood hydrophilic performanceLiquid repellent fibresPolyesterPolymer science

The invention relates to the technical field of non-woven fabrics, and discloses a finishing process of moisture-absorbing and sweat-wicking polyester non-woven fabrics. The finishing process of the moisture-absorbing and sweat-wicking polyester non-woven fabrics comprises the following steps that (1) the polyester non-woven fabrics are placed in an ethanol solution for ultrasonic vibration cleaning; (2) a vinyl acetate-maleic anhydride copolymer is added to absolute ethanol, the mixture is heated and stirred to be dissolved to obtain a vinyl acetate-maleic anhydride copolymer solution, a sodium hydroxide ethanol solution is added dropwise to the vinyl acetate-maleic anhydride copolymer solution, the mixture is stirred and subjected to alcoholysis to obtain an alcoholysis solution, modified zeolite is added to the alcoholysis solution, and the mixture is uniformly dispersed by ultrasonic oscillation to obtain a hydrophilic finishing agent; (3) the polyester non-woven fabrics are immersed in the hydrophilic finishing agent, a glutaraldehyde crosslinking agent is added dropwise to carry out the crosslinking reaction, and nascent moisture-absorbing and sweat-wicking polyester non-woven fabrics are obtained; (4) the nascent moisture-absorbing and sweat-wicking polyester non-woven fabrics are arranged in an oven for heat drying treatment to obtain the moisture-absorbing and sweat-wicking polyester non-woven fabrics. The polyester non-woven fabrics have excellent moisture-absorbing and sweat-wicking performance and are comfortable to wear.

Owner:段尚军

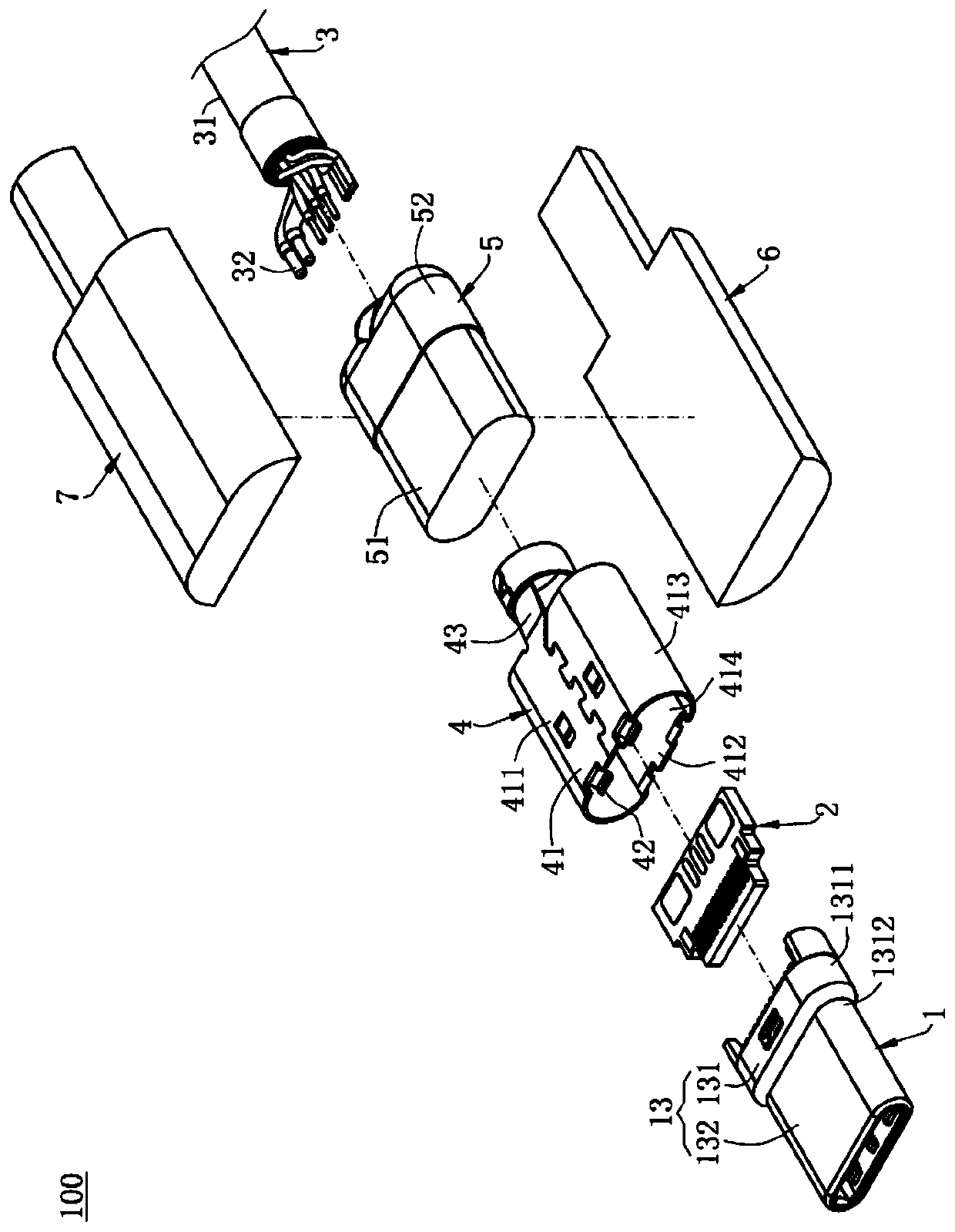

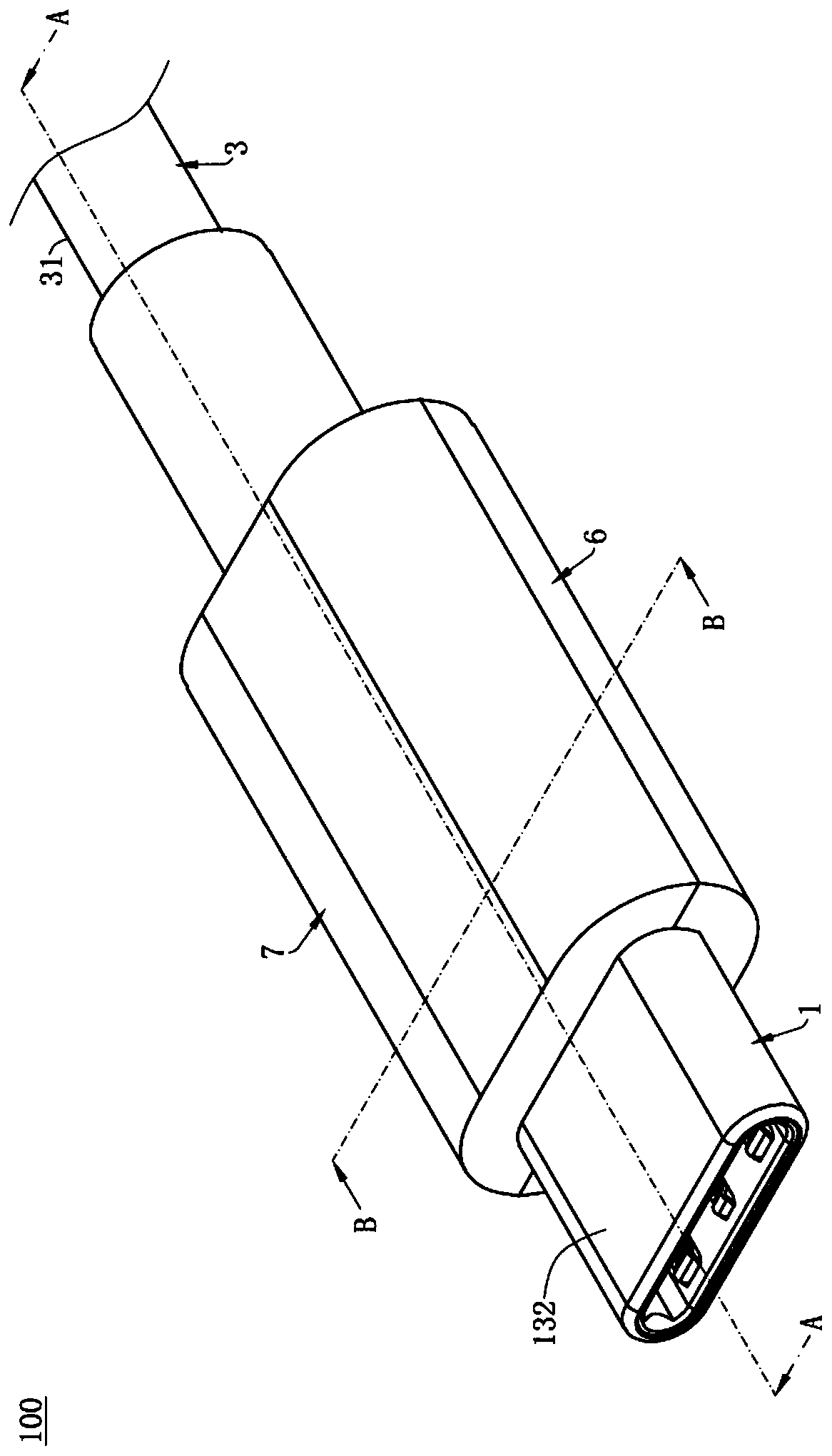

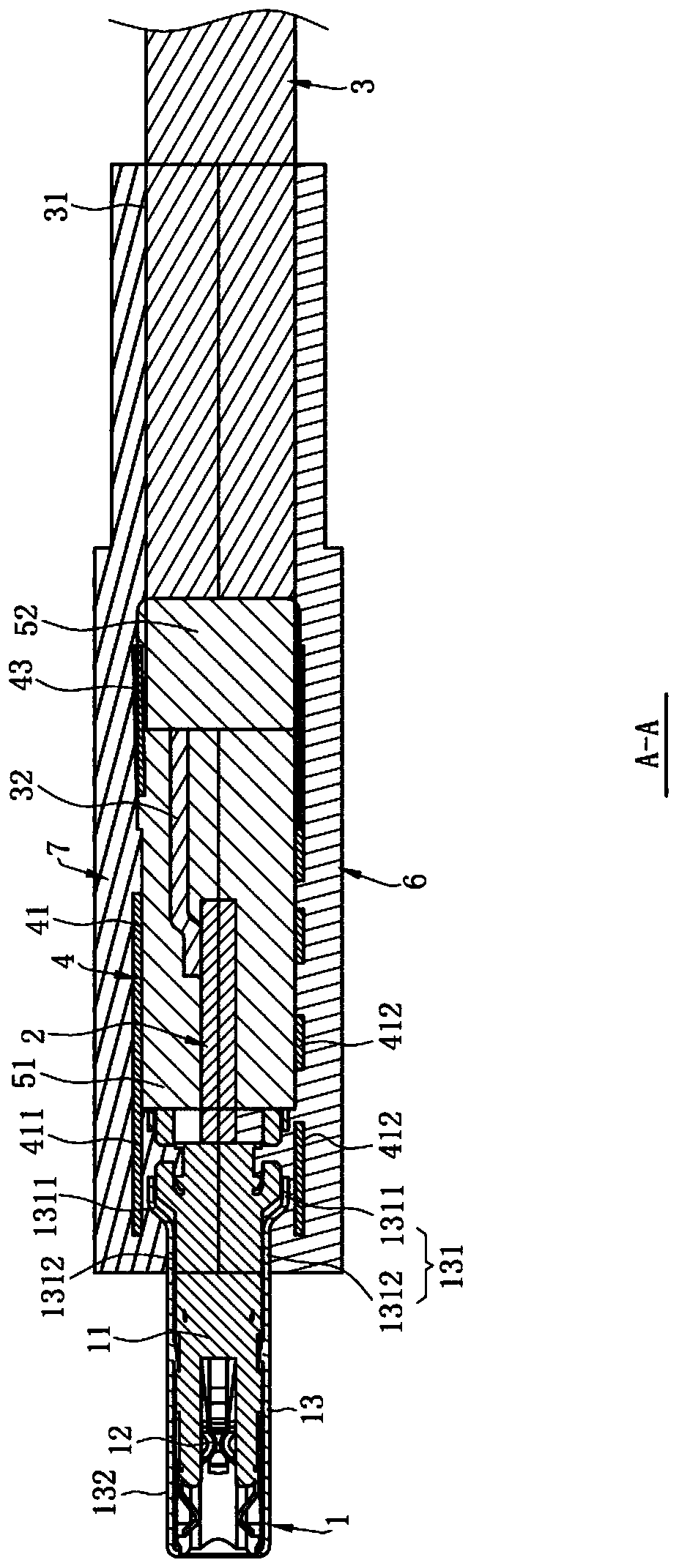

Manufacturing method of cable connector assembly

ActiveCN110112630AUniform structureUniform structure distributionContact member manufacturingContact member assembly/disassemblyInjection mouldingMechanical engineering

The invention discloses a manufacturing method of a cable connector assembly. The manufacturing method is characterized by comprising the following steps: step S1: a plug connector is provided, wherein the plug connector comprises an insulating body, multiple terminals accommodated in the insulating body and a shielding case surrounding the insulating body, and the shielding case is provided witha base and a butting part extending from the base to be inserted into a pair of connectors and electrically connects a cable and the terminals; step S2, a shell covers the base and the cable and fixesthe shell and the shielding case; step S3, injection molding of an inner mold is performed in the shell and the cable is fixed; step S4, the upper surface of the shell is located and injection molding of a first outer mold is performed to cover the lower surface of the shell and the lower surface of the inner mold; and step S5: the lower surface of the first outer mold is located and injection molding of a second outer mold is performed to cover the upper surface of the shell and the upper surface of the first outer mold so that the second outer mold and the first outer mold are joined and the structure of the first outer mold and the second outer mold is uniform.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com