Method for in-situ integrated preparation of Ti (C, N)-based metal ceramic cutter material with high heat resistance

A technology of ceramic knives and cermets, which is applied to other manufacturing equipment/tools, engine components, turbines, etc., can solve the problems of reducing the strength and toughness of materials, easily causing chipping, and rapid failure, and achieve dense grain structure distribution and realization Industrial application, good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing Ti(C,N)-based cermet cutting tool materials in situ with high heat resistance, comprising the following steps:

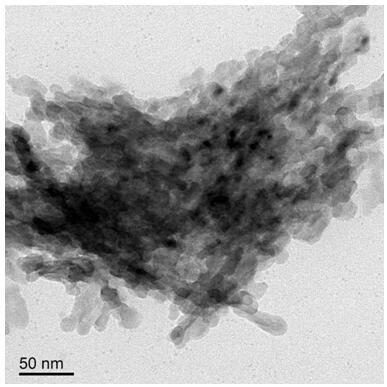

[0030] Step 1: Preparation of nanocrystalline AlCoCrFeNiTi high-entropy alloy powder: Weigh various raw material powders, according to atomic percentage Al: Co: Cr: Fe: Ni: Ti = 1: 1: 1: 1: 1: 1; The raw materials were subjected to mechanical planetary ball milling, the ball milling medium was cemented carbide balls, the ball-to-material ratio was 1:10, the ball milling speed was 300r / min, and the ball milling time was 40h. A total mass of 5wt% n-heptane was added into the ball mill as a process control agent, and the mill was shut down every 5 hours, with an interval of 30 minutes between shutdowns. In addition, 0.05MPa of Ar gas is introduced for protection after the powder is filled into the tank. Sieve through a 270-mesh sieve after ball milling.

[0031] Step 2: Carry out the proportioning and mixing of reaction raw materials; th...

Embodiment 2

[0038] A method for preparing Ti(C,N)-based cermet cutting tool materials in situ with high heat resistance, comprising the following steps:

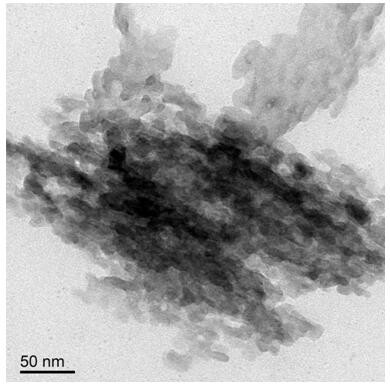

[0039] Step 1: Nanocrystalline Al 0.3 Preparation of CoCrFeNiTi high-entropy alloy powder: Weigh various raw material powders, according to atomic percentage Al: Co: Cr: Fe: Ni: Ti = 0.3: 1: 1: 1: 1: 1; Type ball mill, the ball milling medium is cemented carbide balls, the ball-to-material ratio is 1:10, the ball milling speed is 250r / min, and the ball milling time is 24h. Add 10wt% n-heptane in the ball mill as a process control agent, and shut down the mill every 5 hours with an interval of 30 minutes. In addition, 0.05MPa of Ar gas is introduced for protection after the powder is filled into the tank. Sieve through a 270-mesh sieve after ball milling.

[0040] Step 2: Carry out the proportioning and mixing of the reaction raw materials; the components included in the reaction raw materials and the weight percentages of each compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com