Manufacturing method of cable connector assembly

A cable connector and manufacturing method technology, applied in the field of cable connector assembly manufacturing, can solve problems such as uneven pressure, unevenness, shrinkage, and reduce the defect rate, uniform structure distribution, and volume reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

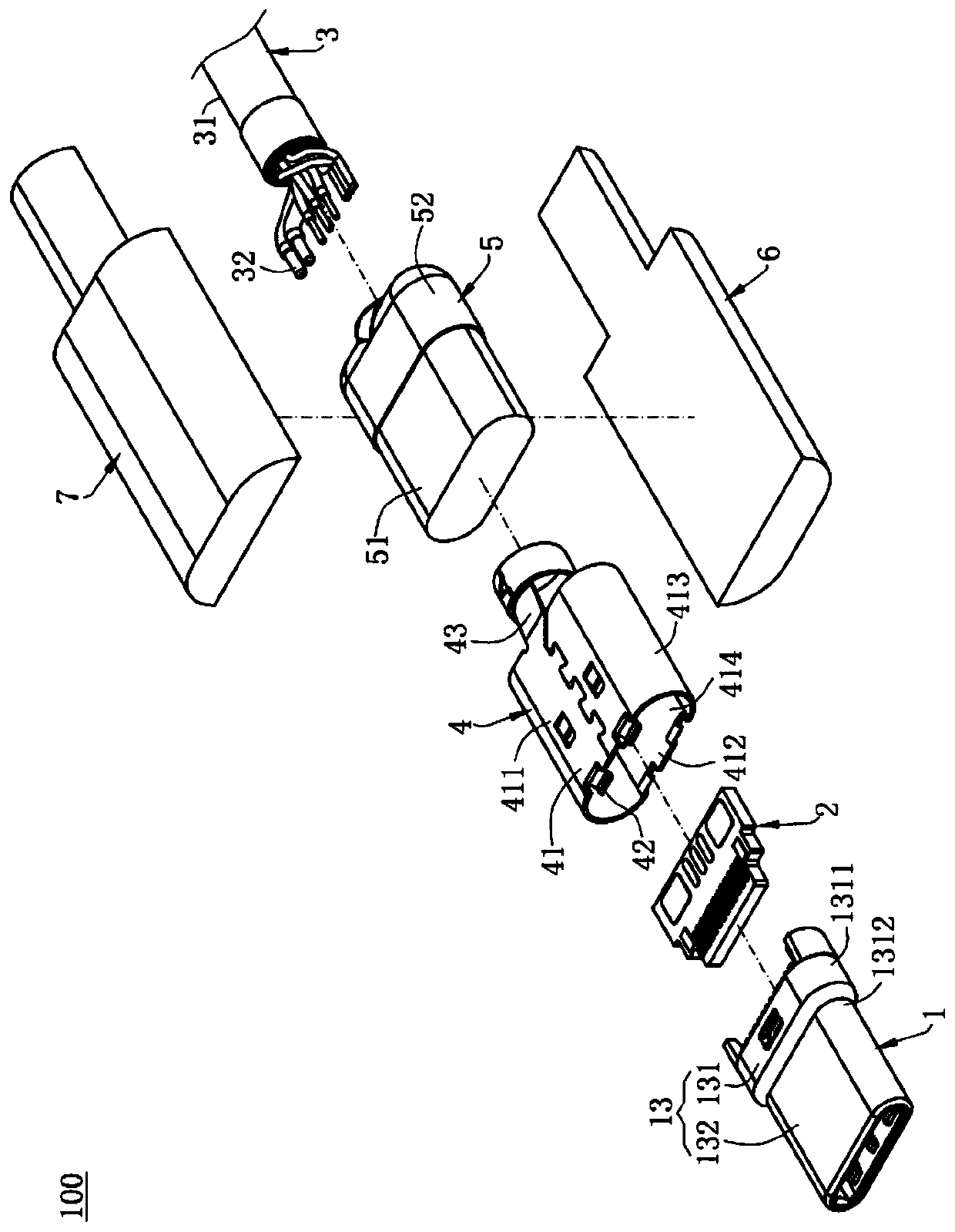

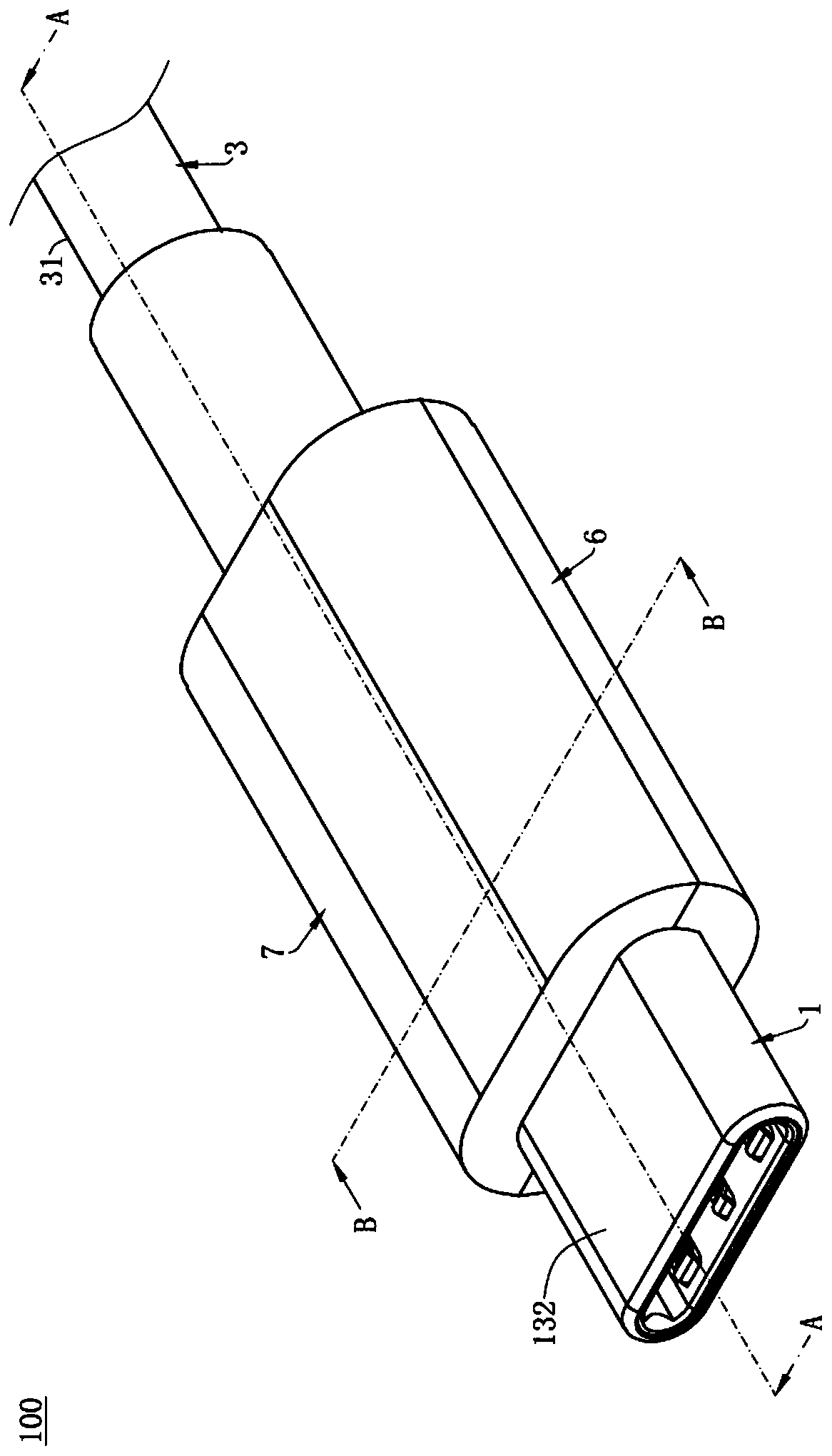

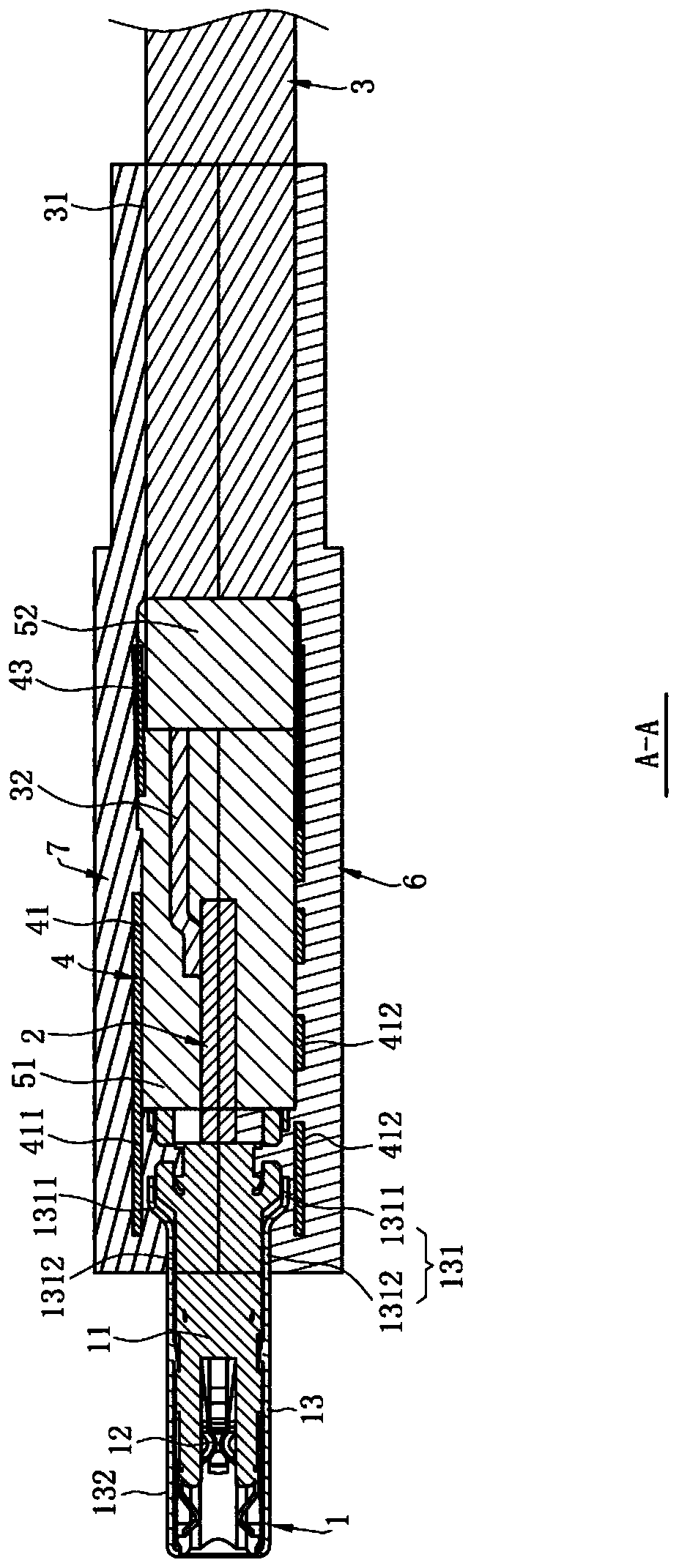

[0037] Please refer to Figure 1 to Figure 7 , is the main embodiment of a manufacturing method of a new cable connector assembly 100 of the present invention, and the cable connector assembly 100 includes a plug connector 1, a circuit board 2, a cable 3, and a housing 4 , an inner mold 5, a first outer mold 6, a second outer mold 7.

[0038] Please refer to figure 1 , Image 6, the plug connector 1 is a connector conforming to the Type-C standard in this embodiment, and the plug connector 1 includes an insulating body 11, a plurality of terminals 12 accommodated in the insulating body 11, and a shielding sheet (unnumbered) and two metal sheets (unnumbered), a shielding shell 13 surrounding the insulating body 11. The shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com