Diketene preparation device and diketene preparation method

A preparation device and a technology for diketene, which are applied to the diketene preparation device and the preparation field, can solve the problems of high energy consumption, affect product quality and yield, and large power consumption for refrigeration, achieve large heat transfer area, reduce refrigerant level, The effect of improving flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

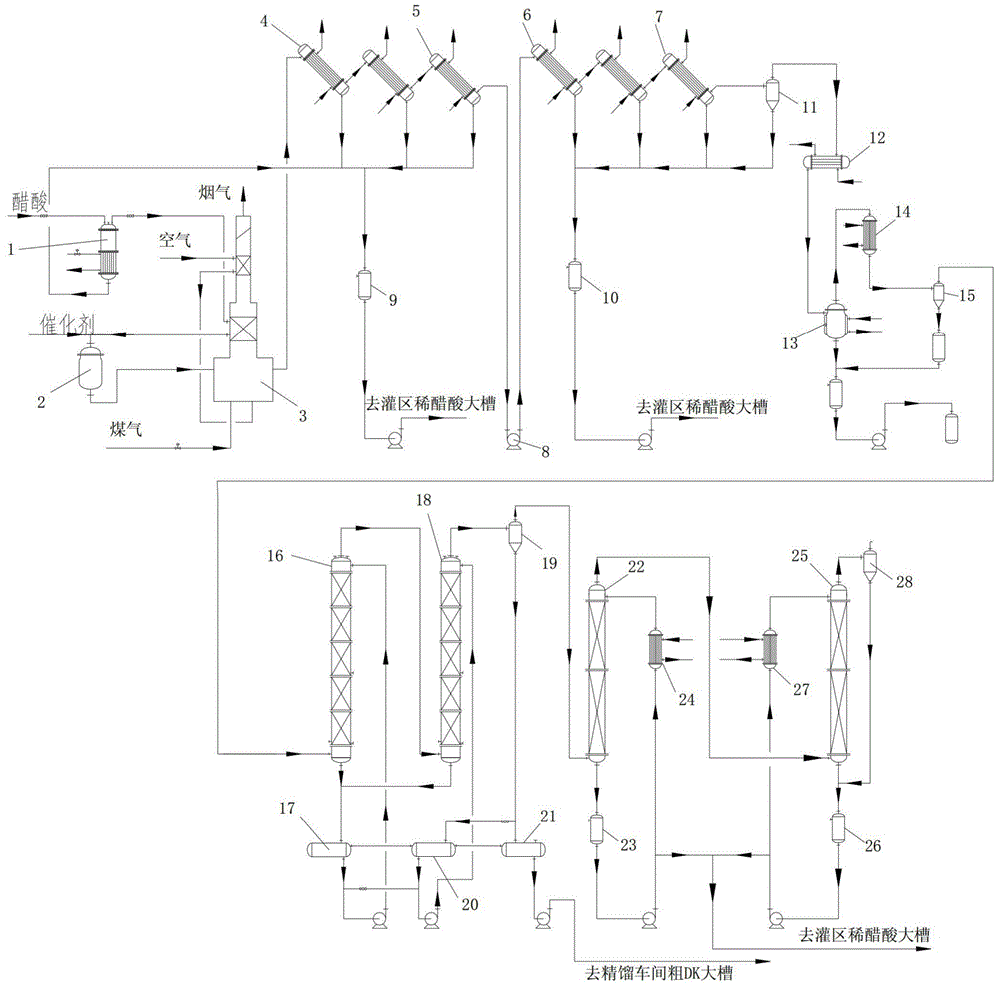

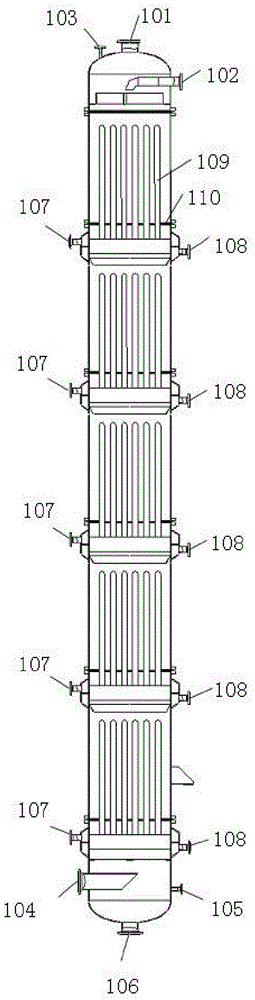

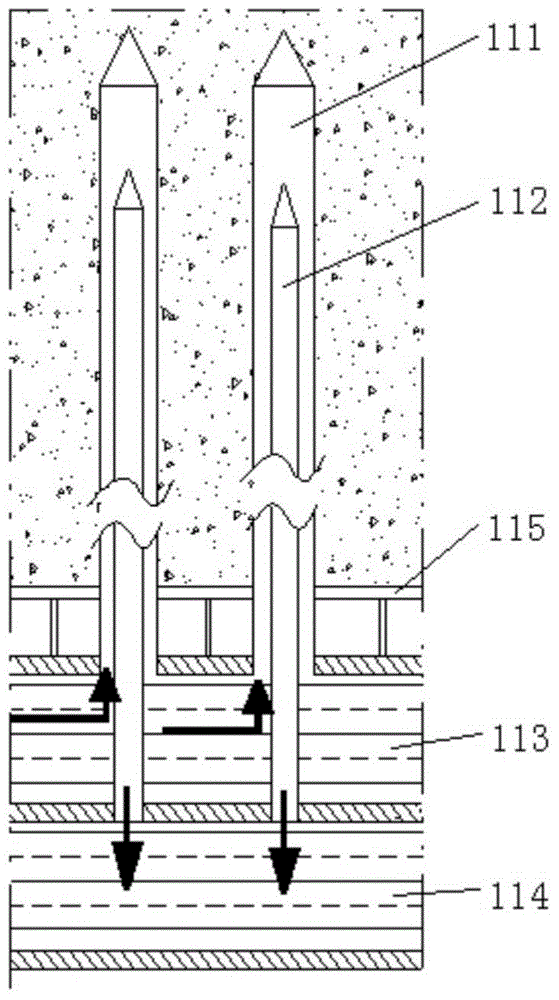

[0063] Such as figure 1 Shown, a kind of diketene preparation device comprises acetic acid evaporator 1, mixer 2, cracking furnace 3, quenching condenser and absorption tower, the outlet of acetic acid evaporator 1 and mixer 2 connects cracking furnace 3, and cracking furnace 3 connects six The first-stage quenching condenser, the sixth-stage quenching condenser 7 is connected to the absorption tower, one branch of the absorption tower is connected to the polymerization tank, and the other branch is connected to the water absorption tower, and the outlet of the third-stage quenching condenser 5 is connected to the rear via a liquid ring pump 8 Quench the condenser. The quenching condenser adopts a hot water lithium bromide absorption refrigerator, uses water as the refrigerant, and lithium bromide aqueous solution as the absorbent.

[0064] The outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com