Novel preparation method of edge functionalized graphene catalyst

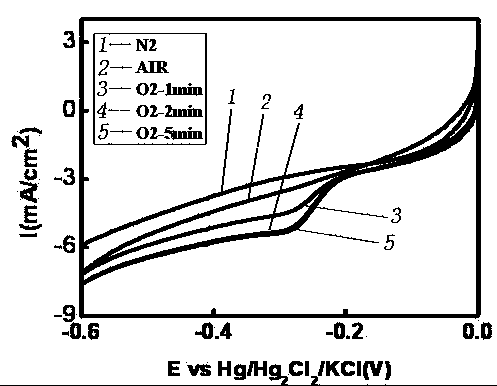

A catalyst and edge technology, which is applied in the field of new preparation of edge functionalized graphene catalysts, can solve the problem of graphene product sheets, uneven size and quality, difficult to modify, and high requirements for equipment assembly and experimental safety. problem, to achieve the effect of uniform lamellar structure distribution, high electrochemical catalytic activity, and enhanced catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

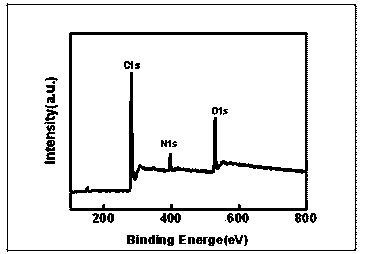

[0019] Mix graphite powder and conductive polymer monomers such as pyrrole in a certain proportion and add them to the ball milling tank. After ball milling at a speed of 500 rpm for 5 hours at room temperature and pressure, humidity 50-60 degrees, ball milled with ethanol Graphite powder and nitrogen-containing conductive polymer monomers are transferred to vials. After centrifugation at a speed of 4000 rpm, the mixture of graphite powder and nitrogen-containing conductive polymer monomer at the bottom was taken, dispersed and dissolved in ethanol again, and dialyzed to obtain graphene with conductive polymer edge functionalization. During the ball milling process, through the mechanochemical reaction and pyrrole volatilization, the edge functionalized graphite, and the small molecular pyrrole monomer was introduced to the edge of the graphite sheet. As the reaction proceeds, under the heat generated by ball milling, pyrrole monomers are polymerized into polypyrrole polymer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com