Paper sintering metal fiber load molecular sieve membrane and preparation method thereof

A technology of sintering metal and supporting molecules, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as the preparation of composite materials that have not been reported, achieve enhanced adsorption and catalytic efficiency, reduce volume and weight, The effect of reducing the pressure drop in the bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

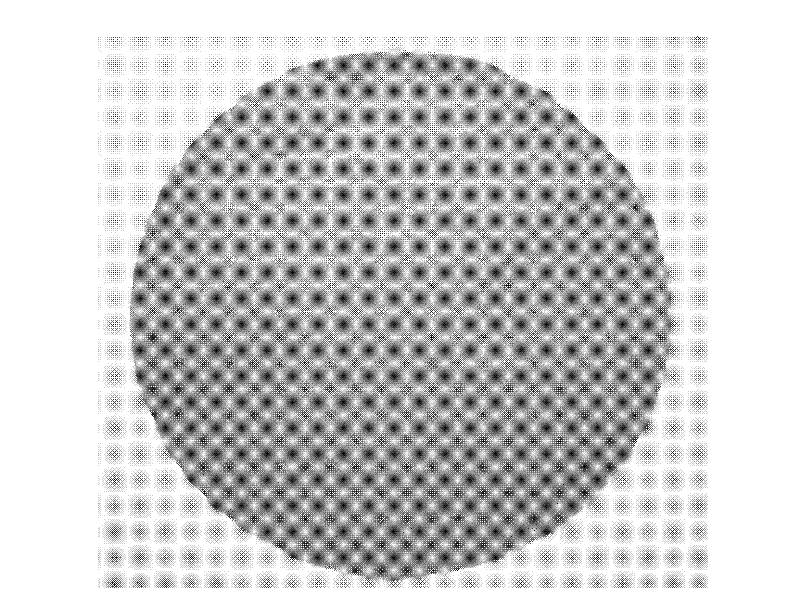

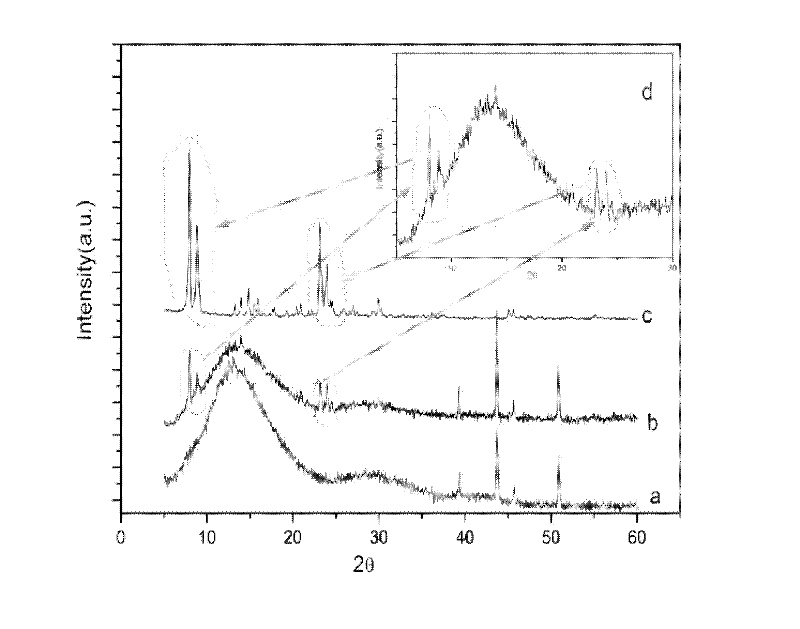

[0030] (1) Preparation method of paper-like sintered stainless steel fiber carrier

[0031] Add 3g coniferous wood fiber and 6g stainless steel fiber into appropriate amount of water, and stir at high speed for 10min in a fiber standard dissociator to form a uniform slurry, in which the diameter of the stainless steel fiber is 6.5μm. The uniformly mixed slurry is sliced with a slicer, and a wet filter cake is formed after water filtration. The filter cake was pressed under a pressure of 3 bar and dried at 105° C. for 120 min. Put the dried precursor in N 2 Sintering at 1050° C. for 40 minutes under gas protection to obtain a paper-like sintered stainless steel microfiber carrier, and the gas flow rate was controlled at 200 ml / min.

[0032] (2) The preparation method of MFI molecular sieve membrane, including the following steps:

[0033] A) Vector pretreatment :

[0034] Cut the carrier into a suitable size, and use 10wt% NaOH aqueous solution and 10wt% H 2 SO 4 The a...

Embodiment 2

[0043] Except the following difference, all the other are the same as embodiment 1.

[0044] The metal fiber used in step (1) is copper fiber with a diameter of 6.5 μm, the amount of coniferous wood fiber and copper fiber added are 3 g and 4 g respectively, the sintering temperature is 900° C., and the sintering time is 35 min.

Embodiment 3

[0046] Except the following difference, all the other are the same as embodiment 1.

[0047] The metal fiber used in the step (1) is an alloy fiber of iron, cobalt and vanadium, which contains 52% cobalt and 9% to 23% vanadium, and its diameter is 2.5 μm. The amount of coniferous wood fiber and alloy fiber 1g and 4g respectively, the sintering temperature is 900°C, and the sintering time is 30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com