Preparation method of anti-high-temperature-oxidation crystal whisker modified Ti(C,N) base composite metal ceramic

A high-temperature oxidation-resistant and composite metal technology, which is applied in the field of high-speed cutting tool materials, can solve the problems of poor chemical stability of SiC whiskers and TiC whiskers, reduced tool strength and hardness, etc., to improve high-temperature oxidation resistance , Improve the effect of strength, toughness and dense structure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

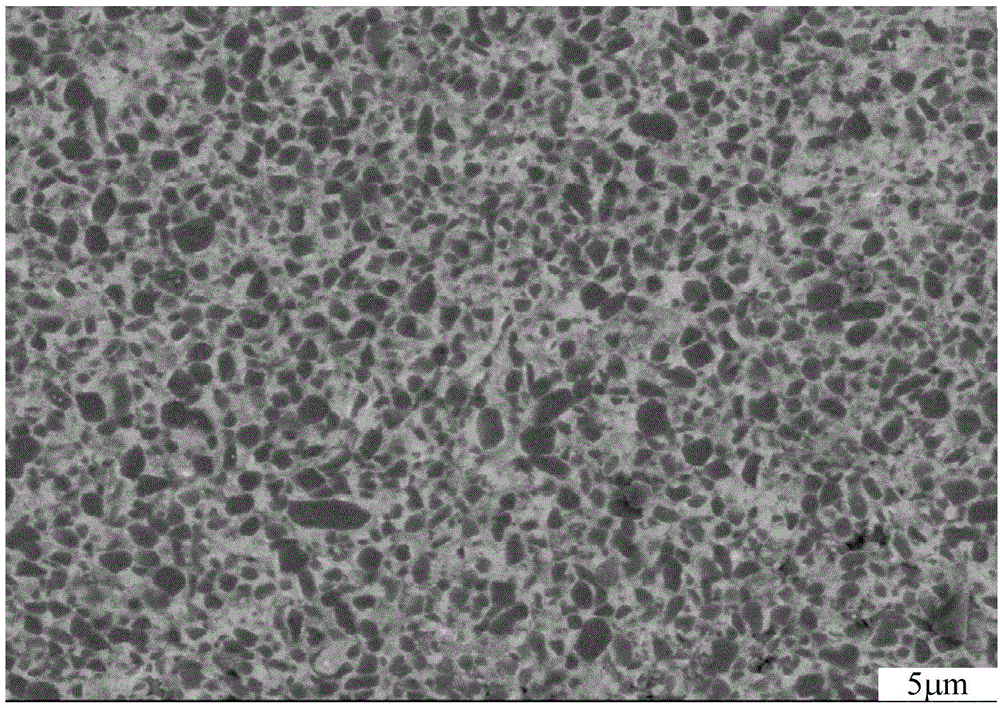

[0030] A method for preparing a high-temperature oxidation-resistant whisker-modified Ti(C,N)-based composite cermet according to this embodiment includes the following steps:

[0031] (1) Take Ti(C 0.5 N 0.5 ):60g, ZrO 2 Whiskers: 10g, WC: 15g, Co: 5g, Mo 2 C: 5g, Ni: 5g, put in a ball mill jar, add 800g of cemented carbide balls and 100ml of absolute ethanol; control the speed of ball milling on the jar ball mill at 300r / min for 24h, pour it out and place it at 85±5°C Dry in an oven, grind the dried powder, spray granulate, and pass through a 200-mesh sieve for use. The above ZrO 2 Whiskers choose high-strength ZrO 2 Whiskers, the whisker diameter is between 50 and 300nm, and the aspect ratio is between 1:8 and 1:15.

[0032] (2) According to the shape of the tool, take the appropriate amount of powder above, place it in an alloy abrasive tool and dry press it at 200MPa, and then place it in a vacuum hot-press furnace for sintering, with a vacuum degree of ≤1.0Pa. The...

Embodiment 2

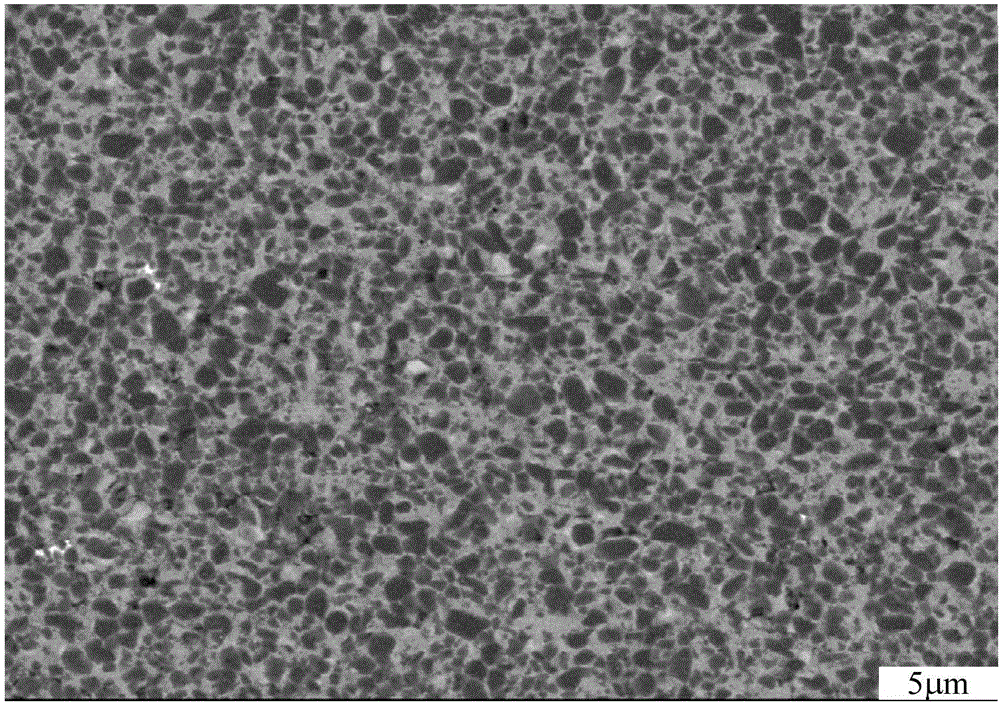

[0035] A method for preparing a high-temperature oxidation-resistant whisker-modified Ti(C,N)-based composite cermet according to this embodiment includes the following steps:

[0036] (1) Take Ti(C 0.5 N 0.5 ):55g, ZrO 2 Whiskers: 15g, WC: 10g, Co: 8g, Mo 2 C: 5g, Ni: 7g, put in a ball mill jar, add 800g of cemented carbide balls and 100ml of absolute ethanol; control the speed of ball milling on the jar ball mill at 300r / min for 24h, pour it out and place it in an oven at 85°C After drying, the dried powder is ground, sprayed and granulated, and passed through a 100-mesh sieve for use. The above ZrO 2 Whiskers choose high-strength ZrO 2 Whiskers, the diameter of the whiskers is between 50 and 300nm, and the aspect ratio is between 1:8 and 1:15.

[0037] (2) According to the shape of the tool, take the appropriate amount of powder above, place it in an alloy abrasive tool and dry press it at 200MPa, and then place it in a vacuum hot-press furnace for sintering, with a v...

Embodiment 3

[0040] A method for preparing a high-temperature oxidation-resistant whisker-modified Ti(C,N)-based composite cermet according to this embodiment includes the following steps:

[0041] (1) Take Ti(C 0.5 N 0.5 ):60g, Al 2 o 3 Whiskers: 10g, WC: 15g, Co: 5g, Mo 2 C: 5g, Ni: 5g, put in a ball mill jar, add 800g of cemented carbide balls and 100ml of absolute ethanol; control the speed of ball milling on the jar ball mill at 300 r / min for 24 hours, pour it out and place it in an oven at 85°C Dry in medium temperature, grind the dried powder, spray granulate, and pass through a 100-mesh sieve for later use. Al above 2 o 3 Whiskers select high-strength Al 2 o 3 Whiskers, the diameter of the whiskers is between 50 and 300nm, and the aspect ratio is between 1:8 and 1:15.

[0042] (2) According to the shape of the tool, take the appropriate amount of powder above, place it in an alloy abrasive tool and dry press it at 220MPa, and then place it in a vacuum sintering furnace for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com