Patents

Literature

48results about How to "Strong resistance to high temperature oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of anti-high-temperature-oxidation crystal whisker modified Ti(C,N) base composite metal ceramic

The invention discloses a preparation method of anti-high-temperature-oxidation crystal whisker modified Ti(C,N) base composite metal ceramic, and belongs to the field of high-speed cutter materials. The preparation method of the crystal whisker modified Ti(C,N) base composite metal ceramic comprises the steps of raw material matching, ball milling and material mixing, material drying, vacuum hot pressed sintering and the like. The crystal whisker modified Ti(C,N) base composite metal ceramic comprises, by weight, 45-60% of Ti(C<0.5>N<0.5>), 10-25% f Al2O3 crystal whisker or ZrO2 crystal whisker, 8-15% of WC, 5-10% of Co, 5-10% of Mo2C and 5-10% of Ni. The Ti(C,N) base composite metal ceramic obtained through the preparation method has excellent compactness, high-strength toughness and high temperature oxidation resistance, and can serve as a (semi) precision-machined cutter material of a special steel material.

Owner:TAIZHOU UNIV

Method for preparing metal ceramic composite powder body suitable for hot spraying

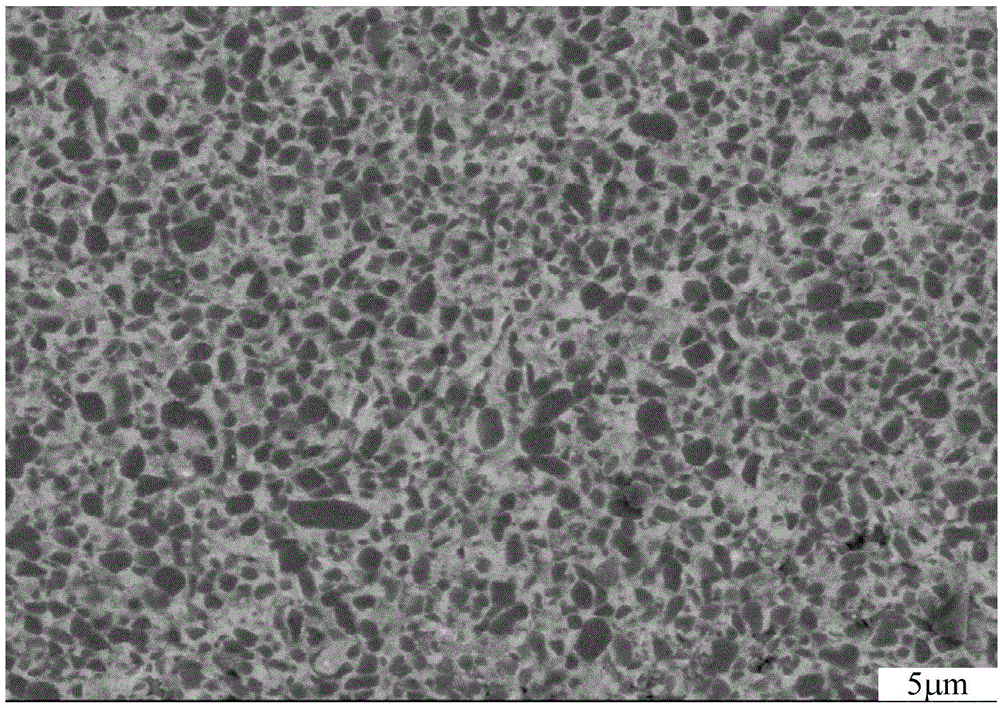

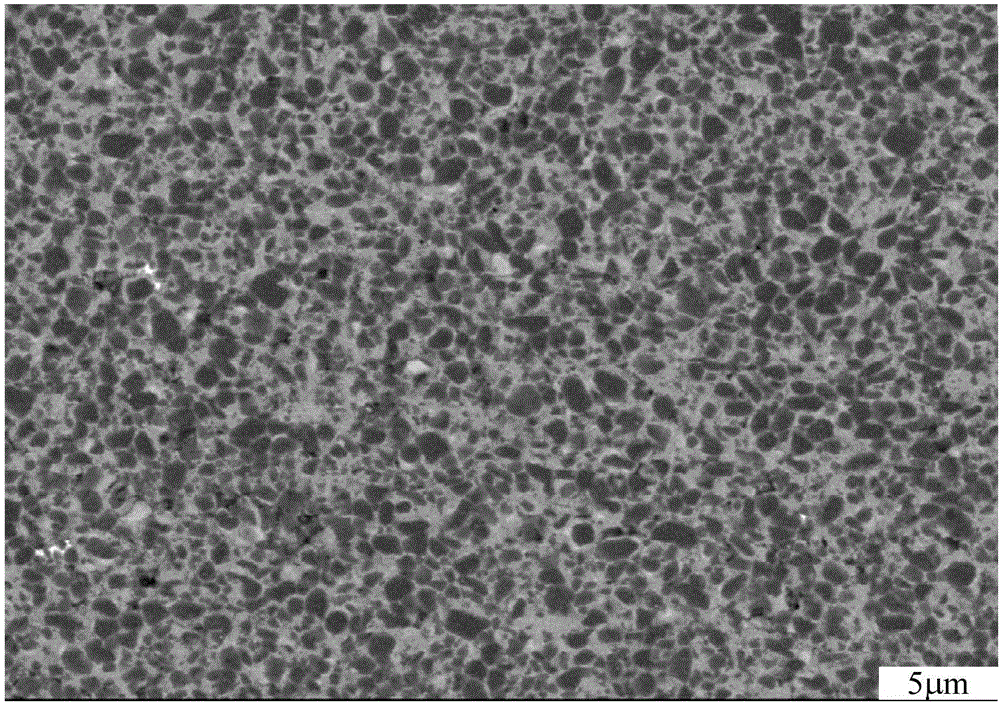

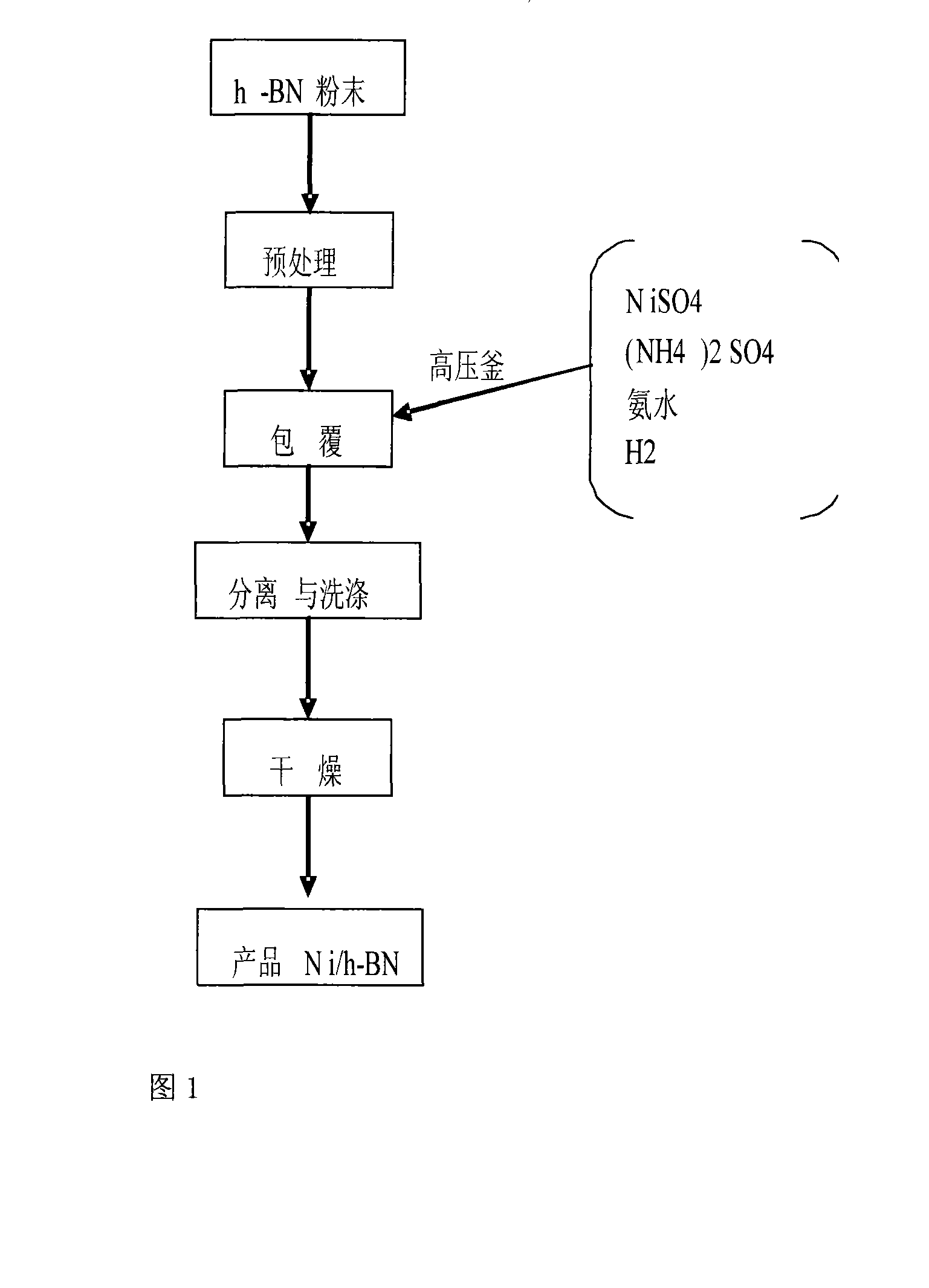

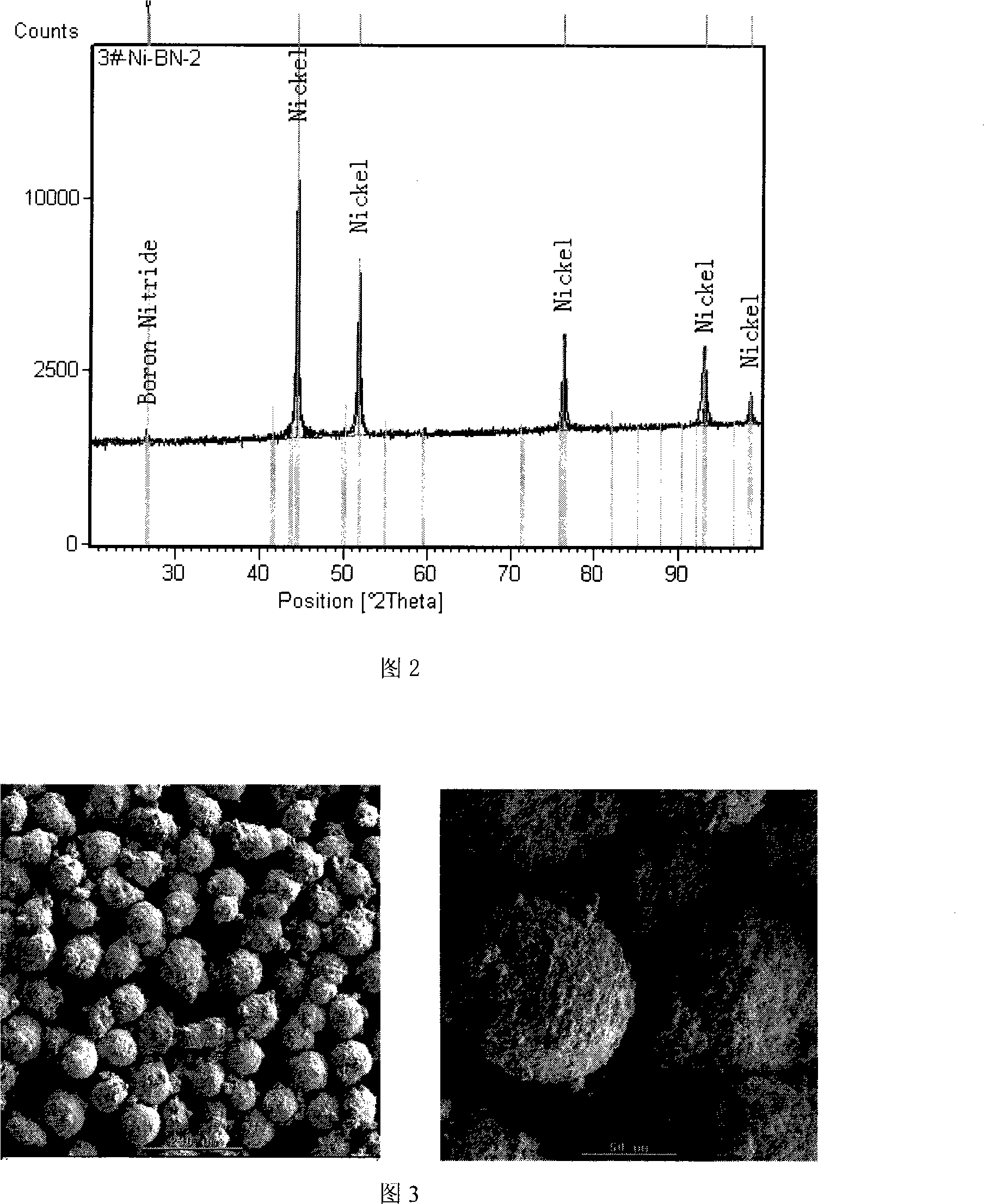

The invention relates to a method for preparing nickel-coated kubonit cermet compound powder body with complete subsphaeroidal topography suitable for plasma spraying, supersonic speed flame spraying and hot spraying. The technical scheme includes the following steps: preparing NaOH liquor, sensitizing liquor and active liquor with a consistency of 1 to 20 percent; (2) carrying through preliminary treatment on hexagonal boron nitride ceramics powder, weighing the hexagonal boron nitride with a certain proportion and using the liquor prepared by step (1) to carry through the preliminary treatment; (3) preparing a reaction liquor;(4) simultaneously adding the hexagonal boron nitride after treated in step (2) and the reaction liquor prepared by step (3) into a high pressure reaction kettle to react, cooling, opening the kettle and discharging after the reaction is finished; (5) carrying through washing, filtering and drying after washing on the acquired powder body to get the nickel-coated kubonit powder body.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

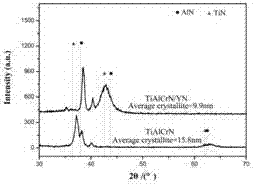

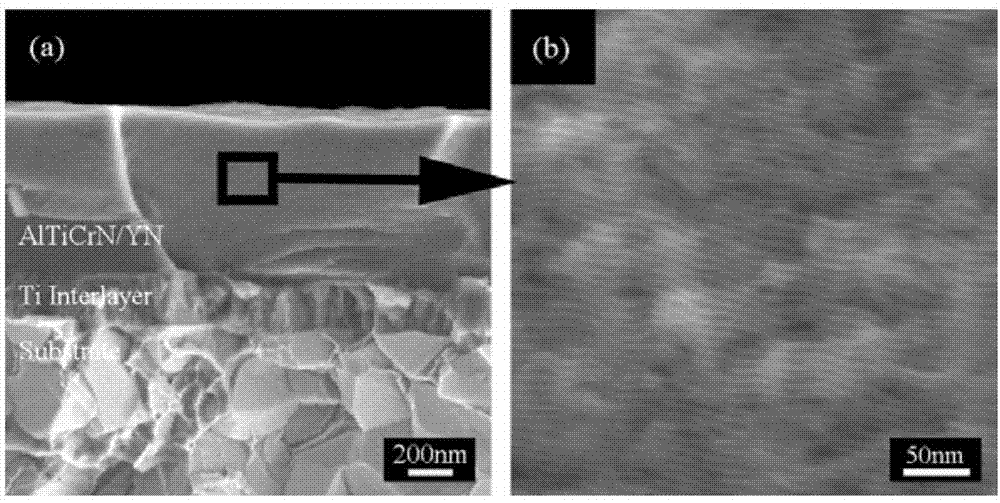

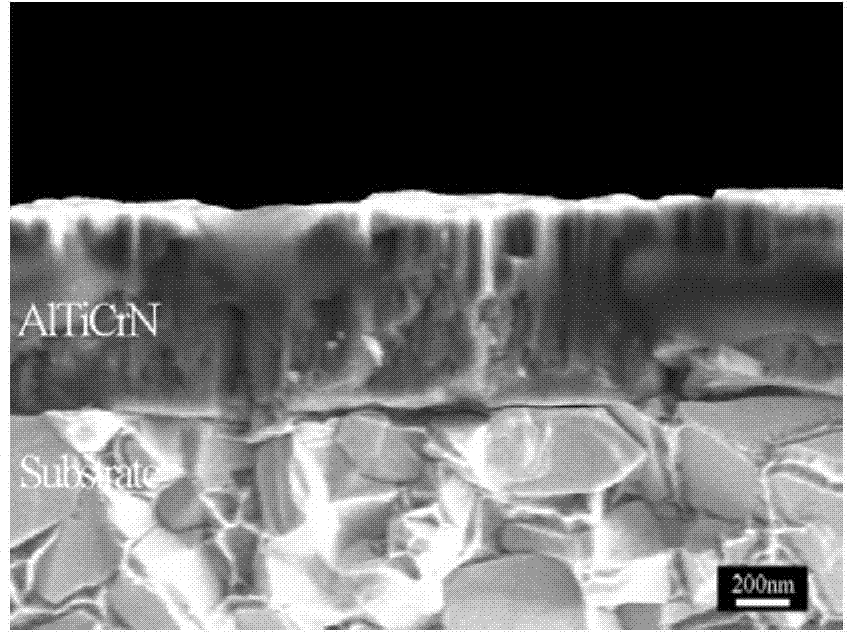

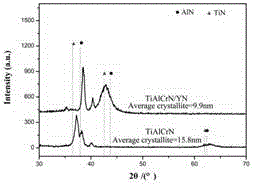

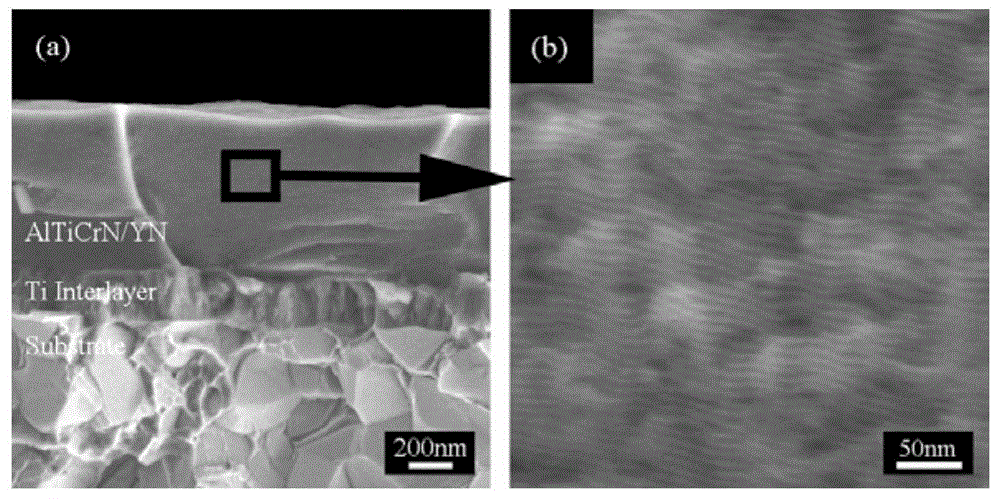

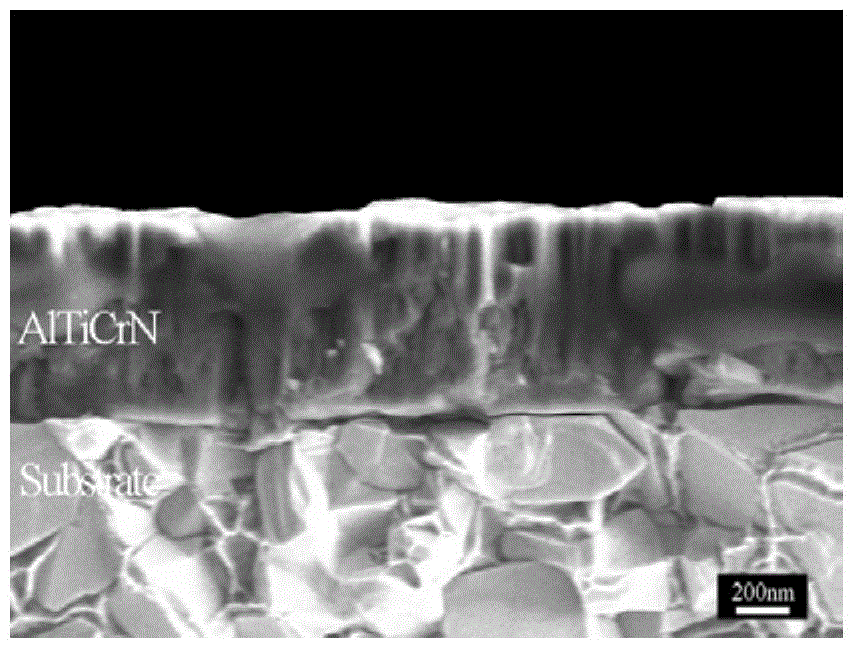

AlTiCrN/YN nano multilayer hard coating and preparation method thereof

InactiveCN103789724ADense tissueFine grainVacuum evaporation coatingSputtering coatingSputteringEtching

The invention discloses a preparation method of an AlTiCrN / YN nano multilayer hard coating. The preparation method comprises the following steps: cleaning, heating, etching and cleaning, preparing a Ti or Cr adhesion layer and preparing an AlTiCrN / YN wear-resistant layer. According to the preparation method provided by the invention, a Ti or Cr bonding layer is deposited on a tool matrix by adopting an evaporation coating method, and AlTiCrN layers and YN layers are alternatively periodically deposited on the Ti or Cr bonding layer by adopting an intermediate frequency reaction magnetron sputtering technology, thus the prepared AlTiCrN / YN nano multilayer hard coating tissue is of a non-columnar crystal structure, is compact, and is small in grain, is firmly bound with a tool matrix; the coating has higher hardness and excellent high-temperature oxidization resistance performance, and is especially suitable for making a high-speed dry type cutting stainless steel, an iron-based high-temperature alloy, a high-strength structural steel and a wear-resistant cast steel tool. The AlTiCrN / YN nano multilayer hard coating is simple in coating process, easy to implement and more suitable for industrialized production.

Owner:SICHUAN UNIV

0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube and production process thereof

The invention discloses a 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube. The 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube comprises the following chemical components in percentage by mass: 0.029-0.031% of C, 0.55-0.59% of Si, 1.12-1.14% of Mn, 0.001-0.003% of S, 0.015-0.017% of P, 17.55-17.75% of Cr, 10.15-10.25% of Ni, 0.33-0.35% of Nb, 0.022-0.024% of Mo, 0.04-0.06% of N, 0.149-0.151% of Ti, 0.0013-0.0015% of Sb, 0.0007-0.0009% of Pb, 0.0012-0.0014% of Ce, 0.08-0.12% of rare earth elements and the balance of Fe and unavoidable impurities. The invention further discloses a production process of the 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube. The 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube has good flexibility, corrosion resistance, high temperature resistance, wear resistance, tensile strength and water resistance and also has excellent electromagnetic shielding performance.

Owner:WUXI XINCHANG STEEL PIPE

Method for preparing protective coating material of boiler tube

The invention discloses a method for preparing a protective coating material of a boiler tube. The coating material consists of the following components in percentage by weight: 12 to 14 percent of Cr, 0.4 to 0.6 percent of Mn, 2 to 3 percent of Ti, 3 to 5 percent of Al, 2 to 4 percent of Si, 1 to 2 percent of Nb, 8 to 12 percent of Fe, 1 to 3 percent of Co, 3 to 5 percent of Mo, less than or equal to 0.025 percent of S, less than or equal to 0.035 percent of P and the balance of Ni. The method for preparing the protective coating material comprises the following steps of: 1) smelting waste steel, intermediate alloy and nickel ingots according to the components and refining to prepare coating material alloy ingots; 2) placing the prepared alloy ingots in a crucible for prepare powder through atomization, heating and melting, and atomizing to prepare powder by taking helium as atomization gas; and 3) screening the prepared atomization powder to obtain the coating powder with the diameter of -200 meshes.

Owner:NINGBO SUNLIGHT MOTOR PARTS

Aluminizing agent and method for preparing Si-B-Y coating on surface of tantalum and tantalum alloy

InactiveCN107267915AEnhanced resistance to peelingImprove liquiditySolid state diffusion coatingOxidation resistantPre treatment

The invention belongs to the technical field of high-temperature coatings and particularly relates to an aluminizing agent and method for preparing a Si-B-Y coating on the surface of tantalum and tantalum alloy. The aluminizing agent disclosed by the invention comprises, by weight, 12%-17% of aluminized element Si (with the purity greater than or equal to 99%), 1.0%-2.0% of aluminized element Y2O3 (with the purity greater than or equal to 99%), 1.0%-2.0% of aluminized element B (with the purity greater than or equal to 98%), 5%-8% of catalyst NaF (analytically pure), and the balance fillers Al2O3. The invention further discloses the preparation method of the coating. The preparation method comprises the steps of (1) conducting surface pretreating on a sample; (2) conducting ball milling and refining on the prepared aluminizing agent; (3) putting the sample and the aluminizing agent into an aluminizing tank and sealing the aluminizing tank; (4) conducting heating, heat preservation and cooling on the aluminizing tank put in a high-temperature furnace; and (5) finally, taking out the sample and then cleaning and drying the sample. The obtained coating is uniform and compact in structure, can be well bonded to a matrix and can remarkably improve the thermal protection properties of matrix alloy and resist the high temperature of 1000 DEG C for 100 h or more, and the thermal protection properties mainly include the high-temperature antioxidation property, the anti-corrosion property and the anti-wear property. Equipment required by the method is simple, and the method is reliable in process, low in cost and suitable for production and application.

Owner:BEIFANG UNIV OF NATITIES

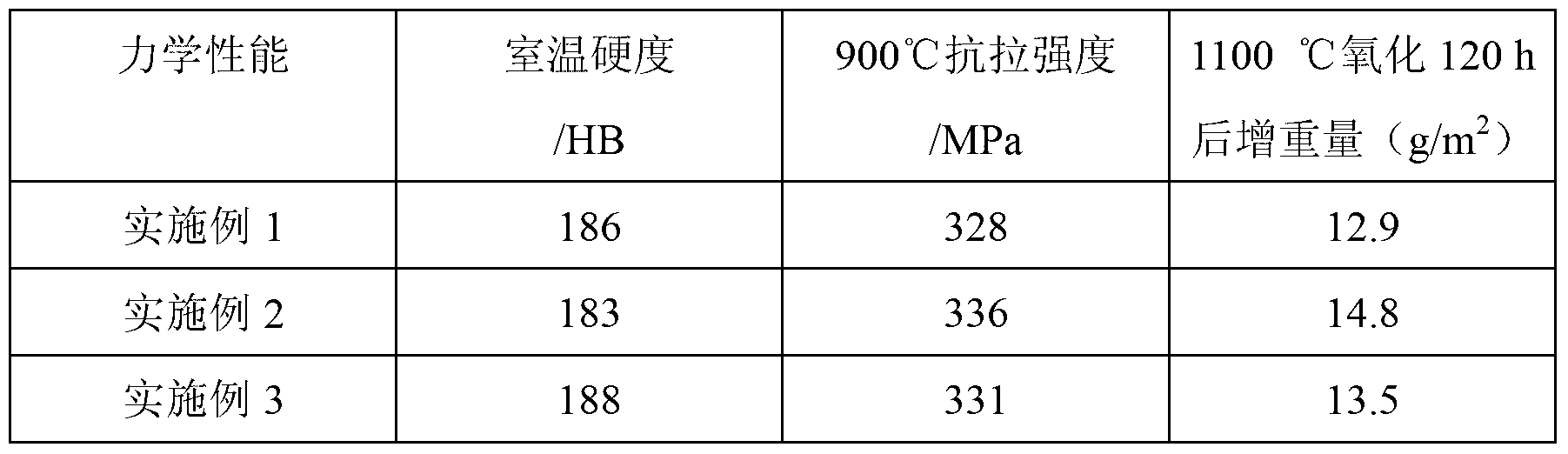

High-temperature-oxidation-resisting alloy steel and preparation method thereof

InactiveCN103320673AStrong resistance to high temperature oxidationExcellent high temperature mechanical propertiesFerrosiliconRare earth

The invention discloses a high-temperature-oxidation-resisting alloy steel and a preparation method thereof. The alloy steel is composed of the raw materials of, by mass, 39.0-41.5% of Q235 waste steel, 25.0-28.0% of stainless steel scrap, 14.0-16.0% of Ni-based alloy scrap, 2.0-2.2% of manganese iron, 8.0-8.5% of high-carbon ferrochrome, 4.5-4.8% of metal aluminum, 1.0-1.2% of ferrosilicon, 1.0-1.2% of ferrotungsten, 0.8-1.0% of yttrium-based heavy rare earth silicon-iron-magnesium alloy, and 0.30-0.45% of silicon-calcium alloy. The alloy steel is processed through electric furnace smelting, casting forming, and 600-650 DEG C heat treatment, and is provided with excellent antioxidant performance.

Owner:XI AN JIAOTONG UNIV +1

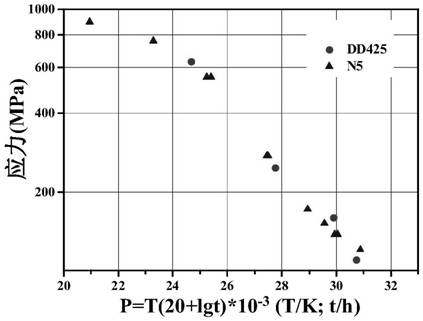

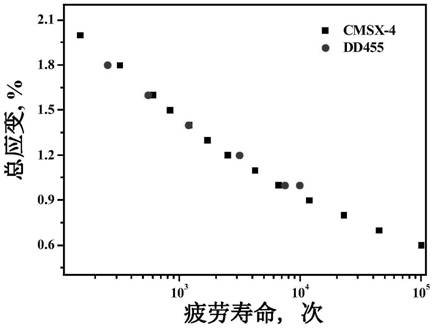

Rhenium-free second-generation nickel-based single-crystal superalloy with high strength and resistance to high temperature oxidation and heat treatment process thereof

InactiveCN112593121ALow costStrong resistance to high temperature oxidationRheniumChemical composition

The invention discloses a rhenium-free second-generation nickel-based single-crystal superalloy with high strength and resistance to high temperature oxidation and a heat treatment process thereof, and belongs to the field of nickel-based single-crystal superalloys. The alloy comprises the following chemical components in percentage by weight: 6.0-8.0% of Cr, 8.0-10.0% of Co, 6.0-9.0% of W, 1.0-3.0% of Mo, 0-2% of Nb, 4.0-7.0% of Al, 0.5-1.5% of Ti, 1.0-5.0% of Ta, 0.02-0.06% of C, 0.001-0.003% of B, 0-0.02% of Ce, 0-0.01% of Y, 0-0.2% of Hf and the balance of Ni. The alloy has excellent low-temperature strength, medium-temperature strength, high-temperature strength and oxidation resistance and is durable, the tensile property and the low-cycle fatigue property of the alloy are equivalentto those of a second-generation single-crystal superalloy Rene N5 containing 3wt.% of Re, and the alloy reaches the complete oxidation resistance level.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

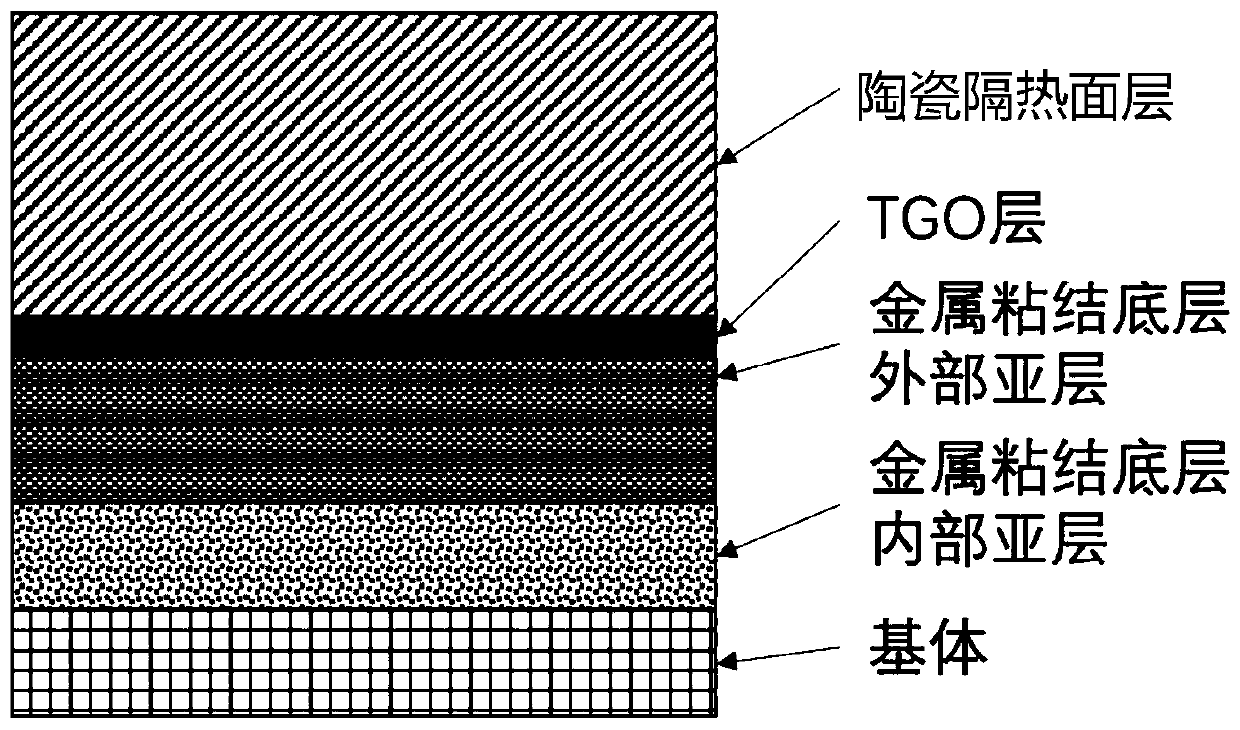

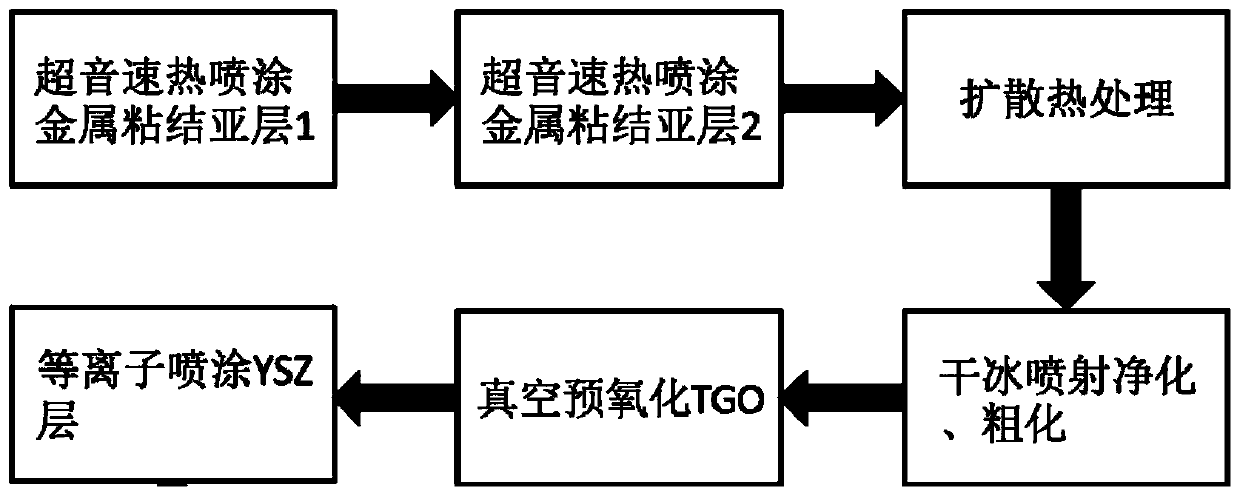

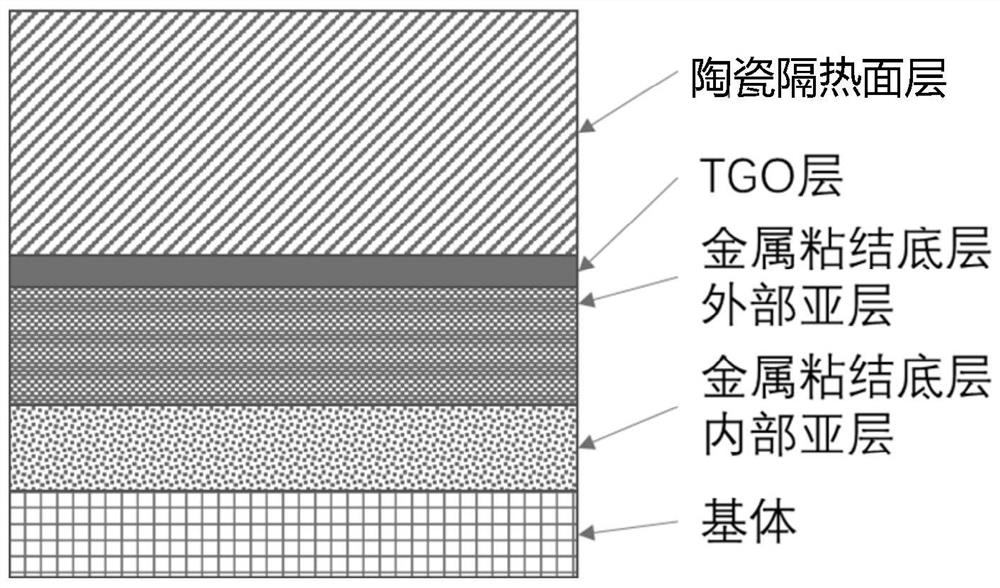

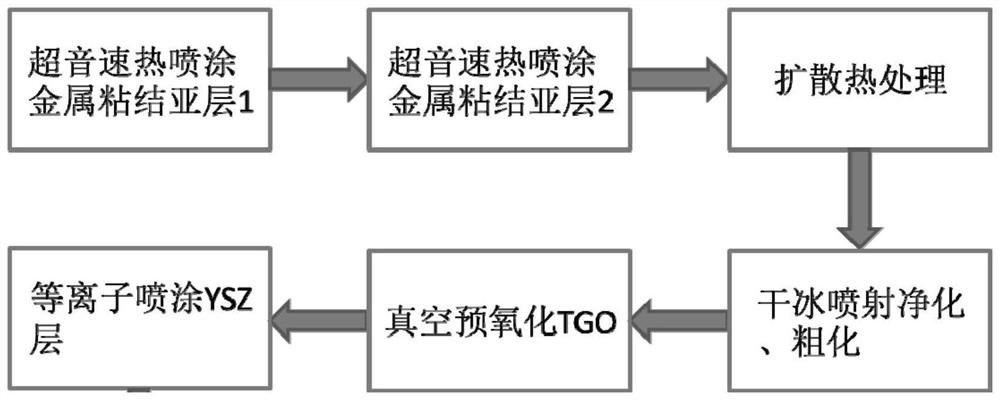

Novel preparation process for thermal barrier coating

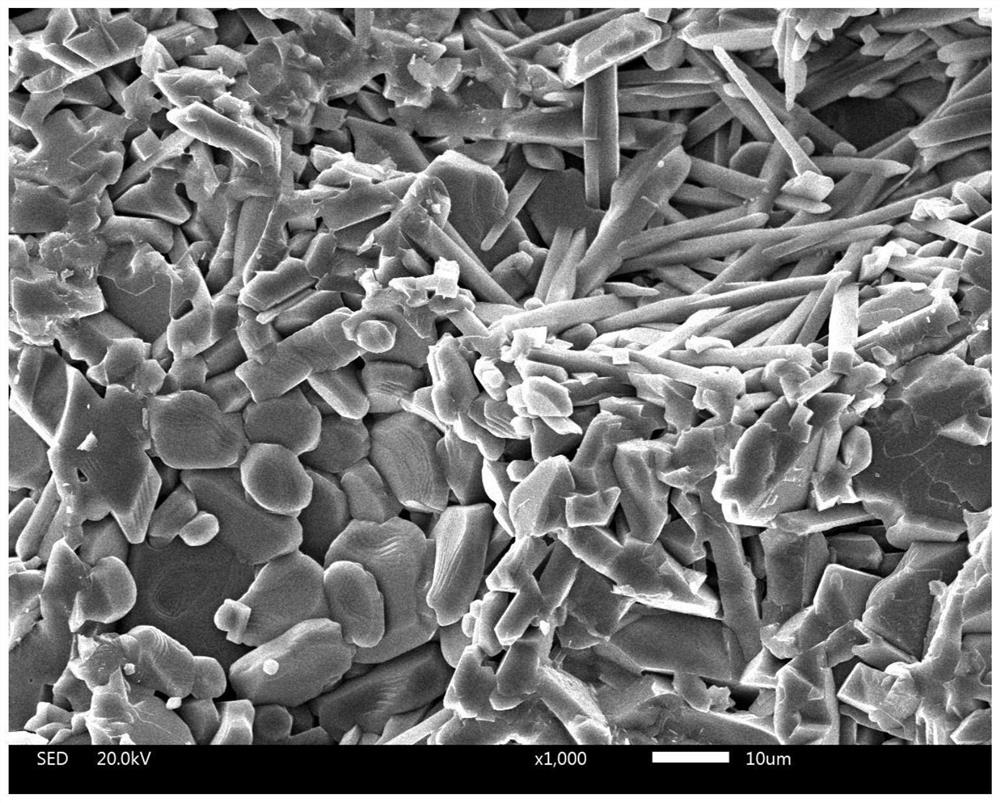

ActiveCN109930102AHigh densityImprove selective oxidation abilityMolten spray coatingSurface layerDry ice

The invention relates to a novel preparation process for a thermal barrier coating. The novel preparation process comprises the following steps: generating a metal bonding bottom layer on the surfaceof a matrix; generating an in-situ thermal growth oxide layer (TGO); and generating a ceramic heat-insulating surface layer, wherein the TGO layer is pre-grown before the matrix serves. The TGO layercomprises alpha-aluminum oxide. A compact and continuous TGO layer which takes alpha-aluminum oxide as the principal component is preset through large-particle dry ice jetting and purifying rougheningtreatment and pre-vacuum argon gas oxidizing treatment. An oxide film has very good high-temperature oxidization resistance, prevents quick oxidization, reduces a layer thickness increase rate of theTGO layer, and achieves the purpose of reducing thermal barrier coating peel-off probability.

Owner:江苏源清动力技术有限公司

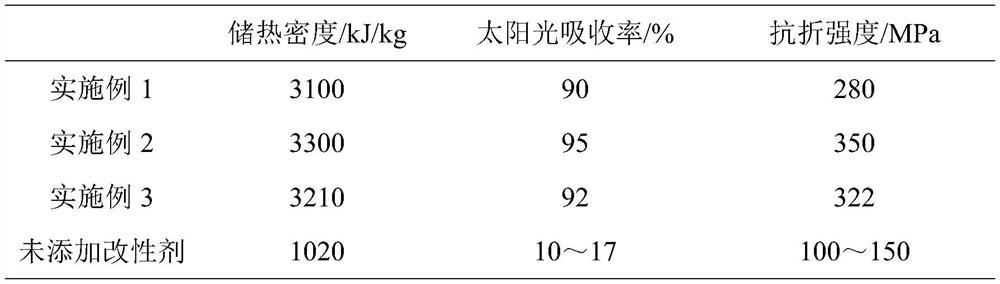

Antioxidant and long-life heat absorption and storage integrated corundum-mullite ceramic and preparation method thereof

The invention discloses an antioxidant and long-life heat absorption and storage integrated corundum-mullite ceramic and a preparation method thereof. The ceramic is prepared from the following raw materials and modifiers in percentage by mass: 65-75 wt% of aluminum oxide, 15-20 wt% of Suzhou clay, 3-5 wt% of titanium oxide, 3-6 wt% of molybdenum oxide, 5-7 wt% of iron oxide and 2-3 wt% of nickel oxide. The ceramic prepared by the invention has excellent heat storage capacity, excellent heat storage and heat absorption capacity, high-temperature oxidation resistance, high breaking strength, good mechanical property and thermal shock resistant cycle stability, and longer service life.

Owner:WUHAN UNIV OF TECH

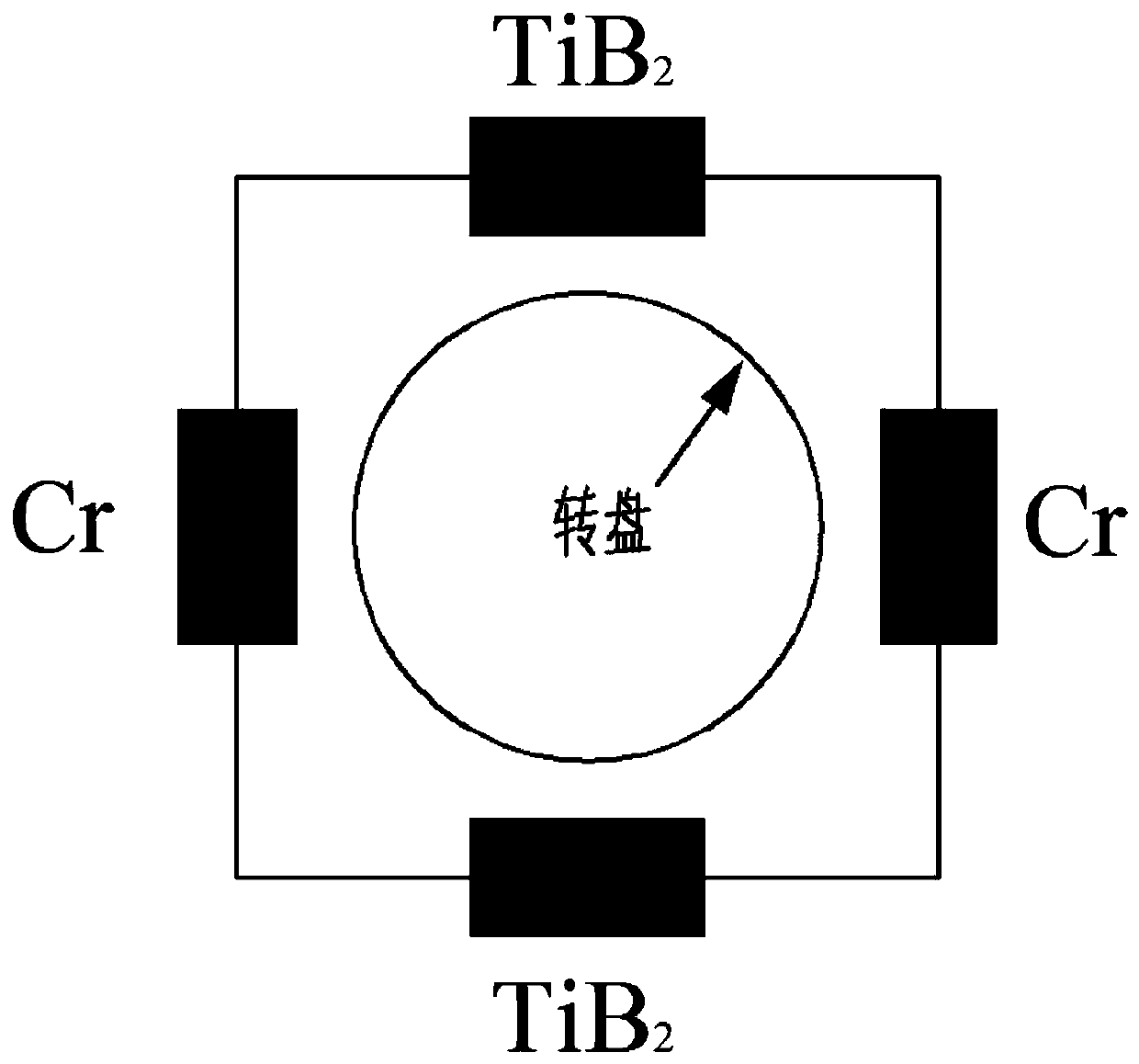

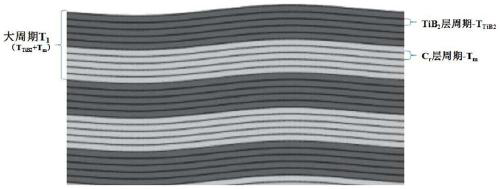

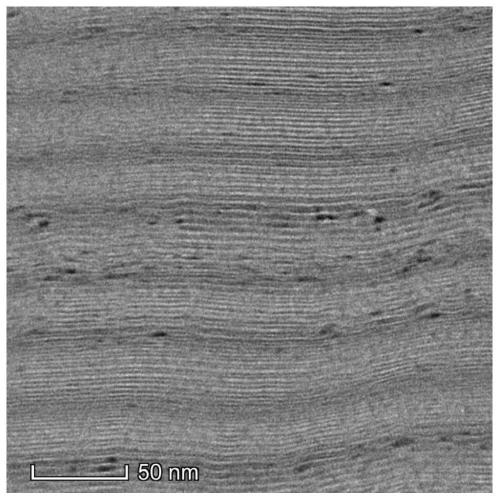

TiB2-based coating with multicycle structure and preparation method and application thereof

ActiveCN110042343AImprove high temperature oxidation resistancePrevent mobilityVacuum evaporation coatingSputtering coatingHardnessHigh intensity

The invention belongs to the technical field of surface protection, and discloses a TiB2-based coating with a multicycle structure and a preparation method thereof. The TiB2-based coating is formed bysputtering deposition on a substrate by taking a TiB2 target and a metal target as raw materials and adopting magnetron sputtering coating; and the TiB2-based coating is of a multicycle structure inwhich a TiB2 layer and an elemental metal layer are overlapped with each other, the adjacent TiB2 layer and the elemental metal layer are in a large period, meanwhile, periodic structures exist in theTiB2 layer and the elemental metal layer respectively, the period in the TiB2 layer is formed by alternately overlapping a TiB2-rich layer and a TiB2-poor layer, and the period in the elemental metallayer is formed by alternately overlapping a metal-rich layer and a metal-poor layer. The coating not only reduces the residual stress, but also integrates the characteristics of high hardness, highstrength, high high-temperature oxidation resistance and good bonding force of the single-layer TiB2, and is used for protecting the surfaces of products such as mechanical parts and knife molds.

Owner:GUANGDONG UNIV OF TECH

Protective coating material for boiler pipeline

The invention discloses a protective coating material for a boiler pipeline. The protective coating material comprises the following components by weight percent: 12%-14% of Cr, 0.4%-0.6% of Mn, 2%-3% of Ti, 3%-5% of Al, 2%-4% of Si, 1%-2% of Nb, 8%-12% of Fe, 1%-3% of Co, 3%-5% of Mo, less than or equal to 0.025% of S, less than or equal to 0.035% of P and the balance of Ni.

Owner:NINGBO SUNLIGHT MOTOR PARTS

Hardfacing alloy containing silicon and chromium composite ceramic phases and manufacturing process thereof

ActiveCN103737196AGuaranteed hardnessGuaranteed wear resistanceMetallic material coating processesPlasma welding apparatusComposite ceramicBall mill

The invention provides a hardfacing alloy containing silicon and chromium composite ceramic phases and a manufacturing process thereof. The hardfacing alloy is characterized that ingredients of the hardfacing alloy comprises 10-20 percent of chromium, 0.5-5 percent of silicon, 1-4 percent of nickel, 5-10 percent of carbon, balance ferrum and inevitable impurities. The manufacturing process of the hardfacing alloy includes the first step of carrying out calculation and mechanical mixing on ferrochromium powder, molybdenum powder, nickel powder, graphite and reduced iron powder according to element mass percent, mixing all the powder evenly in a dry-type ball milling mode through a ball grinding mill to enable the granularity of the powder to reach 60-160 meshes, and taking out the powder, the second step of drying the powder in a drying oven for one to two hours and then enabling the temperature in the oven to cool down to the indoor temperature, and the third step of adding the powder into a powder feeder and then carrying out plasma arc surfacing on the powder to form a hardfacing layer. The manufacturing process is easy to operate, the kinds of the additive alloys are fewer, and the obtained hardfacing alloy is low in cost, good in binding performance between the hardfacing layer hard phases and base materials and not prone to falling off, and has the advantages of high hardness, high abrasion resistance and high temperature oxidation resistance.

Owner:辽宁谱瑞科技有限公司

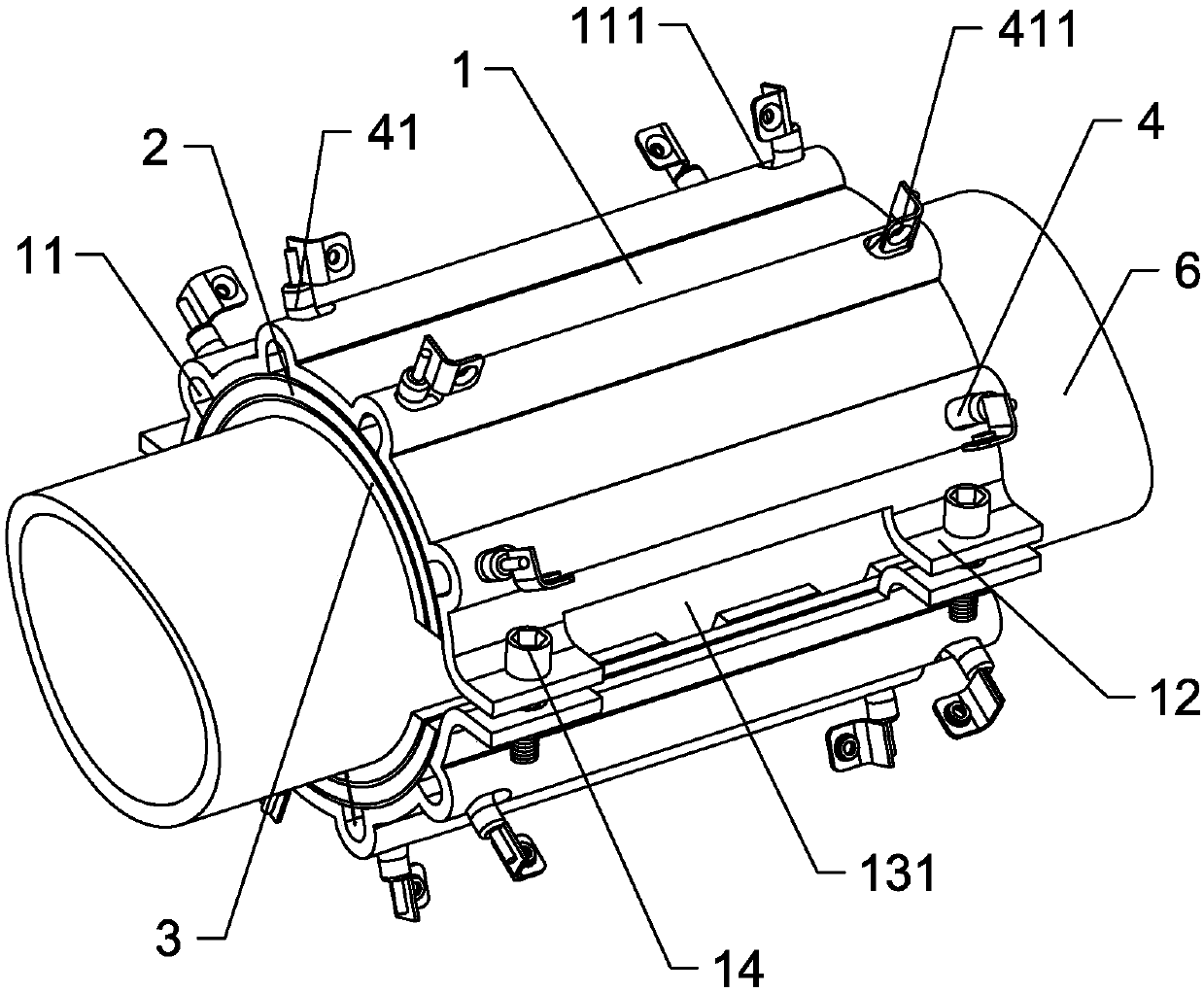

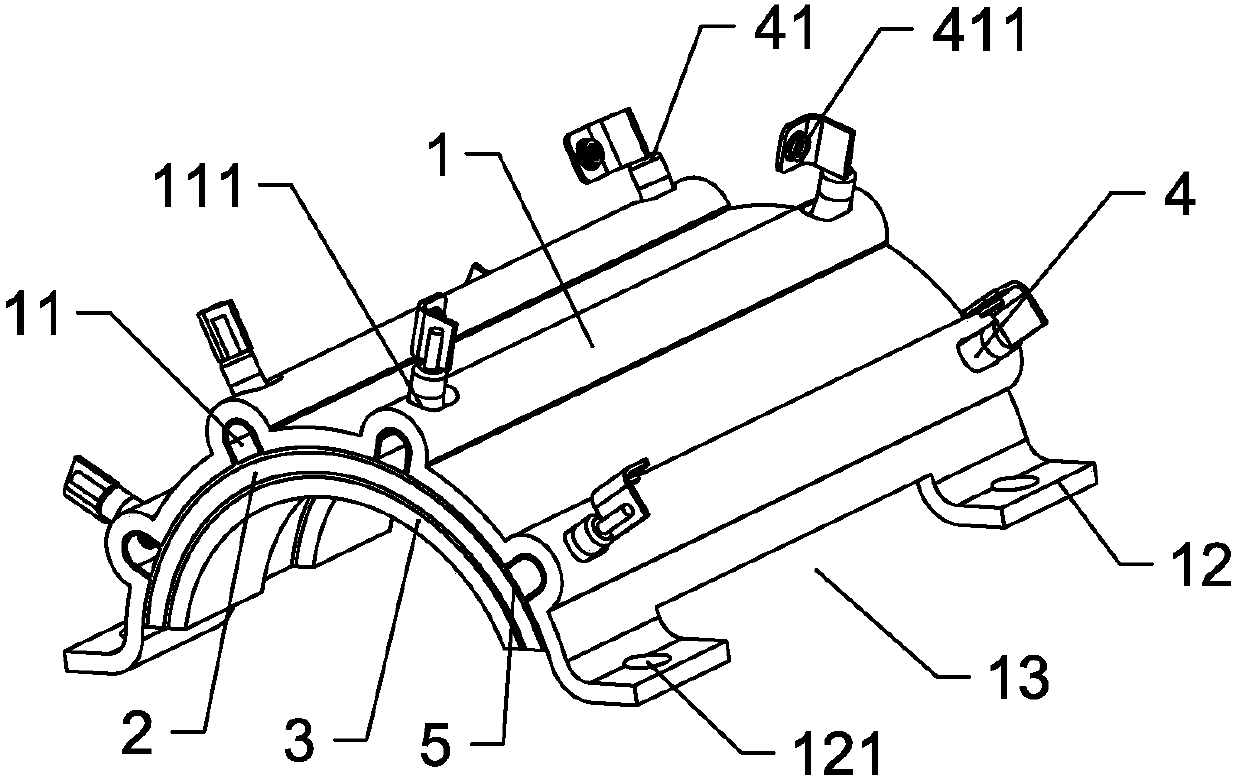

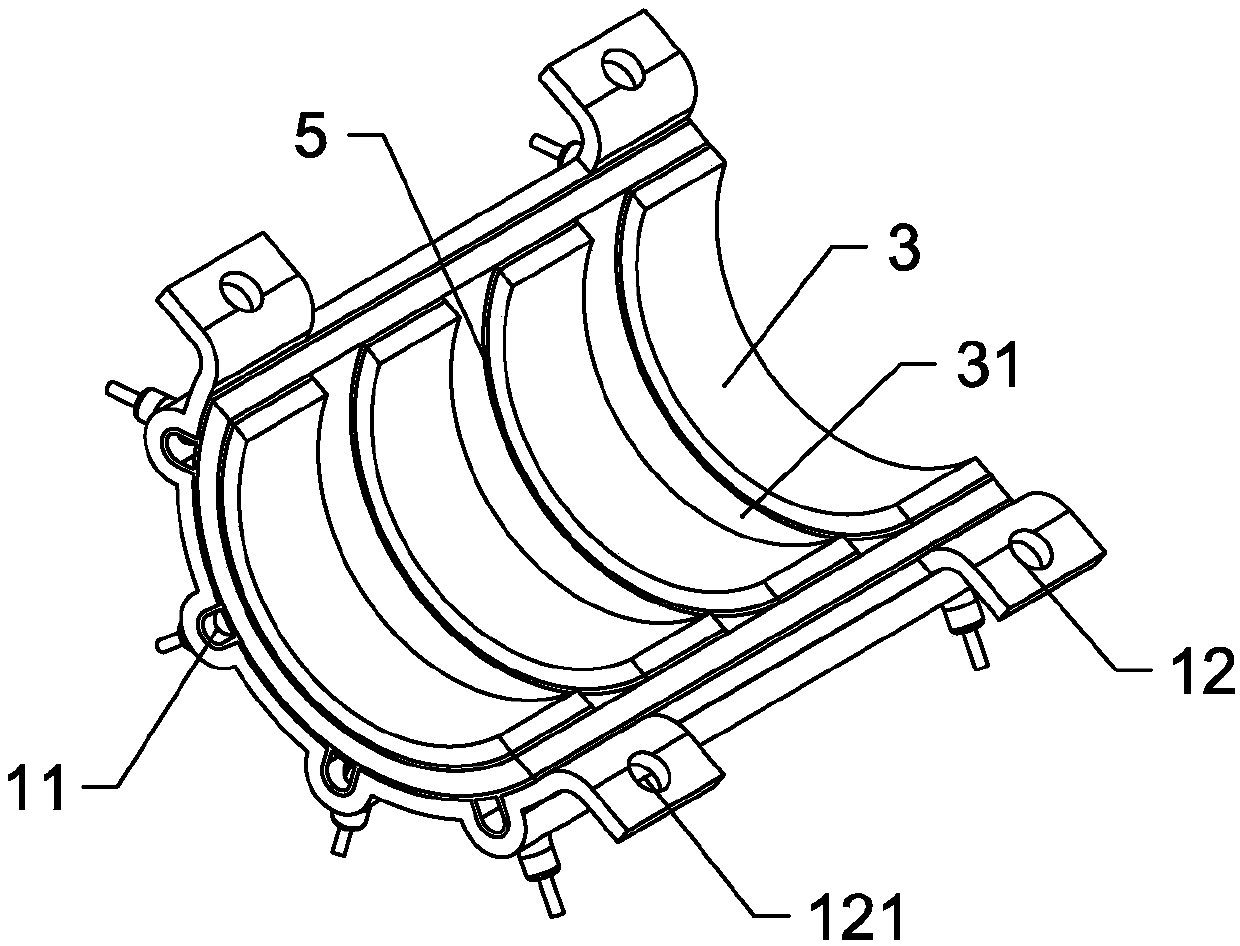

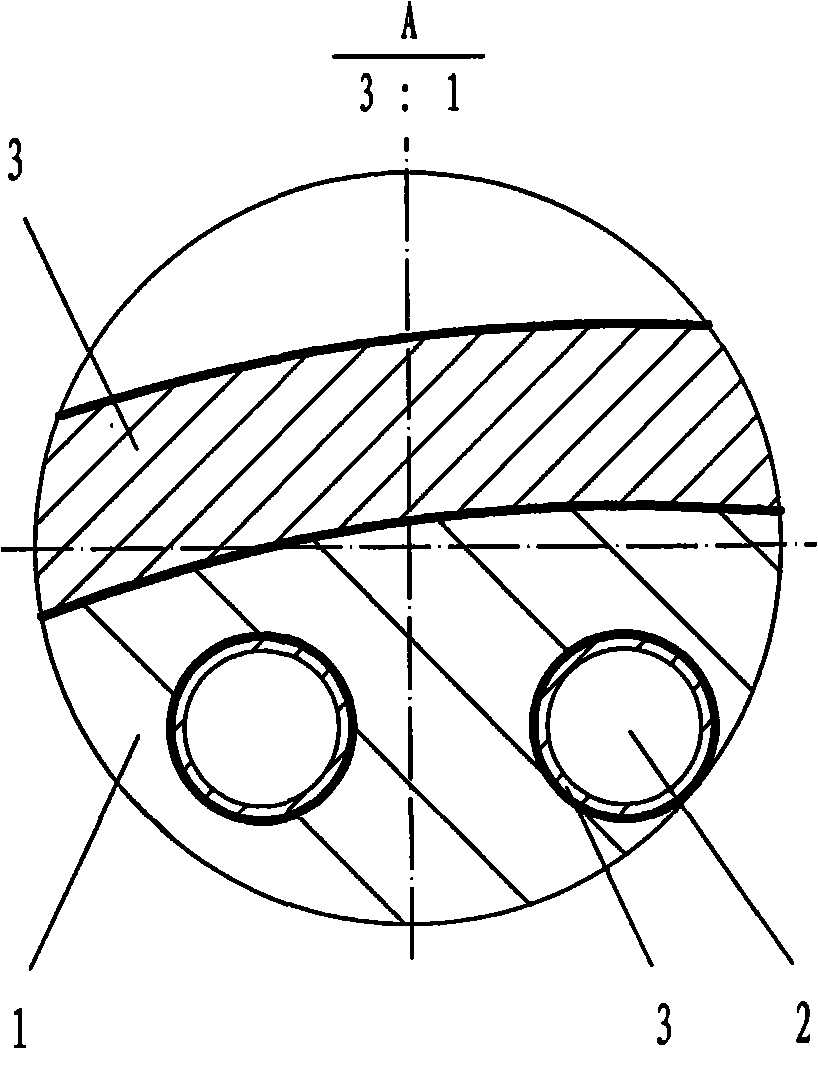

Novel aluminum heating ring and manufacturing method thereof

ActiveCN110072300AImprove heat transfer efficiencyImprove thermal utilizationOhmic-resistance heatingPollutionMaterials science

The invention provides a novel aluminum heating ring and a manufacturing method thereof. The novel aluminum heating ring comprises a heating tube and two semicircular annular heating rings, wherein each semicircular annular heating ring comprises an outer ring, an inner ring and a heat conduction ring; the outer ring, the inner ring and the heat conduction ring are all made of aluminum calenderedplates, and a groove is formed in the inner side surface of the outer ring; the heating tube is arranged in the groove; the heat conduction rings are distributed in a spaced mode along the circumferential direction of the inner ring; lugs are arranged on the circumferential end face of the outer ring; fastening holes are formed in the lugs; and an aluminum brazing layer is arranged between the outer side of the heat conduction ring and the inner side of the inner ring, between the outer side of the inner ring and the inner side of the outer ring, and between the heating tube and the groove. The manufacturing method comprises the following steps of manufacturing the outer rings, the inner rings and the heat conduction rings, preparing a brazing flux solution and a brazing flux material mixture, coating the brazing flux material, and carrying out assembling, brazing, appearance processing, and wiring end assembling or welding. The invention aims to provide the novel aluminum heating ringwith high heat conduction efficiency, no pollution in the manufacturing process, simplicity in manufacturing and low cost, and the manufacturing method of the novel aluminum heating ring.

Owner:青岛中邦凌电器有限公司

Protective coating material for boiler pipeline

The invention discloses a protective coating material for a boiler pipeline. The protective coating material comprises the following components by weight percent: 12%-14% of Cr, 0.4%-0.6% of Mn, 2%-3% of Ti, 3%-5% of Al, 2%-4% of Si, 1%-2% of Nb, 8%-12% of Fe, 1%-3% of Co, 3%-5% of Mo, less than or equal to 0.025% of S, less than or equal to 0.035% of P and the balance of Ni.

Owner:NINGBO SUNLIGHT MOTOR PARTS

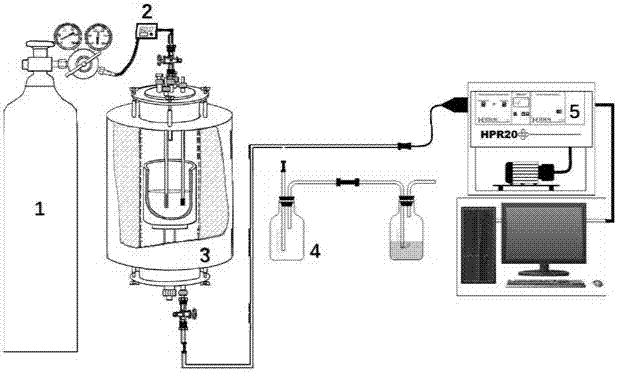

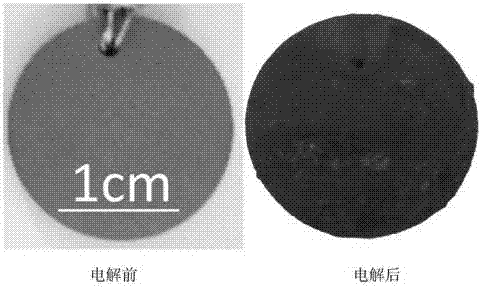

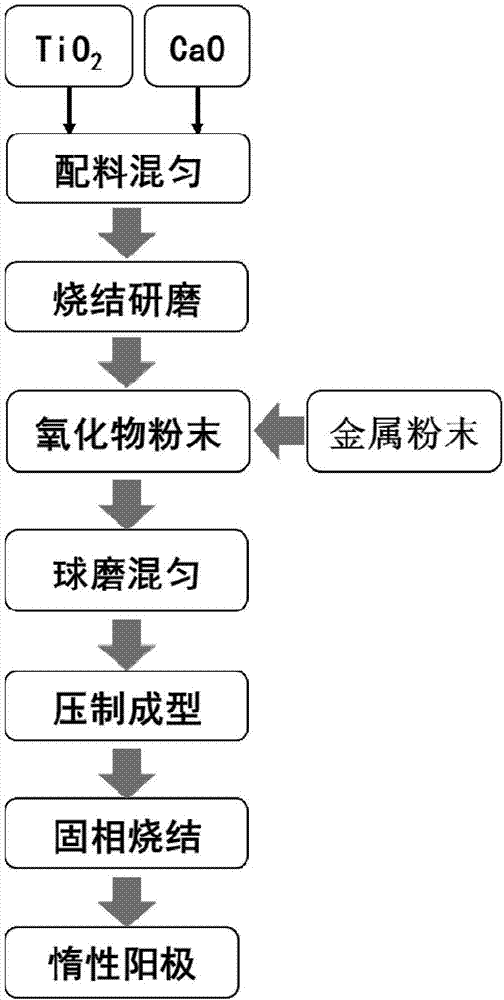

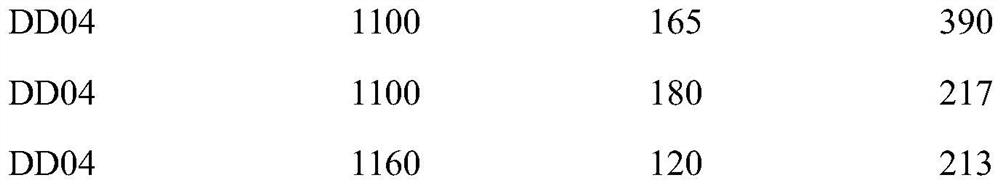

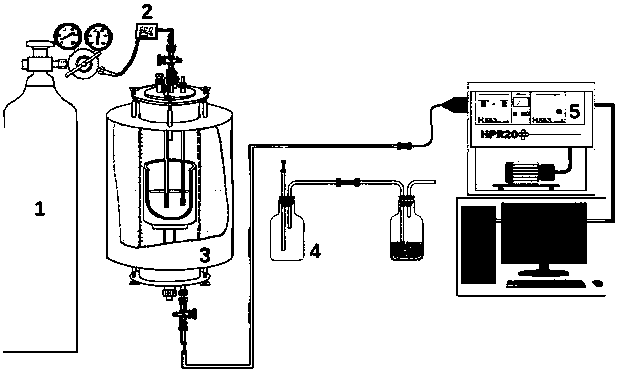

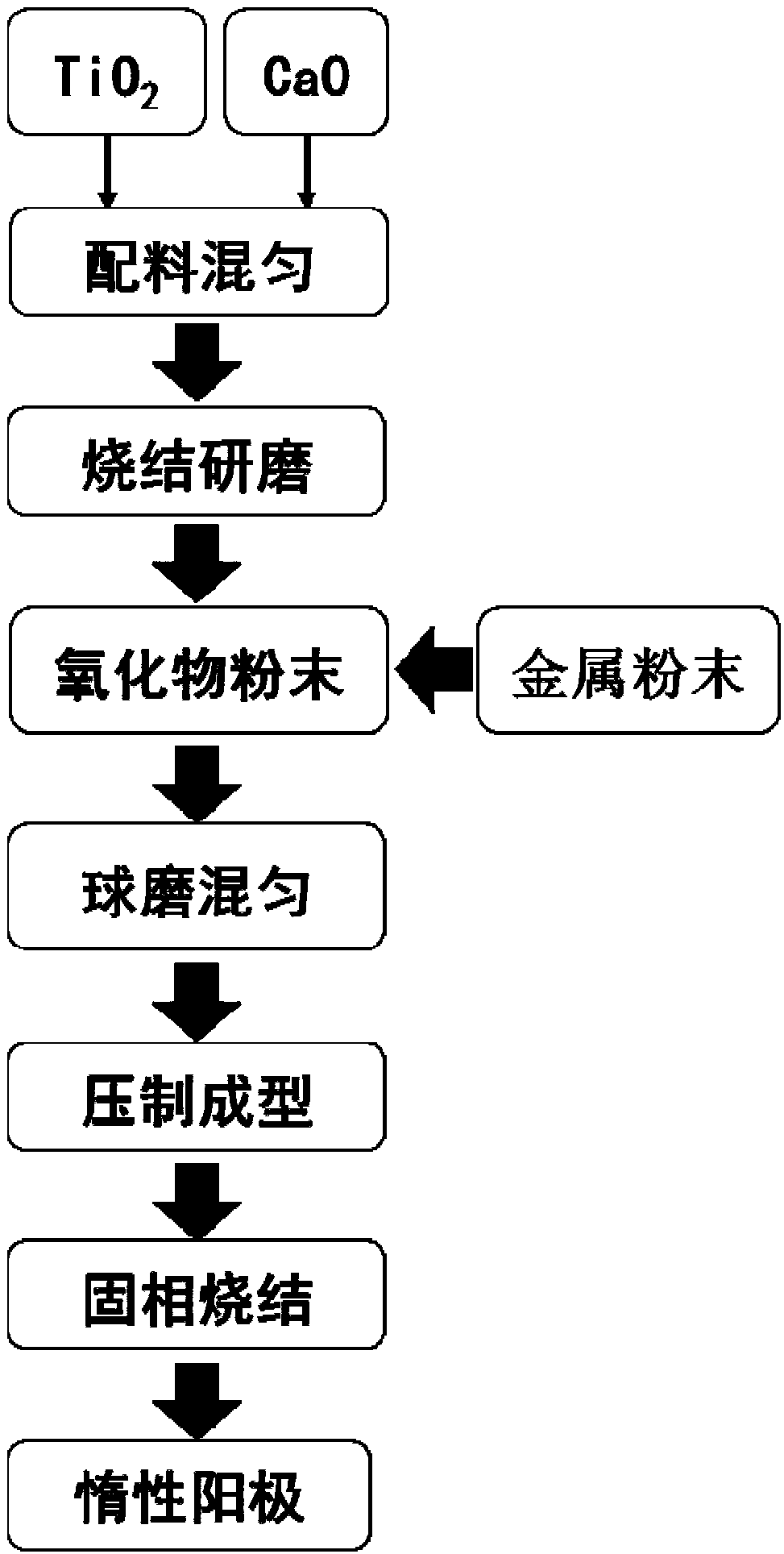

Nickel-based metal oxide ceramic inertia anode, preparing method and application

The invention relates to the technical field of ceramic-metal composite materials, and provides a nickel-based metal oxide ceramic material inertia anode. The nickel-based metal oxide ceramic material inertia anode has a metal phase and a ceramic phase, the metal phase is composed of the principal component Ni and one to two elements of Cu, Co, Zn, Cr, Ag, Fe, Al, V and the like, and an oxide phase is composed of CaO and TiO2; and the inertia anode is prepared through the steps that oxide and metal powder are subject to common ball milling, press molding is carried out, protective atmosphere sintering is carried out, and machining is carried out. The nickel-based metal oxide ceramic material inertia anode has the beneficial effects that electrical conductivity is good, high-temperature oxidation resistance is high, fused salt chemistry corrosion resistance and electrochemistry corrosion resistance are high, the thermal shock resistance is good, and the price is relatively low. The inertia anode is used for an electrolysis process in a chloride fused salt system, can serve as a substitution of a carbon anode, and solves the problems of high consumption and high CO2 emission.

Owner:UNIV OF SCI & TECH BEIJING

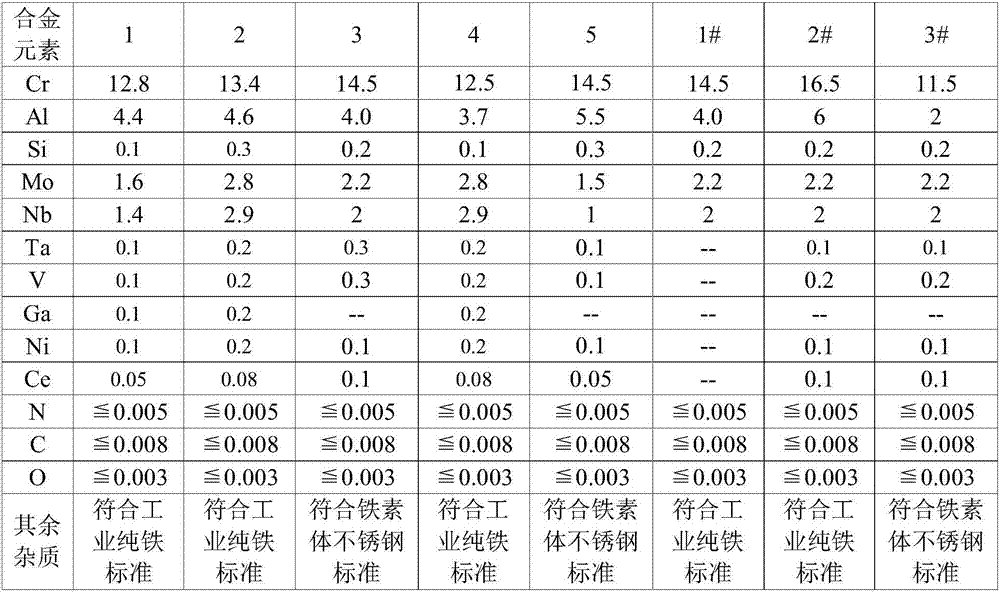

FeCrAl-based alloy for accident-resistant nuclear fuel element and preparation method thereof

The invention discloses a FeCrAl-based alloy for accident-resistant nuclear fuel element and a preparation method thereof. The problems that a FeCrAl-based alloy material cannot meet the requirement on using of reactor core structural bodies suitable for cladding shells, grillages and the like of fuel elements are solved. The alloy comprises the raw materials in percentage by weight: 12.5 to 14.5 percent of Cr, 3.5 to 5.5 percent of Al, 1.5 to 3 percent of Mo, 1 to 3 percent of Nb, 0.1 to 0.3 percent of Si, 0.1 to 0.3 percent of Ta, 0.1 to 0.3 percent of V, 0 to 0.2 percent of Ga, 0.1 to 0.2 percent of Ni, 0.05 to 0.1 percent of Ce, less than or equal to 0.008 percent of C, less than or equal to 0.005 percent of N, less than or equal to 0.003 percent of O, and the balance of Fe and inevitable impurities. The FeCrAl-based alloy has excellent high-tempreature resistant oxidization performance, heat stability, mechanical performance and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

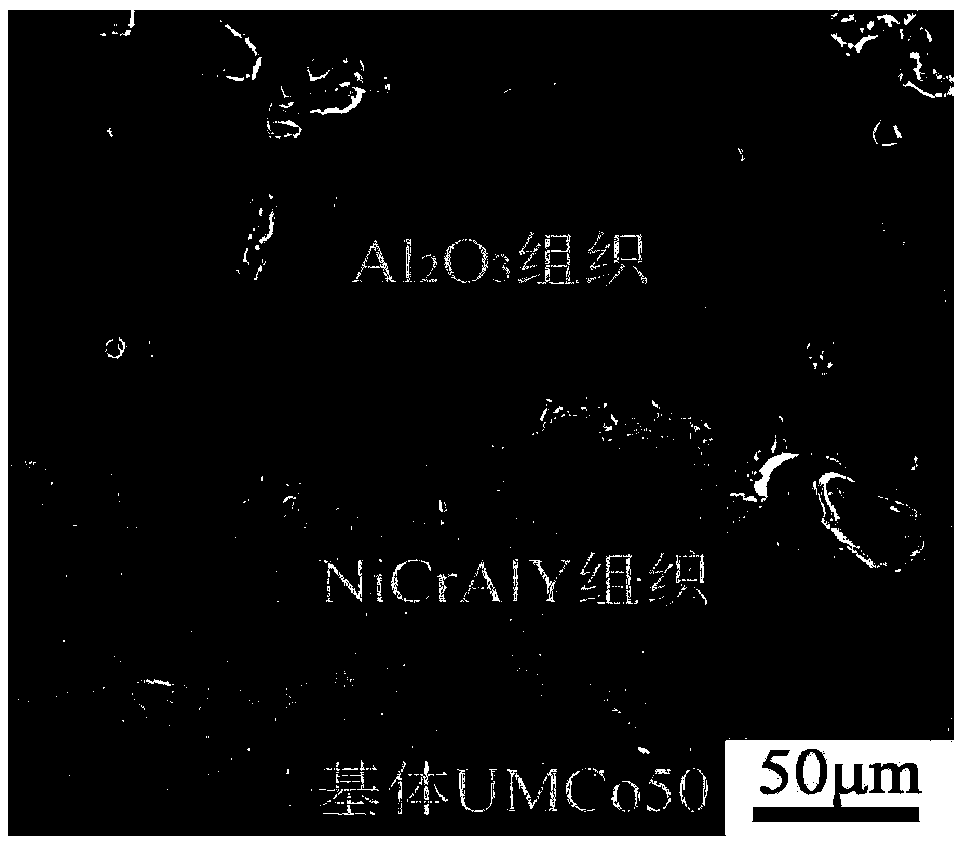

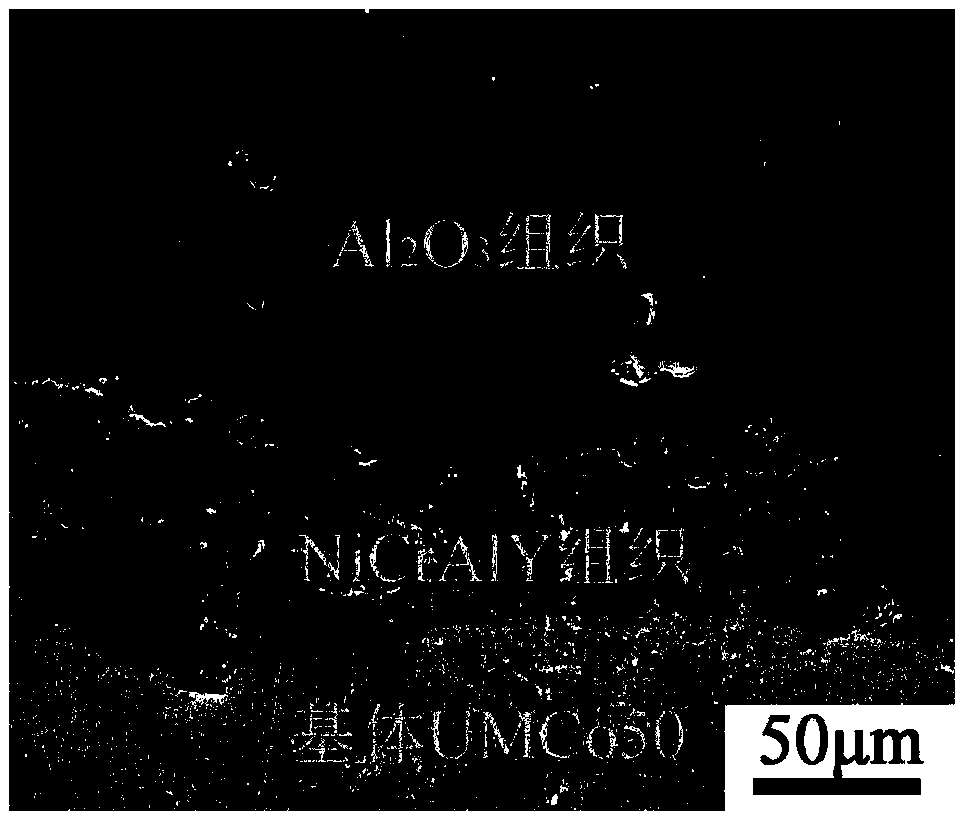

Thermal spraying high temperature resistant oxidation coating for gasifier burner and preparation method of thermal spraying high temperature resistant oxidation coating

InactiveCN110835719AImprove high temperature oxidation resistanceExpand the scope of servicesMolten spray coatingCombustorBond coat

The invention discloses a thermal spraying high temperature resistant oxidation coating for a gasifier burner. The thermal spraying high temperature resistant oxidation coating structurally includes abonding layer and a working layer, the bonding layer is placed at the bottom end of the working layer, the bonding layer is a NiCrAlY bonding layer, the working layer is an Al2O3 working layer, the coating thickness of the bonding layer is 50 [mu]m to 150 [mu]m , and the coating thickness of the working layer is 200 [mu]m to 400 [mu]m . The high temperature resistant oxidation performance of thecoating can be significantly improved, and the service range of the coating is expanded.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Rare earth heavy oil vanadium inhibitor

InactiveCN101054539AInhibit corrosionStrong resistance to high temperature oxidationLiquid carbonaceous fuelsFuel additivesMaleic anhydrideCorrosion

The invention discloses a rare-earth heavy oil vanadium inhibitor, which is produced by following materials by weight: 60-100 shares of mixing rare-earth, 100-250 shares of magnesia, 60-120 shares of sodium dodecyl sulfate, 10-20 shares of maleic anhydride and 800-1000 shares of 2-ethylhexyl hydrogen 2-ethylhexylphosphate. The inventive rare-earth heavy oil vanadium inhibitor can inhibit the vanadium corrosion at 1800 DEG C, resists to the high temperature oxidation capacity; has an ultra high alkali value, a strong neutralization and sulfur-fixing ability, can effectively reduce the discharge of the acidic gas such as sulfur dioxide, nitrogen oxide and etc and is beneficial to the environment protection; has powerful cleaning and dispersing functions; has a good oil-dissolving property and can be completely mixed with heavy oil, crude oil, and resid, widely used for gas turbine vanadium inhibitor which has the heavy oil as fuel. The dregs obtained after heavy oil burning becomes loose and easily for washing so as to obviously improve the gas turbine power and efficiency.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI

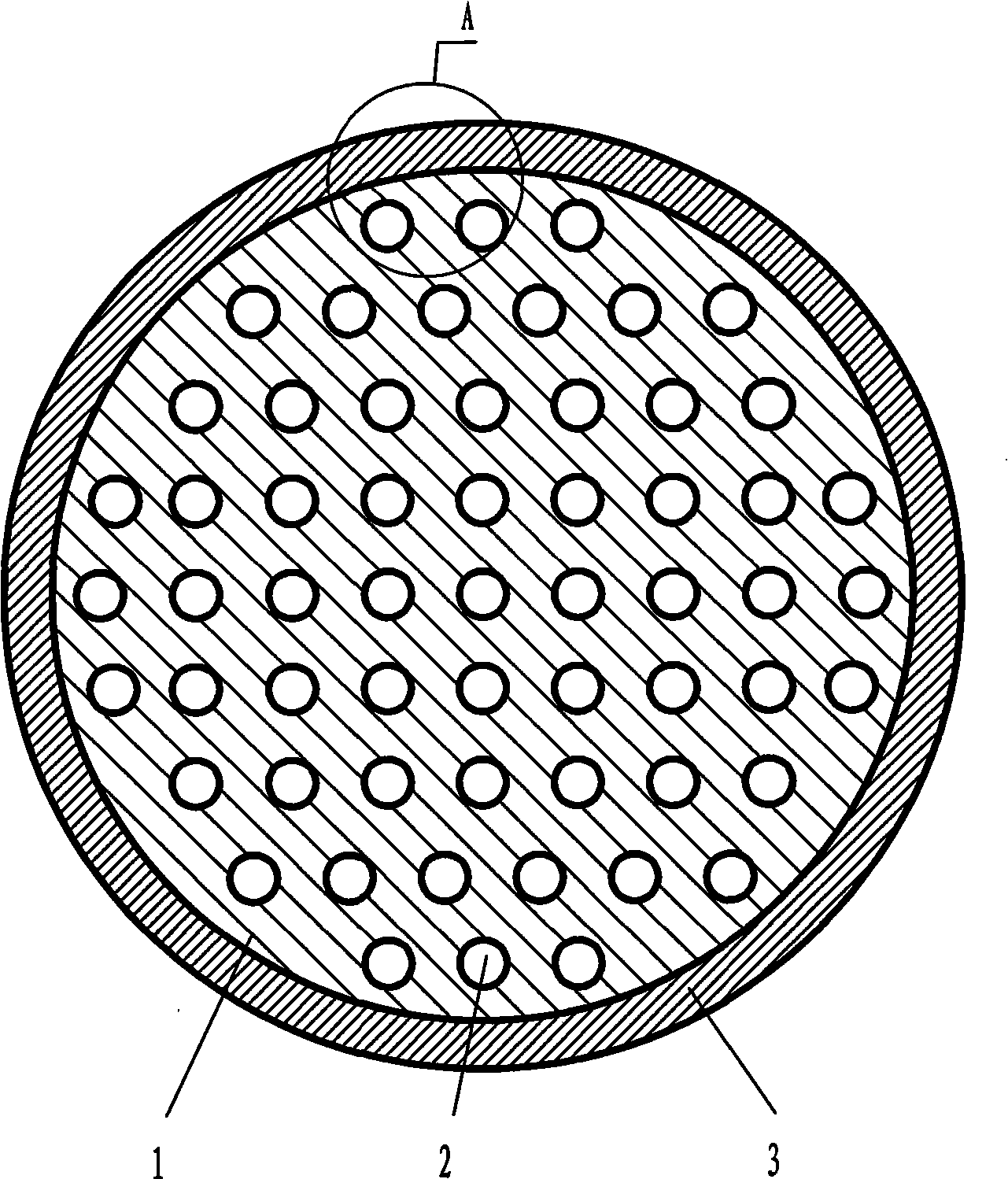

Honeycomb heat accumulator for shock resistance and high temperature oxidation resistance

InactiveCN101308000AImprove impact resistance, rapid cooling and rapid heat resistanceWith comprehensive performanceHeat storage plantsHeat transfer modificationShock resistanceSoot

The invention belongs to the industrial furnace air / fuel gas preheating technique field, in particular to a honeycomb regenerative body with impact and high temperature oxidation resistance mainly comprising a refractory material honeycomb regenerative body on which a plurality of parallel honeycomb through holes are arranged, the external surface of the refractory material honeycomb regenerative body is wrapped with a metallic layer with the average thickness larger than or equal to 0.1mm, and the external surface of the metallic layer is provided with a molybdenum disilicide high temperature infiltration layer. The honeycomb regenerative body has the advantages that: the honeycomb regenerative body with low cost of manufacture and resistance to impact, thermal shock and high temperature oxidation is provided, and a most important foundation is laid for adopting the thermal explosion pulse soot-blowing technique by the honeycomb regenerative body.

Owner:BEIJING GAOZHAN SCI & TECH

A kind of alticrn/yn nanometer multi-layer hard coating and preparation method thereof

InactiveCN103789724BDense tissueFine grainVacuum evaporation coatingSputtering coatingSputteringEtching

Owner:SICHUAN UNIV

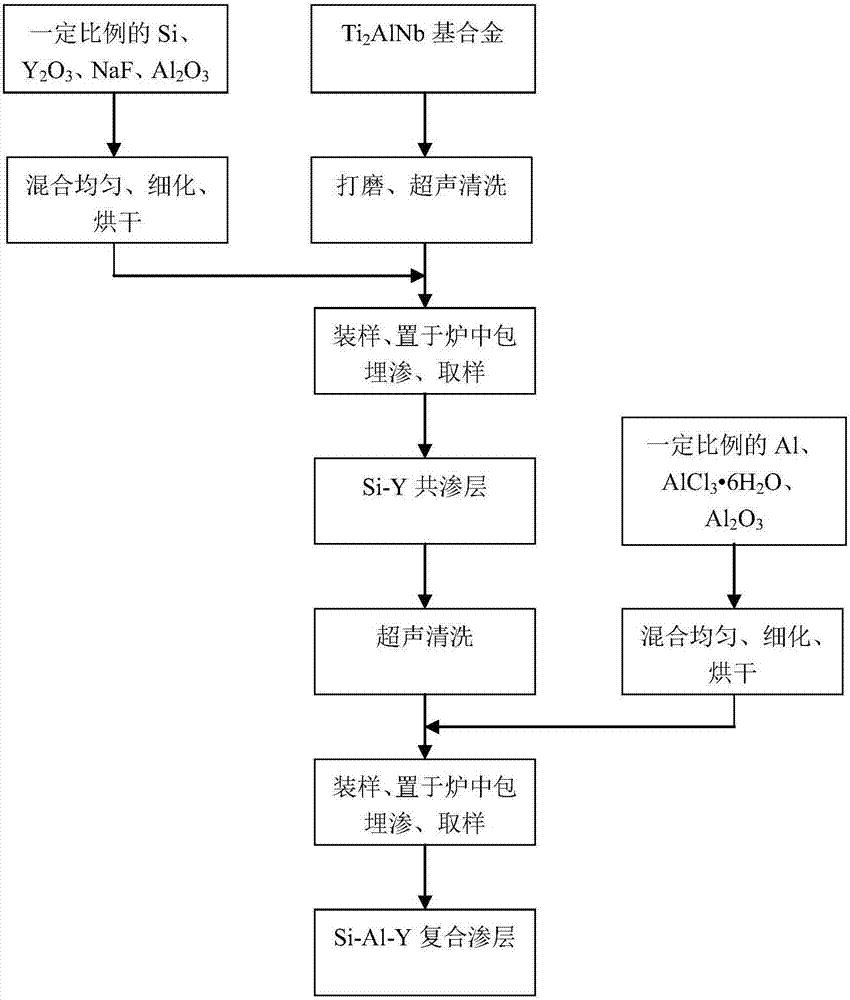

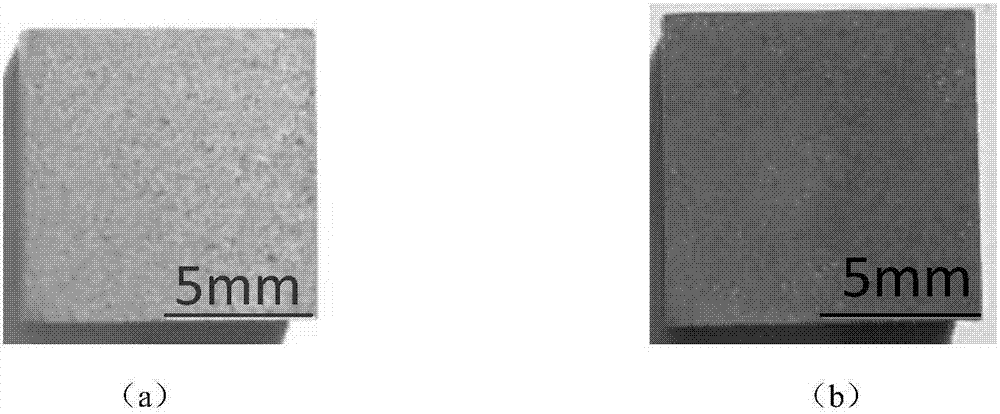

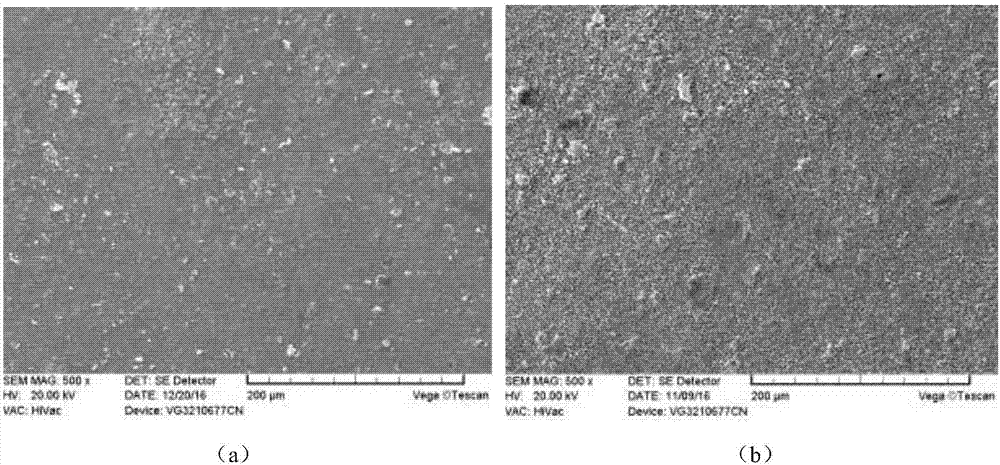

Method for preparing Si-Al-Y composite infiltrated layer on surface of Ti2AlNb alloy by two-step method

The invention relates to a method for preparing a Si-Al-Y composite infiltrated layer on the surface of Ti2AlNb alloy by a two-step method. The method comprises the following steps: arranging Si-Y2O3 on the surface of Ti2AlNb-based alloy in a pack infiltration manner; and then carrying out Al pack cementation to prepare a high-temperature-resistant oxidized infiltrated layer with certain Si, Al and Y contents on the surface. A one-step Si-Al-Y infiltration process is divided into two steps or multiple steps, and although a preparation process of the infiltrated layer is slightly complicated, element infiltration procedures can be adjusted flexibly according to characteristics of various elements about to be infiltrated. In every procedure, process parameters such as the type, the temperature and the time of a catalyst can be selected in a targeted manner according to physical and chemical properties of the infiltrated elements, and therefore, the infiltrated layer with a designed structure can be easily obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

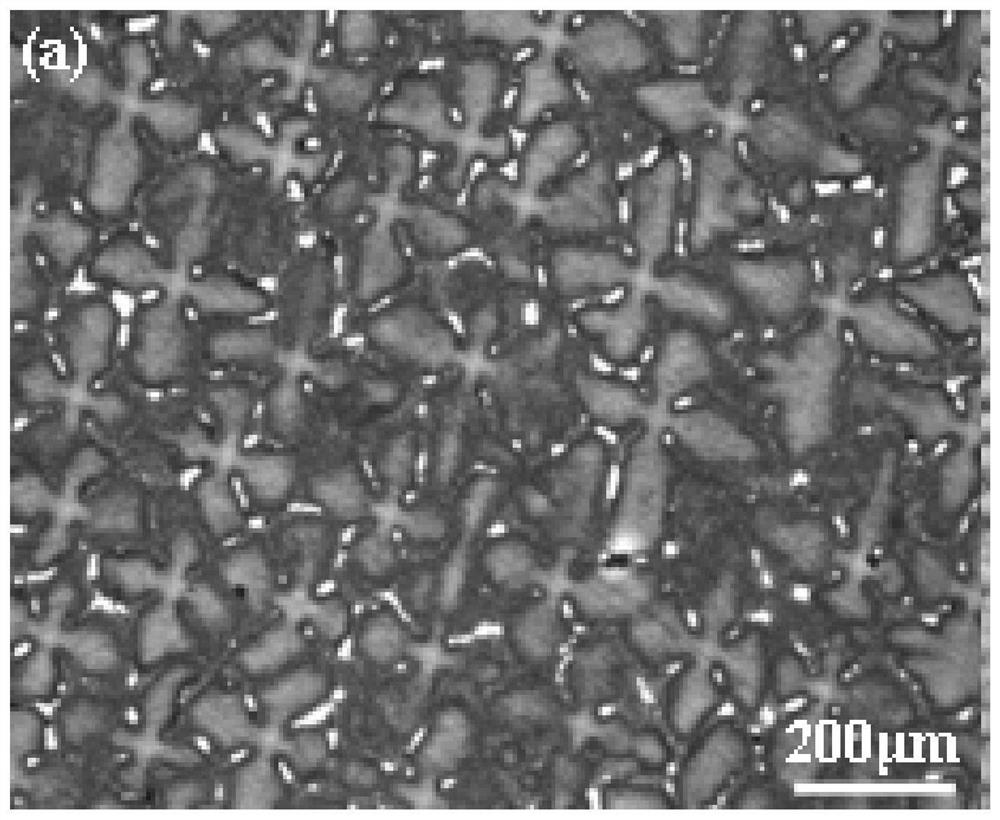

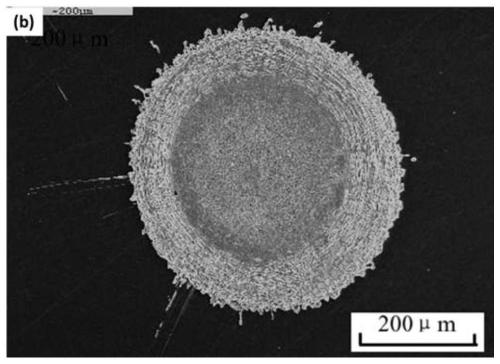

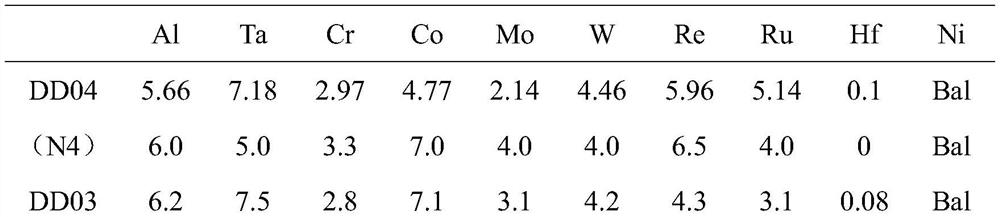

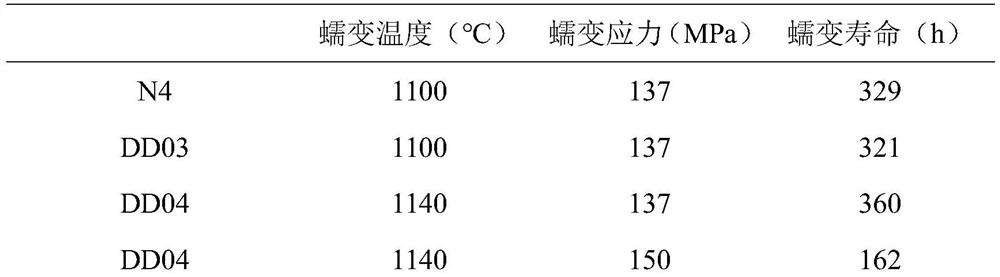

High-concentration Re/Ru nickel-based single crystal superalloy with high temperature bearing capacity and high creep resistance

InactiveCN112522543ADistribution ratio is goodImprove thermal stabilityPolycrystalline material growthAfter-treatment detailsRheniumHigh concentration

The invention relates to a high-concentration Re / Ru nickel-based single crystal superalloy with high temperature bearing capacity and high creep resistance, and belongs to a new material for special purposes. The nickel-based superalloy comprises the following components of, in percentage by mass, 5.4-6.2% of aluminum, 7.2-7.8% of tantalum, 2.6-3.5% of chromium, 1.7-2.5% of molybdenum, 4.2-4.8% ofcobalt, 4.2-5.0% of tungsten, 5.8-6.4% of rhenium, 4.7-5.4% ruthenium, 0.07-0.12% of hafnium and the balance nickel. The preparation method of the nickel-based superalloy comprises a heat treatment process. The single-crystal nickel-based alloy has high temperature bearing capacity, good high-temperature mechanical property and creep property, good creep strength and long service life under the ultrahigh-temperature condition, and is a nickel-based single-crystal superalloy suitable for producing blades of hot end parts of high-thrust-ratio aero-engines and gas turbines.

Owner:GUIZHOU UNIV OF ENG SCI

A kind of nickel-based metal oxide ceramic inert anode, preparation method and application

The invention relates to the technical field of ceramic-metal composite materials, and provides a nickel-based metal oxide ceramic material inertia anode. The nickel-based metal oxide ceramic material inertia anode has a metal phase and a ceramic phase, the metal phase is composed of the principal component Ni and one to two elements of Cu, Co, Zn, Cr, Ag, Fe, Al, V and the like, and an oxide phase is composed of CaO and TiO2; and the inertia anode is prepared through the steps that oxide and metal powder are subject to common ball milling, press molding is carried out, protective atmosphere sintering is carried out, and machining is carried out. The nickel-based metal oxide ceramic material inertia anode has the beneficial effects that electrical conductivity is good, high-temperature oxidation resistance is high, fused salt chemistry corrosion resistance and electrochemistry corrosion resistance are high, the thermal shock resistance is good, and the price is relatively low. The inertia anode is used for an electrolysis process in a chloride fused salt system, can serve as a substitution of a carbon anode, and solves the problems of high consumption and high CO2 emission.

Owner:UNIV OF SCI & TECH BEIJING

A hot rolling preparation method of 1700mpa grade high cr-si thin gauge hot forming steel

The invention belongs to the technical field of metal processing, and in particular relates to a hot-rolling preparation method of 1700MPa high-Cr-Si thin-gauge hot-formed steel. Aiming at the problems in the prior art that steel sheets for hot forming need to be added with cold rolling to be prepared, and coatings are required for hot forming, the present invention provides a low-cost 1700MPa high-Cr-Si alloyed coating-free hot-forming steel, and A hot-rolling preparation method for thin-gauge coating-free hot-formed steel with this composition is proposed. The hot forming steel of the invention has simple preparation process and low cost, and the produced hot forming steel has uniform microstructure, excellent mechanical properties and high temperature oxidation resistance.

Owner:NORTHEASTERN UNIV LIAONING +1

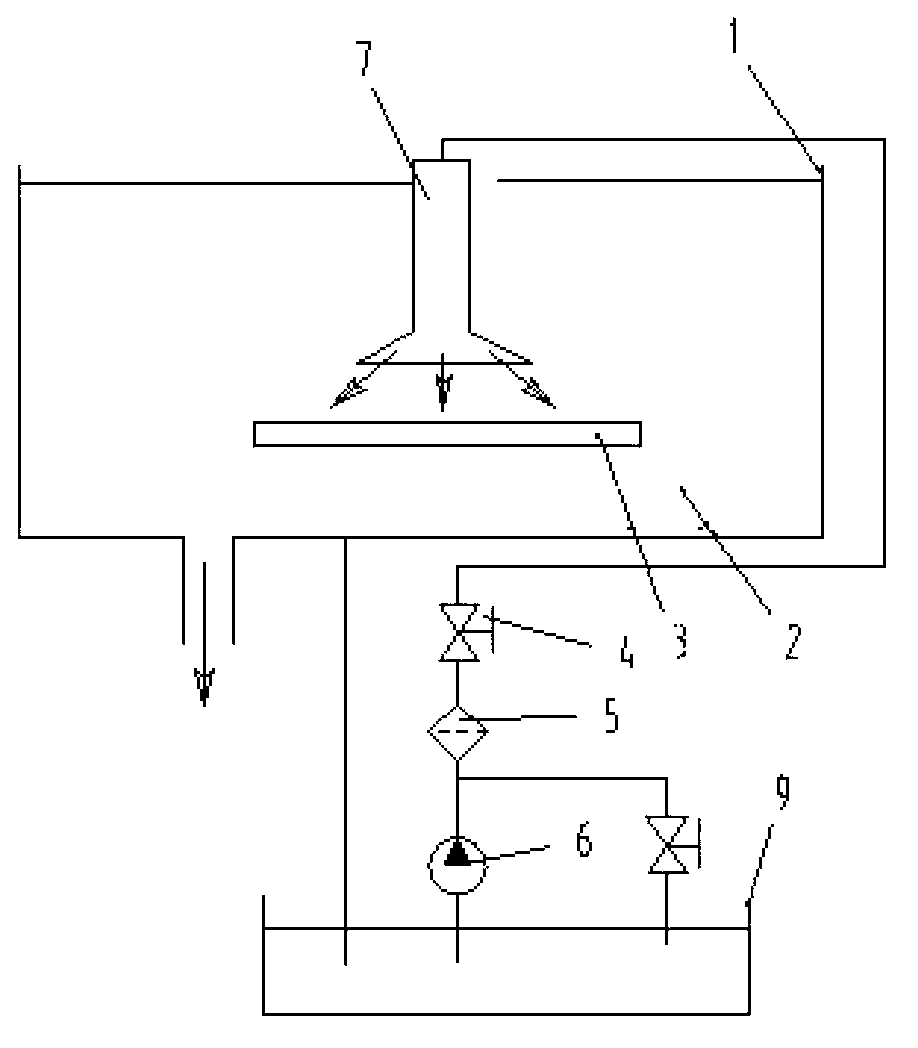

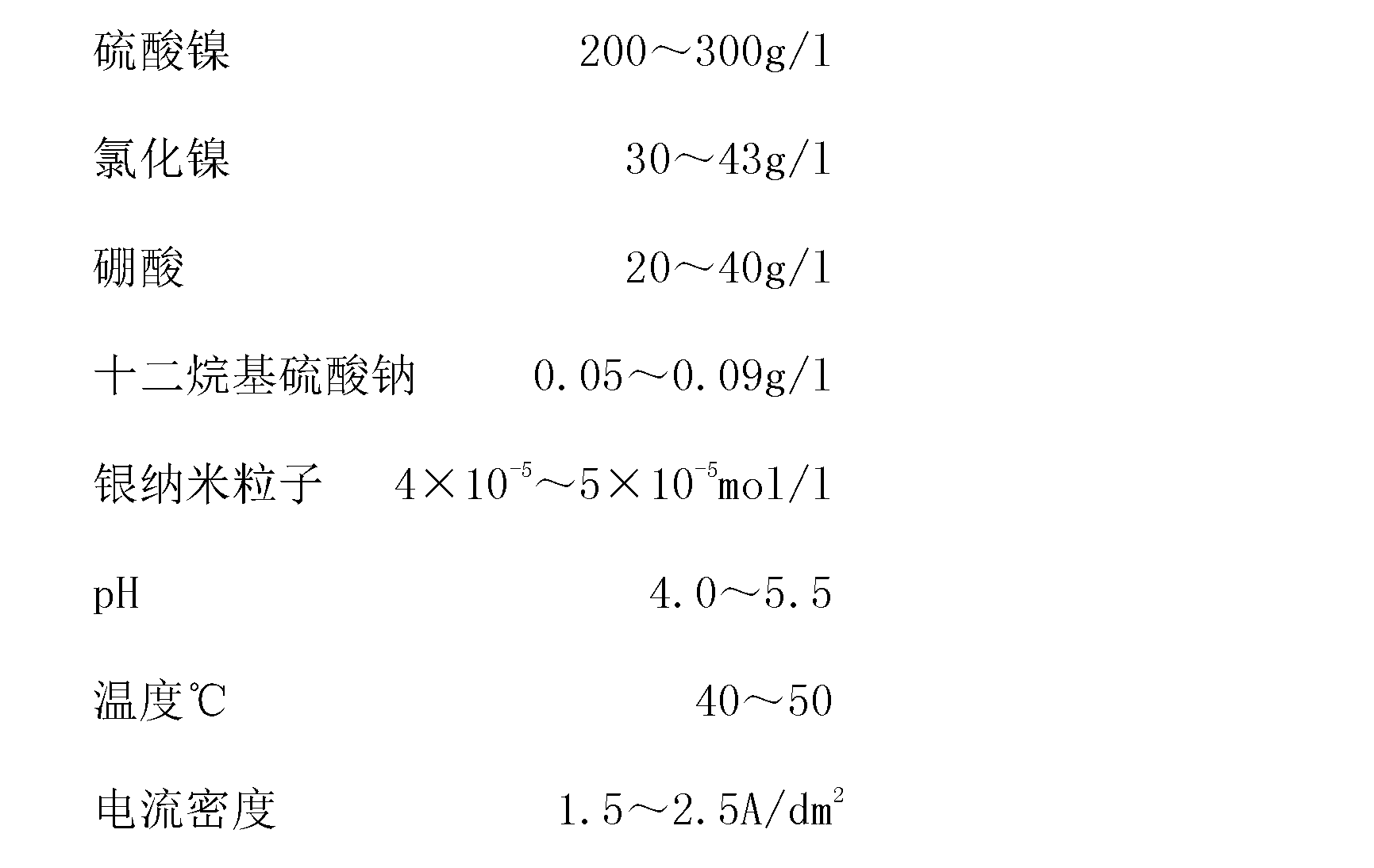

Metal nano electroplating technology

InactiveCN103074664AImprove dispersionEvenly distributedElectrolytic coatingsSulfateLiquid storage tank

The invention relates to a surface treatment technology, in particular to a metal nano composite electroplating technology. The invention discloses a metal nano electroplating technology, comprising an electroplating device and an electroplating formula; the electroplating device comprises hard particles, an electroplating bath, a liquid storage tank, a pump, a spray head and a core model, wherein the core model is arranged inside the electroplating bath, the upper part of the core model is provided with the spray head, an opening is formed at the lower part of the electroplating bath, electroplating liquid and the hard particles are sucked out from the liquid storage tank and conveyed to the spray head by the pump, and the electroplating liquid and the hard particles are rushed downwards from the upper part of the core model; and the formula of the electroplating liquid is as follows: 200-300 g / l of nickel sulfate, 30-43 g / l of nickel chloride, 20-40 g / l of boric acid, 0.05-0.09 g / l of lauryl sodium sulfate, and 4 * 10<-5> to 5 * 10<-5> mol / l of silver nanoparticles. Through the utilization of the metal nano composite electroplating technology disclosed by the invention, excellent electroplated layer can be prepared in an efficient and energy-saving manner. Through the motion of the hard particles, the dispersed state of the nanoparticles in the electroplating liquid is further improved, so that the nanoparticles are distributed in the electroplating liquid more uniformly.

Owner:余胜东

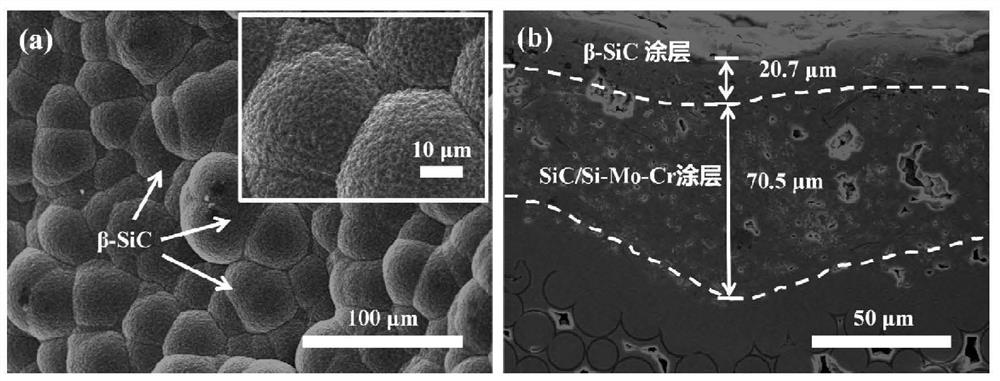

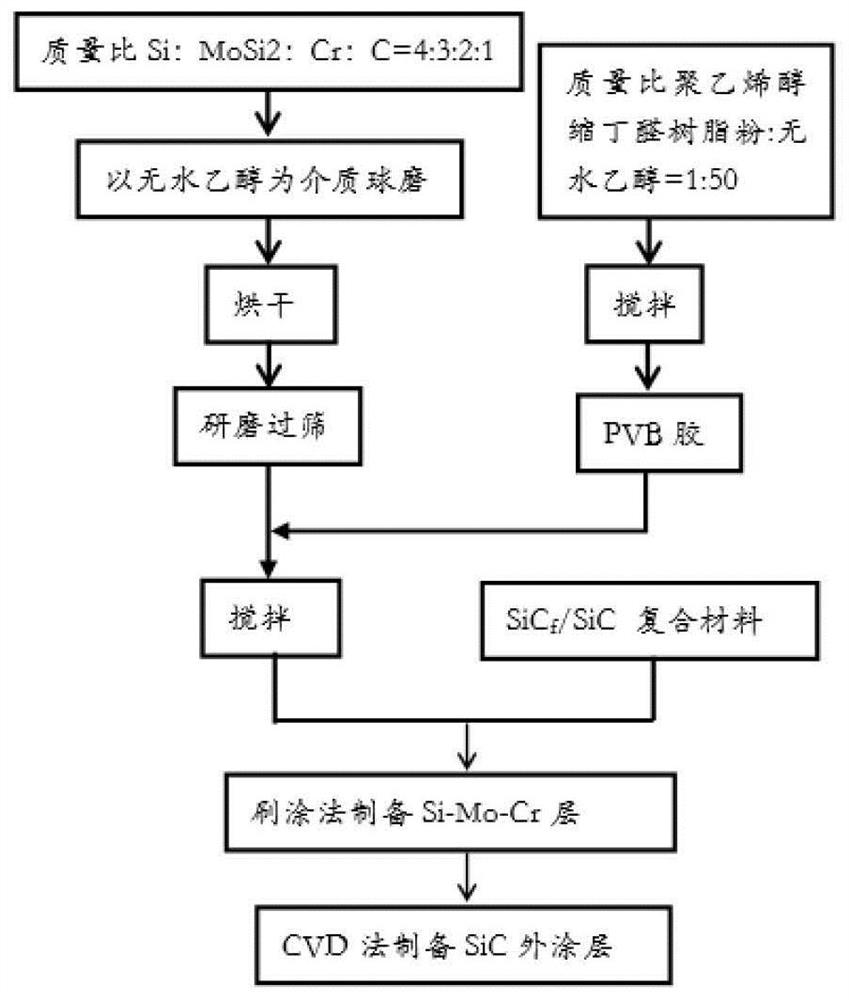

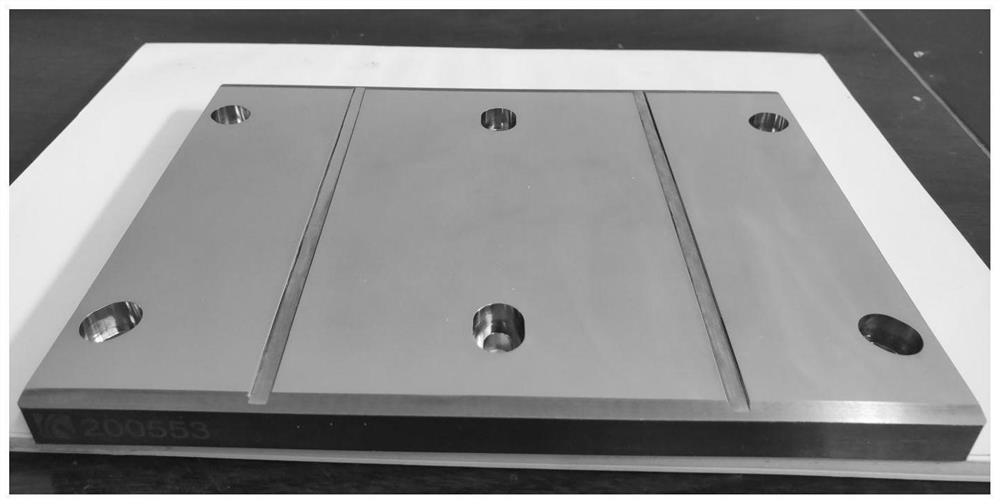

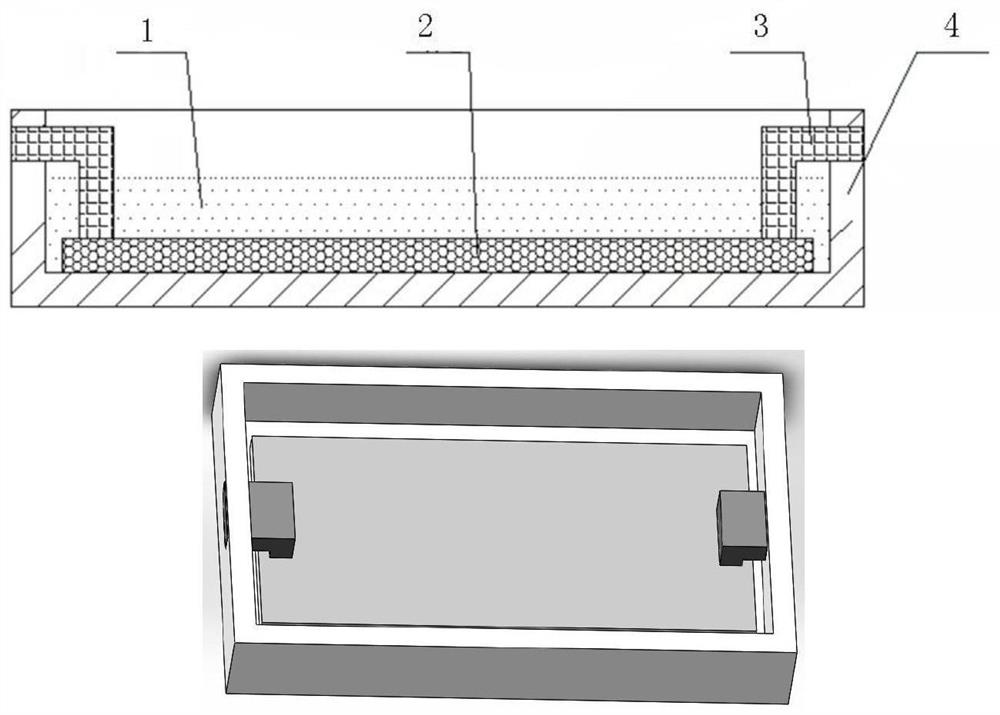

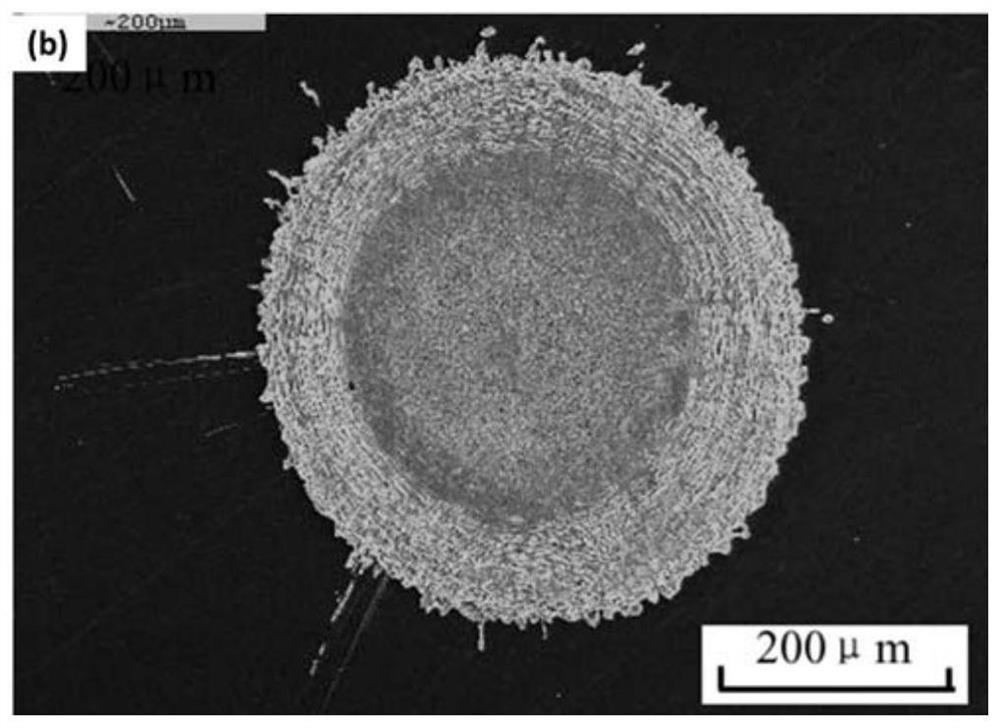

a kind of sic f /sic composite material surface anti-radiation anti-air oxidation composite coating and preparation method thereof

ActiveCN113024283BStrong resistance to high temperature oxidationImprove radiation resistanceOxidation resistantUltimate tensile strength

The invention discloses a SiC f / SiC composite material surface anti-radiation anti-air oxidation composite coating and preparation method thereof, the composite coating comprises successively coating SiC f The inner coating and the outer coating formed on the surface of the SiC composite material, the main component of the inner coating is MoSi 2 , Si and Cr and contains C elements, and the outer coating is high-purity β-SiC. Made by brush coating + one CVD process. Composite coating provided by the present invention: on the one hand, the outer coating fully infiltrates the inner coating, and the coating structure is uniform and compact, and SiC f / SiC composite materials are well combined; on the other hand, the composite coating has excellent oxidation resistance, thermal shock resistance and radiation resistance, and the resulting SiC composite coating contains f / SiC composite material, the strength retention rate after oxidation at 1400 ° C for 10 h is greater than 92.20%, and the strength after 30 thermal cycles from 1400 ° C to room temperature is the same as that of pristine SiC f / SiC composite material has increased by more than 12.23%, and the ion energy is 6MeV Si 2+ The strength retention rate after irradiation is over 84.15%.

Owner:CENT SOUTH UNIV

Formula of high-temperature-resistant vapor chamber for 3D glass hot bending machine and preparation processes thereof

InactiveCN112760544AStrong resistance to high temperature oxidationSmall thermal denaturationGlass reforming apparatusCompression moldingMachining

The invention discloses a formula of a high-temperature-resistant vapor chamber for a 3D glass hot bending machine, and belongs to the field of high-temperature vapor chambers and preparation processes. The high-temperature-resistant vapor chamber for the 3D glass hot bending machine comprises, by mass, 10%-40% of nickel, 30%-60% of spherical alumina powder and 20%-40% of tungsten carbide powder. The invention further discloses the two preparation processes of the formula of the high-temperature-resistant vapor chamber for the 3D glass hot bending machine. One method comprises eight steps of mixed ball milling, soaking, ball-free ball milling, compression molding, degreasing and hardening treatment, rough machining of a blank, sintering and machining, and the other method comprises seven steps of ball milling, drying and molding, degreasing, rough machining of the blank, preliminary sintering, sintering in nickel powder and machining. The vapor chamber prepared according to the formula is high in high-temperature oxidation resistance, small in thermal denaturation, low in production cost and long in service life, and the use requirements of the vapor chamber are met.

Owner:湖南天益高技术材料制造有限公司

Spray coating material prepared by titanium-containing high-chromium-nickel alloy, preparation method and use thereof

InactiveCN101260487BExtended service lifeImprove anti-sulfur performanceMetal-working apparatusRheniumVulcanization

The invention relates to a titanium contained high chromel alloy and application thereof in spraying materials. The components of the alloy are (by weight percentage) as follows: the content of chromium is more than or equal to 15 percent and less than or equal to 25 percent, the content of titanium is more than or equal to 1 percent and less than or equal to 6 percent, the content of silicon is more than or equal to 1 percent and less than or equal to 6 percent, the content of carbon is more than or equal to 0 percent and less than or equal to 0.02 percent, the content of nickel is more thanor equal to 20 percent and less than or equal to 55 percent, the content of rhenium is more than or equal to 0.5 percent and less than or equal to 6 percent, the content of aluminum is more than or equal to 0 percent and less than or equal to 6 percent, the content of sulfur is more than or equal to 0 percent and less than or equal to 0.035 percent, he content of phosphorus is more than or equal to 0 percent and less than or equal to 0.035 percent, the content of manganese is more than or equal to 0 percent and less than or equal to 0.2 percent, and the rest is iron. After the parts of workingequipment are sprayed at high temperature oxidation and high temperature corrosion environments by the spraying material produced by the alloy, since the coating has good high temperature oxidation and vulcanization resistance and hot corrosion resistance performances, the service life of the parts can be greatly improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

A New Preparation Technology of Thermal Barrier Coating

The invention relates to a novel thermal barrier coating preparation process, which comprises the following steps: forming a metal bonded underlayer on the surface of a substrate; forming an in-situ thermally grown oxide layer (TGO); and forming a ceramic heat-insulating surface layer. The TGO layer is pre-grown before the substrate is put into service. The composition of the TGO layer includes alpha-alumina. In the present invention, a layer of dense and continuous TGO layer mainly composed of α-alumina is preset through large-particle dry ice jet purification and roughening treatment and pre-vacuum argon oxidation treatment. The oxide film will have good resistance to high temperature oxidation, prevent rapid oxidation, reduce the growth rate of TGO layer thickness, and achieve the purpose of reducing the occurrence probability of thermal barrier coating peeling.

Owner:江苏源清动力技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com