High-temperature-oxidation-resisting alloy steel and preparation method thereof

A technology of high temperature oxidation resistance and alloy steel, which is applied in the field of alloy steel, can solve the problems of high addition of precious alloy elements, insufficient high temperature oxidation resistance of materials, and high material cost, and achieve good high temperature oxidation resistance, excellent high temperature mechanical properties, Effect of improving carburization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

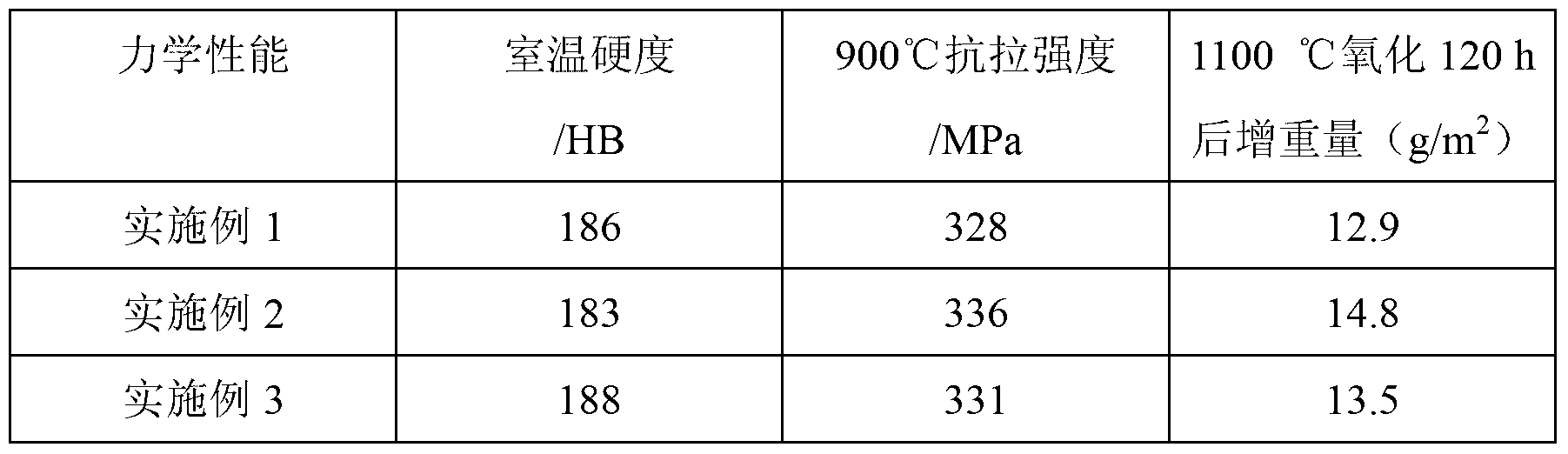

Examples

Embodiment 1

[0037] Adopt 1000 kilograms of electric induction furnaces to smelt the material of the present invention, concrete process step is:

[0038] (1) Q235 steel scrap with a mass fraction of 40.0% (mass percent: 0.14~0.22C, 0.30~0.65Mn, Si≤0.30, S≤0.050, P≤0.045, Fe balance), 26.5% stainless steel scrap (% is: ≤0.07C, ≤1.0Si, ≤2.0Mn, 17.0~19.0Cr, 8.0~11.0Ni, ≤0.035P, ≤0.03S, Fe balance), 15.0% nickel-based alloy waste (mass percentage % is: ≤0.10C, ≤0.50Mn, ≤0.50Si, ≤0.015P, ≤0.015S, 20.0~23.0Cr, 58.0~60.0Ni, 8.0~10.0Mo, ≤0.40Ti≤0.40Al, ≤5.0Fe, 3.15 ~4.15Nb), 8.3% high-carbon ferrochrome (mass percent: 62.0~68.0Cr, 7.0~8.5C, 2.0~3.5Si, the balance is Fe) and 1.1% tungsten iron (mass percent: 75.0~85.0W, ≤0.4C, ≤0.05P, ≤0.07S, the balance Fe) mixed and heated to melt, the molten steel is melted and then the temperature is measured. When the molten steel temperature reaches 1562°C, add 1.1% ferrosilicon (mass The percentage % is: 74.0-80.0Si, ≤0.5Al, ≤1.0Ca, ≤0.035P, ≤0.02S, ≤0.1C...

Embodiment 2

[0042] Adopt 1000 kilograms of electric induction furnaces to smelt the material of the present invention, concrete process step is:

[0043] (1) Q235 steel scrap with a mass fraction of 40.5% (mass percent: 0.14~0.22C, 0.30~0.65Mn, Si≤0.30, S≤0.050, P≤0.045, Fe balance), 25.0% stainless steel scrap (% is: ≤0.07C, ≤1.0Si, ≤2.0Mn, 17.0~19.0Cr, 8.0~11.0Ni, ≤0.035P, ≤0.03S, Fe balance), 16.0% nickel-based alloy waste (mass percentage % is: ≤0.10C, ≤0.50Mn, ≤0.50Si, ≤0.015P, ≤0.015S, 20.0~23.0Cr, 58.0~60.0Ni, 8.0~10.0Mo, ≤0.40Ti≤0.40Al, ≤5.0Fe, 3.15 ~4.15Nb), 8.0% high-carbon ferrochrome (mass percent: 62.0~68.0Cr, 7.0~8.5C, 2.0~3.5Si, the balance is Fe) and 1.2% tungsten iron (mass percent: 75.0~85.0W, ≤0.4C, ≤0.05P, ≤0.07S, balance Fe) are mixed and heated to melt, and the temperature is measured after the molten steel is melted. The percentage % is: 74.0-80.0Si, ≤0.5Al, ≤1.0Ca, ≤0.035P, ≤0.02S, ≤0.1C, the balance Fe) and the mass fraction of 2.2% ferromanganese (mass percenta...

Embodiment 3

[0047] Adopt 1000 kilograms of electric induction furnaces to smelt the material of the present invention, concrete process step is:

[0048](1) Q235 steel scrap with a mass fraction of 39.55% (mass percent: 0.14~0.22C, 0.30~0.65Mn, Si≤0.30, S≤0.050, P≤0.045, Fe balance), 28.0% stainless steel scrap (% is: ≤0.07C, ≤1.0Si, ≤2.0Mn, 17.0~19.0Cr, 8.0~11.0Ni, ≤0.035P, ≤0.03S, Fe balance), 14.0% nickel-based alloy waste (mass percentage % is: ≤0.10C, ≤0.50Mn, ≤0.50Si, ≤0.015P, ≤0.015S, 20.0~23.0Cr, 58.0~60.0Ni, 8.0~10.0Mo, ≤0.40Ti≤0.40Al, ≤5.0Fe, 3.15 ~4.15Nb), 8.5% high-carbon ferrochrome (mass percent: 62.0~68.0Cr, 7.0~8.5C, 2.0~3.5Si, the balance is Fe) and 1.0% tungsten iron (mass percent: 75.0~85.0W, ≤0.4C, ≤0.05P, ≤0.07S, balance Fe) mixed and heated to melt, the molten steel is melted and the temperature is measured, when the temperature of the molten steel reaches 1569°C, add 1.2% ferrosilicon (mass The percentage % is: 74.0-80.0Si, ≤0.5Al, ≤1.0Ca, ≤0.035P, ≤0.02S, ≤0.1C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com