Formula of high-temperature-resistant vapor chamber for 3D glass hot bending machine and preparation processes thereof

A preparation process and hot bending machine technology, which is applied in glass manufacturing equipment, manufacturing tools, glass forming, etc., can solve the problems of difficult densification, loss of bonding ability of alumina particles, separation from the matrix, etc., and achieve high temperature oxidation resistance Strong, improve high temperature oxidation resistance, reduce the effect of expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

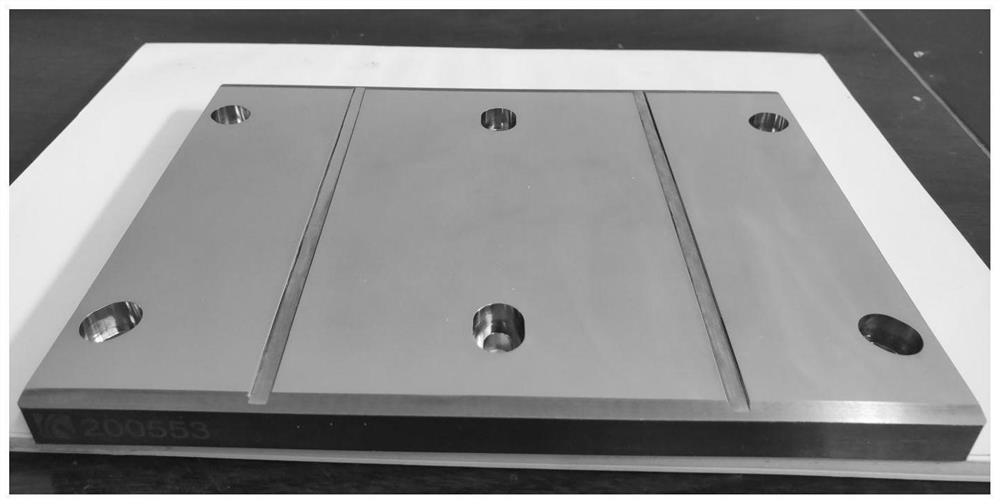

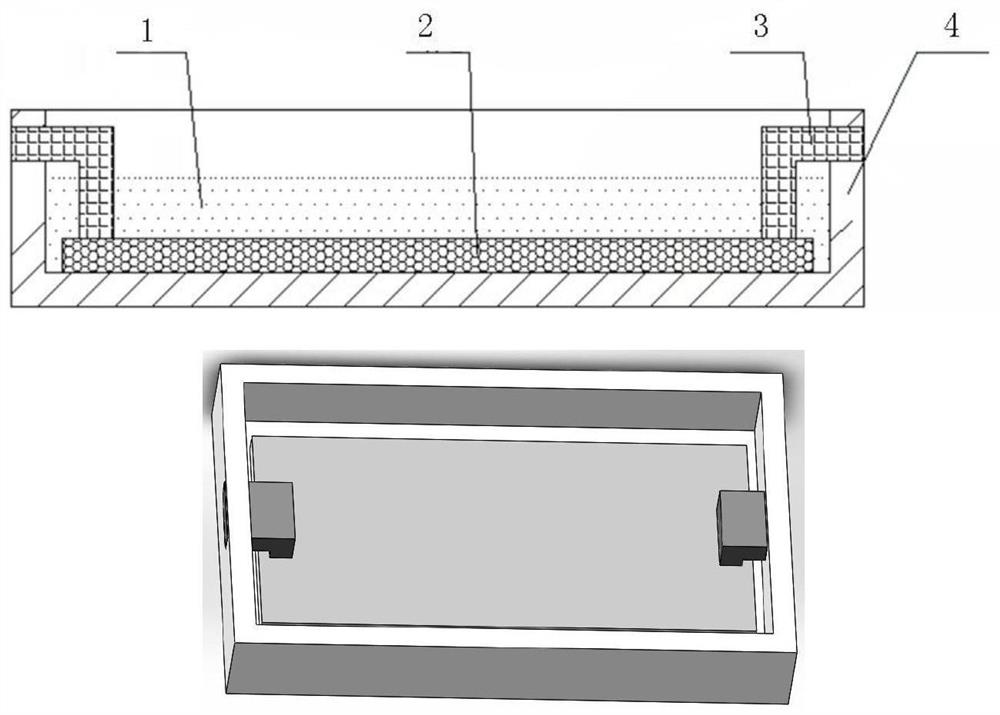

Image

Examples

Embodiment 1

[0036] A high-temperature-resistant vapor chamber formula for a 3D glass hot bending machine, including the following components in mass percentages: 25% nickel, 40% spherical alumina powder, 30% tungsten carbide powder, and 5% chromium carbide.

[0037] A preparation process of a high-temperature-resistant vapor chamber formula for a 3D glass hot bending machine, comprising the following steps:

[0038] Step 1. Mixed ball mill: Weigh nickel, tungsten carbide powder, and chromium carbide in the above mass ratio, put them into a ball mill for ball milling, use cemented carbide balls as ball milling balls, the ball-to-material ratio is 6:1, and the speed is 36r / min , the ball milling time is 60h, adding absolute ethanol as the wet milling medium, after the ball milling is completed, wet sieve to obtain a uniform mixed slurry;

[0039] Step 2. Soaking: Put the spherical alumina powder with the above mass ratio in another ball mill. There are no ball milling balls in the ball mill...

Embodiment 2

[0047] A high-temperature vapor chamber formula for a 3D glass hot bending machine, comprising the following components in mass percentages: 25% nickel, 50% spherical alumina powder, 20% tungsten carbide powder, and 5% molybdenum carbide powder.

[0048] A preparation process of a high-temperature-resistant vapor chamber formula for a 3D glass hot bending machine, comprising the following steps:

[0049] Step 1. Mixing ball milling: Weigh nickel, tungsten carbide powder, and molybdenum carbide powder in the above mass ratio, put them into a ball mill for ball milling, use cemented carbide balls as ball milling balls, the ball-to-material ratio is 10:1, and the speed is 30r / min, the ball milling time is 20h, add absolute ethanol as the wet milling medium, after the ball milling is completed, wet sieve to obtain a uniform mixed slurry;

[0050] Step 2. Soaking: Put the spherical alumina powder with the above mass ratio in another ball mill. There are no ball milling balls in th...

Embodiment 3

[0058] A high-temperature-resistant vapor chamber formula for a 3D glass hot bending machine, comprising the following components in mass percentages: 20% nickel, 50% spherical alumina powder, 25% tungsten carbide powder, and 5% chromium.

[0059] A preparation process of a high-temperature-resistant vapor chamber formula for a 3D glass hot bending machine, comprising the following steps:

[0060] Step 1. Mixed ball milling: Weigh the nickel, tungsten carbide powder, and chromium in the above mass ratio, put them into a ball mill for ball milling, use cemented carbide balls as ball milling balls, the ball-to-material ratio is 8:1, and the speed is 70r / min. The ball milling time is 40 hours, add absolute ethanol as the wet milling medium, and wet sieve after the ball milling is completed to obtain a uniform mixed slurry;

[0061] Step 2. Soaking: Put the spherical alumina powder with the above mass ratio in another ball mill. There are no ball milling balls in the ball mill, bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com