a kind of sic f /sic composite material surface anti-radiation anti-air oxidation composite coating and preparation method thereof

A composite coating and composite material technology, applied in the field of functional coatings, can solve the problems that cannot be directly applied to space reactor nuclear energy engines, large neutron absorption cross-section, poor radiation resistance, etc., and achieve better anti-oxidation and corrosion effects, The effect of high density and low CVD temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

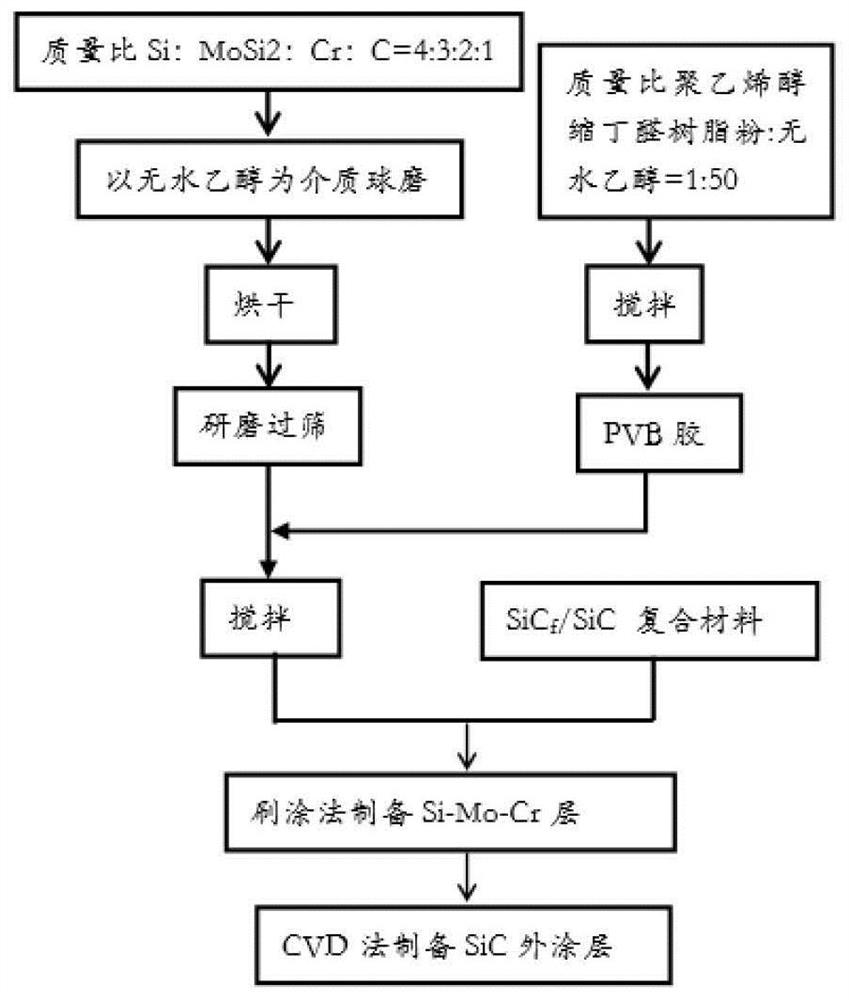

[0053] SiC by using a diamond grinder f / SiC composite material for surface grinding to ensure the flatness of the surface. 10×10×3mm SiC f / SiC composite material is the matrix, and the raw material composition of the inner coating is: 40% Si powder, 30% MoSi 2 powder, 20% Cr powder and 10% C powder.

[0054] Mix the powder according to the above raw material composition, and then use absolute ethanol as a ball milling medium, ball mill the raw materials at a speed of 200r / min for 10h for ball milling and mixing.

[0055] After ball milling, drying and grinding through a 300-mesh sieve to obtain the mixed portion,

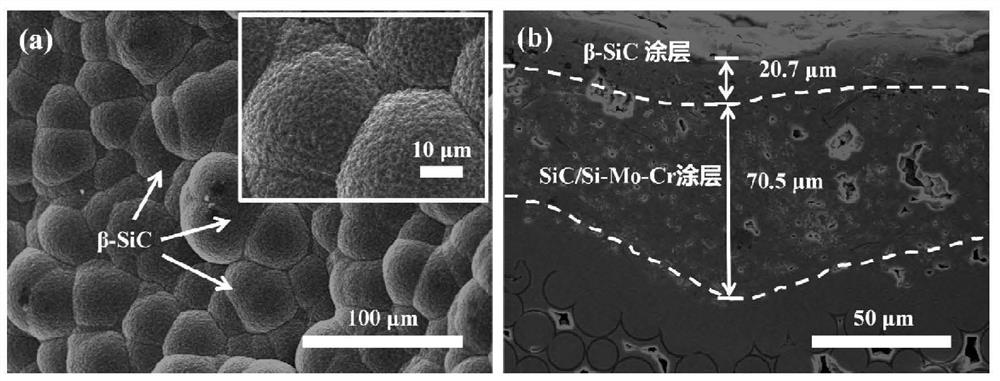

[0056] Use PVB glue prepared with mass ratio of alcohol:PVB=50:1 as binder, prepare brushing slurry with mass ratio of mixed powder:PVB glue=3:10, and brush 3 to 5 times through woven mesh After each brushing, place the sample in an oven at 40°C to fully dry, and the drying time is 40 minutes. The thickness after brushing is about 70.50μm, and the weight gain...

Embodiment 2

[0058] Firstly, the SiCf / SiC composite material was roughened, cleaned and dried with 300-mesh SiC sandpaper, and the alloy powder with the mass percentage of Si 30%, MoSi 240%, Cr 25% and C 5% was ball-milled for 15 hours at a speed of Be 200r / min, subsequent steps are identical with embodiment 1. The CVD process is: deposition temperature: 1050°C, deposition pressure: 400-600Pa, carrier gas H2: 160ml / min, diluted H2: 200ml / min, Ar: 200ml / min, deposition time: 40h. After inspection, the prepared SiC / Si-Mo-Cr coating has good bonding strength with the SiCf / SiC composite material. After the coating is prepared, the mechanical properties are improved by 11.89%, and the oxidation resistance and radiation resistance are excellent: at 1400 ° C After oxidation for 10 hours, the weight gain is 0.20mg.cm-2, the retention rate of bending strength is about 92.30%, and the retention rate of bending strength after irradiation is about 84.50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com