A hot rolling preparation method of 1700mpa grade high cr-si thin gauge hot forming steel

A hot-formed steel, thin-gauge technology, applied in the field of metal processing, can solve the problems of reducing production efficiency and product qualification rate, insufficient toughness of hot-stamped parts, and increasing production costs, reducing hydrogen embrittlement susceptibility, grain size Small size and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Preparation of 1700MPa grade high Cr-Si thin-gauge hot-rolled steel sheet for thermoforming with a thickness of 1.5mm, the process steps are as follows:

[0061] (1) Controlled rolling and controlled cooling treatment

[0062] The chemical composition of the alloy billet by weight percentage is: C: 0.30%, Mn: 0.8%, Si: 1.8%, S: 0.005%, P: 0.008%, Al: 0.01%, Cr: 3.0%, Nb: 0.03%, V: 0.01%, Ti: 0.03%, Cu: 0.05%, the balance is Fe and other unavoidable impurities; the continuous casting slab of the above components is heated to 1300 ° C with the furnace and kept for 2.5 h; after one descaling, Remove the furnace-generated iron scale, the rough rolling start temperature is 1170°C, after 6 rough rolling passes, the total reduction rate of the rough rolling is 87%, and the thickness of the intermediate billet is 30.55mm; the secondary oxidation is removed before the finish rolling After the iron sheet, the steel strip with a thickness of 1.5mm is formed by 7 passes of finish ro...

Embodiment 2

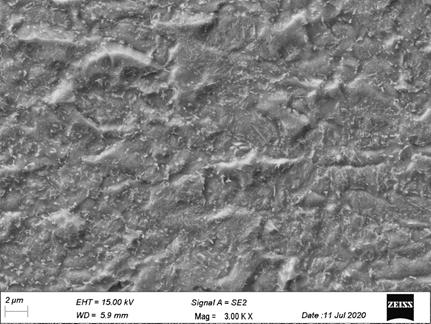

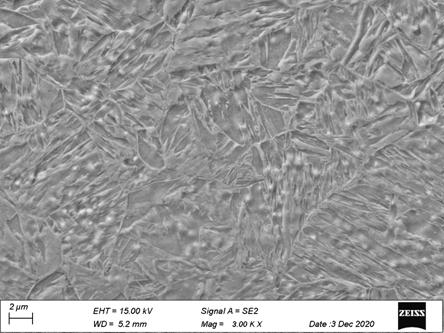

[0066] After decoiling and straightening the hot-rolled steel plate obtained in Example 1, remove the iron scale by mechanical means, heat to 930°C, keep it warm for 350s, and then quickly transfer it to a hot stamping die for hot stamping within 10s, and keep it under pressure. The pressure is 20MPa, and then quenched at a cooling rate of 150°C / s to below 200°C to obtain a hot-formed steel. The structure is martensite and a small amount of retained austenite, such as figure 2 shown.

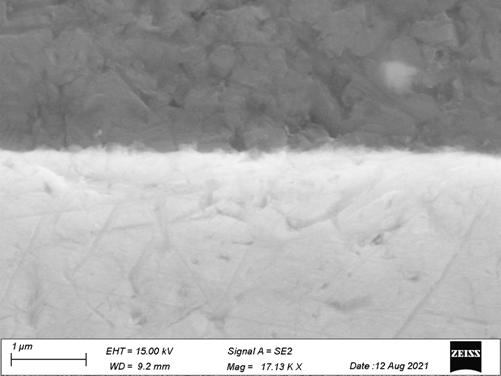

[0067] The mechanical property experiment of the hot-formed steel was carried out, and finally the yield strength of the hot-formed steel was 1390MPa, the tensile strength was 1750MPa, the elongation was 8.5%, and the bending angle was 65°. The surface oxide scale thickness of the bare hot-rolled steel plate after hot forming is about 0.9 μm, such as image 3 As shown, no shot peening is required.

Embodiment 3

[0069] The hot-rolled steel plate obtained in Example 1 is subjected to decoiling tension leveling, and the tension leveling elongation setting range is 1.0%;

[0070] The concentration of hydrochloric acid in the first acid tank: 120 g / L±20 g / L, the temperature of the acid solution is 80±10°C,

[0071] The concentration of hydrochloric acid in the second acid tank: 150 g / L±20 g / L, the temperature of the acid solution is 80±10°C,

[0072] The concentration of hydrochloric acid in the third acid tank: 190 g / L±20 g / L, the temperature of the acid solution is 80±10°C;

[0073] The concentration of iron ions is required to be no more than 100 g / L;

[0074] The process speed is 60m / min.

[0075] After pickling with hydrochloric acid, most of the iron scale on the edge and middle of the hot-rolled steel plate has been removed. The thickness of the iron oxide scale at the edge is 0.7 μm to 1 μm, and the thickness of the iron oxide scale at the middle is between 0.7 μm and 4 μm. bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com