Hardfacing alloy containing silicon and chromium composite ceramic phases and manufacturing process thereof

A composite ceramic and alloy technology, applied in the field of material science, can solve the problems of complex preparation process of surfacing alloy, expensive alloy elements, increase production cost, etc., and achieve the effects of improved bonding, simple preparation method and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A wear-resistant surfacing alloy containing Si and Cr composite ceramic phase. According to the mass percentage of elements, Cr 20%, Si 0.5%, Ni 1%, C 6%, and the balance is iron element and other inevitable impurities.

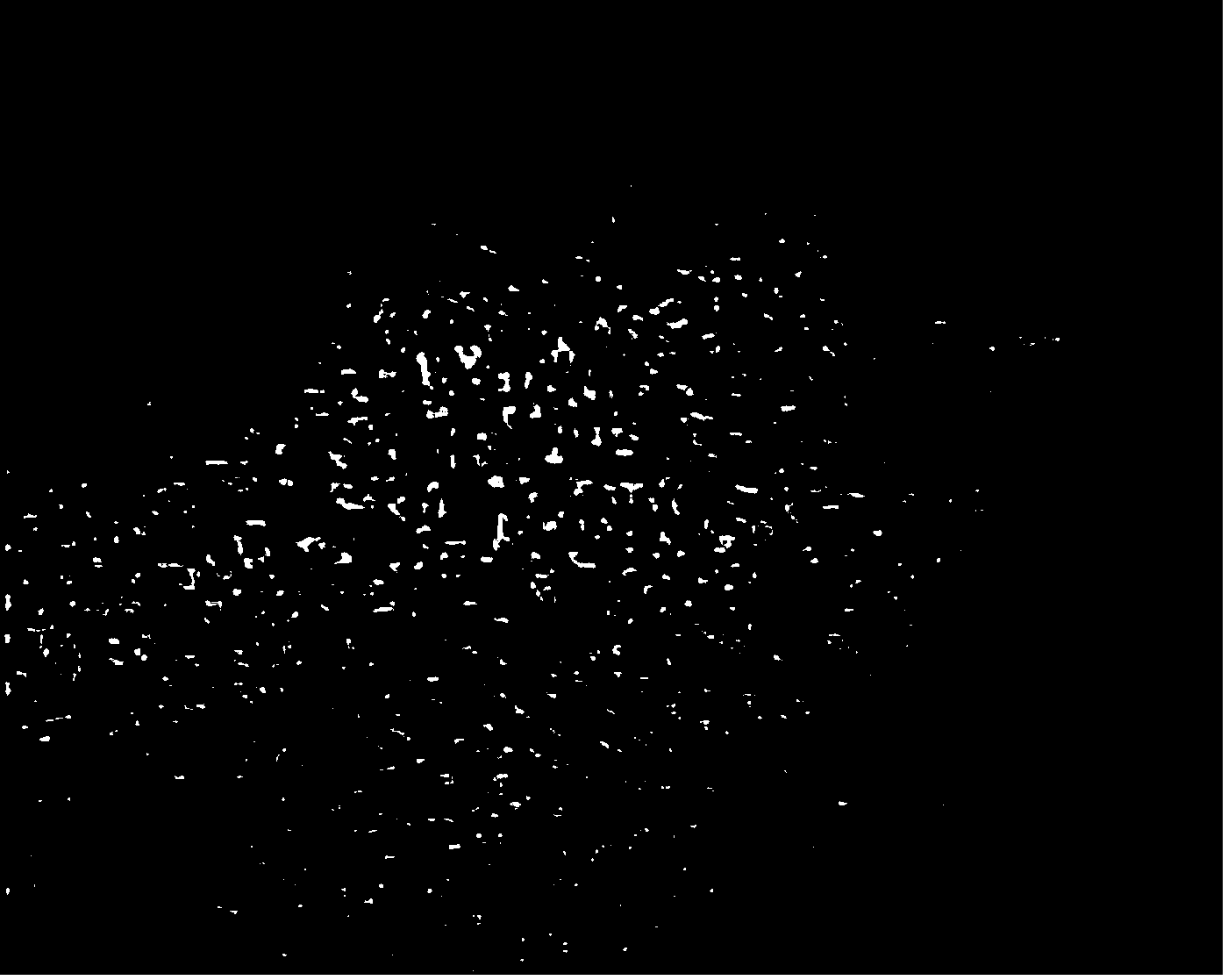

[0025] The above alloy system and preparation method are used for plasma surfacing welding. The hardness of the surfacing layer is 55-62HRC. The MMU-5G material end face high temperature friction and wear testing machine is used for the pin wear test. The wear test parameters: speed 300r / min, test force 200N , the wear time is 3min, the wear amount of the surfacing layer is 0.0011g, and the microstructure of the surfacing alloy is shown in figure 1 .

Embodiment 2

[0027] A wear-resistant surfacing alloy containing Si and Cr composite ceramic phase. According to the mass percentage of elements, Cr 15%, Si 2%, Ni 1%, C 8%, and the balance is iron element and other inevitable impurities.

[0028] The above-mentioned alloy materials are used for plasma surfacing welding. The hardness of the surfacing layer is 50-58HRC. The MMU-5G material end face high-temperature friction and wear testing machine is used for the pin wear test. The wear test parameters are rotation frequency 300r / min and test force 200N. The wear time is 3 minutes, the wear amount of the surfacing layer is 0.0012g, and the microstructure of the surfacing alloy is shown in figure 2 .

Embodiment 3

[0030] A wear-resistant surfacing alloy containing Si and Cr composite ceramic phase. According to the mass percentage of elements, Cr 10%, Si 3%, Ni 3%, C 8%, and the balance is iron element and other inevitable impurities.

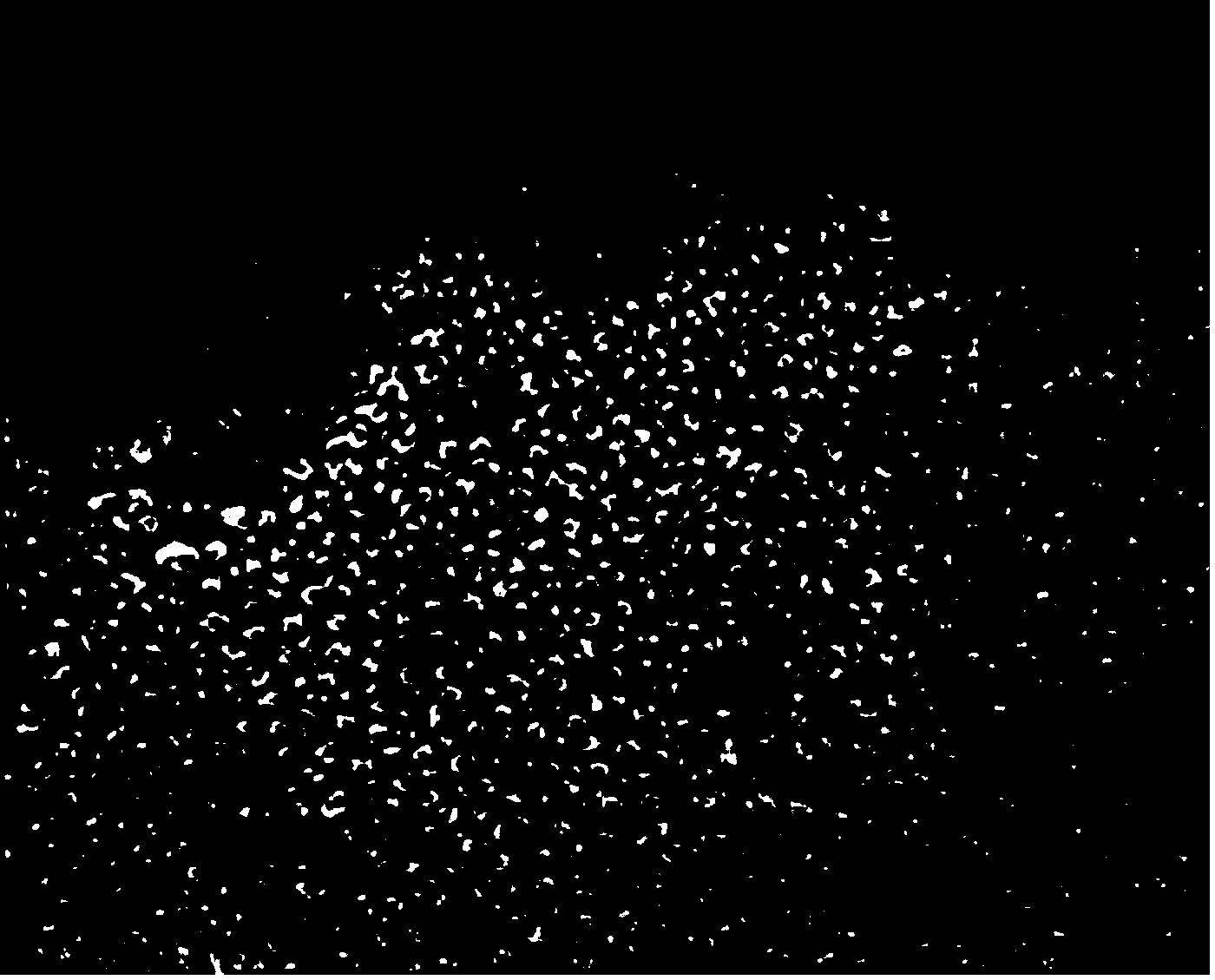

[0031] The above-mentioned alloy materials are used for plasma surfacing welding. The hardness of the surfacing layer is 50-55HRC. The MMU-5G material end face high-temperature friction and wear testing machine is used for the pin wear test. The wear test parameters are rotation frequency 300r / min and test force 200N. The wear time is 3 minutes, the wear amount of the surfacing layer is 0.0019g, and the microstructure of the surfacing alloy is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com