Patents

Literature

179results about How to "To achieve the purpose of sustained release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

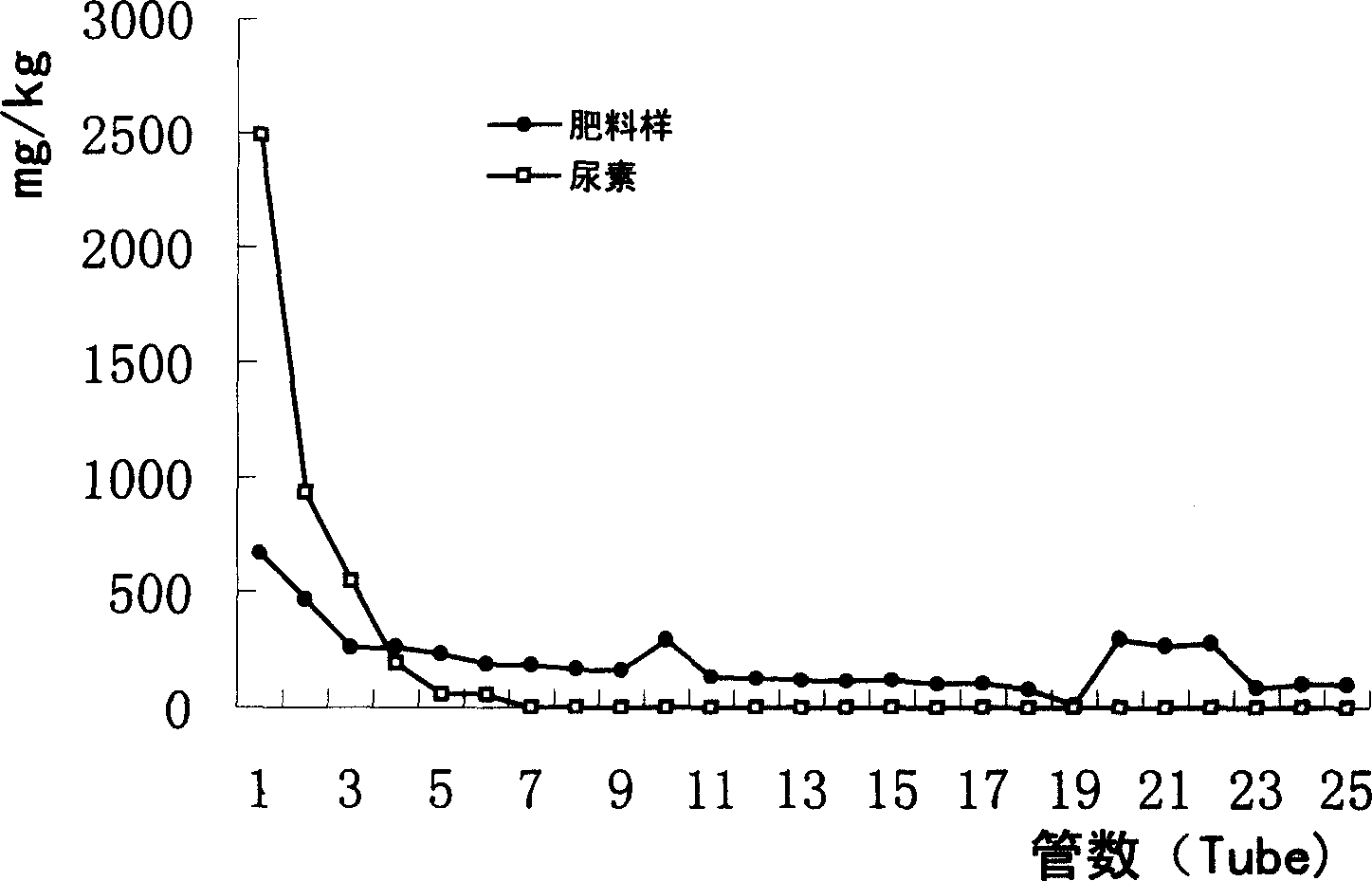

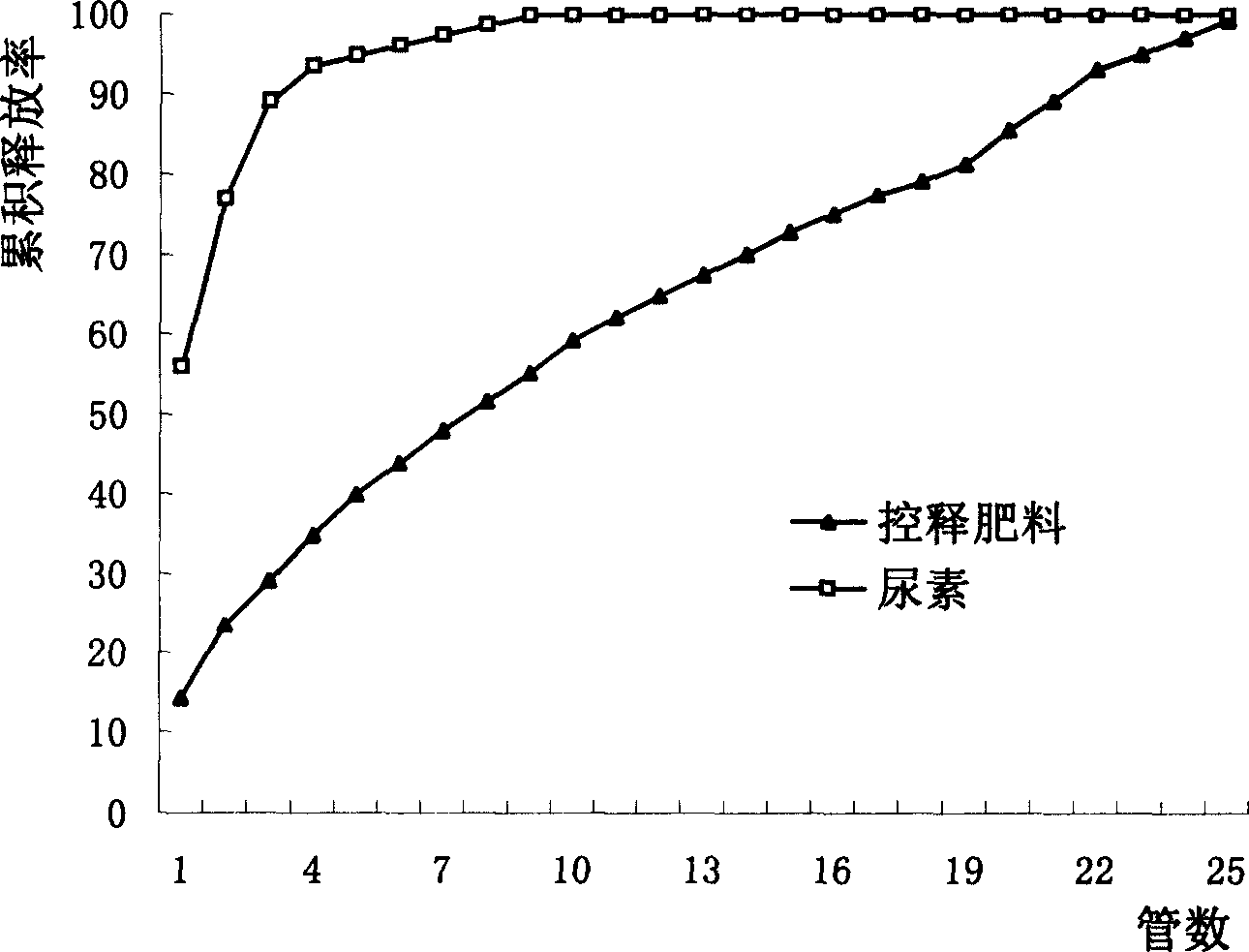

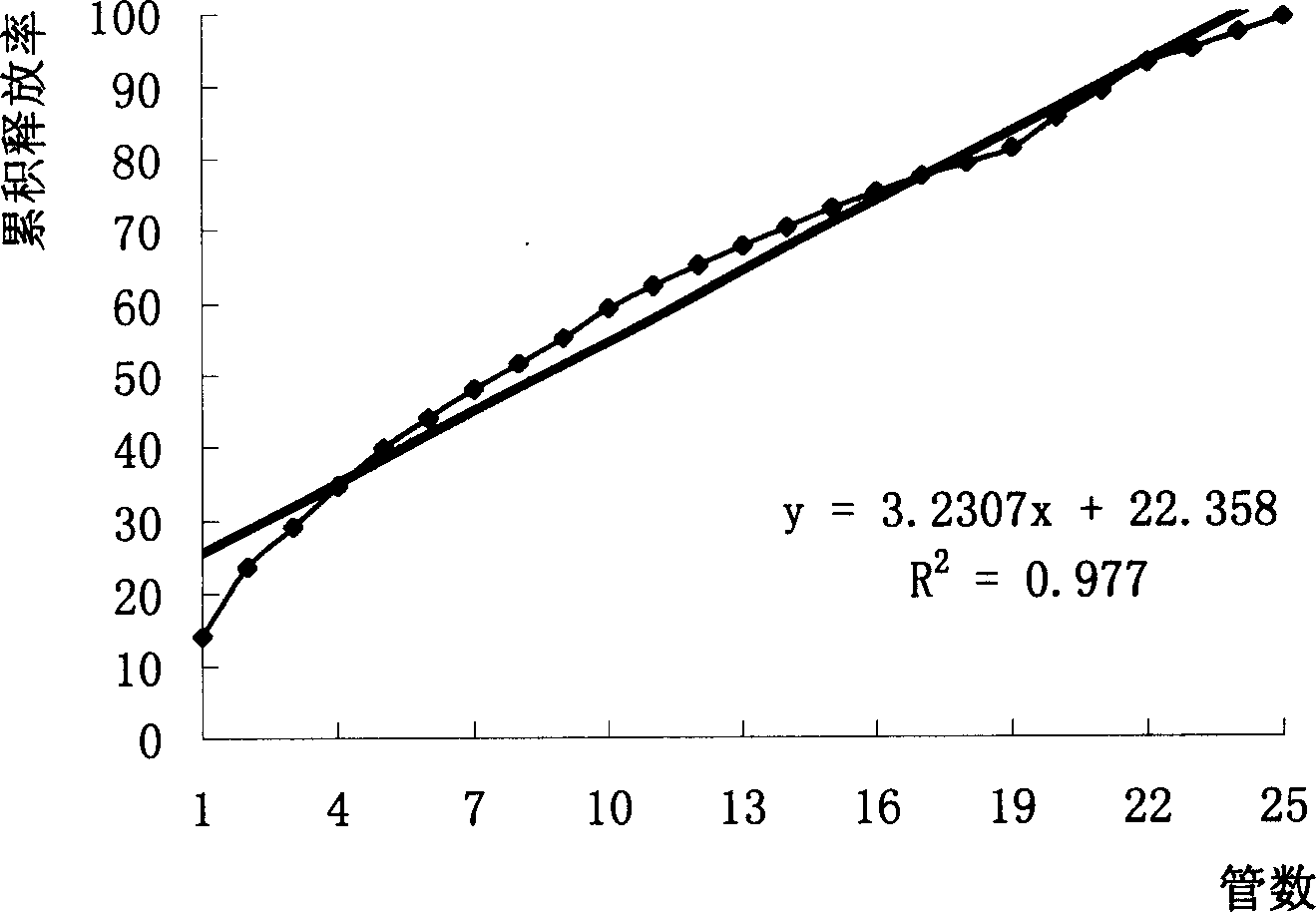

Carrier type slow-release fertilizer and its preparing method

InactiveCN1470485AGood hygroscopicityImprove hydrophilicityFertilizer mixturesGeneral chemistChemistry

The present invention discloses a carrier type slowly-released fertilizer and its preparation method. It not only has basic composition of general chemical fertilizer, but also contains carrier material, and its preparation method includes: firstly, dissolving carrier material with a certain quantity in water, then mixing general chemical fertilizer with it according to a certain proportion, uniformly stirring them to make them implement full reaction, adding cross-linking agent, making them implement further full reaction, removing water, finally pulverizing dried material and granulating.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

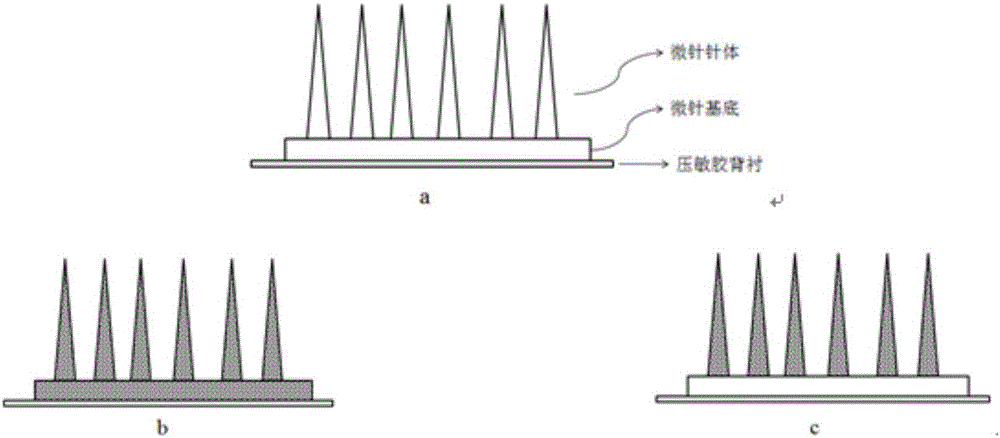

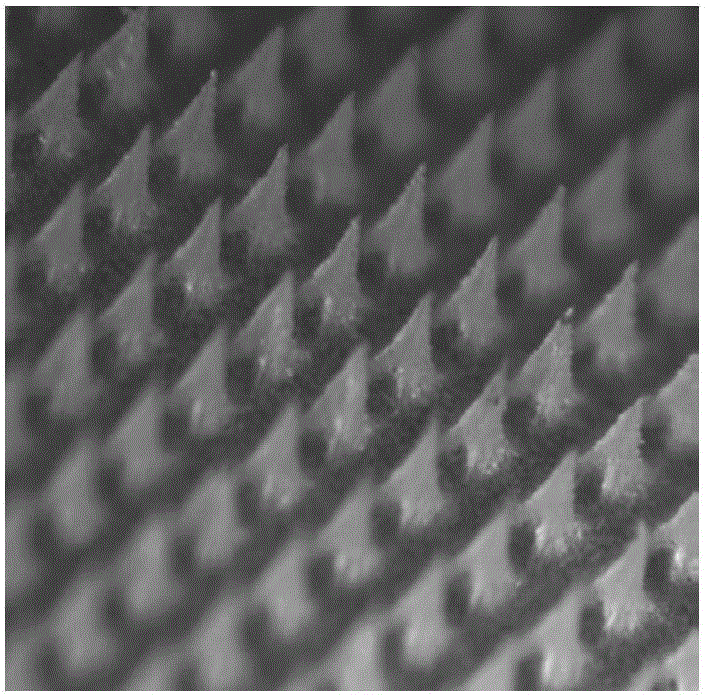

Flexible slow-release micro-needle patch and preparation method thereof

InactiveCN106422045AGood dispersionGood sustained releaseOrganic active ingredientsMicroneedlesSolubilityMedicine

The invention discloses a flexible slow-release micro-needle patch and a preparation method thereof. The micro needle patch comprises a micro-needle, a substrate and a back lining, wherein the micro-needle and the substrate form a micro-needle array; a base material of the micro-needle or a base material of the micro-needle array contains a drug in a crystal form; the solubility of the drug in the crystal form in water is less than 100 microgram / ml. The micro-needle patch has the characteristics of simple process, high preparation safety, low process cost and high drug loading capacity.

Owner:BEIJING CAS MICRONEEDLE TECH LTD

Protocyanidin slow release capsule

InactiveCN1383819AKeep activeImprove stabilityOrganic active ingredientsPharmaceutical delivery mechanismPhosphoric acidA-type proanthocyanidin

A protocyanidin sloow release microcapsule has microcapsule size smaller than 3 mm, protocyanidin content of 0.25-25 wt% and sustained release period of 12-48 hr in buffering phosphoric acid solutionof pH 7.4. The wall of the microcapsule is one three layer structure including agglomerate calcium alginate layer, chitosan and alginate complex layer and deposited chitosan layer. The microcapsule is prepared through compounding water solution of calcium alginate containing protocyanidin, preparing chitosan-CaCl2 solution, adding miniature liquid drop of water solution of calcium alginate containing protocyanidin into chitosan-CaCl2, solution and subsequent processing. The release rate of the coated protocyanidin is adjustable.

Owner:天津市园艺工程研究所

Fertilizer specially used for rice and preparation method thereof

ActiveCN103964971AIncrease profitEasy to breatheFertilizer mixturesPotassiumMagnesium ammonium phosphate

The invention discloses a fertilizer specially used for rice and a preparation method thereof. The fertilizer comprises an organic fertilizer and an inorganic fertilizer, wherein the inorganic fertilizer is prepared from the following raw materials: urea, monoammonium phosphate, potassium chloride, lime nitrogen, magnesium ammonium phosphate, zinc sulfate, boric acid, a sterilizing agent, urea formaldehyde, diatomite, ATS and dicyandiamide; the urea formaldehyde containing ammonium thiosulfate and dicyandiamide serves as a coating, and the diatomite is attached to the outer side of the coating; the other raw materials are contained in the coating. The organic fertilizer is prepared from the following raw materials: sterilizing agent decoction dregs, chicken manure, bagasse, xylitol residue, cottonseed cake and plant ash. The fertilizer can meet the requirement of the whole rice growth period after being applied once, manual labor is saved, the soil aeration, fertilizer absorption and water retention characteristics can be improved, steady growth of rice plants is promoted, and the yield is increased by 10-20 percent per mu.

Owner:JINAN BADUN FERTILIZER

Composite organism slow release fertilizer product and producing method

InactiveCN101054314AOvercome the disadvantages of easy exceeding the standardOvercoming pollutionAgriculture gas emission reductionOrganic fertilisersMoisturePollution

The present invention relates to a chemical fertilizer and a manufacturing method thereof, specifically to a composite biological slow-release fertilizer product and its manufacturing method. Said composite biological slow-release fertilizer product in accordance with the present invention comprises granular fertilizer cores and coatings packing outside of the fertilizer cores, wherein said fertilizer cores are grains formed by a mixture of ternary compound fertilizer and the slow-release components which are mixture of urea and humic acids. Said coatings comprises at least animal oil and fat, bone meal and bacillus components. By replacing steam for heat spraying granulation with urea and humic acids melting complexing liquor, the manufacturing method in accordance with the present invention resolves the problem of moisture exceeding standard in 'three (organics, inorganics and bilogies) in one' fertilizer production and achieves the goal of nitrogen slow-release. At the same time, by adopting animal oil and fat and bone meal which can provide food such as lipids to animalcules and are easy to degrade as bacillus preparation carrier, said method overcomes the problems that the mixing of bacillus preparation and other fertilizer components leads to bacterial agent pollution and bacterium poisoning phenomenna. The present invention provides a 'three (organics, inorganics and bilogies) in one' composite biological slow-release fertilizer product which exhibits quick results, slow results and long results integrally, and a manufacturing method thereof.

Owner:王怀欣

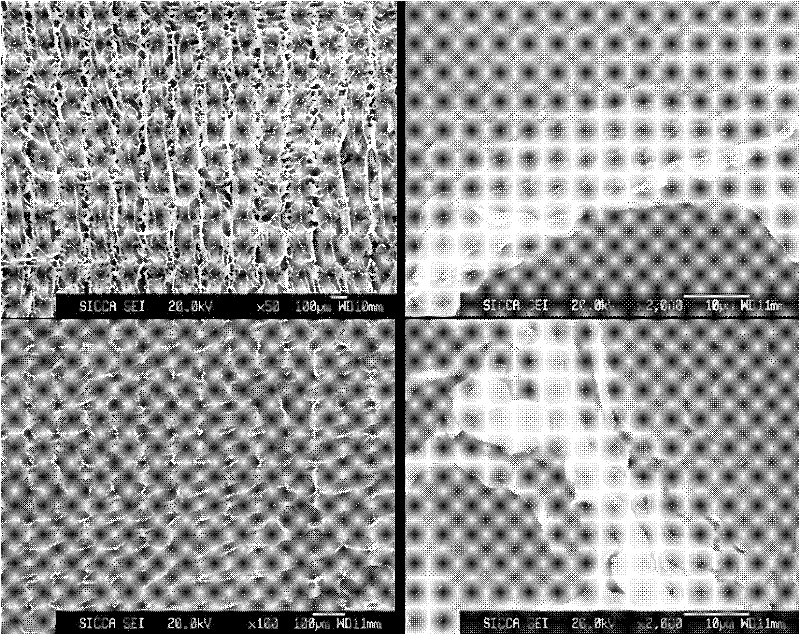

3D porous bracket with mesoporous biological glass coating and preparation method thereof

The invention relates to a 3D porous bracket with a mesoporous biological glass coating and a preparation method thereof. Polymer porous bracket substrate is prepared by utilizing freeze-extraction technique, by dipping precursory sol of the mesoporous biological glass and the approach of evaporation-induced self-assembly, a novel 3D porous bracket with a mesoporous biological glass coating for tissue engineering. The preparation method has the advantages of simple to carry out, low cost, high efficiency and easy operation. The 3D porous bracket with a mesoporous biological glass coating prepared by the invention is suitable for drug loading and releasing, sterilization, inducing the adhesion and proliferation of cells, with good application prospect in tissue engineering.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

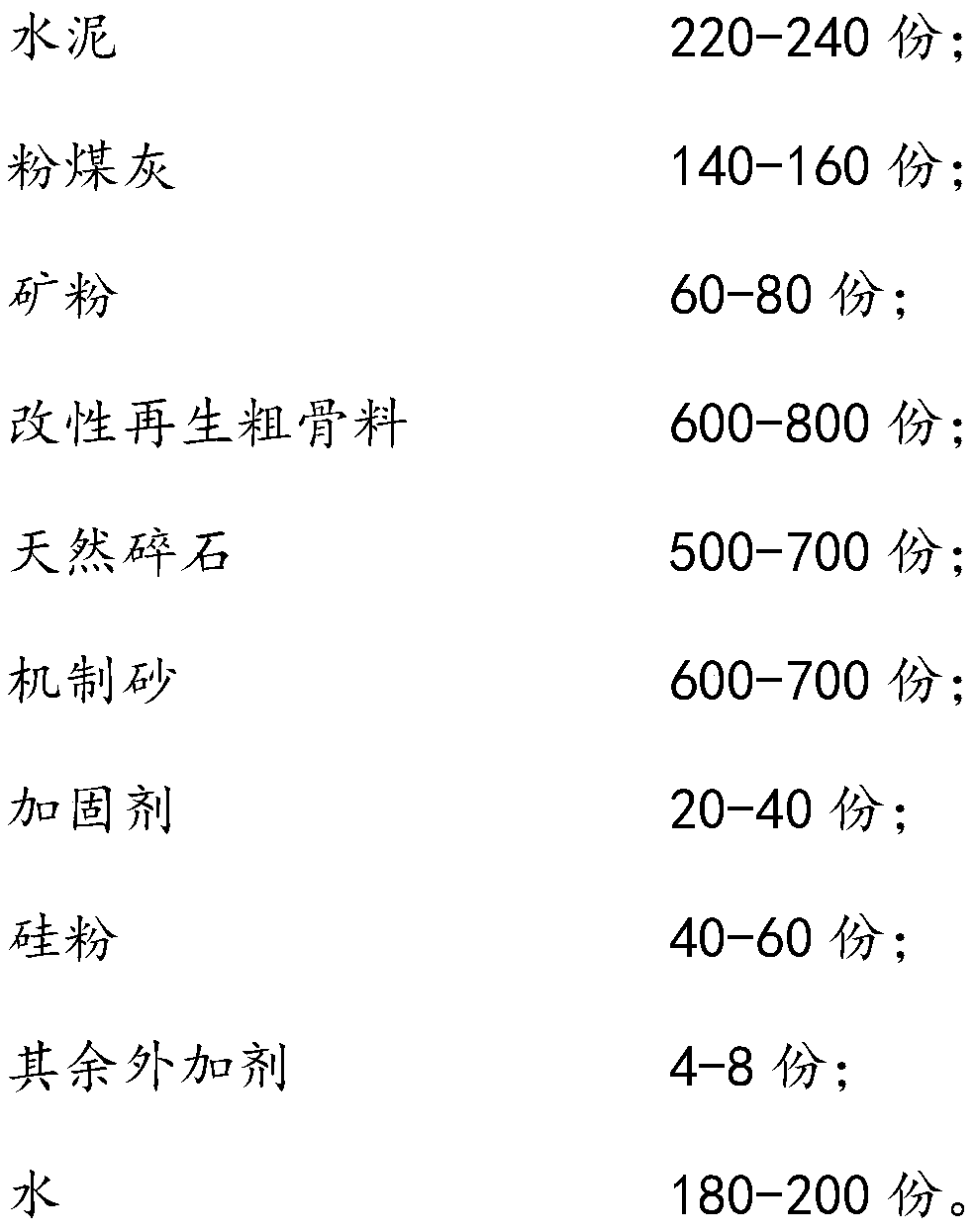

High-performance recycled concrete and preparation process thereof

ActiveCN110540389AImprove work performanceImprove compactnessBuilding material handlingWork performanceChipseal

The invention discloses high-performance recycled concrete and a preparation process thereof, and relates to the technical field of concrete preparation. The concrete includes the following raw materials in parts by weight: 220-240 parts of cement; 140-160 parts of fly ash; 60-80 parts of mineral powder; 600-800 parts of modified recycled coarse aggregate; 500-700 parts of natural gravel; 600-700parts of machined sand; 20-40 parts of a reinforcing agent; 40-60 parts of silicon powder; 4-8 parts of other additives; and 180-200 parts of water. By adjusting the ratio of the various raw materialsof the concrete, adding the reinforcing agent and modifying the recycled aggregate, the working performance of the concrete can be effectively improved, and the compactness and overall strength of the concrete can be improved.

Owner:ZHEJIANG YUEDA TRAFFIC ENG CO LTD

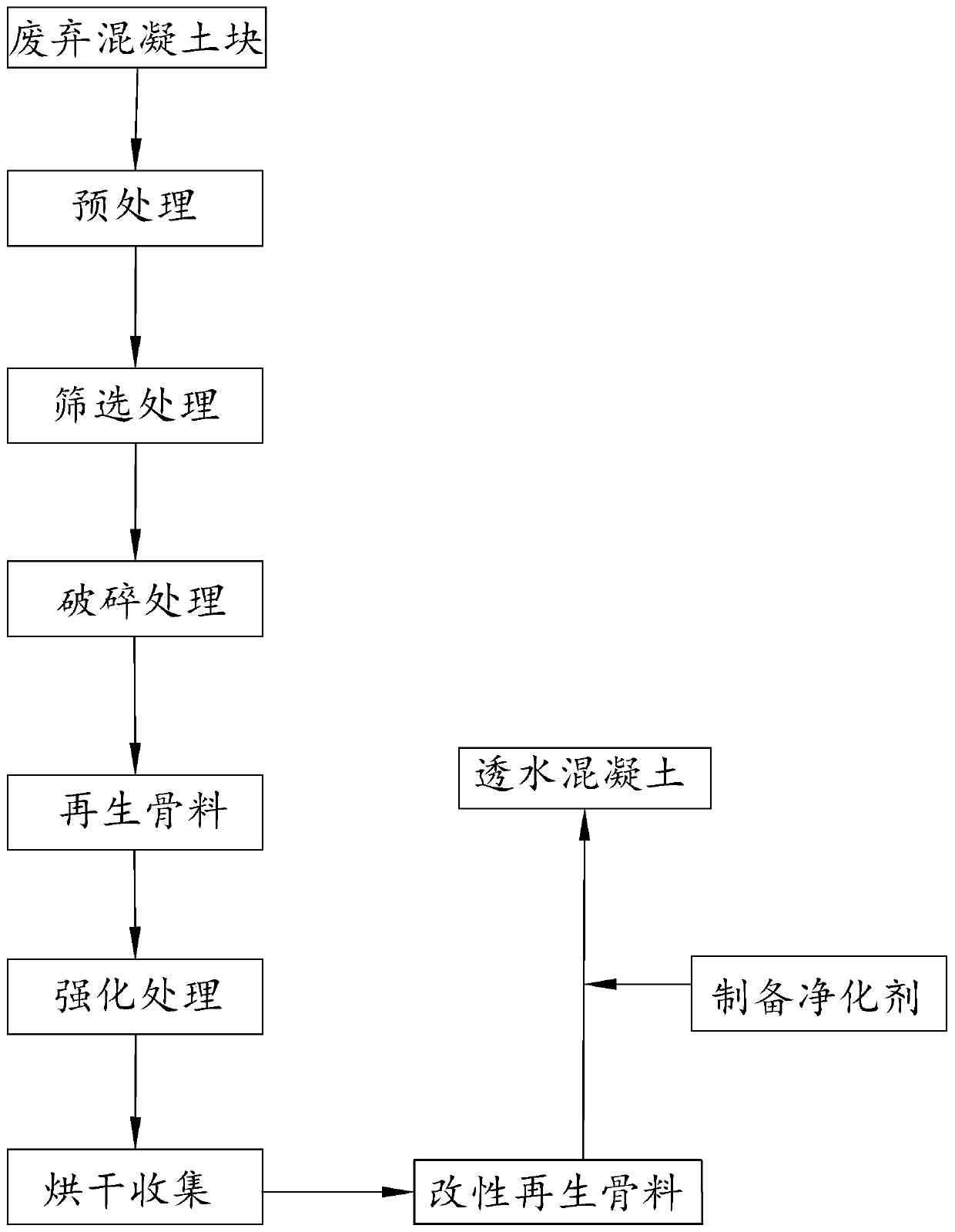

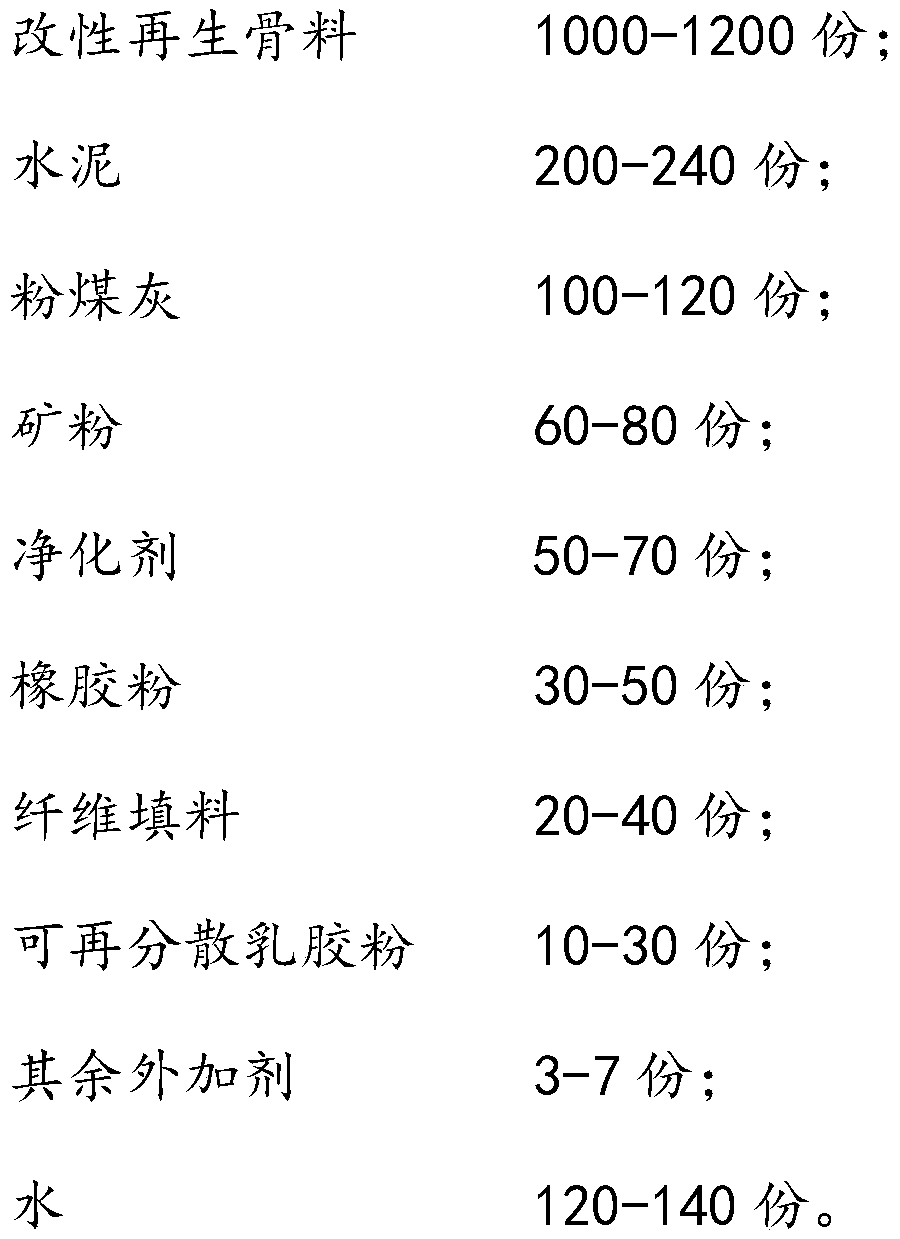

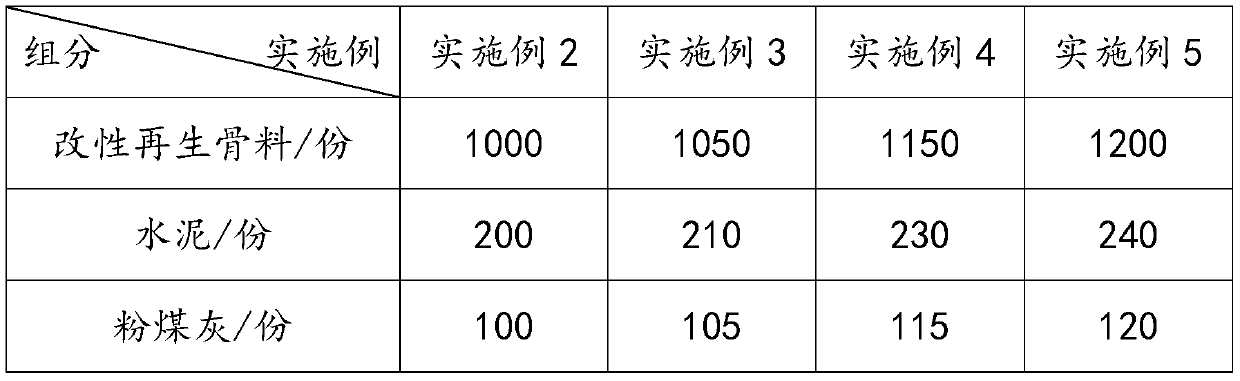

Pervious concrete prepared from recycled aggregate and preparation process of pervious concrete

InactiveCN110482936AHigh strengthWith self-cleaning effectSolid waste managementUltimate tensile strengthFly ash

The invention discloses pervious concrete prepared from recycled aggregate and a preparation process thereof, and relates to the technical field of concrete preparation, the pervious concrete is prepared from the following raw materials in parts by weight: 1000 to 1200 parts of modified recycled aggregate; 200 to 240 parts of cement; 100 to 120 parts of fly ash; 60 to 80 parts of mineral powder; 50 to 70 parts of a purifying agent; 30 to 50 parts of rubber powder; 20-40 parts of a fiber filler; 10 to 30 parts of redispersible latex powder; 3-7 parts of other additives; and 120-140 parts of water. The pervious concrete is prepared by modifying the recycled aggregate, so that the strength of the recycled aggregate is improved, and the application range of the pervious concrete is widened.

Owner:ZHEJIANG YUEDA TRAFFIC ENG CO LTD

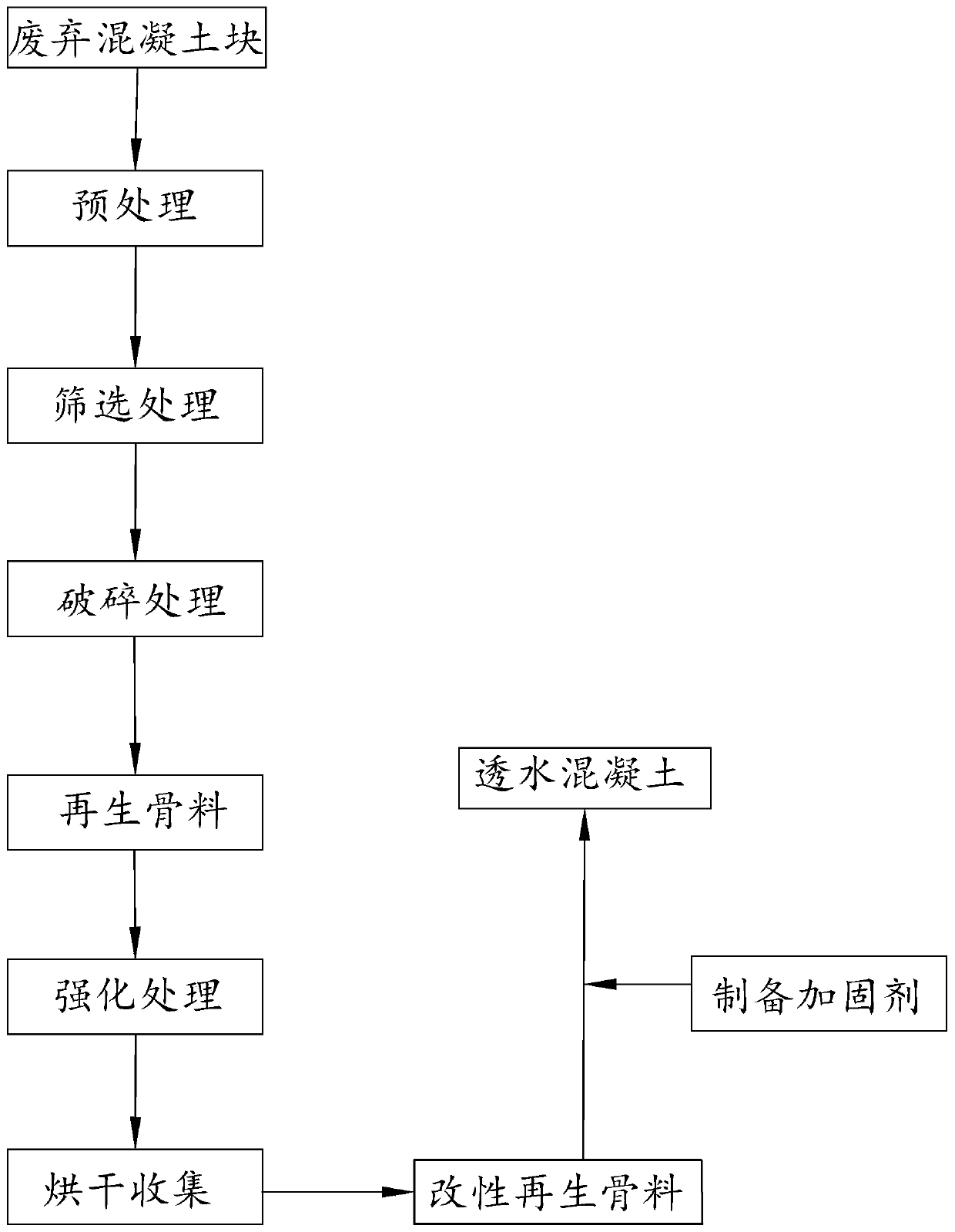

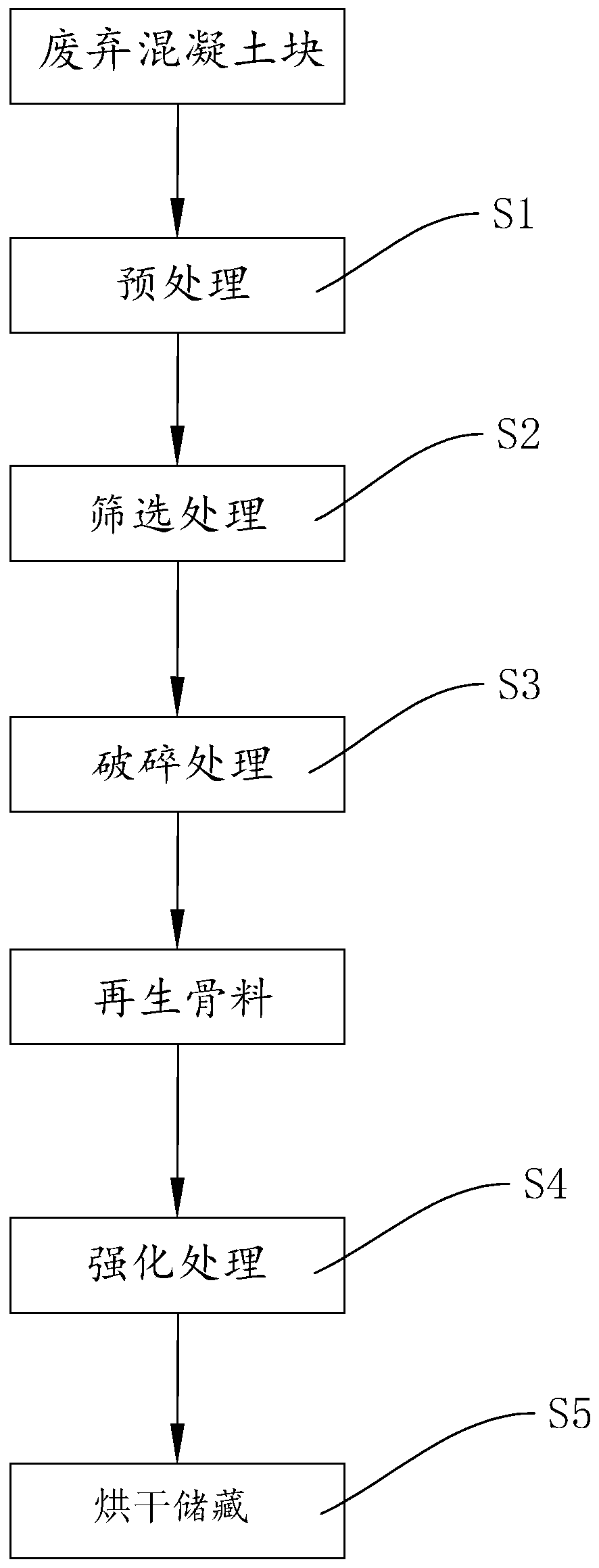

Production technology for preparing recycled aggregate from waste concrete

ActiveCN110563370AReduce wasteIncrease profitSolid waste managementPre treatmentConstruction aggregate

The invention relates to a production technology for preparing recycled aggregate from waste concrete. The technology comprises the following steps: S1, preprocessing: carrying out jet wetting and epidemic prevention treatment on waste concrete blocks, and then hammering the waste concrete blocks to make the diameter of the hammered concrete blocks less than 50 mm; S2, screening: screening the preprocessed material obtained in step S1; S3, crushing: crushing the screened waste concrete blocks obtained in step S2 to prepare recycled aggregate; S4, reinforcing: reinforcing the recycled aggregateobtained in step S3; and S5, conveying the reinforced recycled aggregate to a storage bin for storage. The recycled aggregate is prepared by preprocessing, screening, crushing, reinforcing, drying and collecting the waste concrete, so that the effective utilization of the waste concrete is realized, the waste of resources is reduced, and the utilization rate of energy is increased.

Owner:ZHEJIANG YUEDA TRAFFIC ENG CO LTD

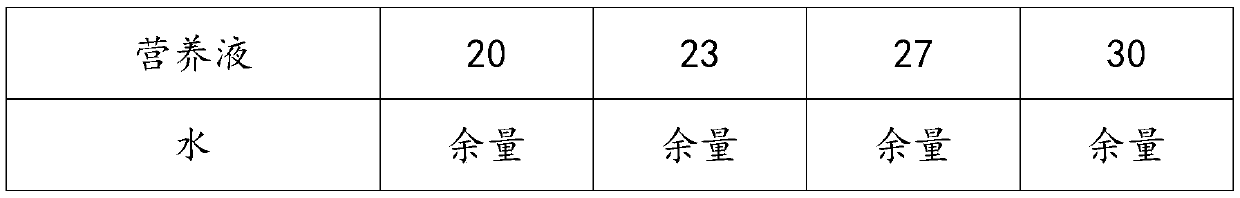

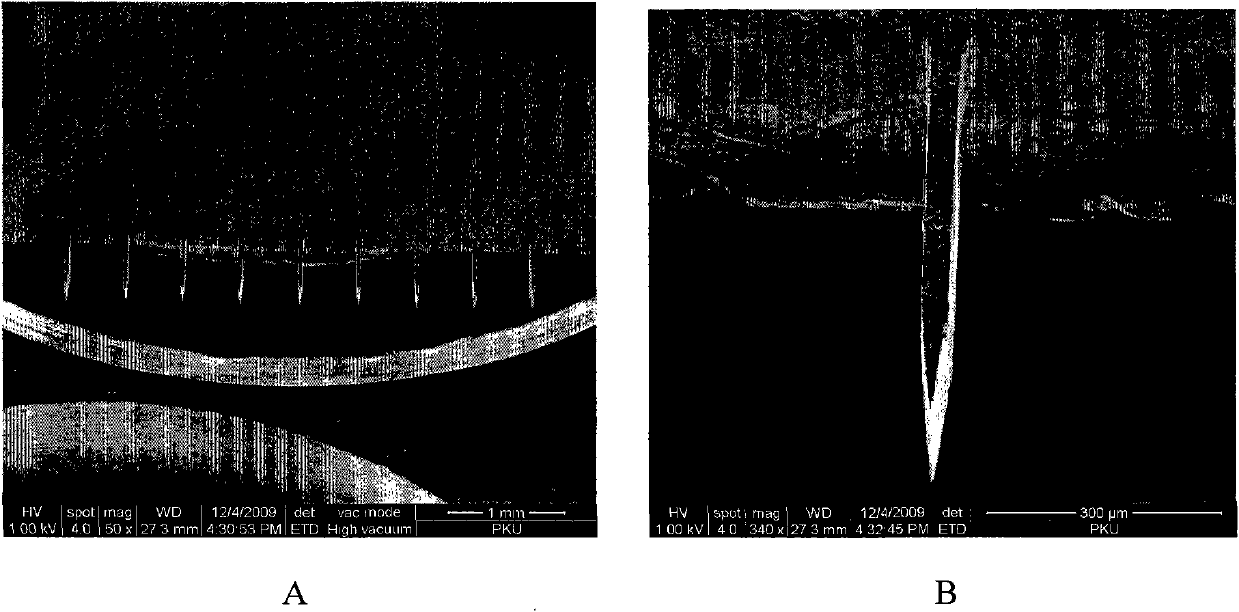

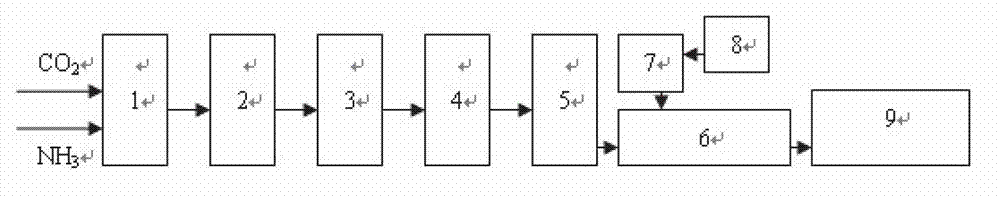

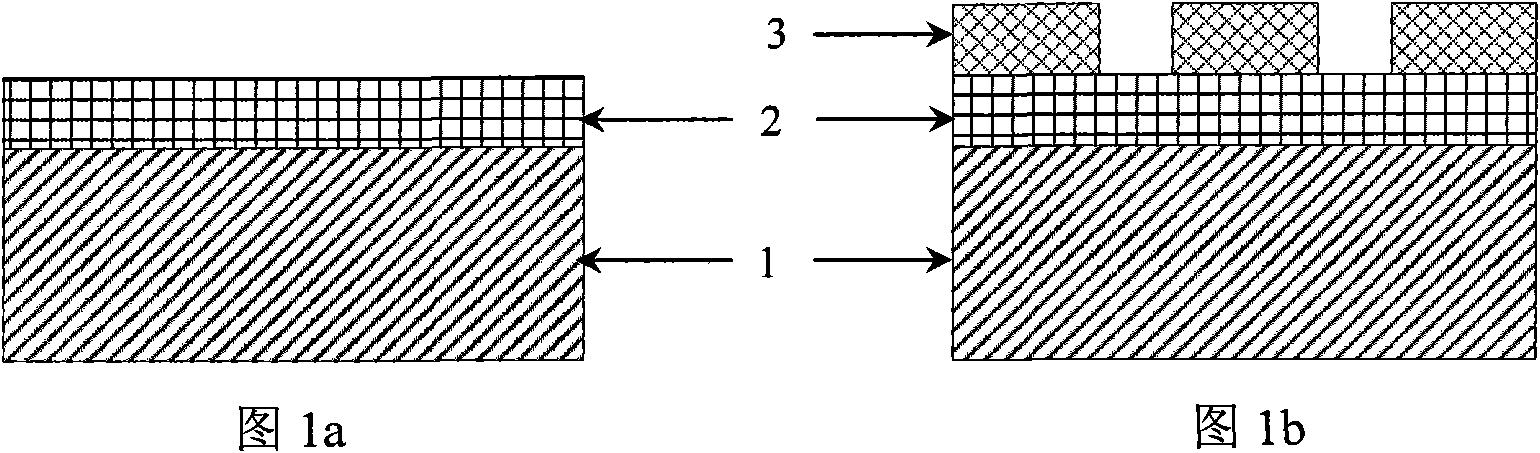

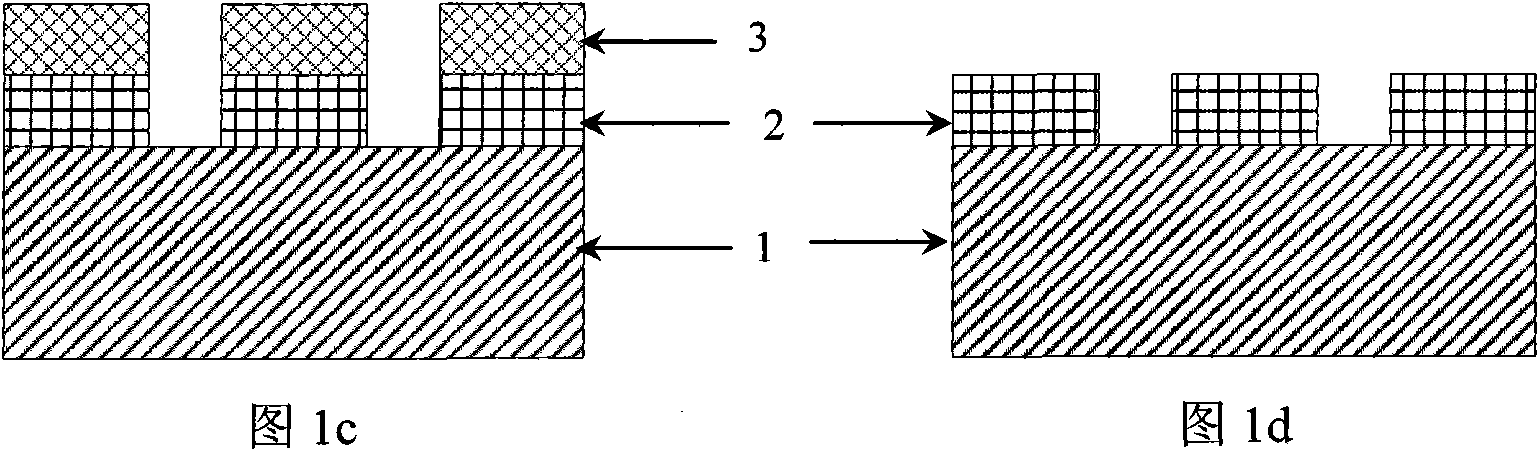

Method for preparing plane hollow microneedle for transdermal administration

InactiveCN101905856ATo achieve the purpose of sustained releasePrecise deliveryDecorative surface effectsMicroneedlesEnteral administrationChannel pattern

The invention discloses a method for preparing a plane hollow microneedle for transdermal administration, which comprises the following steps of: defining a microneedle flow channel pattern on one surface of a first metal substrate to form a trench, and defining a microneedle pattern on the other surface to form a cutting sign, wherein the central axis of the flow channel pattern is aligned with that of the microneedle pattern; bonding a second metal substrate with a trench surface of the first metal substrate; thinning a non-bonding surface of the second metal substrate, and allowing the cutting sign on the first metal substrate to align with and transfer to the non-bonding surface of the second metal substrate; and thinning a non-bonding surface of the first metal substrate, and cutting by aligning with the cutting sign on the second metal substrate to form the plane hollow microneedle. Based on the micromachining technology and by combining the conventional technology of machining and cutting at the same time, the method reduces the process difficulty, increases the using reliability of the microneedle, and is favorable for quantity production.

Owner:PEKING UNIV

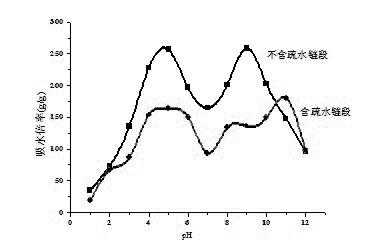

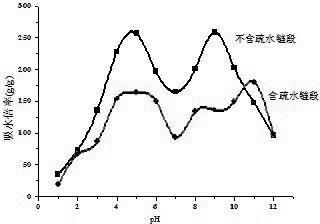

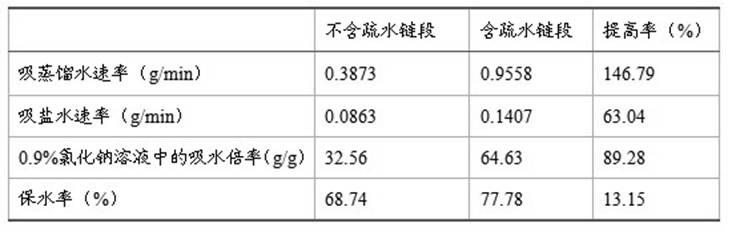

Preparation method of salt-tolerance controlled-release high-water-absorption resin with hydrophobic chain segments

InactiveCN102633944ATo achieve the purpose of sustained releaseTo achieve the purpose of salt toleranceIsooctyl acrylateCellulose

The invention relates to a preparation method of salt-tolerance controlled-release high-water-absorption resin with hydrophobic chain segments. At present, acrylic-acid-series high-water-absorption resin has many defects and particularly has the defects that the salt tolerance is poor and the water absorbing capacity is easy to be weakened remarkably and normally is weakened to dozens of times from hundreds of times under the action of metal ions, therefore, the improvement of the salt tolerance of the high-water-absorption resin has significance. According to the invention, the high-water-absorption resin with a three-dimensional cross-linked network is formed through copolymerization of acrylic-acid hydrophobic monomers such as butyl methacrylate, iso-octyl methacrylate, n-decyl methacrylate, lauryl methacrylate, lauryl methacrylate or octadecyl methacrylate with acrylic acid, acrylic amide and carboxymethy cellulose under the existence of initiator and cross-linking agent. Compared with the high-water-absorption resin without the hydrophobic chain segments, the high-water-absorption resin disclosed by the invention has the advantages that the magnification on absorption of 0.9% sodium chloride solution is improved by 89.28%, and the water retention is improved by 13.15%.

Owner:SHAANXI UNIV OF SCI & TECH

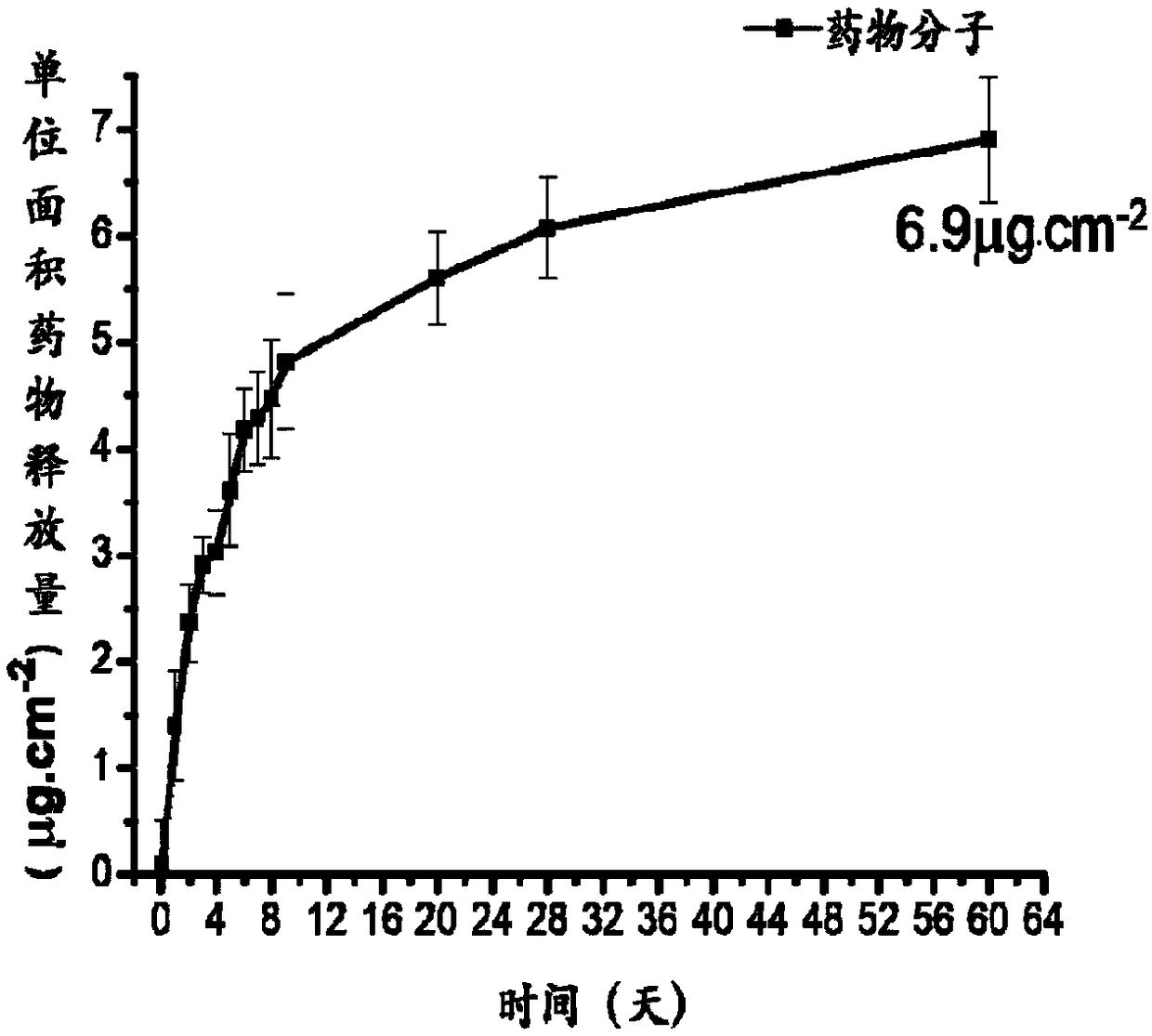

Multi-drug controllable-loading and long-acting slow-released biomedical coating material and preparation method thereof

ActiveCN108815552AControl loading typeControl releaseSurgical adhesivesAbsorbent padsLayer by layer self assemblyDopamine

The invention provides a multi-drug controllable-loading and long-acting slow-released biomedical coating material and a preparation method thereof. A preparation process comprises the following steps: polishing, washing and drying a substrate material, soaking in dopamine solution (a negative charge layer), and using a catechol-modified multi-amino biomacromolecule (with a positive charge), electronegative macromolecular solution (with a negative charge), and micelle (with a negative charge) loading multiple drugs as three components of layer-by-layer self-assembly, and preparing a coating modified material on a dopamine-processed substrate by using the above three components through a layer-by-layer self-assembly method. Multiple assembling layers can be repeatedly coated, and multiple drug molecules are largely and orderly fixed on a self-assembling coating, so that controllable long-acting release of a drug is realized.

Owner:SICHUAN UNIV

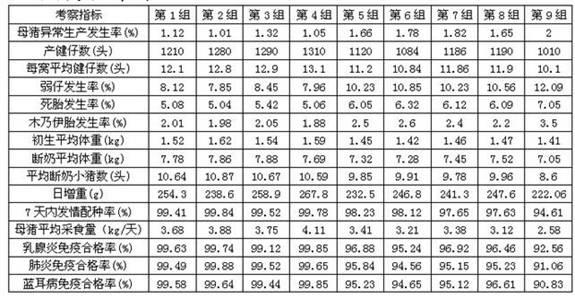

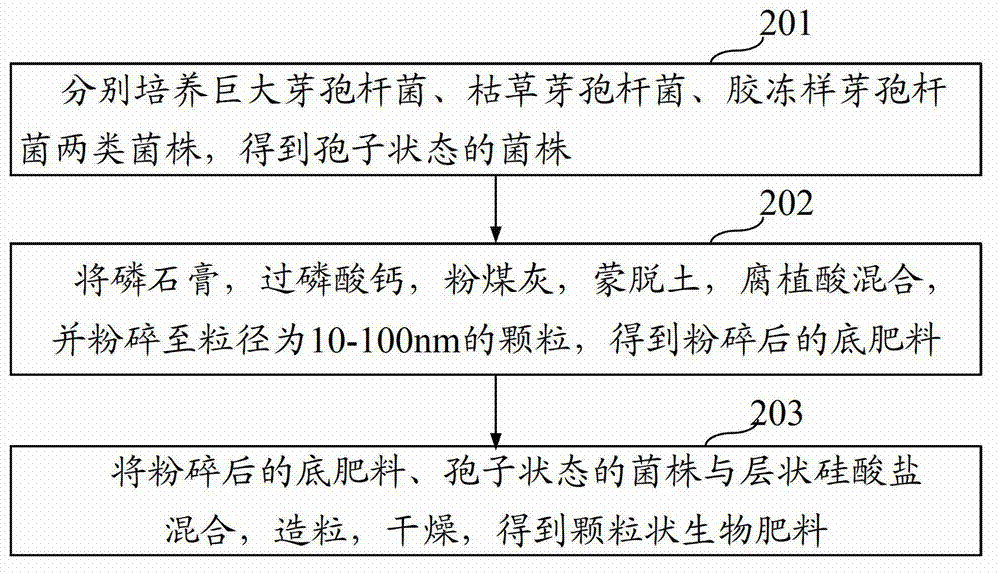

Tilmicosin micro-capsule preparation and preparation method thereof

InactiveCN102688220AMask bitternessProlong the action timeAntibacterial agentsOrganic active ingredientsWaxAcrylic resin

The invention relates to a tilmicosin micro-capsule preparation, and in particular relates to a tilmicosin micro-capsule preparation and a preparation method of the tilmicosin micro-capsule preparation, belonging to the technical field of veterinary medicine. The tilmicosin micro-capsule preparation comprises an inner core layer and a coating layer, wherein the inner core layer comprises a tilmicosin raw material and macromolecule auxiliary materials, the macromolecule auxiliary materials are selected from one or more than one of 12-carbon fatty acid-18-carbon fatty acid, paraffins and vegetable wax; and the coating layer comprises an inner coating layer and an outer coating layer, wherein the material of the inner coating layer is one or more than one of starch, calcium carbonate and calcium hydrophosphate, and the material of the outer coating layer is acrylic resin. The tilmicosin micro-capsule preparation disclosed by the invention is tasteless, enteric, and good in palatability. According to the invention, the tilmicosin is packed by the macromolecule auxiliary materials, a layer of enteric coating layer is sprayed on the surfaces of the tilmicosin grains in the process of rolling circle when the materials are prepared, and the strong bitter taste and odor of the tilmicosin can be completely covered due to the double-layer package, and the preparation method is simple in technology, and low in cost.

Owner:HUZHOU AIBAOLAI ANIMAL PHARMA

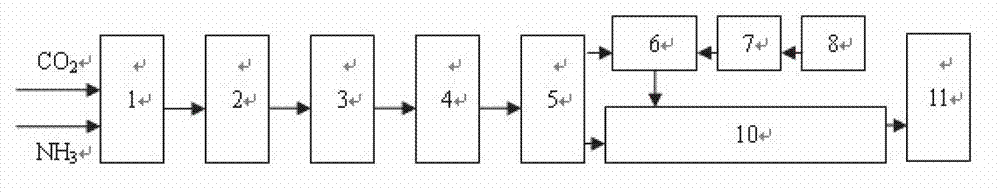

Slow release urea and preparation method thereof

ActiveCN102898234ARich sourcesLow priceUrea compound fertilisersFertilizer mixturesCoated ureaMoisture

The invention discloses a slow release urea, which comprises the following effective components in parts by weight: 85-98.8 parts of urea, 1-14% parts of bentonite, 0.01-0.5 part of polyacrylamide and 0.01-0.5 part of sodium salt or solution of the sodium salt on the basis of the sodium content. The invention provides a new thought for lowering the urea releasing rate, the slow release action on the urea is different from coated urea and stable urea, the slow release action of the slow release urea is through the diffusion process of moisture in a urea crystal, and water-proof layers are formed layer by layer from outside to inside along with moisture osmosis so as to achieve the slow release purpose.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Microcapsule containing dimethyl phthalate, mosquito repellent water and preparation method thereof

ActiveCN106137780AReduce stimulationAchieve slow releaseCosmetic preparationsToilet preparationsPolythylene glycolLotion

The invention provides a microcapsule containing dimethyl phthalate, mosquito repellent water and a preparation method thereof. The microcapsule disclosed by the invention comprises dimethyl phthalate, chitosan and gamma-polyglutamic acid. The dimethyl phthalate is coated by utilizing chitosan and polyglutamic acid and is separated from skin, so that irritation to skin is reduced, slow release of the mosquito repellent is realized, and then a mosquito repellent effect is lasting. The mosquito repellent water disclosed by the invention comprises the following main components: the microcapsule containing dimethyl phthalate, aloe extract, hyaluronic acid, polyethylene glycol, propylene glycol, rose hydrosol, water and the like, has the effects of moisturizing, resisting bacteria, diminishing inflammation, relieving itching and the like and is safe and non-toxic. The microcapsule is simple in preparation process, and the wall material has renewability and biodegradability and is non-irritating to skin. According to the mosquito repellent water disclosed by the invention, the dimethyl phthalate is separated from the skin by utilizing the microcapsule, so that bad reactions are reduced; and moreover, a slow release aim of the dimethyl phthalate is achieved, the concentration of the dimethyl phthalate in toning lotion can be reduced, and the effective mosquito repellent time is prolonged.

Owner:广州睿森生物科技有限公司

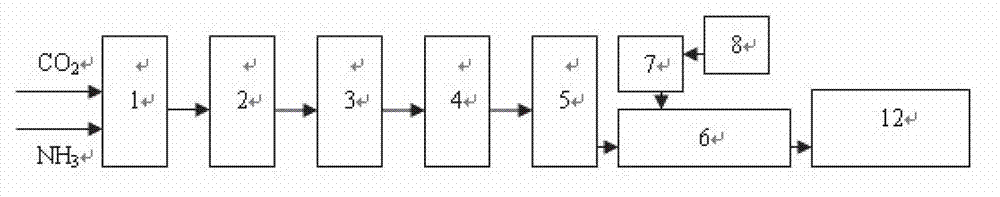

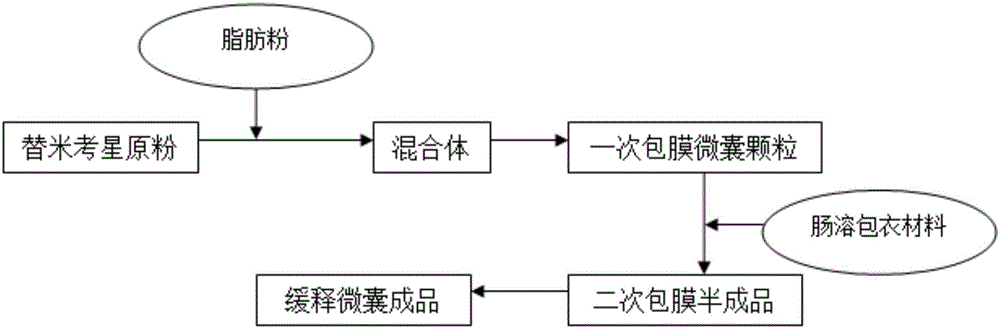

Enteric-coated tilmicosin sustained release microcapsule and preparation method thereof

InactiveCN106176680AProlong the action timeTo achieve the purpose of sustained releaseAntibacterial agentsOrganic active ingredientsDispersityAcrylic resin

The invention discloses an enteric-coated tilmicosin sustained release microcapsule and a preparation method thereof, and belongs to the field of tilmicosin preparations. The enteric-coated tilmicosin sustained release microcapsule is prepared from 10wt%-50wt% of raw tilmicosin powder, 40wt%-88wt% of an auxiliary fatty powder material and 2wt%-10wt% of an enteric coating material, wherein the enteric coating material is prepared from one or more of cellulose acetate phthalate, hydroxypropyl methylcellulose phthalate, L-type acrylic resin, S-type acrylic resin, polyvinyl acetate phthalate and hydroxypropyl methylcellulose acetate succinate; the diameter of the prepared microcapsule is 50-200 mu m. The preparation method comprises the steps as follows: the raw tilmicosin powder and the auxiliary material are subjected to primary coating, are subjected to secondary coating with the enteric coating material and then are dried, and a finished product is obtained. According to the enteric-coated tilmicosin sustained release microcapsule and the preparation method thereof, the sustained release purpose is achieved, the acting time of tilmicosin is prolonged, the fluidity and the dispersity of a drug are improved, the pharmacodynamical function is remarkably improved, and the dosage of the drug is reduced.

Owner:GUANGZHOU GREAT BIOLOGICAL TECH

Nano microorganism organic and inorganic compound fertilizer and production method thereof

ActiveCN103030471APromote growthTo achieve the purpose of disease resistanceFertilizer mixturesBacillus megateriumPotassium

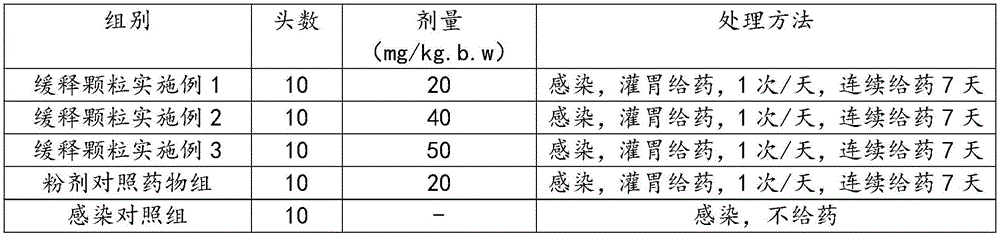

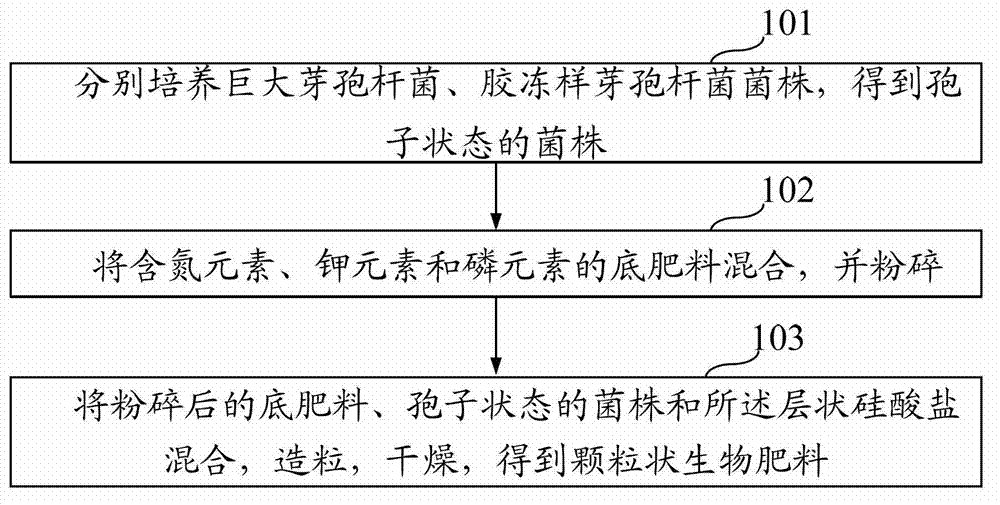

The invention relates to the agricultural field and the environment-friendly field, in particular to nano microorganism organic and inorganic compound fertilizer and a production method thereof. The fertilizer comprises the following components in parts by weight: 5 to 40 parts of layered silicate, 0.1 to 0.25 part of bacillus megaterium, 0.1 to 0.25 part of bacillus mucilaginosus, 0.1 to 0.25 part of bacillus subtilis, and 0.1 to 0.25 part of base fertilizer containing nitrogen element, potassium element and phosphor element, wherein the nitrogen element, the potassium element and the phosphor element are 6-18% of total weight of the base fertilizer. The production method comprises the following steps: strains of the bacillus megaterium, the bacillus mucilaginosus and the bacillus subtilis are cultivated respectively to obtain strains in a spore state; the base fertilizer is mixed and smashed; and the smashed base fertilizer, the strains in the spore state and the layered silicate are mixed, pelletized and dried. The fertilizer can provide the nutrition needed by crops, and can decompose nitrogen fertilizer, potassium fertilizer and phosphor fertilizer adsorbed and fixed in the soil, so that soil damage is avoided.

Owner:ZIGONG HUAQI ZHENGGUANG ECOLOGY AGICULTURE FORESTRY +1

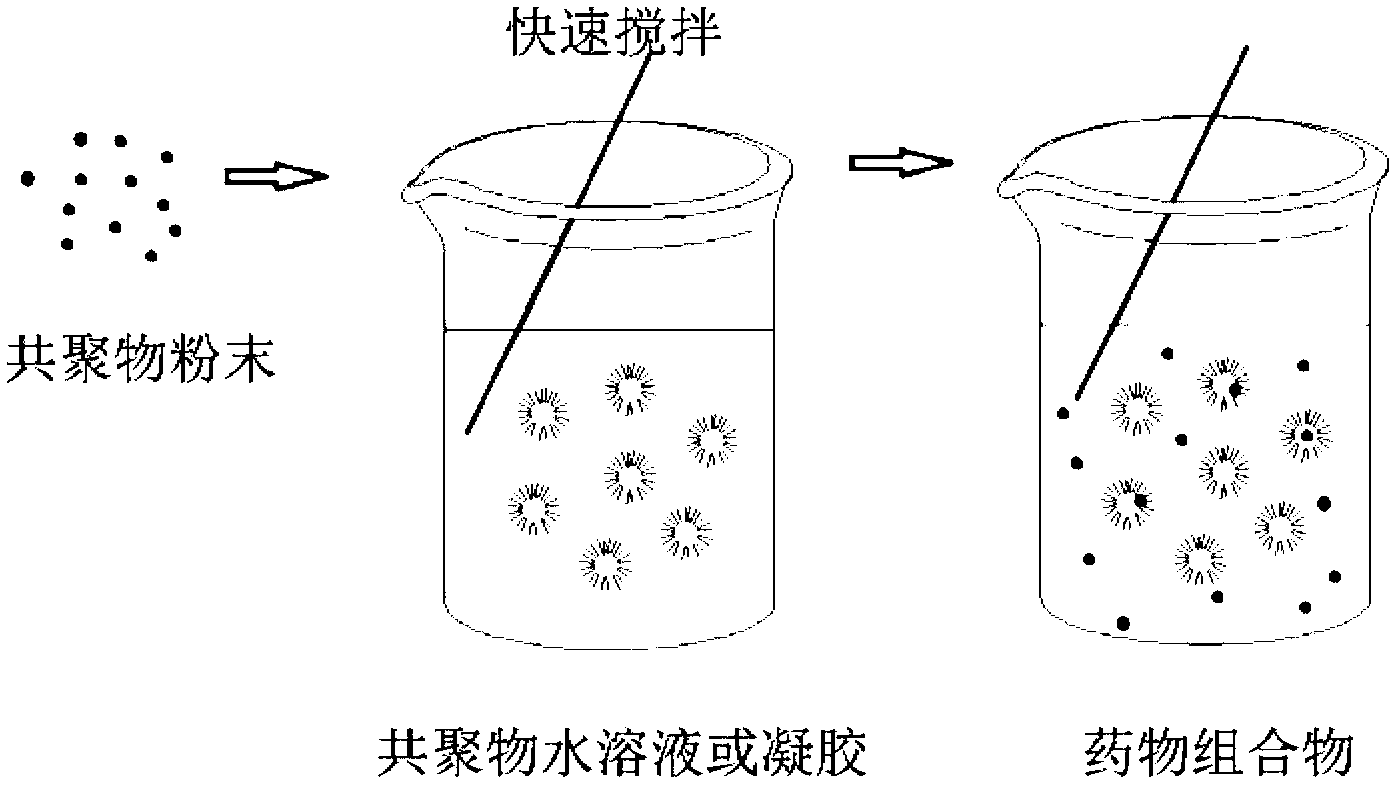

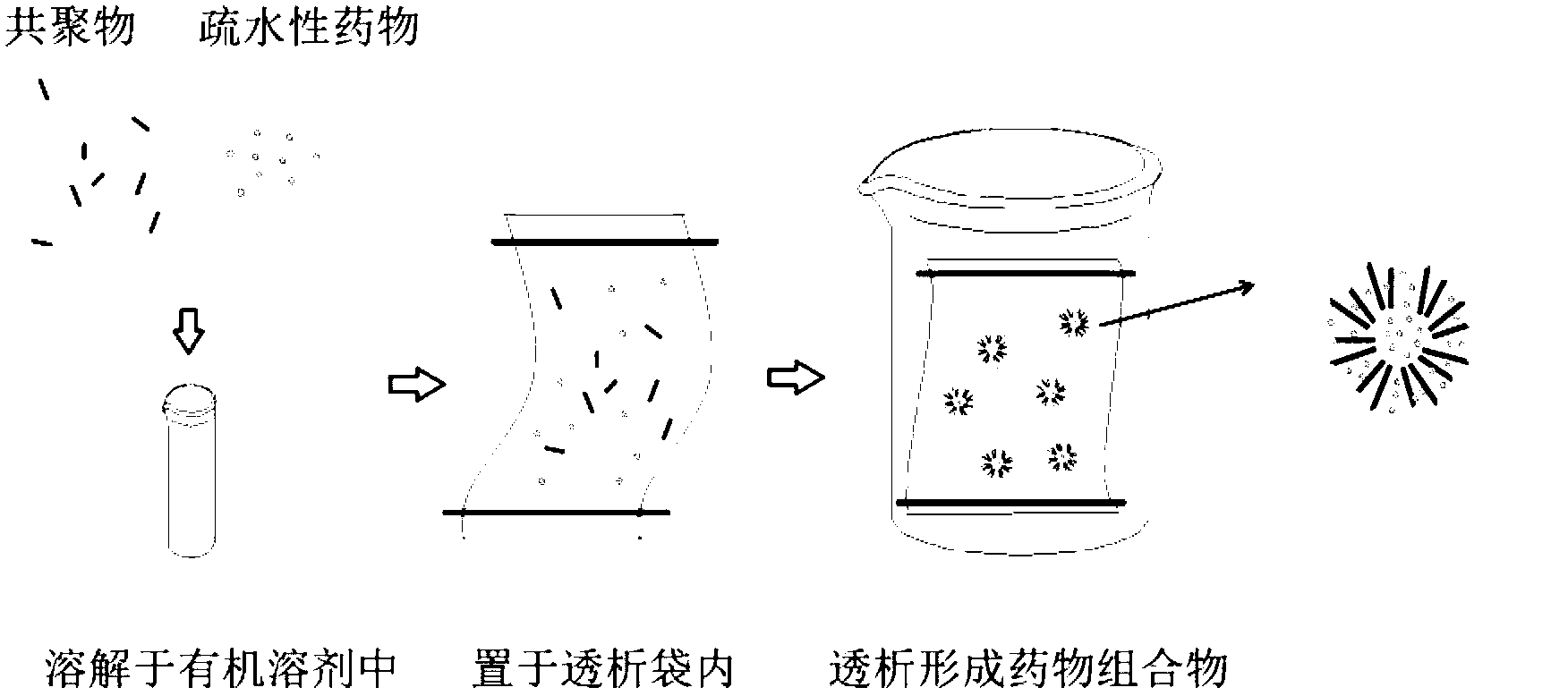

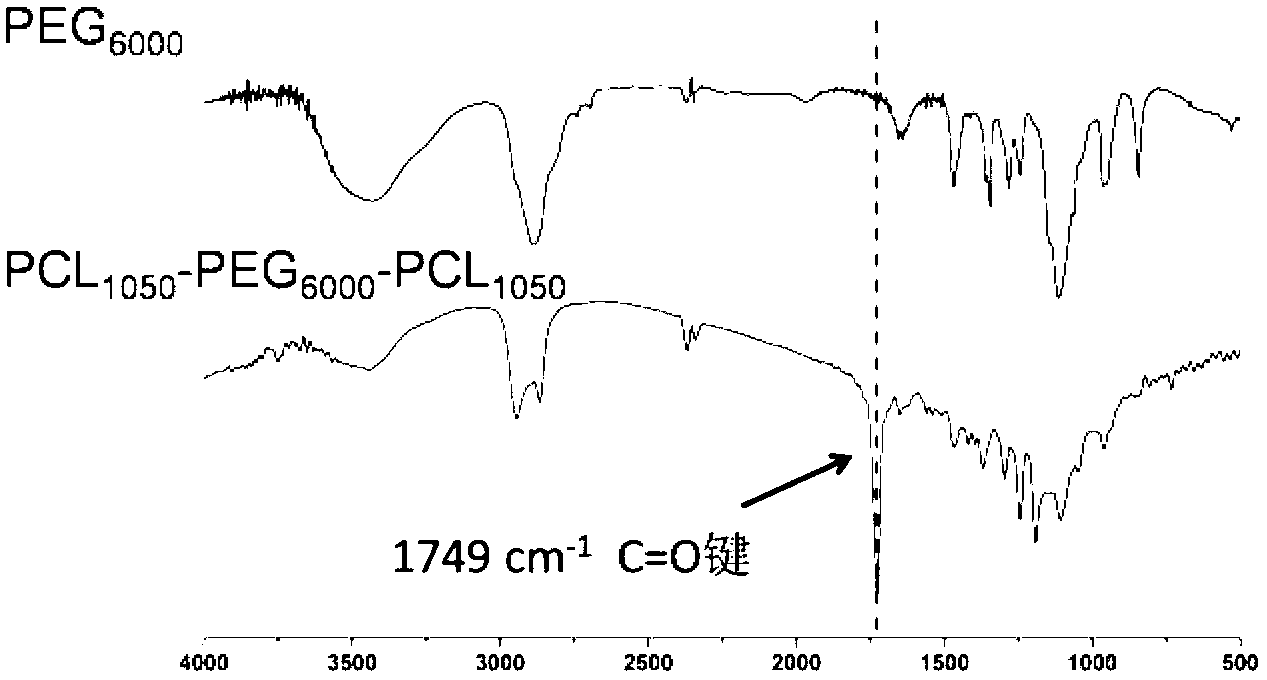

Thermo-sensitive self-assembled tri-block copolymer, pharmaceutical composition, and preparation method and application of pharmaceutical composition

ActiveCN102850532AAccurate and controllable molecular weightThe synthesis steps are simplePharmaceutical non-active ingredientsProsthesisDrug carrierPharmaceutical drug

The invention provides a PCLm-PEG6000-PCLm thermo-sensitive self-assembled tri-block copolymer, wherein the copolymer presents two-phase transition characteristics, and can be applied to a controlled release drug delivery system as a drug carrier or can be applied to tissue engineering as a biodegradable material. The invention further provides a pharmaceutical composition containing the tri-block copolymer, and a preparation method and an application of the pharmaceutical composition. A system consisting of PCLm-PEG6000-PCLm tri-block copolymer and water can both load water-soluble drugs, and can efficiently load water-insoluble drugs, and has an excellent controlled-release effect.

Owner:ZHEJIANG UNIV

Sodium iron chlorophyllin-chitosan/sodium alginate microcapsules and preparation method thereof

InactiveCN102120169ALimited dissolutionLimit diffusionOrganic active ingredientsPharmaceutical non-active ingredientsVegetable oilFiltration

The invention discloses sodium iron chlorophyllin-chitosan / sodium alginate microcapsules and a preparation method thereof. In the method, chitosan / sodium alginate is used as a capsule material, sodium iron chlorophyllin is used as capsule content, and the sodium iron (II) chlorophyllin is microencapsulated by an emulsification-gel method. The preparation method comprises: dissolving sodium iron chlorophyllin in sodium alginate solution at a certain concentration, adding the prepared solution in vegetable oil containing Span-60, and stirring at high steep and emulsifying for 20 minutes; dripping acetic acid aqueous solution containing 2.0-percent chitosan and calcium chloride, continuously stirring for 30 minutes, standing for 2 hours and removing an oil phase; and washing the microcapsules with petroleum ether and isopropanol for three times respectively, performing suction-filtration, and drying at room temperature to obtain the sodium iron chlorophyllin-chitosan / sodium alginate microcapsules. The chitosan which is a natural polysaccharide with high biocompatibility and biodegradability and the sodium alginate serve as sustained and controlled release agent and targeting preparation, the sodium iron chlorophyllin is encapsulated in the center of the microcapsules to be protected from instability caused by change in a light or placing condition, a new formulation is provided in pharmacy, and the microcapsules are suitable to be further developed and used as iron-supplying health-care food and new medicinal preparation for treating iron-deficiency anemia, and have a bright application prospect.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Litsea cubeba essence oil clathrate and preparation method thereof

InactiveCN102925290ASlow down the speed of fumigationEasy to carryEssential-oils/perfumesFreeze-dryingBULK ACTIVE INGREDIENT

The invention discloses Litsea cubeba essence oil clathrate and a preparation method of the Litsea cubeba essence oil clathrate. The method comprises the following steps: (1) preparing beta-cyclodextrin (beta-CD) saturated aqueous solution at a controlled temperature of 40-80 DEG C, stirring until smooth, and adding Tween 20 until the volume fraction of Tween 20 in beta-CD aqueous solution is 0.1%-0.5% to obtain Tween 20-containing beta-CD saturated aqueous solution; (2) adding Litsea cubeba essence oil into a solvent at volume ratio of 1:(1-4) to obtain Litsea cubeba essence oil solution; and (3) dropping Litsea cubeba essence oil solution into Tween 20-containing beta-CD saturated aqueous solution according to a ratio of 1:(8-12) mL / g of Litsea cubeba essence oil to beta-CD, stirring for 3-5 h at 40-80 DEG C, standing for 12-48 h at 0-4 DEG C for precipitation, filtering, collecting precipitate, washing, and freeze-drying to obtain Litsea cubeba essence oil clathrate. The clathrate can slowly release active ingredients of Litsea cubeba essence oil, has lasting effects in resisting mildew / bacteria and refreshing air, and is convenient to carry and use.

Owner:GUANGDONG INST OF MICROORGANISM

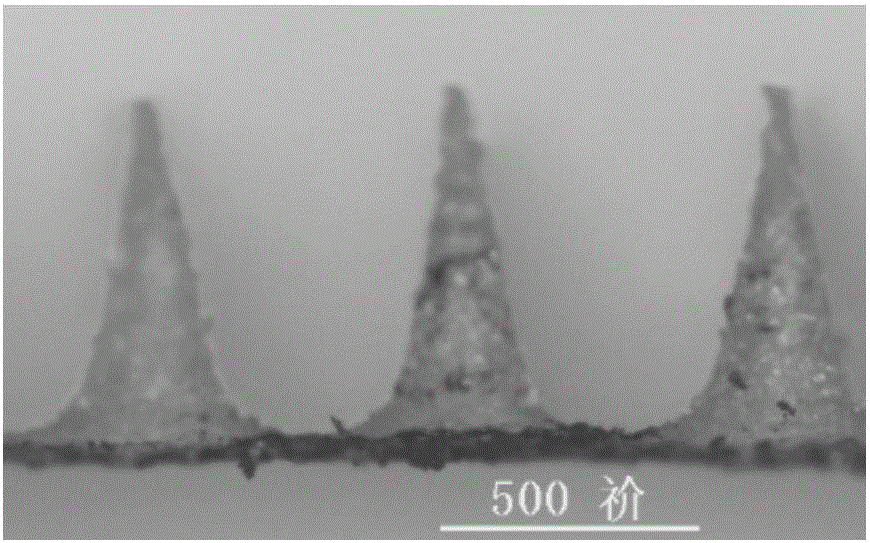

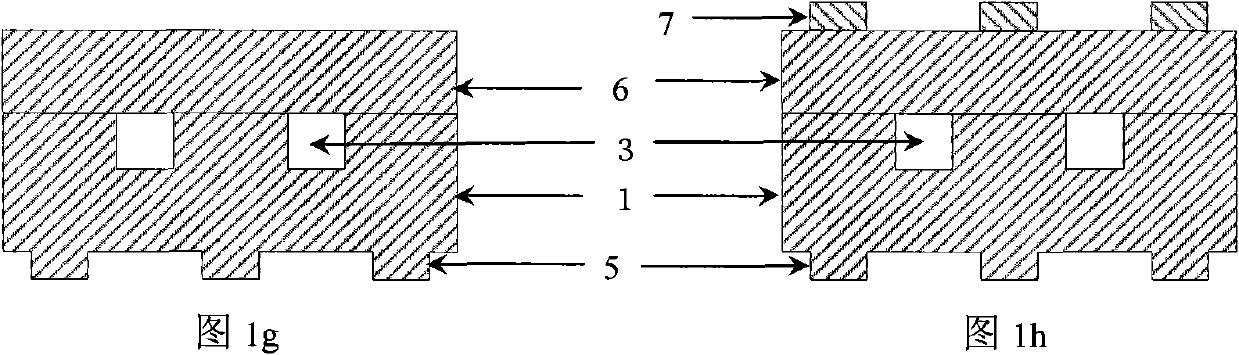

Method for preparing off-plane hollow microneedle array for use in transdermal medicament administration

InactiveCN101862503ATo achieve the purpose of sustained releasePrecise deliveryMicroneedlesMedical devicesMaterial PerforationMicro-needle

The invention discloses a method for preparing an off-plane hollow microneedle array for use in transdermal medicament administration, which comprises: growing a mask film on one side of a metal substrate, defining a microneedle array pattern to form a mask film pattern, and forming a perforation mark which is aligned with the mask film pattern on the other side of the metal substrate; protectingthe side with the perforation mark, and etching the metal substrate till the mask film falls off to form the off-plane microneedle array; and removing the protection of the side with the perforation mark, and performing perforation according to the perforation mark to form the off-plane hollow microneedle array. In the invention, based on a micromechanical process and a positioning perforation technique, the off-plane microneedle array preparation is realized, the process is simple, the processing process of the metal substrate body of off-plane hollow microneedles is made possible, he manufacturing level of the off-plane hollow microneedles is improved greatly, and the reliability and insertion property of the microneedle array are improved.

Owner:PEKING UNIV

Antifouling polyurethane coating

InactiveCN105482677AIncrease elasticityHigh tensile strengthAntifouling/underwater paintsPaints with biocidesSilanesButanediol

The invention discloses an antifouling polyurethane coating. The antifouling polyurethane coating comprises the raw materials of perfluoroalkyl ethyl alcohol, polytetrahydrofuran ether glycol, polycarbonate diol, diphenylmethane diisocyanate, isophorone diisocyanate, 1,4-butanediol, stannous octoate, stannous oleate, amino silane, nano titanium dioxide, nano zinc oxide, nano calcium carbonate, nano ferric oxide, talc powder, a modified antifouling agent, a dispersant, ethyl cellulose, a leveling agent, propylene glycol, a film forming assistant, and deionized water. The antifouling polyurethane coating disclosed by the invention, is strong in adhesive force with a substrate, excellent in antifouling performance, and good in heat resistance, weather resistance and water resistance.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

Method for preparing hydrophobic medicament nuclear shell granule-type solid dispersion by static electricity spraying method

InactiveCN103099785AAvoid degradationInhibitory activityPowder deliveryPharmaceutical product form changeOrganic solventPropeller

The invention discloses a method for preparing a hydrophobic medicament nuclear shell structure micro / nano granule-type solid dispersion by a high-voltage static electricity spraying method, relating to the pharmaceutics and biomedical field. The method comprises the following steps of: dissolving hydrophobic medicaments and fat soluble high polymer materials together into an organic solvent, and emulsifying and dispersing the mixture into an aqueous solution containing water soluble high polymer material; then placing oil-in-water emulsion into a trace propeller, and carrying out electrostatic spraying under the effect of high-voltage electrostatic field, thereby obtaining the hydrophobic medicament nuclear shell structure micro / nano granule-type solid dispersion finally. According to the preparation method, the operation is simple, the cost is low, environmental protection is realized and industrial production is facilitated. The particle size of the prepared hydrophobic medicament nuclear shell structure micro / nano granule-type solid dispersion is controllable, and the solid dispersion has tissue and organ targeting; and the granules of the nuclear shell structure is beneficial to prolonging the medicament action time.

Owner:杨晔

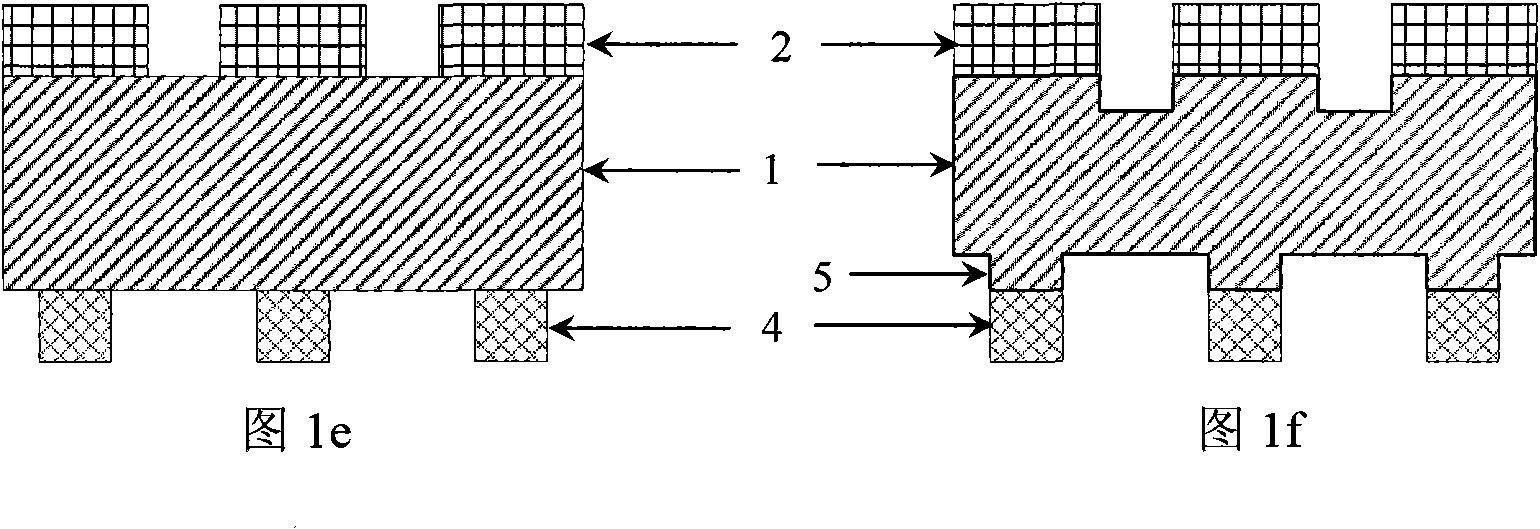

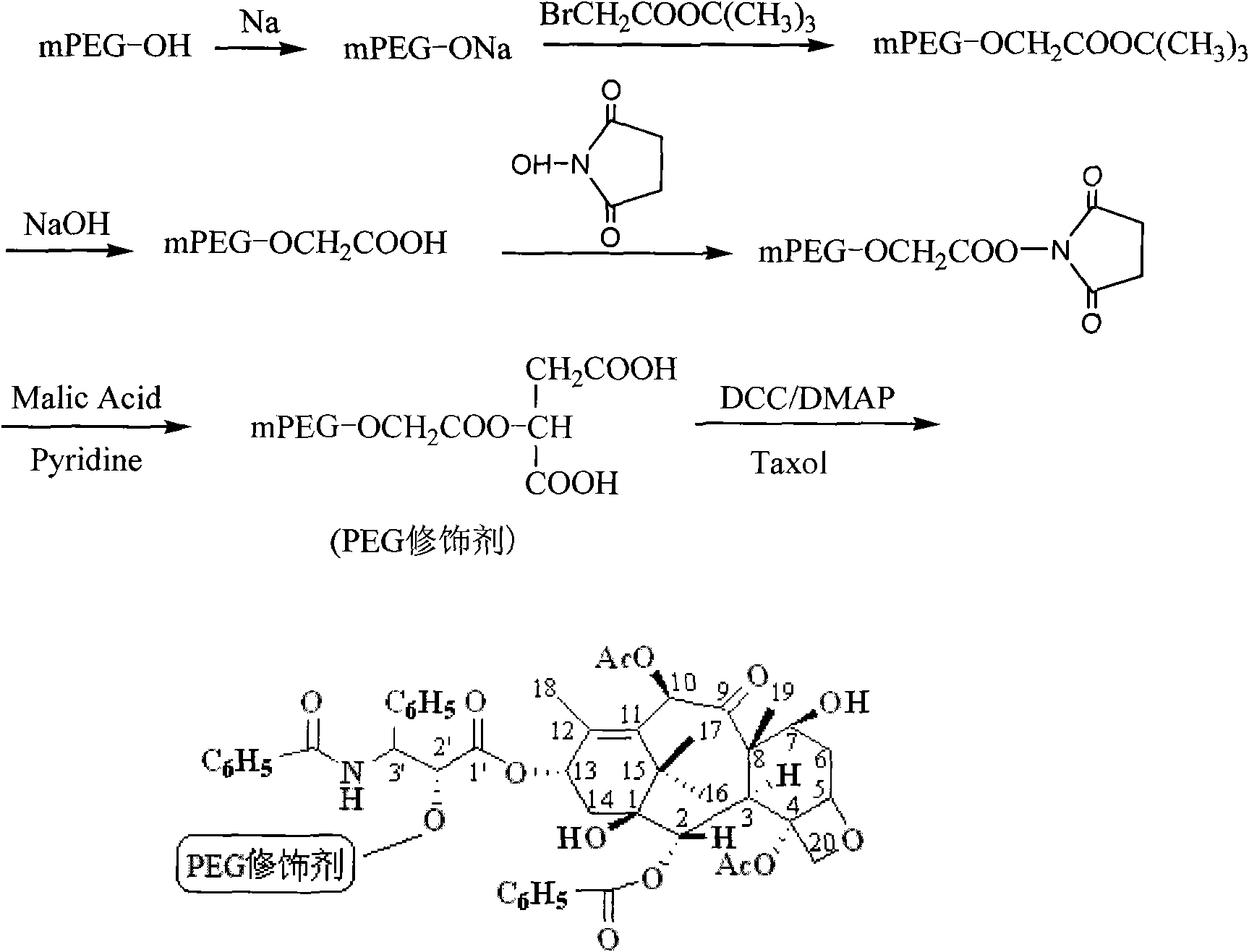

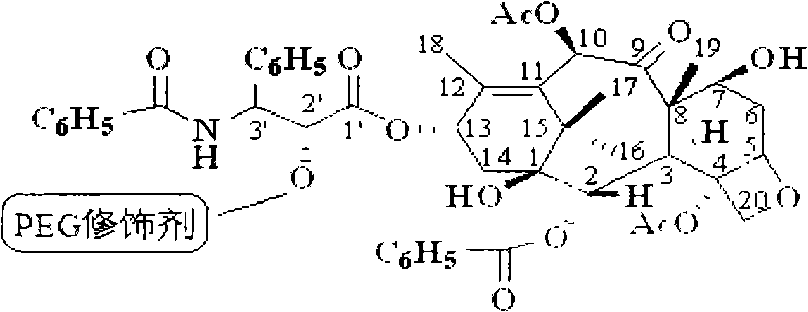

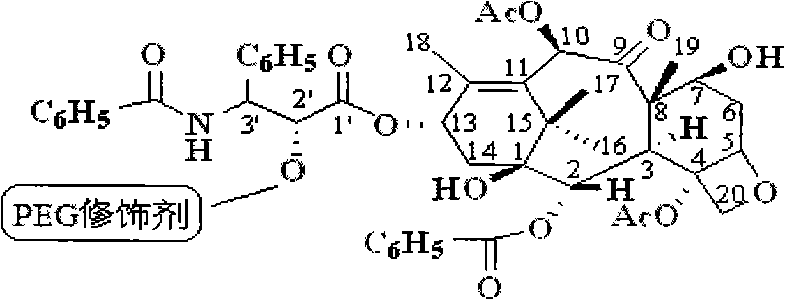

Taxol prodrug using polyethylene glycol as carrier as well as preparation method and chemical modifier thereof

InactiveCN101569747AIncrease carrying capacityImprove solubilityOrganic active ingredientsPharmaceutical non-active ingredientsSolubilityPolyethylene glycol

The invention provides a water-soluble taxol prodrug using polyethylene glycol as a carrier as well as a preparation method and a chemical modifier thereof. The water-soluble taxol prodrug uses polyethylene glycol as the carrier and malic acid as a connecting arm to prepare a branching-type polyethylene glycol derivative containing a plurality of carboxy groups. The derivative is used for decorating taxol, can greatly improve the taxol carrying capability of the polyethylene glycol, and obviously improves the dissolubility of the taxol so that the solubility of the decorated taxol is from 0.1mg / ml to 6.0mg / ml, and the taxol content in the prodrug is from 1 percent to 38 percent. The invention is beneficial to the improvement of medicament performance.

Owner:NINGBO UNIV

Preparation method of slow-release potassium ferrate water treatment agent

InactiveCN103408125AImprove stabilityProlong the action timeWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationNitrateDecomposition

The invention belongs to the technical field of environmental protection, and particularly relates to a preparation method of a slow-release potassium ferrate water treatment agent. The invention aims to provide a potassium ferrate water treatment agent with slow-release effect. The preparation method provided by the technical scheme comprises the following steps: dissolving calcium hypochlorite in a saturated potassium hydroxide solution, adding iron nitrate nonahydrate, stirring, adding kieselguhr, carrying out ice segregation, standing, and carrying out vacuum filtration, wherein the filter cake is the slow-release potassium ferrate water treatment agent. The slow-release potassium ferrate water treatment agent provided by the invention can implement slow release of potassium ferrate in a water treatment process, lower the noneffective decomposition of the potassium ferrate, and enhance the utilization effectiveness of the potassium ferrate, thereby achieving the goals of lowering the reagent consumption and enhancing the water treatment effect.

Owner:CHONGQING UNIV

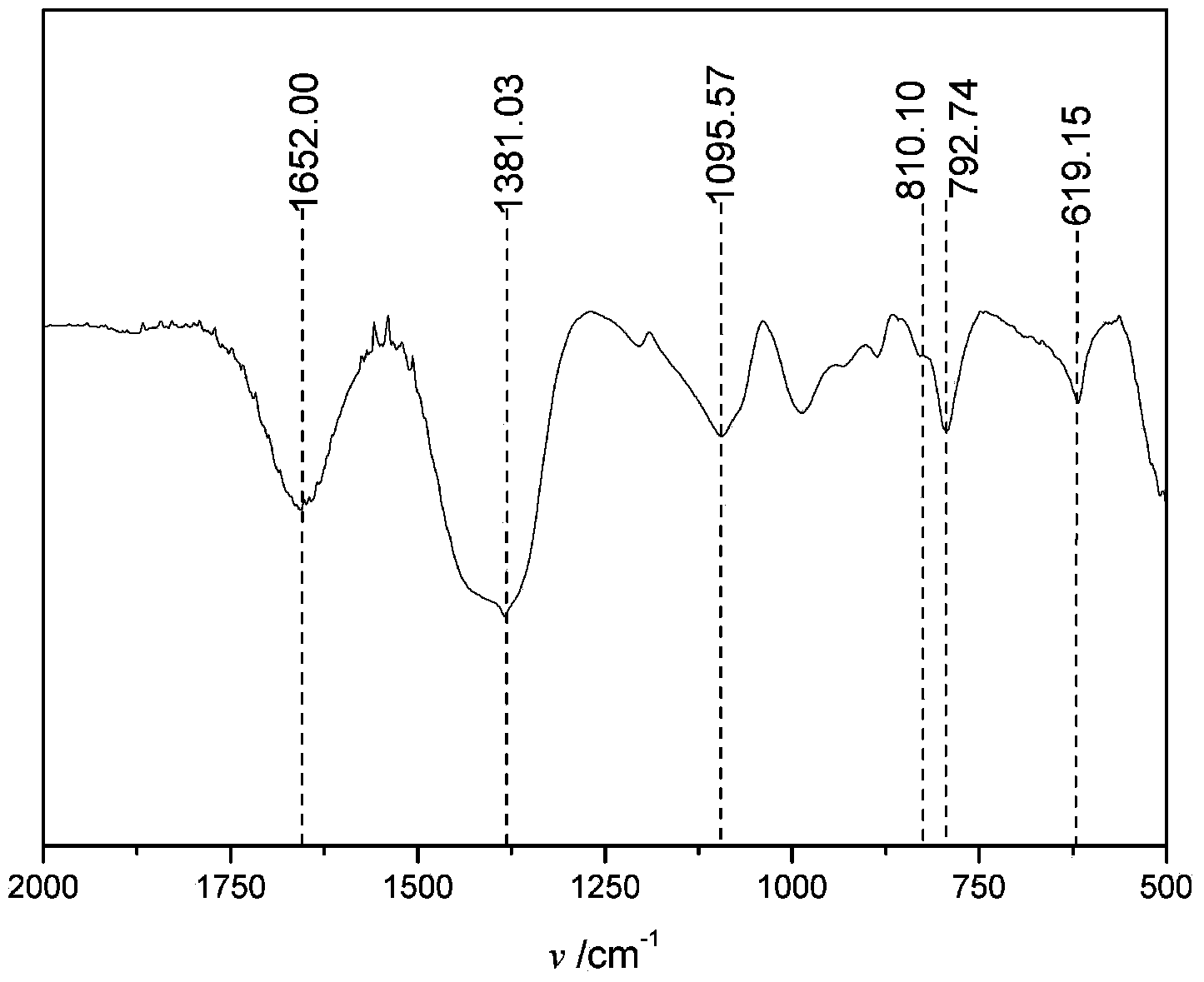

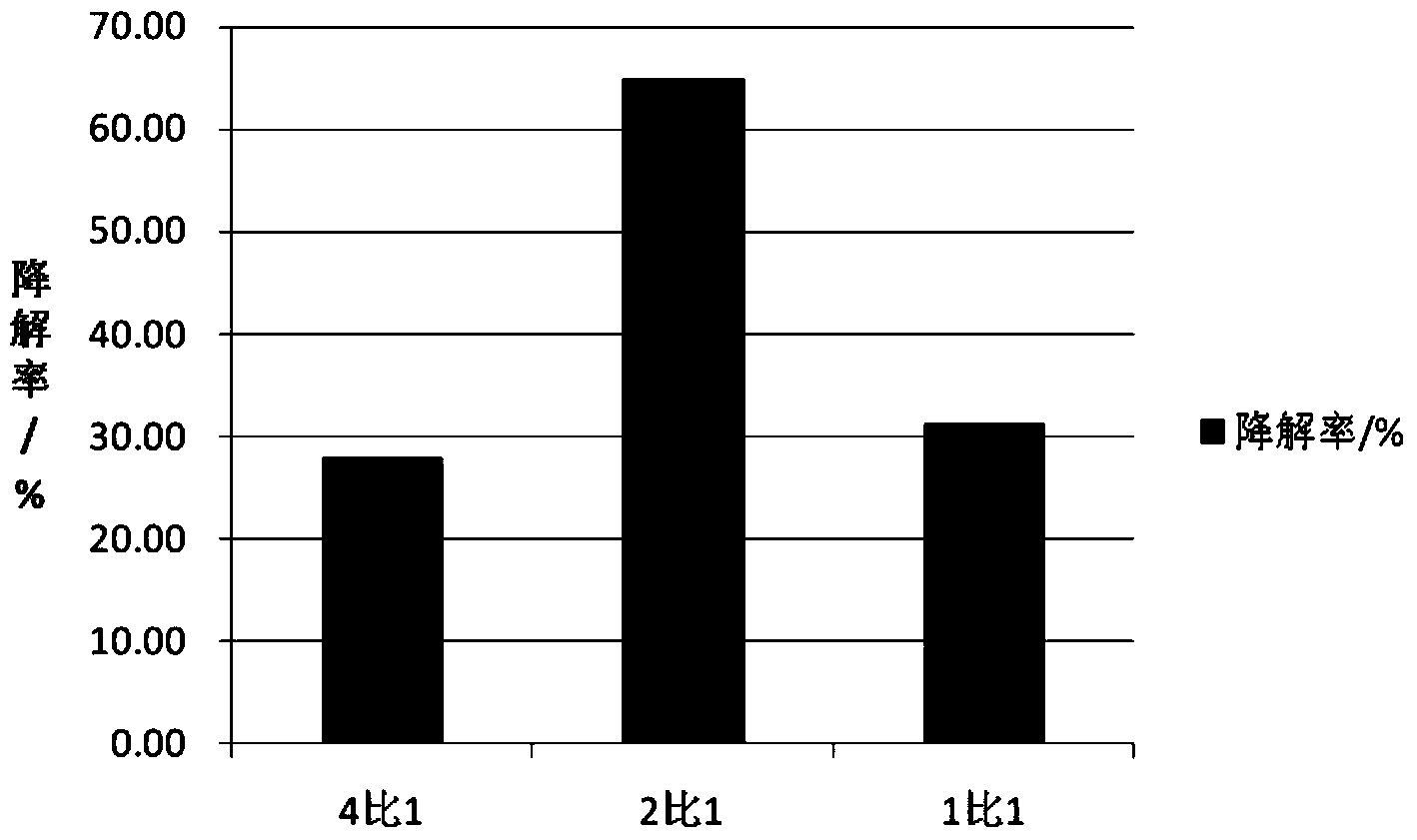

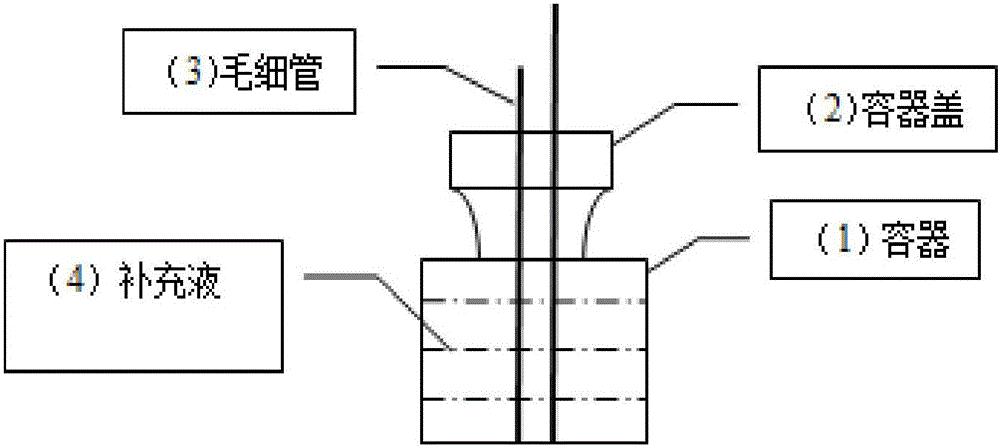

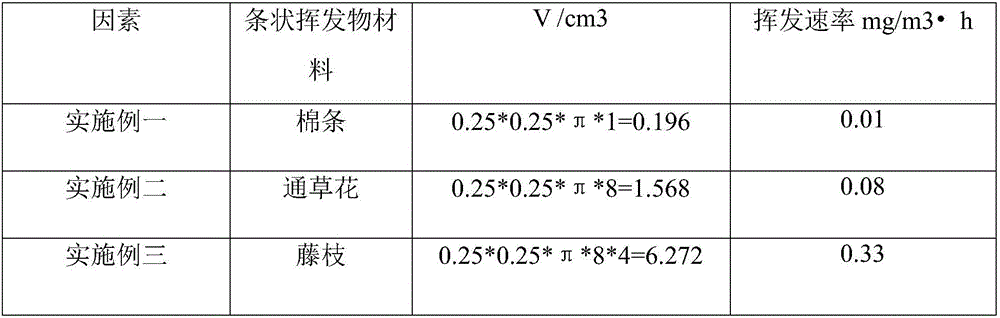

Chlorine dioxide sustained-release device and chlorine dioxide replenisher thereof

The invention relates to a chlorine dioxide slow-release device and its replenishment liquid, in particular to a chlorine dioxide slow-release device and its replenishment liquid for epidemic prevention and disinfection, food antisepsis and air purification. The device includes three parts: a container, a container cover, and a strip-shaped volatile matter. The supplement liquid includes the following parts by weight: 1-15 parts of sodium chlorite, 1-15 parts of activator, 1-10 parts of thickener, 1-5 parts of stabilizer, 0.5-2 parts of air barrier agent, 53-5 parts of purified water 95.5 servings. The beneficial effect of the device is to stably preserve the activated chlorine dioxide liquid, and to control the amount of moisture and air in contact with the strip-shaped volatiles by increasing and / or reducing the total area exposed to the strip-shaped volatiles in the air. Control the amount of chlorine dioxide released. According to the scale prompt on the container, when the chlorine dioxide liquid drops to a certain level, open the container cover, add replenishing liquid, and it can be recycled. It has the advantages of simple preparation process, low cost, convenient use and environmental protection.

Owner:兰州泰坦生物科技有限责任公司

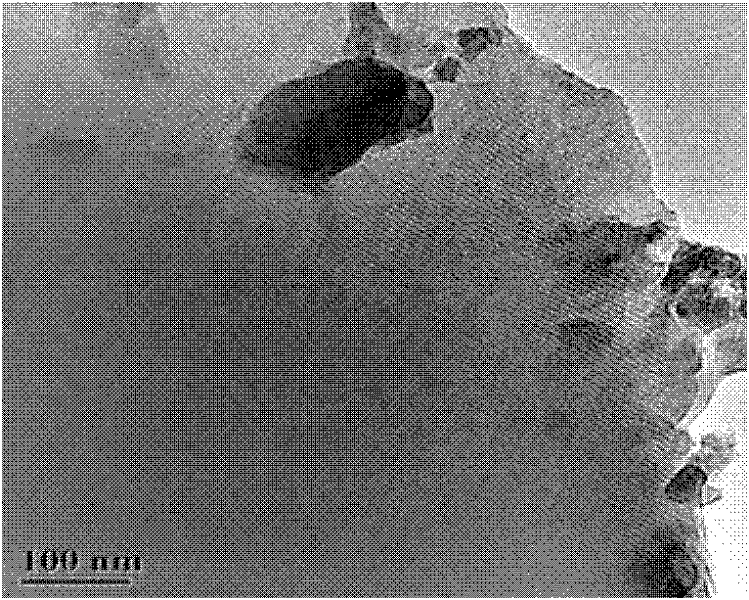

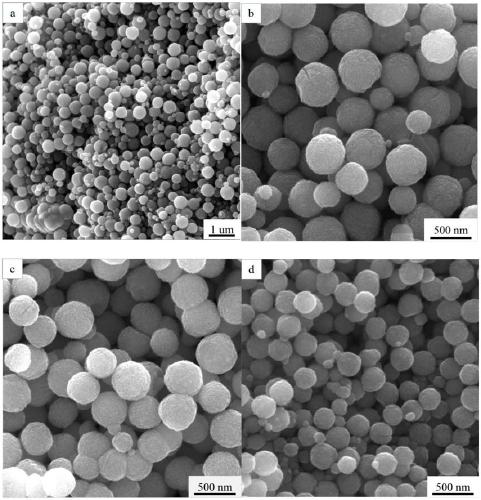

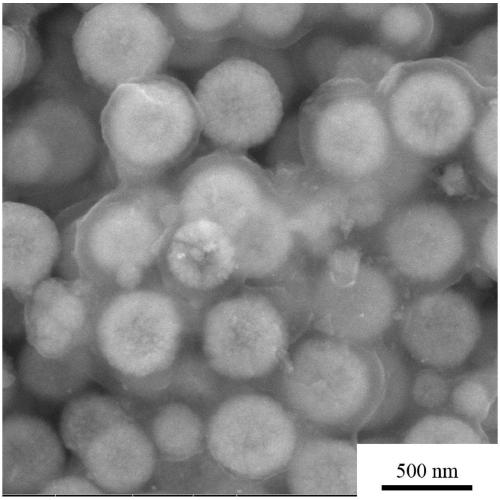

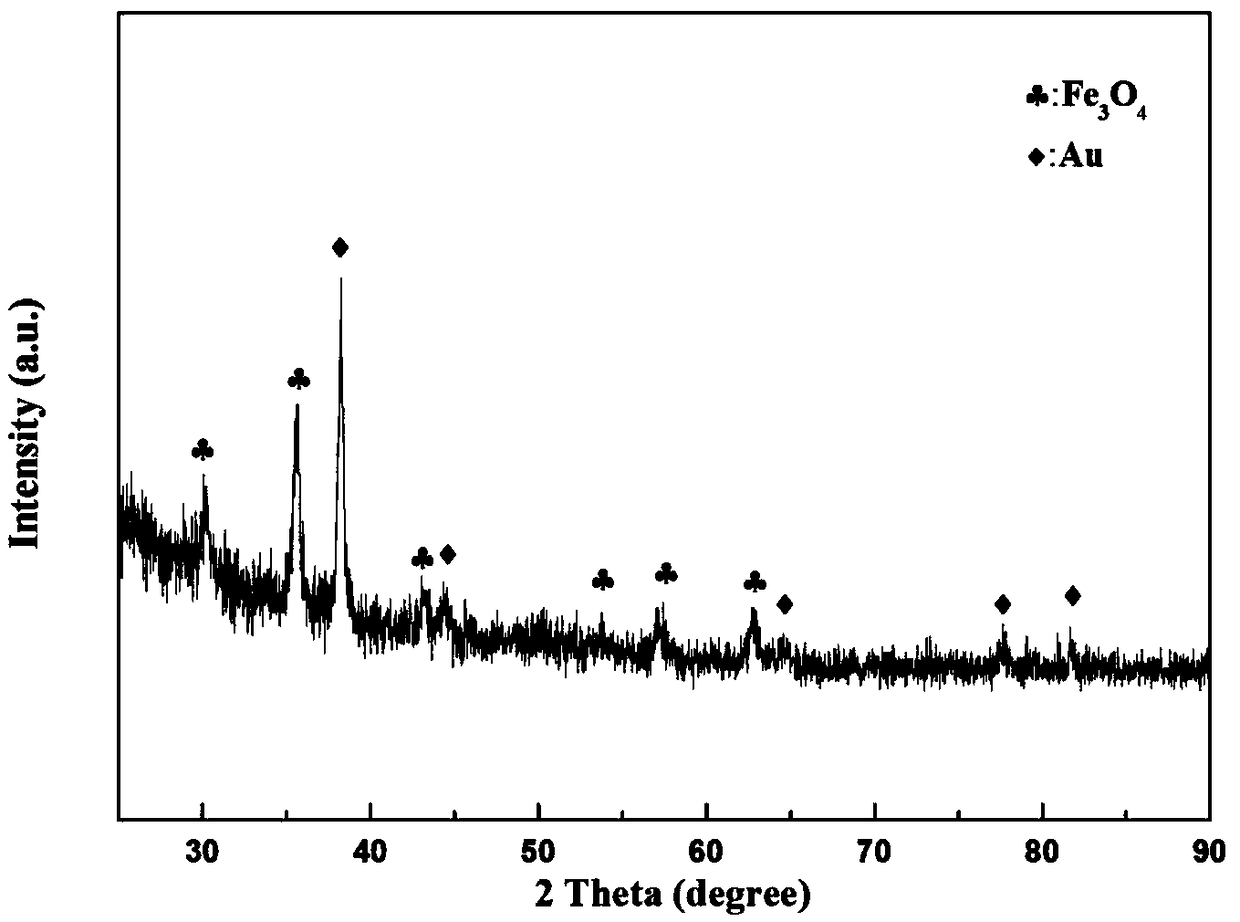

Preparation method for carbon-coated ferroferric oxide nano-shell-loaded nano gold particles

InactiveCN109133189AReaching Medical Imaging PropertiesTake advantage of medical imaging featuresOrganic active ingredientsTransportation and packagingGold particlesCarbon coated

The invention discloses a preparation method for carbon-coated ferroferric oxide nano-shell-loaded nano gold particles. The method is capable of, according to an Ostwald ripening theory, and through aferroferric oxide nano-shell prepared by using a soft template method in advance, using glucose as a carbon source and performing hydrothermal coating, finally loading nanogold by using a chemical reduction method. The obtained ferroferric oxide nano-shell is a carbon-coated ferroferric oxide hollow-core nano-shell. Compared with a solid nano-shell, the carbon-coated ferroferric oxide hollow-corenano-shell is large in specific surface area, and high in drug loading ratio. On the other hand, a shell structure is capable of controlling burst release of a drug so as to achieve a purpose of slowrelease.

Owner:HEBEI UNIV OF TECH

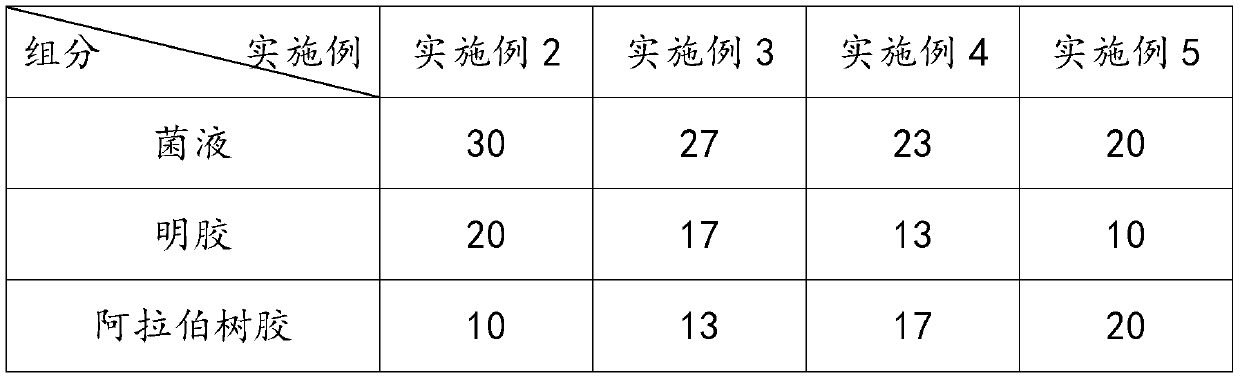

Preparation method of peppermint oil microcapsules

InactiveCN105413597ATo achieve the purpose of sustained releaseHydrophobicMicroballoon preparationMicrocapsule preparationPeppermintsSolvent

The invention discloses a preparation method of peppermint oil microcapsules. The preparation method comprises steps as follows: ethanol and tween-80 are mixed, and a carrier solution is obtained; peppermint oil is added to the carrier solvent and dissolved, and a core material I is obtained after uniform stirring and mixing; the core material I is added to a hydroxypropyl beta cyclodextrin solution and uniformly stirred, and a core material II is obtained; the core material II is added to a gelatin solution and has a sufficient reaction, and an Arabic gum solution is added; the systematic solution is adjusted to be acidic, formaldehyde is added for cross-linking and curing after rapid cooling, and the pH (potential of hydrogen) value is adjusted until the mixture is alkaline; the mixture is left to stand until complete precipitation and washed to be neutral with water after filtering, and a product is obtained after vacuum drying. The preparation method has the advantages that the embedding rate of the prepared microcapsule can be up to 90% or higher, the method is simple, effective ingredients of a cooling agent don't easily volatilize and the like.

Owner:ANHUI FENGLE PERFUME

Calophyllum inophyllum kernel oil included lecithin liposome and application thereof in soothing scar-fading products

ActiveCN105662896AStrong anti-inflammatoryPromote regenerationCosmetic preparationsToilet preparationsCalophyllum inophyllumAdditive ingredient

The invention provides calophyllum inophyllum kernel oil included lecithin liposome having a core-shell structure. A core of the liposome is composed of calophyllum inophyllum kernel oil, a shell thereof is composed of lecithin, and the liposome is 19.99-72.70 nm in average particle size and 30-50% in inclusion rate. Further provided is a preparation method of the calophyllum inophyllum kernel oil included lecithin liposome and application of the calophyllum inophyllum kernel oil included lecithin liposome in soothing scar-fading products, the calophyllum inophyllum kernel oil included lecithin liposome has a percent-by-mass concentration of 30-50% in a soothing scar-fading product, and the soothing scar-fading product is scar cream, scar milk or scar gel. The liposome of the invention not only has better stability of the included active ingredient, calophyllum inophyllum kernel oil, but also can release slowly; meanwhile, the calophyllum inophyllum kernel oil included lecithin liposome has good scar-fading effect in the soothing scar-fading product.

Owner:上海京樾医疗科技有限公司

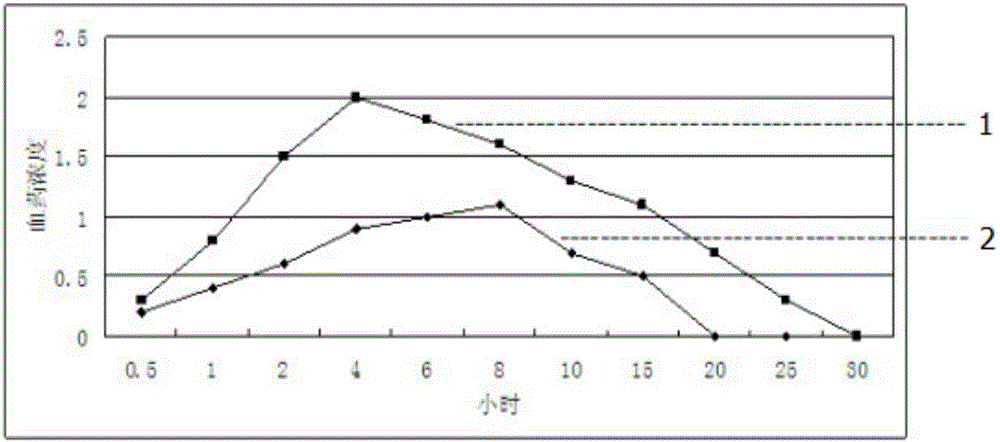

Oral slow release preparation, entrapment material and preparation method

InactiveCN102657871AProlong the action timeLong-lasting hypoglycemic effectPeptide/protein ingredientsMetabolism disorderSodium hyaluronateExenatide

The invention discloses an oral slow release preparation, an entrapment material and a preparation method. A sodium alginate-sodium hyaluronate mixture is taken as an entrapment material; and a prepared protein polypeptide medicament oral slow release preparation consists of the following components in percentage by mass: 0.5-10 percent of medicament and 90-99.5 percent of sodium alginate-sodium hyaluronate mixture. According to the oral slow release preparation, the conventional administration way of a protein polypeptide medicament is changed, the acting time of the protein polypeptide medicament is prolonged, the normal blood sugar level is maintained successfully for 12 hours when exenatide oral microspheres are taken as an example, the administration compliance of a diabetes patient is improved remarkably, and the treatment effect is enhanced.

Owner:CHINA PHARM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com