Production technology for preparing recycled aggregate from waste concrete

A technology for waste concrete and waste concrete blocks, which can be used in solid waste management, sustainable waste treatment, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

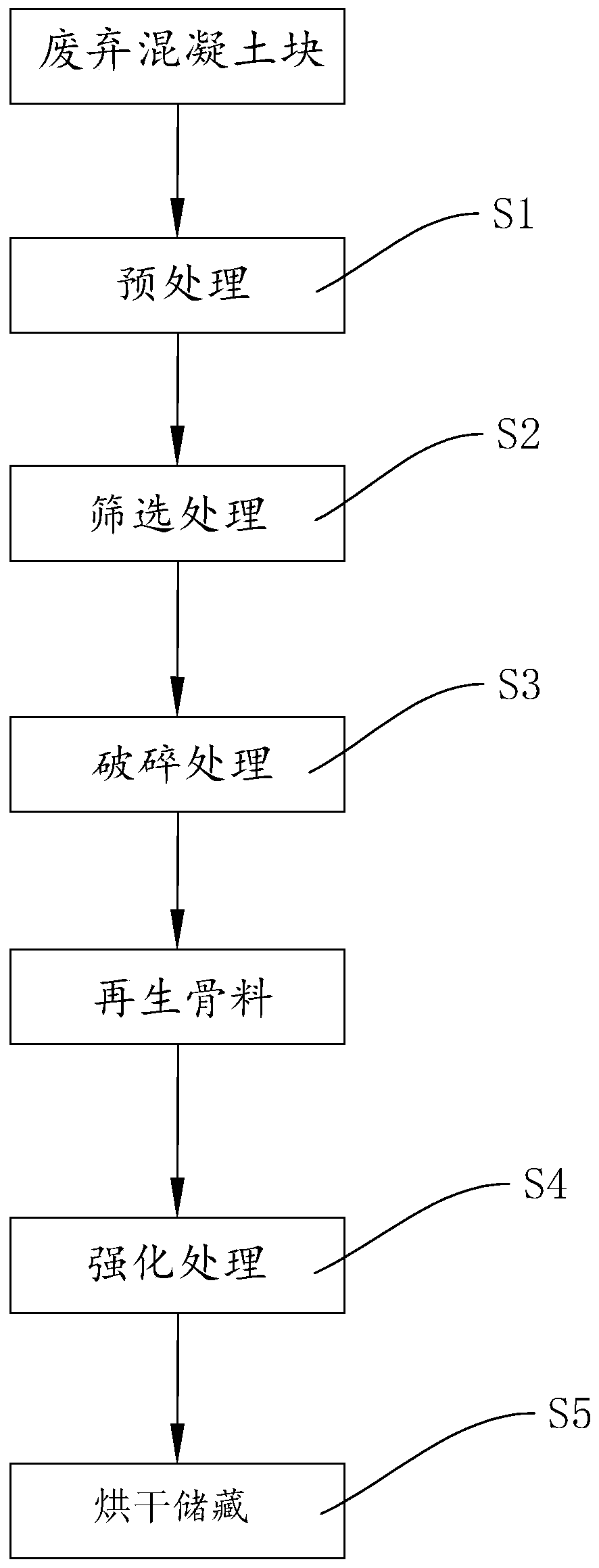

[0088] refer to figure 1 , the invention discloses a production process for preparing recycled aggregate from waste concrete, comprising the following preparation process:

[0089] S1: Pretreatment: First, spray wet treatment and anti-epidemic treatment on the waste concrete blocks, and then hammer the waste concrete blocks so that the diameter of the hammered concrete blocks is less than 50mm;

[0090] S2: screening treatment, including the following process steps:

[0091] a. Manually sort out the larger metal, rubber, plastic, wood and other garbage from the waste concrete blocks after S1 pretreatment;

[0092] b. Transport the waste concrete blocks after primary selection to the vibrating sieve, and the vibrating sieve will screen out the dust with particles smaller than 5mm;

[0093] c. Put the screened discarded concrete blocks into the clean water pool, and use ultrasonic cleaning for 30 minutes. After cleaning, let it stand for 30 minutes to remove the suspended matt...

Embodiment 1

[0120] The difference between embodiment 10-13 and embodiment 1 is that the bacterial content of the bacterial solution is as shown in the following table:

[0121] Example Example 10 Example 11 Example 12 Example 13 Bacteria content 50% 55% 65% 70%

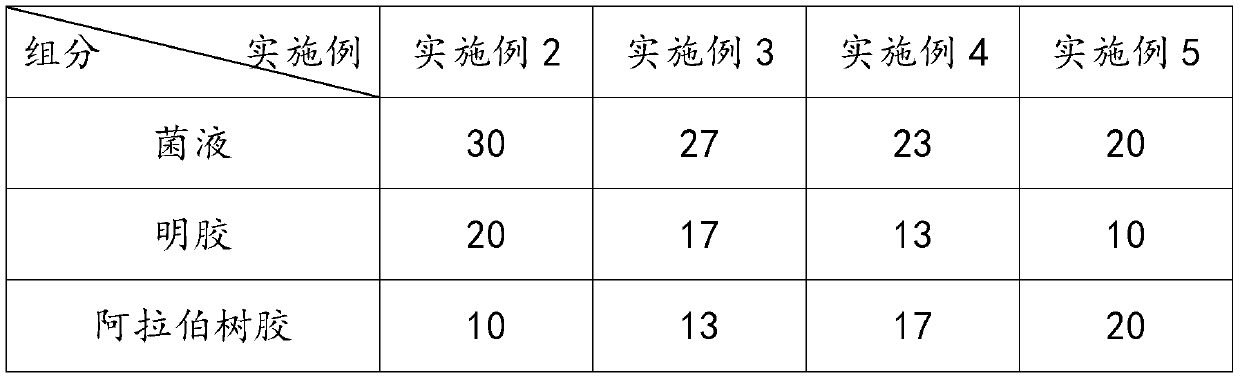

[0122] The difference between Embodiment 14-17 and Embodiment 1 is that the first auxiliary agent includes the following raw materials in weight percentage:

[0123]

[0124]

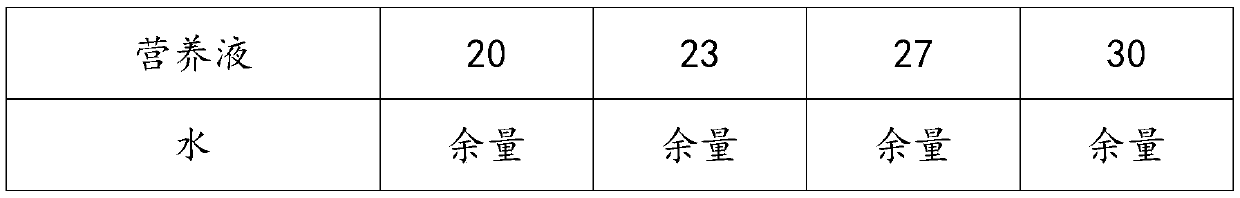

[0125] The difference between Embodiment 18-21 and Embodiment 1 is that the second auxiliary agent includes the following raw materials in weight percentage:

[0126]

[0127] The difference between embodiment 22-25 and embodiment 1 is that CO 2 The throughput is shown in the table below:

[0128] Example Example 22 Example 23 Example 24 Example 25 Throughput / (m 3 / h)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com