Slow release urea and preparation method thereof

A technology of slow-release urea and urea, applied in the field of slow-release urea and its preparation, can solve problems such as complex process, high cost, and secondary pollution of the environment, and achieve the effect of abundant sources, simple production method, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

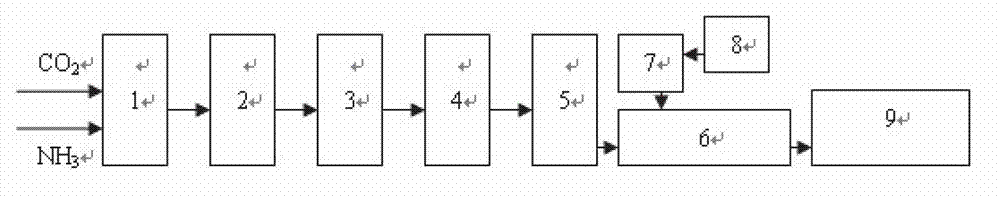

[0037] Refer to the manual attached figure 2 , Adopting industrialized urea production process, calculated according to the production of 1 t / h stable urea, its nitrogen content is 0.42 tons, and 5% bentonite, 0.5% polyacrylamide, and 0.5% sodium sulfate are pumped through a powder transfer pump. Pour the urea melted slurry pipeline after the second steaming, and mix it evenly through the pipeline mixer. Pour the obtained slow-release slurry and the original urea slurry solution into a glass tube with an inner diameter of 1 cm and a length of 10 cm, which is closed at one end. After cooling and crystallization, it was placed horizontally in 1 L of water at room temperature to dissolve and the urea content in the solution was determined. The cumulative dissolution rate-time relationship of pure urea and sustained-release urea is shown in Table 1.

[0038] Table 1 Experimental results of static water dissolution of the new sustained-release urea in Example 1

[0039]

Embodiment 2

[0042] A sustained-release urea, which is prepared from the following weight (kg) raw materials:

[0043]

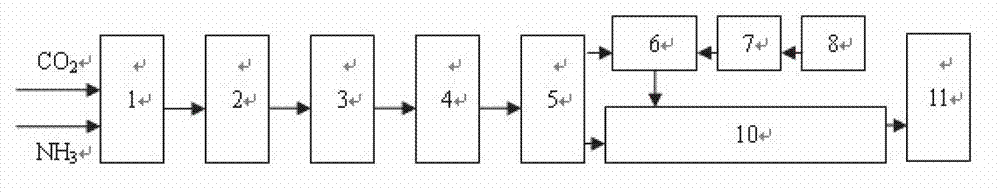

[0044] The preparation method includes the following steps:

[0045] (1) Add natural bentonite, polyacrylamide, and sodium sulfate into the urea melt pipeline, and the urea slurry obtained after melting with urea through a pipeline mixer is evenly mixed by weight to obtain a mixed slurry;

[0046] (2) The mixed slurry enters the fluidized bed through the nozzle to complete the granulation process and produce large particles of slow-release urea.

[0047] The obtained sustained-release urea and ordinary urea were subjected to sand column leaching experiment, the method is as follows: 0.5g absorbent cotton and 150g sand (30 mesh to 60 mesh) were wet packed into the leaching device in turn, and then the same amount of nitrogen was built in Net-type slow-release urea and ordinary urea are spread on the sand in the respective leaching tubes, then covered with 30g dry sand, leached wi...

Embodiment 3

[0051] A slow-release urea, which is prepared from the following weight (kg) raw materials:

[0052]

[0053]

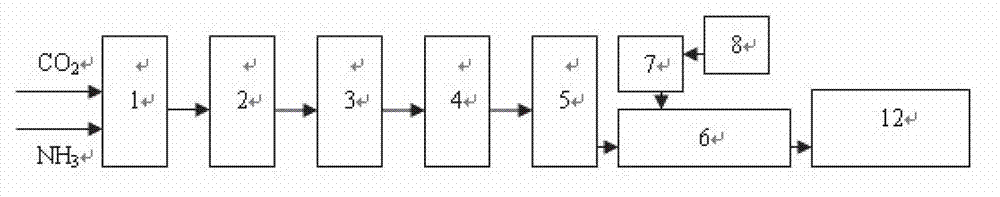

[0054] The preparation method refers to Example 2, and the obtained sustained-release urea and ordinary urea were subjected to a sand column leaching experiment. The leaching rate results are shown in Table 3:

[0055] Table 3 Example 3 Addition method cumulative dissolution rate sand column leaching experiment

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com