Patents

Literature

31results about How to "Promote water swelling" patented technology

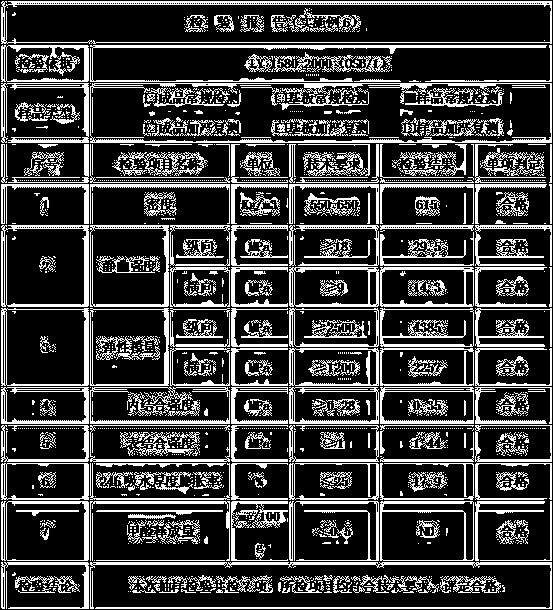

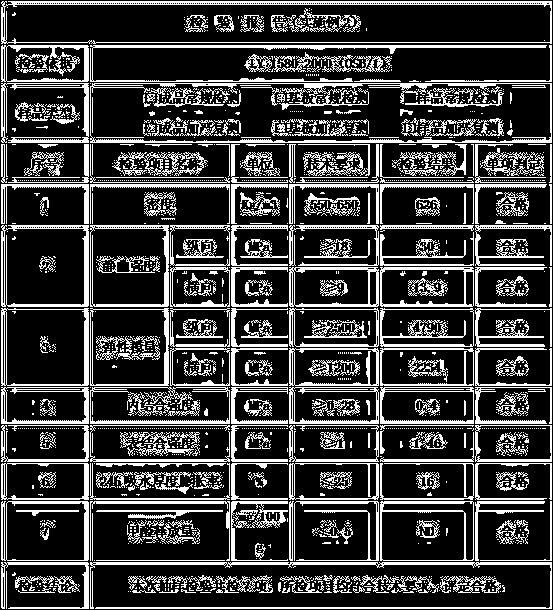

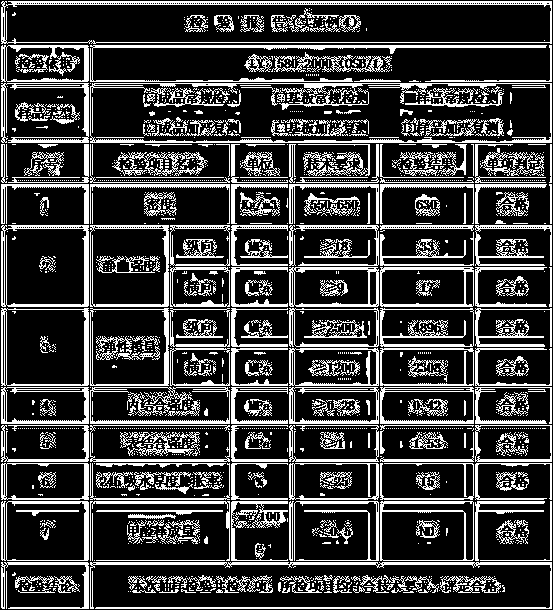

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

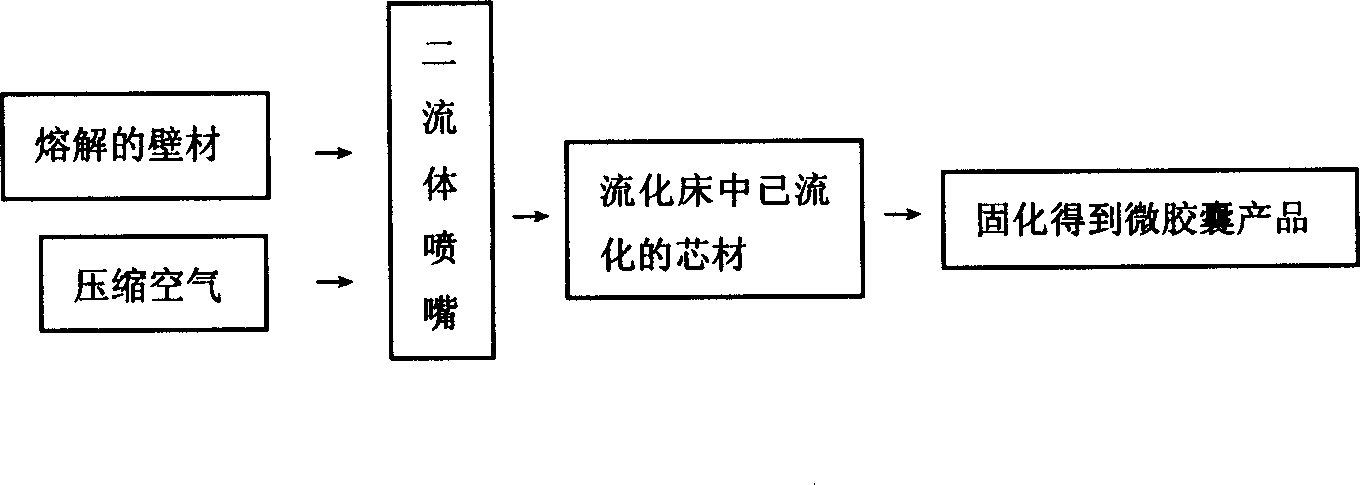

High-hydroscopicity polymer resin microcapsule and its production process

InactiveCN1486782AReduce dosageGood blocking effectSealing/packingMicroballoon preparationAmount of substancePolymer chemistry

The present invention belongs to the field of microcapsule preparing technology. The high-hydroscopicity polymer resin microcapsule has wall material of hardened oil with smelting point higher than 40 deg.c and core material of acrylic acid and acrylamide polymer. The preparation process includes smelting the wall material, fluidizing the core material, air suspension spraying, solidifying and other stages. The present invention solves the problem of high-hydroscopicity polymer to absorb water to denature, makes it possess excellent flowability and prepares microcapsule with targeting release feature. The wrapping material separates the high-hydroscopicity matter from targeting release feature. The wrapping material separates the high-hydroscopicity matter from outer environment, and under certain environment condition, the core material may be released fast to absorb water and to expand. The said process of the present invention is suitable for forming microcapsule with solid core material, and is simple, practical, good in filming performance and homogeneous in embedding.

Owner:DALIAN UNIV OF TECH

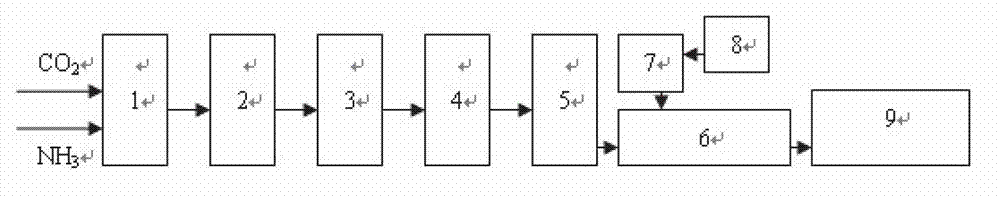

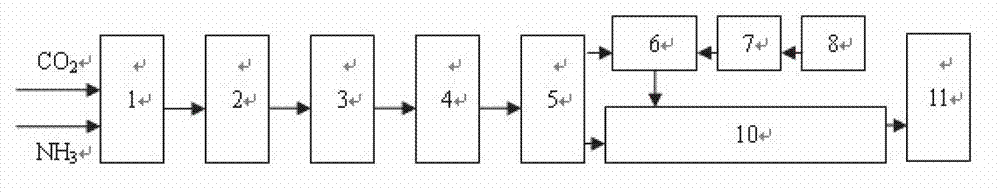

Slow release urea and preparation method thereof

ActiveCN102898234ARich sourcesLow priceUrea compound fertilisersFertilizer mixturesCoated ureaMoisture

The invention discloses a slow release urea, which comprises the following effective components in parts by weight: 85-98.8 parts of urea, 1-14% parts of bentonite, 0.01-0.5 part of polyacrylamide and 0.01-0.5 part of sodium salt or solution of the sodium salt on the basis of the sodium content. The invention provides a new thought for lowering the urea releasing rate, the slow release action on the urea is different from coated urea and stable urea, the slow release action of the slow release urea is through the diffusion process of moisture in a urea crystal, and water-proof layers are formed layer by layer from outside to inside along with moisture osmosis so as to achieve the slow release purpose.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Dietary fiber cake and making method thereof

The invention discloses a dietary fiber cake and a making method thereof. The dietary fiber cake is made of, by weight, 400-800 parts of beaten egg, 400-800 parts of white granulated sugar, 200-600 parts of flour, 10-100 parts of SP (sponge cake), 0-200 parts of water and dietary fibers, wherein the number of parts of the dietary fibers is 3-15% of that of the flour. The dietary fibers are added into the cake, so that the dietary fiber cake is rich in nutrition and has the effects of providing satiety, reducing food intake, promoting excrement to absorb water and swell, promoting intestinal gurgling, helping digestion, reducing cholesterol and the like, the dietary fibers are soluble instead of being insoluble, and accordingly the dietary fiber cake is delicate and tasty and unique.

Owner:杭州秀山美地农业科技有限公司

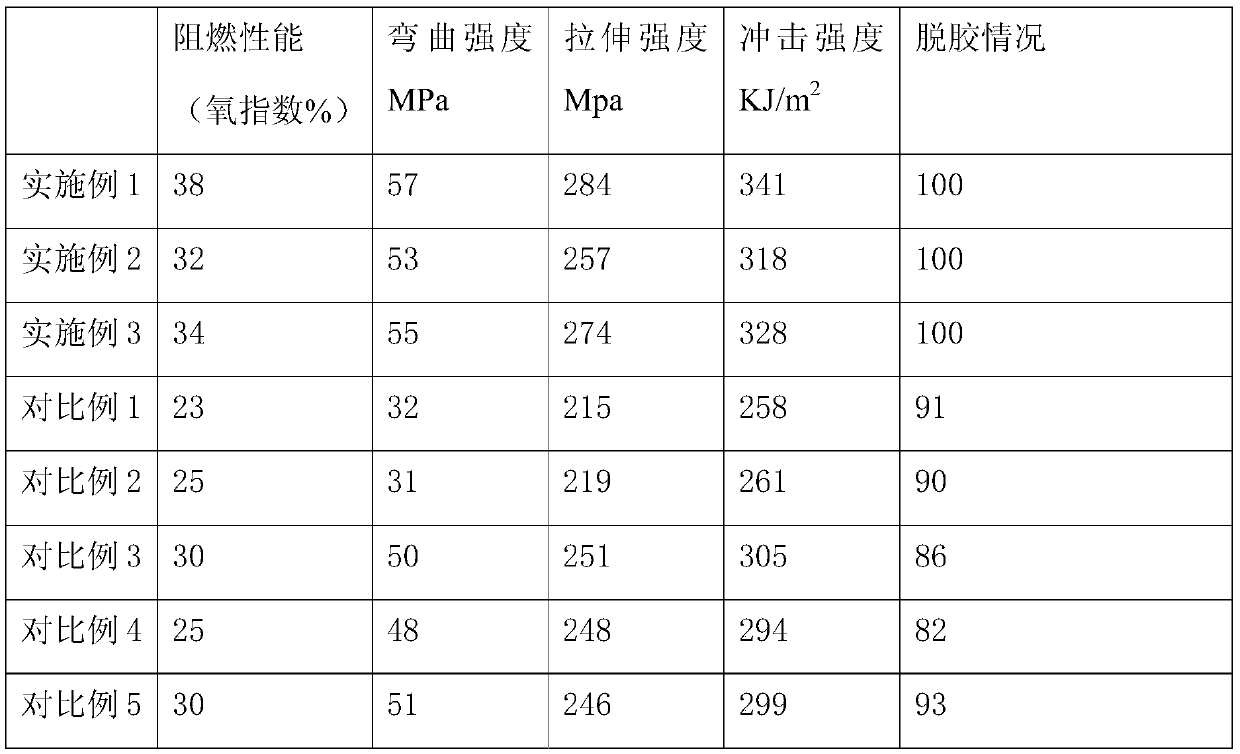

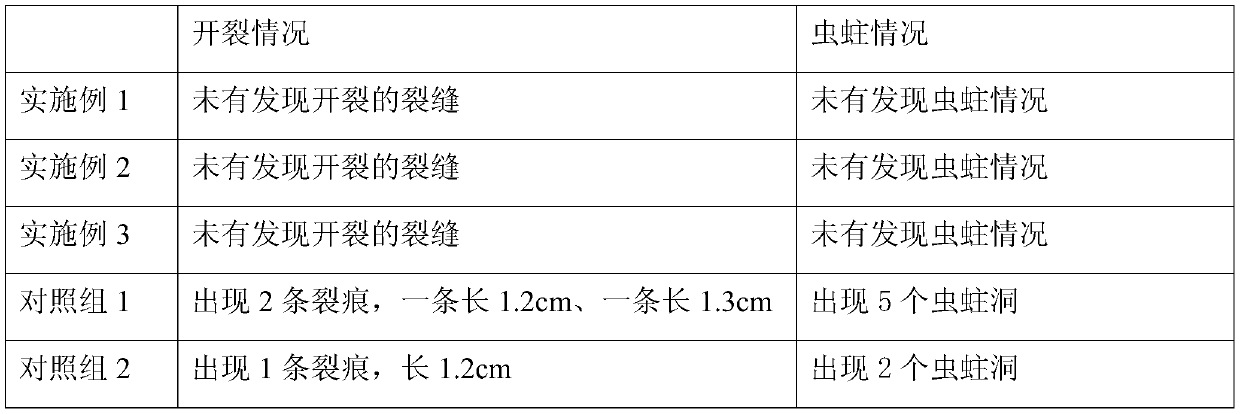

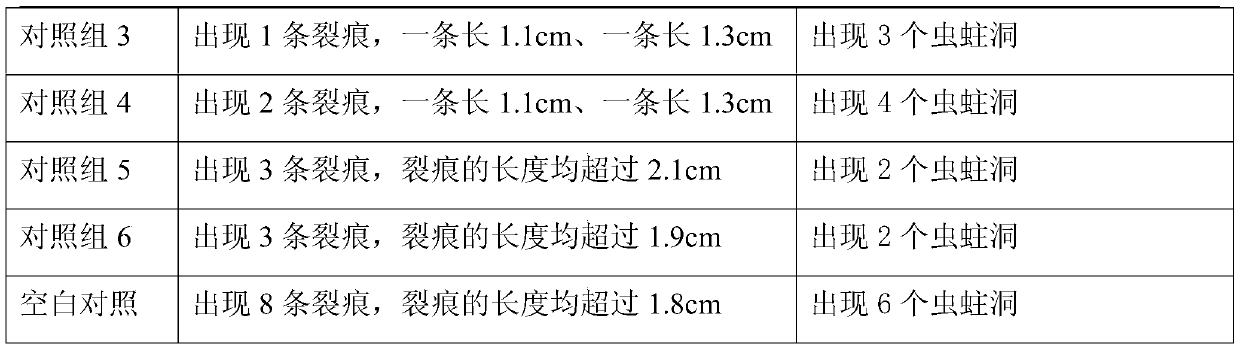

Aldehyde-free face decorating all-bamboo or bamboo-wood composite oriented strand board and manufacturing method thereof

InactiveCN109623980AHigh static bending strengthHigh elastic modulusCane mechanical workingFlat articlesWood shavingsSurface layer

The invention discloses an aldehyde-free face decorating all-bamboo or bamboo-wood composite oriented strand board and a manufacturing method thereof. In the method, all-bamboo or bamboo-wood composite large sheets and wood shavings are adopted as a core layer, oversized materials and fine materials serve as a surface layer, multi-layer all-bamboo or bamboo-wood composite large sheets are overlapped, the surface is smooth after hot pressing, the face decorating condition is completely achieved, and the problem that an ordinary oriented strand board is rough in surface, and face decorating cannot be achieved is solved. Compared with an all-wood oriented strand board, the performance is more excellent. Bamboo and wood materials are selected as raw materials, the problem that existing strandboard wood raw materials are in shortage is solved, and the production cost is reduced; a large number of bamboo large sheets are used in the production technology, a biomass adhesion agent is used onthe surface layer, and the environment protection concept is sufficiently embodied; and the surface layer is the biomass adhesion agent, the core layer is isocyanate, formaldehyde emission is zero, and harm caused by board formaldehyde emission at present is avoided.

Owner:NANNING KETIAN SHUIXING TECH LTD CO

Slow release urea and preparation method thereof

ActiveCN102898234BRich sourcesLow priceUrea compound fertilisersFertilizer mixturesCoated ureaMoisture

The invention discloses a slow release urea, which comprises the following effective components in parts by weight: 85-98.8 parts of urea, 1-14% parts of bentonite, 0.01-0.5 part of polyacrylamide and 0.01-0.5 part of sodium salt or solution of the sodium salt on the basis of the sodium content. The invention provides a new thought for lowering the urea releasing rate, the slow release action on the urea is different from coated urea and stable urea, the slow release action of the slow release urea is through the diffusion process of moisture in a urea crystal, and water-proof layers are formed layer by layer from outside to inside along with moisture osmosis so as to achieve the slow release purpose.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

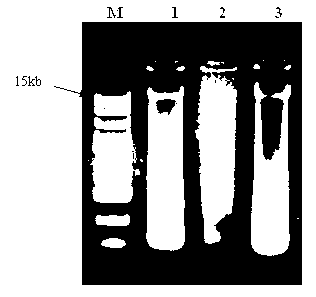

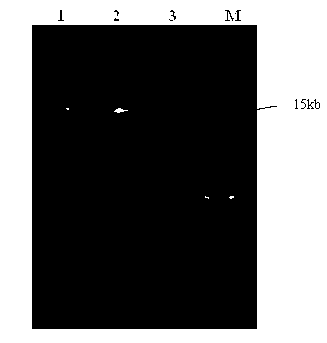

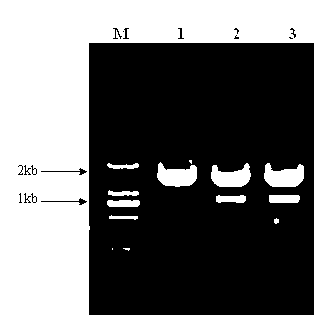

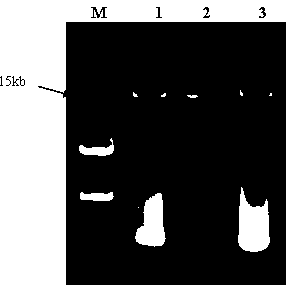

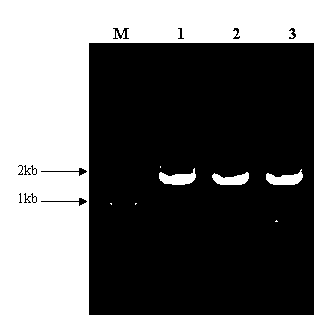

Method for extracting microorganism total DNA (Deoxyribonucleic Acid) in pu'er tea piling fermentation process

The invention discloses a method for extracting microorganism total DNA (Deoxyribonucleic Acid) in a pu'er tea piling fermentation process at high quality. The method comprises the following steps of: separating microorganisms on the surface of pu'er tea by using ultrasonic wave and vortex oscillation; washing the microorganisms by using washing buffer solution; performing rough extraction on the microorganism total DNA by using DNA extract; and purifying the roughly extracted DNA. The method provided by the invention is low in cost and high in DNA extraction rate; the extracted DNA has high completeness and high purity and can meet the requirements of PCR (Polymerase Chain Reaction) without purification or dilution; the purified DNA can meet the requirements of molecular biology research; and meanwhile, the extracted DNA covers bacteria and fungi and the requirements of subsequent researches in microorganism diversity, functional genes, metagenomics and the like can be met.

Owner:KUNMING UNIV OF SCI & TECH

Preparation process of carboxymethyl chitosan hemostatic sponge

PendingCN110559473AGood biocompatibilityPromote water swellingSurgical adhesivesPharmaceutical delivery mechanismFiberMicroorganism

The invention discloses a preparation process of carboxymethyl chitosan hemostatic sponge and relates to the technical field of preparation of carboxymethyl chitosan hemostatic sponge. The carboxymethyl chitosan hemostatic sponge comprises components as follows: 1-10 parts of carboxymethyl chitosan, 1-10 parts of chitosan oligosaccharide, 1-10 parts of beta-chitosan, 1-10 parts of carboxymethyl chitosan fiber, 1-10 parts of collagen and 1-5 parts of glycerin, wherein the collagen is fish collagen. The carboxymethyl chitosan hemostatic sponge prepared by the preparation process has good biocompatibility, expands quickly after absorbing water, permeates quickly, has very high water absorption ratio, allows good gas exchange, has good liquid absorption performance, keeps wet healing environment for wounds and can isolate outer layer structures and prevent invasion of microorganisms so as to create an ideal healing environment for wounds.

Owner:孙与泽

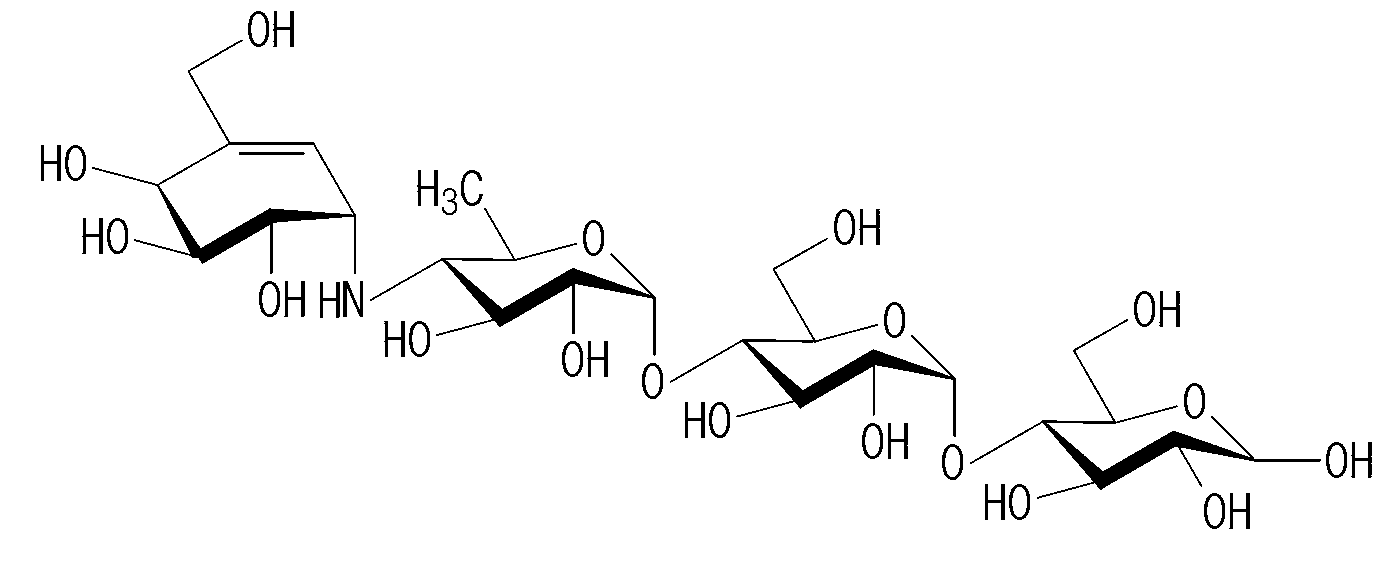

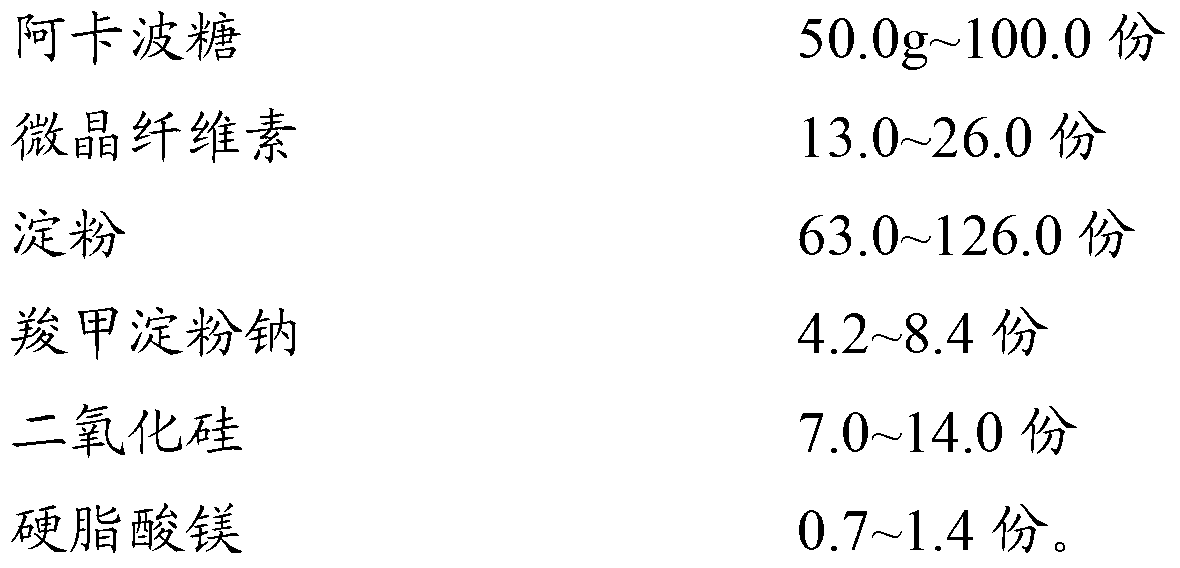

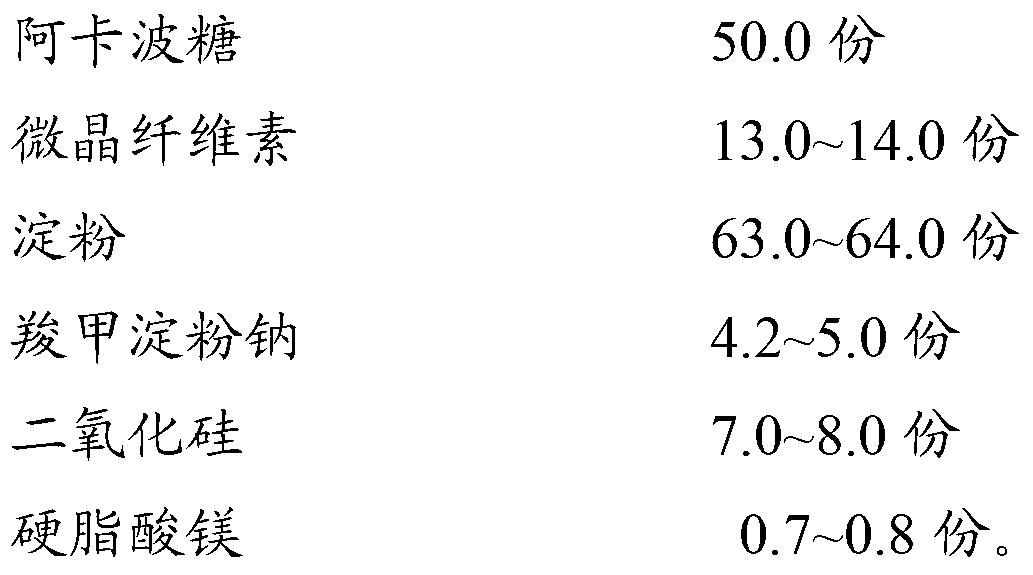

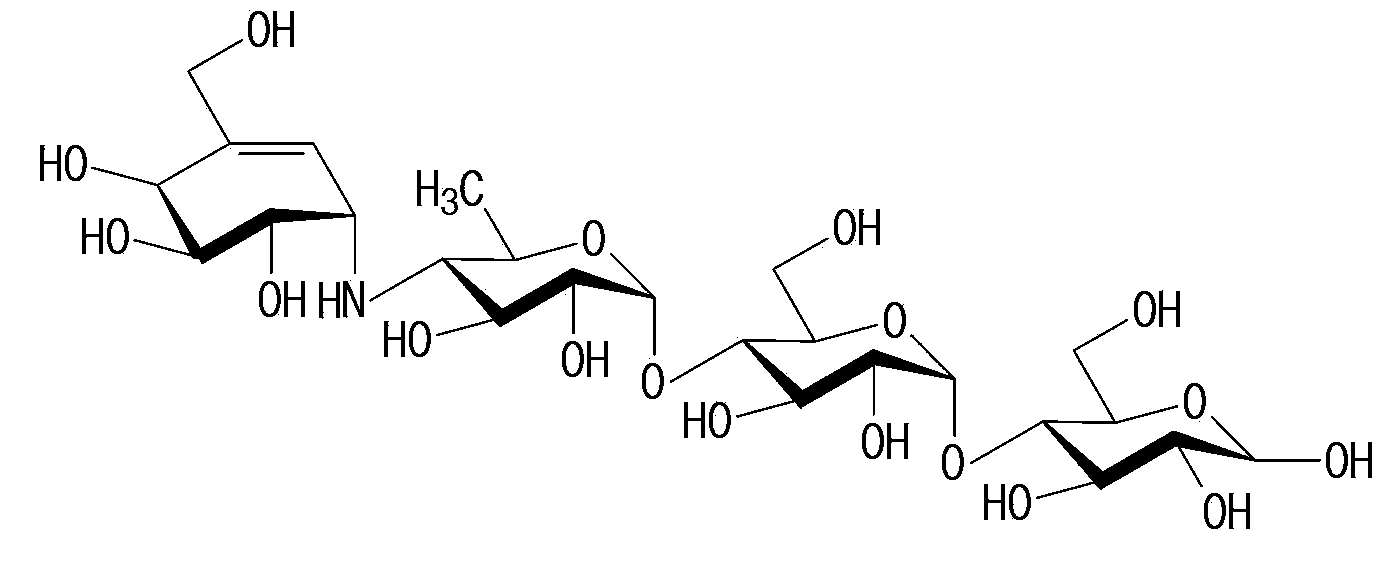

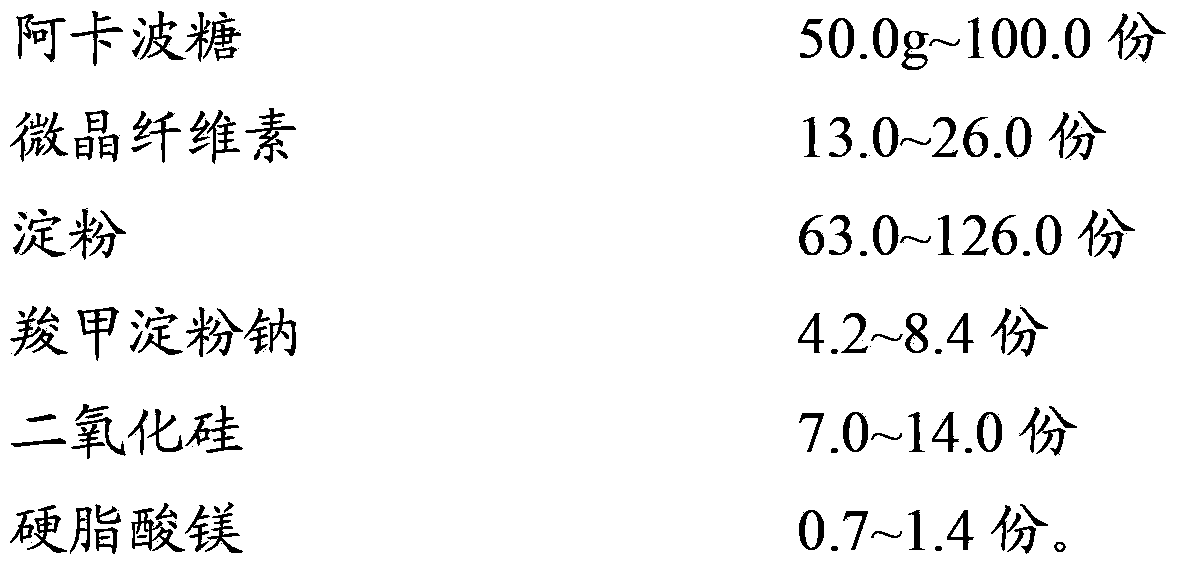

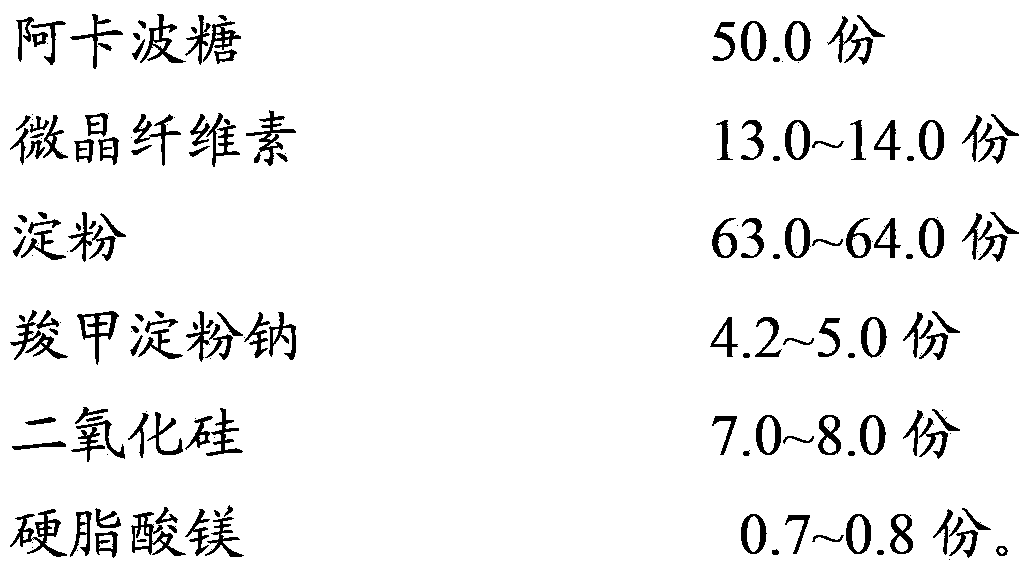

Acarbose tablets and preparation method thereof

ActiveCN103315971ASuitable for industrial productionControllable flyingOrganic active ingredientsMetabolism disorderCarboxymethyl starchHardness

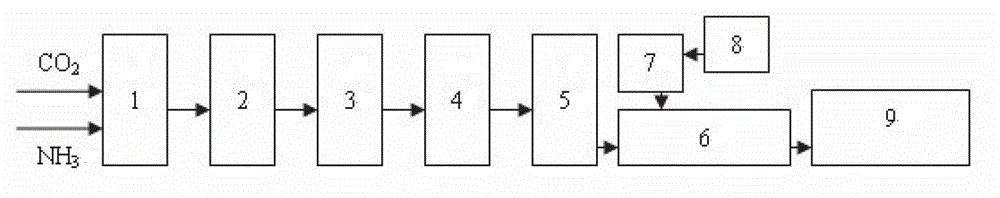

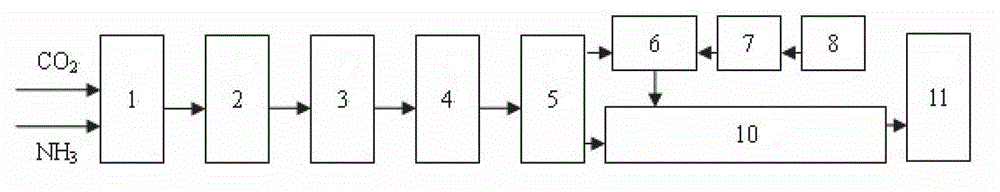

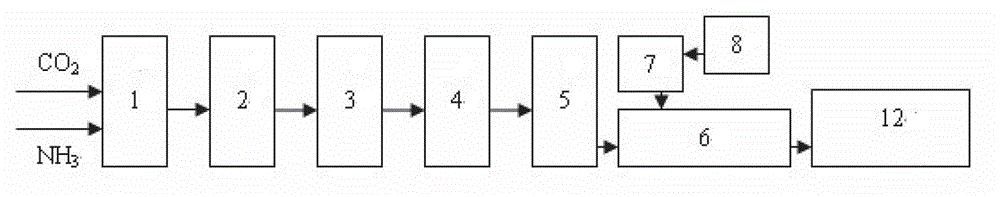

The invention discloses acarbose tablets and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing acarbose, microcrystalline cellulose, starch and 2 / 3 of carboxymethyl starch sodium to form a premix; pelletizing and granulating the premix through a dry process to obtain particles; and uniformly mixing the particles, 1 / 3 of carboxymethyl starch sodium, magnesium stearate and silicon dioxide, tabletting the mixture by a tablet press to obtain the acarbose tablets. According to the tablets prepared by dry-process palletizing and tabletting methods, the hardness and stability of the tablets are effectively improved and the problems of unaccepted disintegration time and unaccepted microorganisms are solved; as a result, the quality of the tablets is improved; and besides, the preparation method is simple in process flow, capable of saving energy source and cost, and suitable for industrial production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

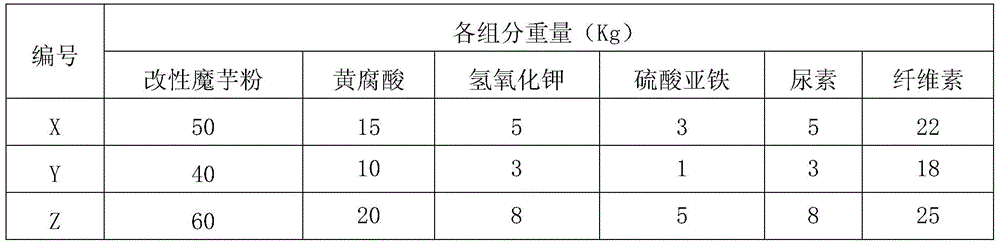

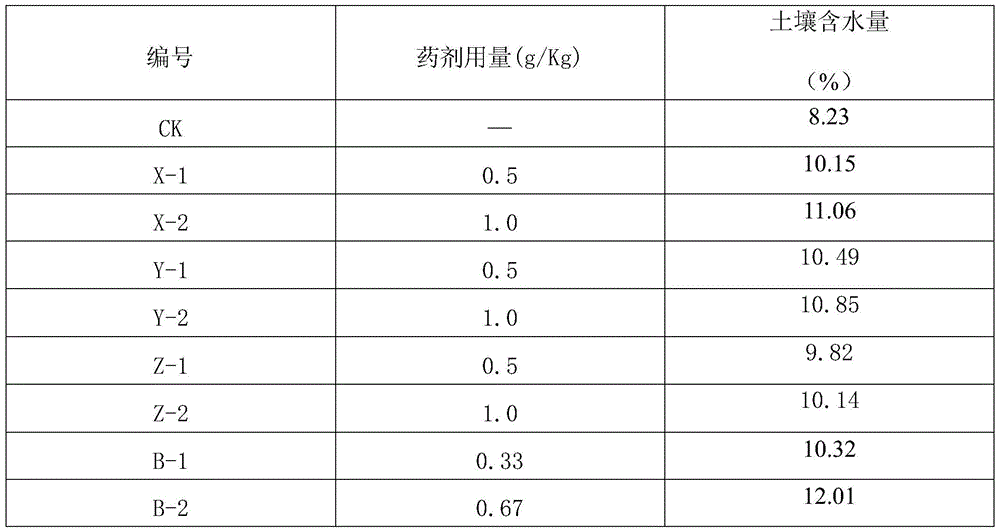

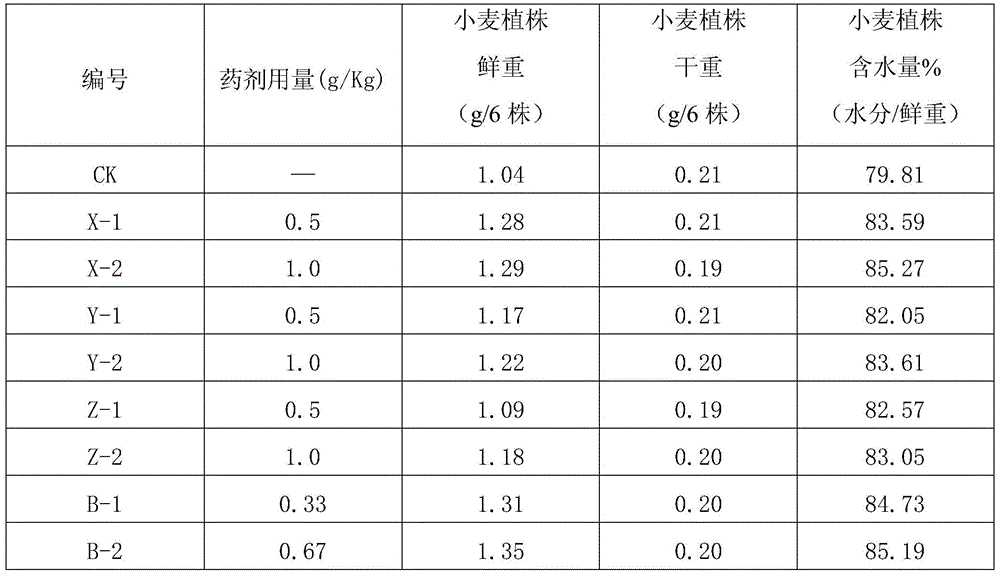

Soil organic water-retaining agent and preparation method thereof

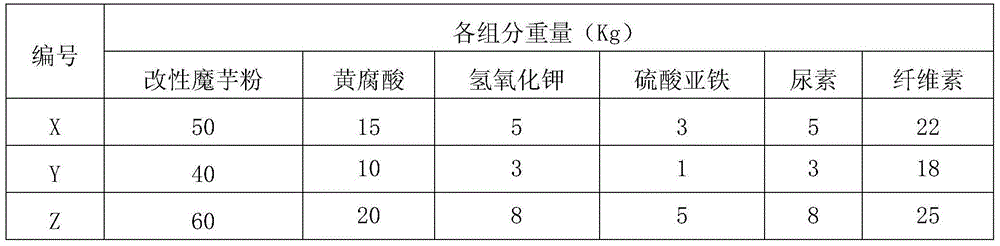

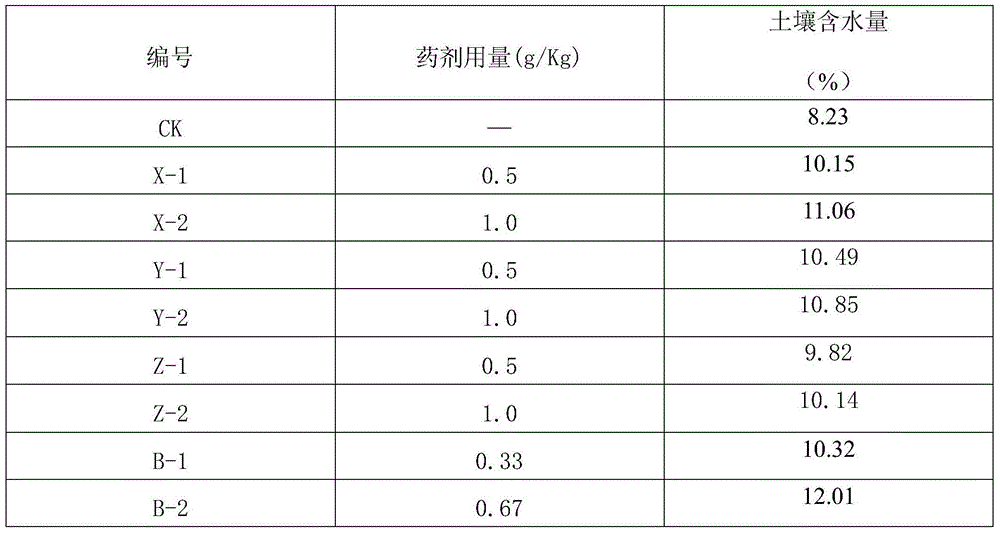

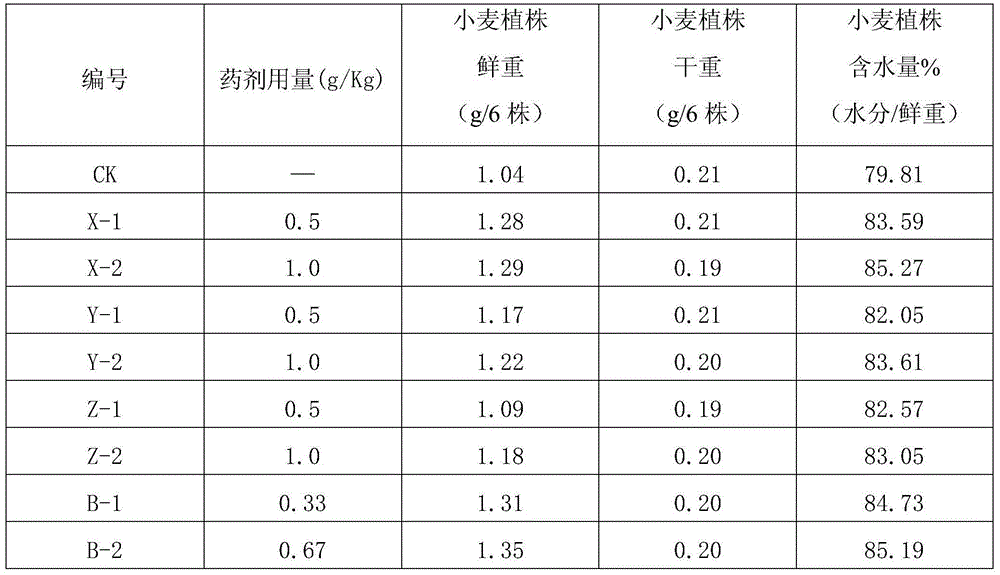

ActiveCN104447120BIncrease moisture contentImprove water absorptionOrganic fertilisersUrea compound fertilisersCelluloseSulfate

The invention relates to an organic soil water-retaining agent and a preparation method thereof, and belongs to the field of production of crops. The organic soil water-retaining agent is prepared from the following components in parts by weight: 40-60 parts of modified konjaku flour, 10-20 parts of fulvic acid, 3-8 parts of potassium hydroxide, 1-5 parts of ferrous sulfate, 3-8 parts of urea and 18-25 parts of cellulose. The organic soil water-retaining agent has a good water absorption property; after water is added, the organic soil water-retaining agent can rapidly absorb the water to be expanded; and thus the organic soil water-retaining agent has a very remarkable effect of improving the moisture content in soil. The water-retaining effect is equivalent to that of an existing water-retaining agent; and meanwhile, all the components in the organic soil water-retaining agent are environmentally friendly, and do not cause the environmental pollution problem.

Owner:CHENGDU NEWSUN CROPSCI

Macromolecular bound water fire extinguishing agent

The invention discloses a macromolecular bound water fire extinguishing agent. The macromolecular bound water fire extinguishing agent consists of macromolecular polymer resin or acrylamide and potassium acrylate cross-linked copolymer powder which have high water absorption, high water retention and sustained-release properties and are soaked in the common water, wherein the macromolecular polymer resin or the acrylamide and the potassium acrylate cross-linked copolymer powder in the volume ration of 1:(500-1,000) fully absorb water to expand to form gelatinous bound water. The macromolecular bound water fire extinguishing agent has high fire extinguishing efficiency and fire extinguishing speed, saves water and energy and can effectively overcome the defect of fire resurgence.

Owner:刘采联

Organic soil water-retaining agent and preparation method thereof

ActiveCN104447120AIncrease moisture contentImprove water absorptionOrganic fertilisersUrea compound fertilisersCelluloseSulfate

The invention relates to an organic soil water-retaining agent and a preparation method thereof, and belongs to the field of production of crops. The organic soil water-retaining agent is prepared from the following components in parts by weight: 40-60 parts of modified konjaku flour, 10-20 parts of fulvic acid, 3-8 parts of potassium hydroxide, 1-5 parts of ferrous sulfate, 3-8 parts of urea and 18-25 parts of cellulose. The organic soil water-retaining agent has a good water absorption property; after water is added, the organic soil water-retaining agent can rapidly absorb the water to be expanded; and thus the organic soil water-retaining agent has a very remarkable effect of improving the moisture content in soil. The water-retaining effect is equivalent to that of an existing water-retaining agent; and meanwhile, all the components in the organic soil water-retaining agent are environmentally friendly, and do not cause the environmental pollution problem.

Owner:CHENGDU NEWSUN CROPSCI

Production process of thick-fragrance seamen-fragrance composite-fragrance bajiu

InactiveCN111423954APromote water swellingPromote generationAlcoholic beverage preparationBiotechnologyYield (wine)

The invention discloses a production process of thick-fragrance seamen-fragrance composite-fragrance bajiu. The production process comprises the following steps: preparing materials, performing proportioning, performing gelatinizing, adding a starter, performing stacking, performing cellaring, and performing distilling, wherein the materials comprises, by weight, 110-130 parts of sorghum, 11-13 parts of bran, 28-32 parts of rice husk and 460-500 parts of steamed hot fermented grains. A mixed starter is added according to a proportion of 28-32% by weight of the sorghum, and a bacterial starteris added according to a proportion of 4-6% by weight of the sorghum; the stacking moisture in the stacking step is controlled to be 46-47%, stacking is performed for 48 hours in autumn, winter and spring, and stacking is performed for24 hours in summer; and in the cellaring step, the water content of the wine making materials for stacking fermentation is controlled to be 56-57%, the temperature ofthe wine making materials for stacking fermentation is controlled to be 23-26 DEG C, and the wine making materials for stacking fermentation are put into a full-mud cellar for fermentation for 67 days. The process has a good gelatinization effect and a high wine yield, and the bajiu product is clear and transparent and has strong fragrance, Maotai fragrance and sesame fragrance. The composite fragrance is elegant, comfortble, thick and plump, the wine body is coordinated, clear aftertaste is achieved.

Owner:内蒙古蒙古王实业股份有限公司

Hpyerglycemic cereal fruit and vegetable bread and preparation method thereof

InactiveCN108967482AGreat tasteImprove anti-agingDough treatmentBakery productsBiotechnologyPolygonum fagopyrum

The invention discloses hpyerglycemic cereal fruit and vegetable bread and a preparation method thereof. Components of raw materials include the followings, apples, pawpaw, carambola, fig, compound enzyme, scallion oil, buckwheat, black soya beans, cowpeas, black rice, seeds of Job's tears, carrots, lotus roots, celery, flour, salt, microbial flora, eggs, and purified water. The method comprises the followings: 1) through enzymolysis, drying, and grinding of fruits, preparing fruit powders; 2) heating the scallion oil, adding the scallion oil into the buckwheat, the black soya beans, and the cowpeas, frying, mixing with the black rice and the seeds of Job's tears, adding into cold water to soak; 3) adding the carrots, the lotus roots, and the celery, boiling, through drying and grinding, preparing cereal vegetable powders; 4) mixing the 1) with the 3), adding flour, salt, and microbial flora, stirring, and then adding eggs and purified water to ferment; 5) proofing fermented paste; 6)baking to obtain the bread. The prepared bread is soft and tasty, and is rich in nutrients, and has very good hpyerglycemic efficacy. The method is simple and easy in production.

Owner:WUHE TONGSHIFU FOOD

Method for fine processing of walnut oil

InactiveCN107474945AAvoid oxidation reactionsEliminate astringencyFatty-oils/fats refiningFatty-oils/fats productionFiltrationMagnetization

The invention discloses a method for fine processing of walnut oil. The method is characterized in that the method comprises the steps of squeezing of walnut oil, wherein walnut kernels are screened, smashed, steamed and boiled and squeezed, and virgin walnut oil is prepared; dehydration and dephosphorization, wherein the walnut oil is poured into a reaction kettle to be subjected to dephosphorization reaction, the dephosphorized walnut oil is put into the reaction kettle and subjected to dehydration, and discharged moisture is collected through a condensation pipe; dewaxing and degreasing, wherein a sodium hydroxide solution is added into the dehydrated and dephosphorized walnut oil in the reaction kettle, stirred, mixed, and heated; decoloration, wherein activated clay is added into the dehydrated and dephosphorized walnut oil, subjected to ultrasonic wave vibration and mixing, and then subjected to magnetization treatment by using a magnetizer; fine filtration, wherein the decolorized walnut oil is put into a vacuum tank and subjected to heating refining, cooled and filtered by using a filter screen.

Owner:界首市致富家庭农场

Brewing-type instant food containing dendrobium flowers and making method thereof

The invention discloses a brewing-type instant food containing dendrobium flowers. The food is prepared from, by weight, 0.1-5 parts of the dendrobium flowers, 0.5-3 parts of tremella, 0.5-2 parts oflilies, 0.5-2 parts of fructus lycii, 0.5-5 parts of lotus seeds, 2-10 parts of rock candy and the balance water. In combination with a making method of the instant food, an airflow puffing technologyis adopted for processing the tremella and the fructus lycii, correspondingly the boiling time of the tremella is shortened by half or above, more effective components can be retained, and the effective components of the fructus lycii can be dissolved more quickly during brewing; the lotus seeds and the lilies are cooked thoroughly and then become soft and convenient to eat, the effective components are more easily absorbed, and combined with the nutrients of the dendrobium flowers, the food achieves an excellent skin caring effect after being eaten.

Owner:ZHEJIANG PROVINCE LANXI CITY JINRONG AGRITECH DEV CO LTD

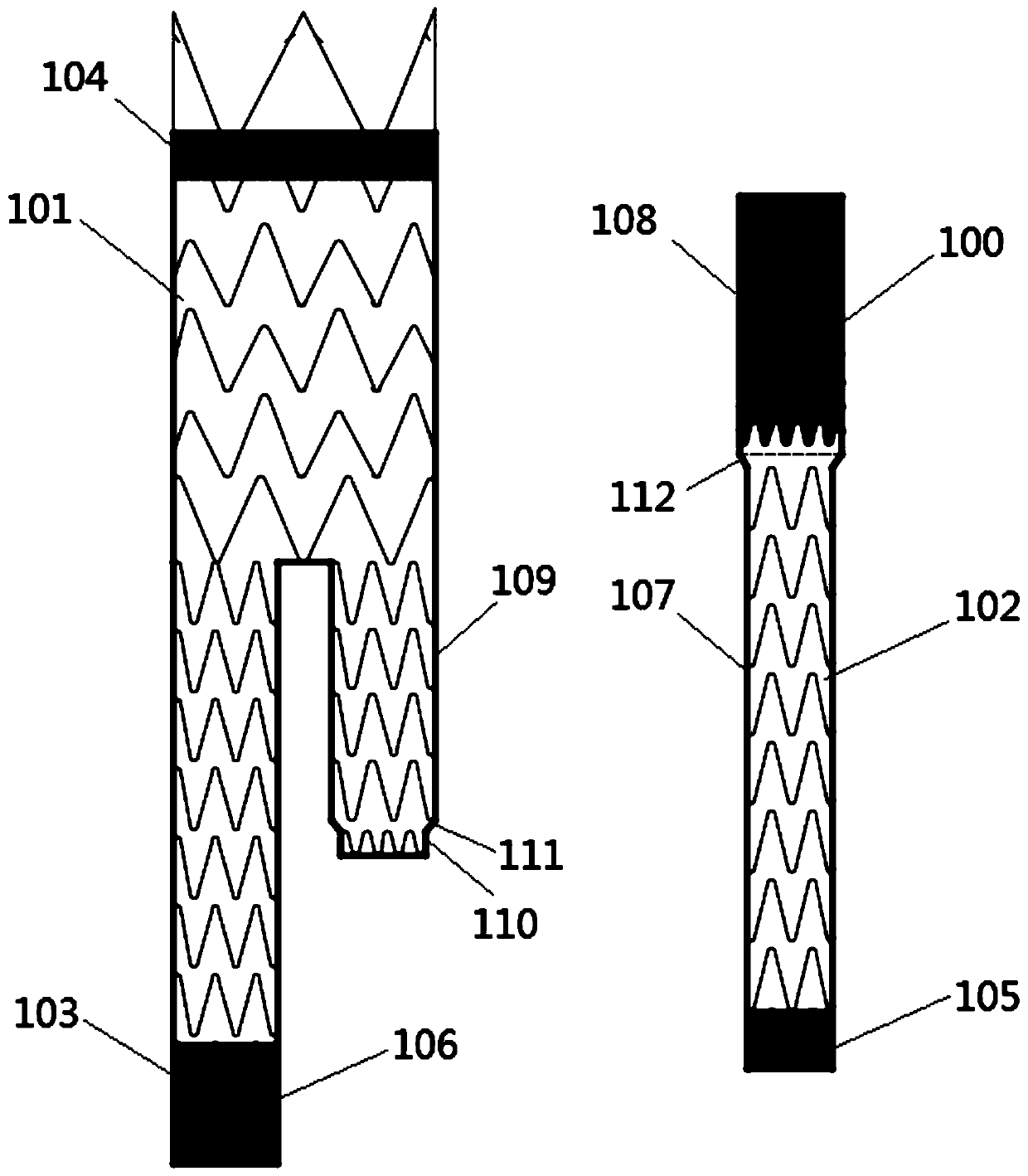

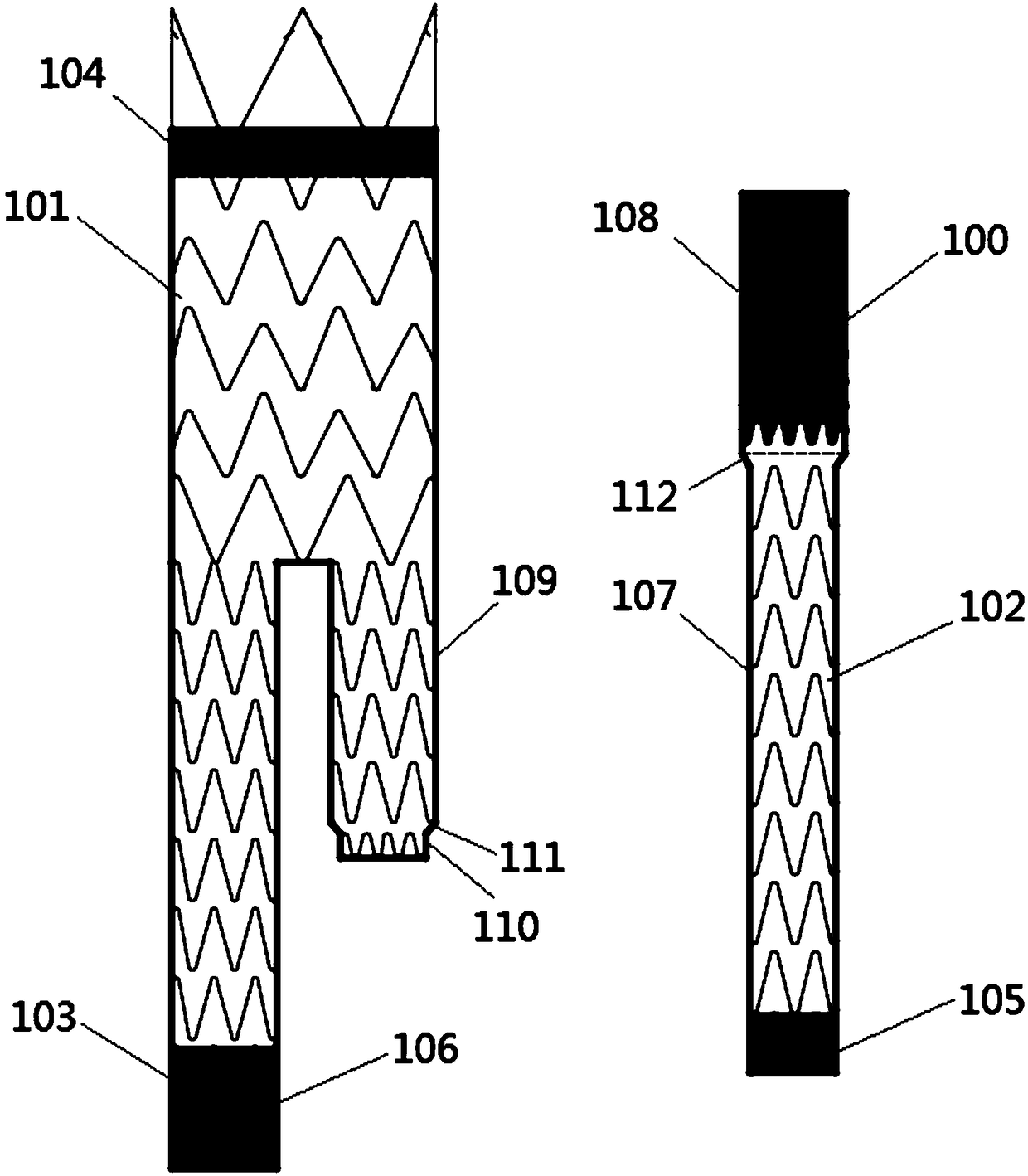

A split type vascular covered stent

The invention discloses a split type blood vessel coating support which comprises a main support and a trouser leg support connected with the main support. Water-absorbing self-expansion material layers are attached to the outer walls of one or all of a connecting part between the main support and the trouser leg support, other ends of the main support and other ends of the trouser leg support. Water-absorbent resin materials covering ports of the support have good biological compatibility and excellent protein-adsorption-resistance performance. The covering materials can quickly expand by absorbing water in a blood environment, are stable in structure after expansion and have a controllable water absorbing rate. The materials used for the support have no damage and side effect on human body blood vessels, the success rate of aortic aneurysm endovascular graft exclusion is increased, and the safety and curing effect of the aortic aneurysm endovascular graft exclusion are further improved.

Owner:ZHEJIANG UNIV

Shell-free pumpkin seed colorful film coating agent and preparation method thereof

InactiveCN111202086AIncrease productionImprove commodityBiocidePlant growth regulatorsMetalaxylPumpkin seed

The invention discloses a shell-free pumpkin seed colorful film coating agent and a preparation method thereof. The coating agent is prepared from 1-2% of thiram, 0.1-0.3% of fludioxonil, 0.1-0.3% ofmetalaxyl-M, 1-4% of a dispersant, 1-3% of an antifreeze agent, 0.1-0.2% of a preservative, 1-2% of a thickening agent, 8-12% of an emerald green color paste, 6-8% of a film-forming agent, 10-12% of green pearl powder, and the balance of water. The invention also provides the preparation method of the coating agent. The seeds coated by the colorful film coating agent are colorful and bright, haveextremely low shedding rate, effectively improve the commodity of shelled pumpkin seeds used as seeds, have good breathability, and can rapidly absorb water and expand after encountering water. The thiram can effectively prevent germs on the surfaces of the seeds and protect the seeds, and the fludioxonil and metalaxyl-M can effectively prevent low-temperature seed powdering, so the germination rate and emergence rate of the pumpkin seeds are guaranteed and increased, the root system is developed, seedlings are neat and strong, stress resistance and disease resistance are improved, and the shell-free pumpkin yield is increased.

Owner:WUWEI CHUNFEI CROP SCI & TECH

Method for extracting microorganism total DNA (Deoxyribonucleic Acid) in pu'er tea piling fermentation process

The invention discloses a method for extracting microorganism total DNA (Deoxyribonucleic Acid) in a pu'er tea piling fermentation process at high quality. The method comprises the following steps of: separating microorganisms on the surface of pu'er tea by using ultrasonic wave and vortex oscillation; washing the microorganisms by using washing buffer solution; performing rough extraction on the microorganism total DNA by using DNA extract; and purifying the roughly extracted DNA. The method provided by the invention is low in cost and high in DNA extraction rate; the extracted DNA has high completeness and high purity and can meet the requirements of PCR (Polymerase Chain Reaction) without purification or dilution; the purified DNA can meet the requirements of molecular biology research; and meanwhile, the extracted DNA covers bacteria and fungi and the requirements of subsequent researches in microorganism diversity, functional genes, metagenomics and the like can be met.

Owner:KUNMING UNIV OF SCI & TECH

Split type blood vessel coating support

The invention discloses a split type blood vessel coating support which comprises a main support and a trouser leg support connected with the main support. Water-absorbing self-expansion material layers are attached to the outer walls of one or all of a connecting part between the main support and the trouser leg support, other ends of the main support and other ends of the trouser leg support. Water-absorbent resin materials covering ports of the support have good biological compatibility and excellent protein-adsorption-resistance performance. The covering materials can quickly expand by absorbing water in a blood environment, are stable in structure after expansion and have a controllable water absorbing rate. The materials used for the support have no damage and side effect on human body blood vessels, the success rate of aortic aneurysm endovascular graft exclusion is increased, and the safety and curing effect of the aortic aneurysm endovascular graft exclusion are further improved.

Owner:ZHEJIANG UNIV

A kind of pretreatment method before rice polishing

ActiveCN109046516BPromote water swellingIncrease lossGrain huskingGrain polishingPretreatment methodFreeze-drying

Owner:安徽省东博米业有限公司

Preparation method of cotton cellulose nano-fibril film

ActiveCN110924238APromote water swellingImprove separation efficiencyPulp properties modificationPulping with inorganic basesEngineeringCellulose fiber

The invention discloses a preparation method of a cotton cellulose nano-fibril film. The method comprises the steps of: taking cotton as a raw material, performing processes such as acidolysis and hydrothermal reaction, preparing slurry by adopting the raw material assisted by refining a pulping process, then refining and pulping the cotton fibers, under the combined action of a plurality of degrading enzymes, degrading and modifying hemicellulose and lignin in cotton cell walls, and performing carboxylation treatment on the cellulose fibers by using chloroacetic acid and the like, so that thecellulose nano-fibril can be effectively obtained through stripping; and adopting common treatment of grinding and homogenizing in the microfibrillating process, then bulking and swelling the microfibril after grinding for many times to form water balls full with moisture, then performing homogeneity extension and expansion to form the cellulose nano-fibril, and finally performing dehydration toprepare the cellulose nano-fibril film. The preparation process is scientific, the process parameters are precise, the reaction conditions are mild, the cost is significantly reduced, and the preparation method of the cotton cellulose nano-fibril film can meet commercial and industrial production requirements.

Owner:安徽竞秀纺织有限公司

A kind of preparation method of Anweiyang Dispersible Tablet

ActiveCN105748428BImprove solubilityImprove inclusion efficiencyDigestive systemPharmaceutical non-active ingredientsCross-linkSodium bicarbonate

The invention discloses a preparation method of Anweiyang dispersible tablets.The preparation method includes following steps: S1, adding Anweiyang and beta-cyclodextrin into a 1% sodium hydrogen carbonate solution respectively, utilizing a colloid mill for milling, and drying to obtain an inclusion compound; S2, granulating the inclusion compound, PPVP, microcrystalline cellulose, stevioside, calcium hydrogen phosphate and a 5% povidone K30 solution to obtain uncoated Anweiyang dispersible tablets; S3, mixing HPMC (hydroxyl propyl methyl cellulose), cross-linked sodium carboxymethyl starch, acrylic resin, glycerin, magnesium stearate, white pigment and cross-linked povidone to form coating liquid, and coating the uncoated Anweiyang dispersible tablets obtained in the S2 to obtain the Anweiyang dispersible tablets.The Anweiyang dispersible tablets obtained through the preparation method are suitable for being used as dispersible tablets and have the advantages of high dissolution speed and quick action.

Owner:惠州市九惠药业有限公司

Cucurbita pepo seed colorful film coating agent and preparation method thereof

InactiveCN111109296AIncrease productionImprove commodityBiocidePlant growth regulatorsCucurbitaPreservative

The invention discloses a cucurbita pepo seed colorful film coating agent and a preparation method thereof. The coating agent is prepared from the following raw materials in percentage by weight: 1-4%of a dispersing agent, 0.5-1% of a wetting agent, 1-4% of an anti-freezing agent, 0.2-0.5% of a preservative, 0.1-0.2% of a thickening agent, 18-20% of color paste, 18-20% of a film-forming agent, 18-20% of pearl powder, 1-2% of an amino acid water-soluble fertilizer and the balance of water. After the cucurbita pepo seeds are coated with the coating agent, the seeds are colorful and bright; thecucurbita pepo seeds used as seeds are good in air permeability, and can rapidly absorb water and expand after encountering water, so that the germination rate and the emergence rate of the cucurbitapepo seeds are guaranteed and improved, the root system is developed, the seedlings are neat and strong, the stress resistance and the disease resistance are improved, and the yield of cucurbita pepois increased.

Owner:WUWEI CHUNFEI CROP SCI & TECH

Antibacterial coating agent and preparation method thereof

InactiveCN108991043ACreate pollutionLow toxicityBiocidePlant growth regulatorsCarboxymethyl cellulosePlanting seed

The invention discloses an antibacterial coating agent and a preparation method thereof. The antibacterial coating agent comprises the following raw materials: radix apium graveolens, cortex bulbus allii, herba houttuyniae, radix coriander, herba taraxaci, radix arctii, fructus xanthii, beta-cyclodextrin, sodium carboxymethyl cellulose, diatomaceous earth and water; the preparation method comprises the following steps: putting the radix apium graveolens, radix coriander, cortex bulbus allii, herba taraxaci and herba houttuyniae in water, soaking for 40-50 min, stewing for 50-60 min, and filtering to obtain traditional Chinese medicine liquid; uniformly mixing pulvis arctii, pulvis fructus xanthii, beta-cyclodextrin, sodium carboxymethyl cellulose and diatomaceous earth with the traditionalChinese medicine liquid, drying to obtain the antibacterial coating agent. The antibacterial coating agent provided by the invention has effects of killing or inhibiting harmful worm eggs and germs,can be widely applied to most plant seeds, and is especially suitable for wheat and corn seeds.

Owner:安徽省金海种业有限公司

A kind of preparation method of cotton cellulose nanofibril film

ActiveCN110924238BPromote water swellingImprove separation efficiencyPulp properties modificationPulping with inorganic basesPolymer scienceCellulose fiber

The invention discloses a method for preparing a cotton cellulose nanofibril film. Cotton is used as a raw material, and the raw material is made into pulp through processes such as acidolysis and hydrothermal reaction. After the fiber is refined and beaten, the hemicellulose and lignin in the cotton cell wall are degraded and modified through the joint action of various degrading enzymes, and then the cellulose fiber is carboxylated by using chloroacetic acid, etc., which can effectively pass the stripping process. The obtained cellulose nanofibrils are treated with grinding and homogenization in the process of microfibrillation. Through multiple grindings, the microfibrils can be fluffed and swollen to form water balls full of water, and then stretched and expanded by homogenization, and finally become The cellulose nanofibrils are finally dehydrated to form a thin film. The preparation process of the present invention is scientific, the process parameters are precise, the reaction conditions are mild, and the cost is significantly reduced, which is suitable for commercial and industrial production requirements.

Owner:安徽竞秀纺织有限公司

Method for rapidly detecting kernel rot resistance by corn dry seeds

InactiveCN109504736AIncrease moisture contentGrowth inhibitionMicrobiological testing/measurementBiological material analysisSporePathogenic bacteria

The invention relates to the field of plant disease resistance, in particular to a method for rapidly detecting kernel rot resistance by corn dry seeds. The method comprises the following steps: (1) preparing before inoculating corn kernels; (2) preparing pathogenic spore suspension liquid; (3) inoculating kernels; and (4) performing moisturizing culture on the kernels. The method has the following advantages: the pathogenic bacteria for inoculation have many varieties; the inoculating materials are dry seeds and can be used while being taken; operation is simple, can be completed indoors andis not limited by seasons; few places are occupied; the efficiency is high; the repeatability is high; the corn kernel rot resistance detection time is effectively shortened; the kernel rot resistancecan be rapidly detected; and the application value is great.

Owner:JINGXI XIUMEI BIANCHENG AGRI SCI & TECH CO LTD

A method for reusing bamboo and wood clothes hanger production tailings

ActiveCN109262774BImprove performancePromote water swellingWood treatment detailsCane mechanical workingMechanical engineeringClothes hanger

The invention belongs to the technical field of clothes hanger processing, in particular to a method for recycling a tail material produced by a bamboo and wood clothes hanger. The method specificallyincludes the following steps: modifying a bamboo broken material; modifying a beech tail material; preparing a molten binder; weighing a raw material; mixing; hot pressing; curing and sanding the outer surface; coating; drying; hooking; printing a trademark mark; and boxing. The method has the advantages that an environment-friendly utilization road is provided for Guangxi bamboo and wood leftovers, and researches show that the the clothes hanger prepared by pressing is durable, does not crack and has better heat resistance.

Owner:GUANGXI GUILIN HUAHAI HOUSEWARES CO LTD

Colorful-film coating agent for sunflower seeds and preparation method thereof

InactiveCN111184014AReduce the chance of sheddingImprove commodityBiocidePlant growth regulatorsFilm coatingCarbendazim

The invention discloses a colorful-film coating agent for sunflower seeds and a preparation method thereof, belonging to the technical field of agriculture. The colorful-film coating agent comprises the following raw materials in parts by weight: 1-2% of carbendazim, 1-2% of thiram, 0.1-0.3% of fludioxonil, 0.1-0.3% of metalaxyl-M, 1-4% of a dispersing agent, 1-3% of an antifreezing agent, 0.1-0.2% of a preservative, 1-2% of a thickening agent, 3-5% of acid golden yellow, 0.2-0.8% of carbon black, 8-12% of a film forming agent and 10-15% of pearl powder, with the balance being water. The seedscoated by the colorful-film coating agent are colorful and bright, and the colorful-film coating agent has an extremely low shedding rate, so the commodity of the sunflower seeds used as seeds can beeffectively improved; the colorful-film coating agent has good breathability, and the seeds can quickly absorb water and expand after meeting water; the carbendazim and the thiram can effectively prevent germs on the surfaces of the seeds and protect the seeds and have a good prevention effect on damping-off in a seedling stage; and the fludioxonil and the metalaxyl-M can effectively prevent sclerotinia sclerotiorum and downy mildew, the germination rate and the emergence rate of the sunflower seeds are guaranteed and increased, obtained seedlings have developed root systems, are neat and strong and are improved in stress resistance and disease resistance, and sunflower yield is increased.

Owner:WUWEI CHUNFEI CROP SCI & TECH

Acarbose tablets and preparation method thereof

ActiveCN103315971BSuitable for industrial productionControllable flyingOrganic active ingredientsMetabolism disorderCarboxymethyl starchMagnesium stearate

Owner:HAINAN HULUWA PHARMA GRP CO LTD

Environmentally-friendly water retaining agent for straw vegetation blankets

InactiveCN106747975AImprove water absorptionIncrease moisture contentOrganic fertilisersAmmonium salt fertilisersCelluloseVegetation

The invention discloses an environmentally-friendly water retaining agent for straw vegetation blankets. The water retaining agent comprises, by weight, 15-24 parts of coconut shells, 18-25 parts of shaddock peel, 20-26 parts of palm, 10-20 parts of fulvic acid, 13-18 parts of potassium hydroxide, 1-5 parts of ferrous sulfate, 3-8 parts of urea, 18-25 parts of cellulose, 2-5 parts of talcum powder, 3-6 parts of deionized water, 5-8 parts of an initiator and 8-12 parts of a foaming agent. Compared with water retaining agents, the water retaining agent disclosed in the invention has good water absorption property, rapidly absorbs water and expands after water addition, and has a substantial increasing effect on the water content of a vegetation blanket matrix.

Owner:安庆市鼎升环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com