Patents

Literature

31results about How to "To achieve the purpose of plugging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

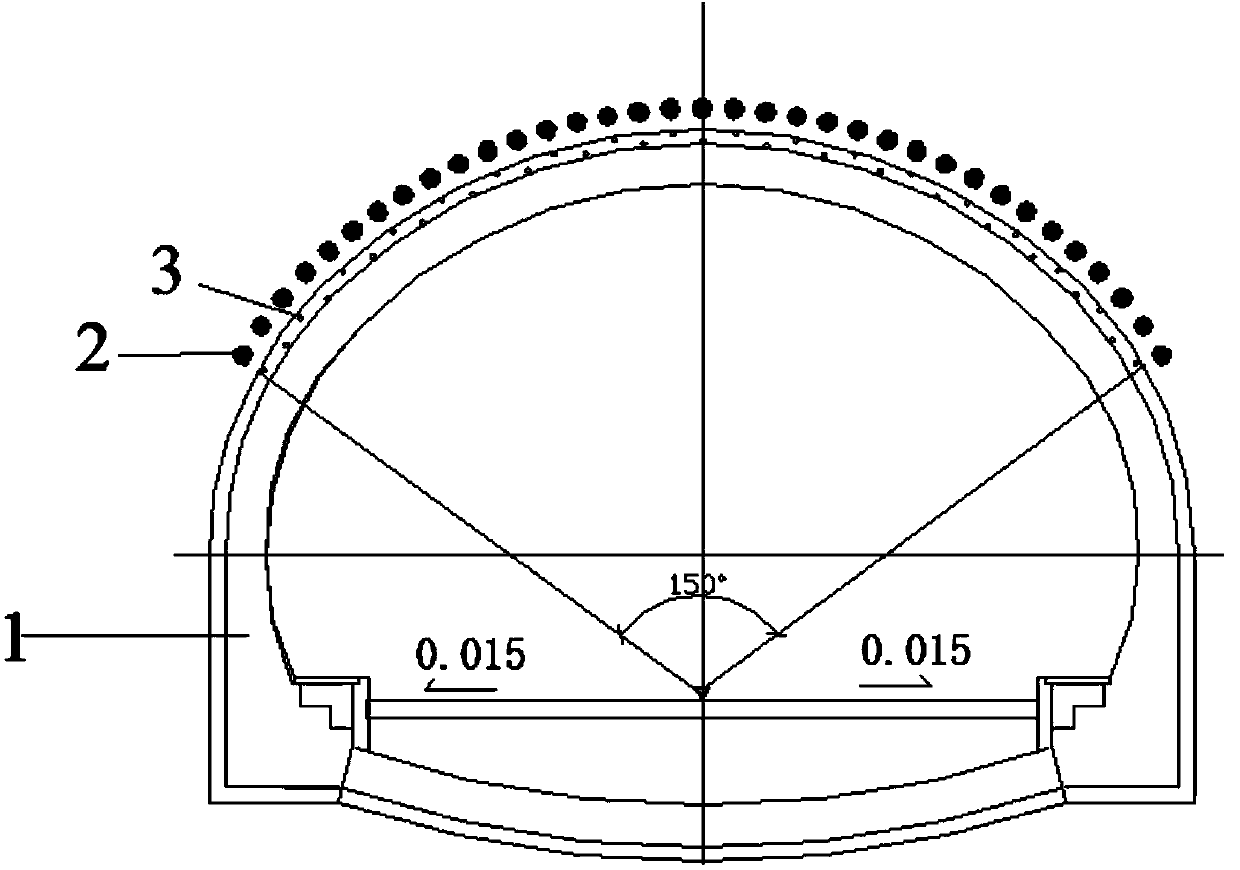

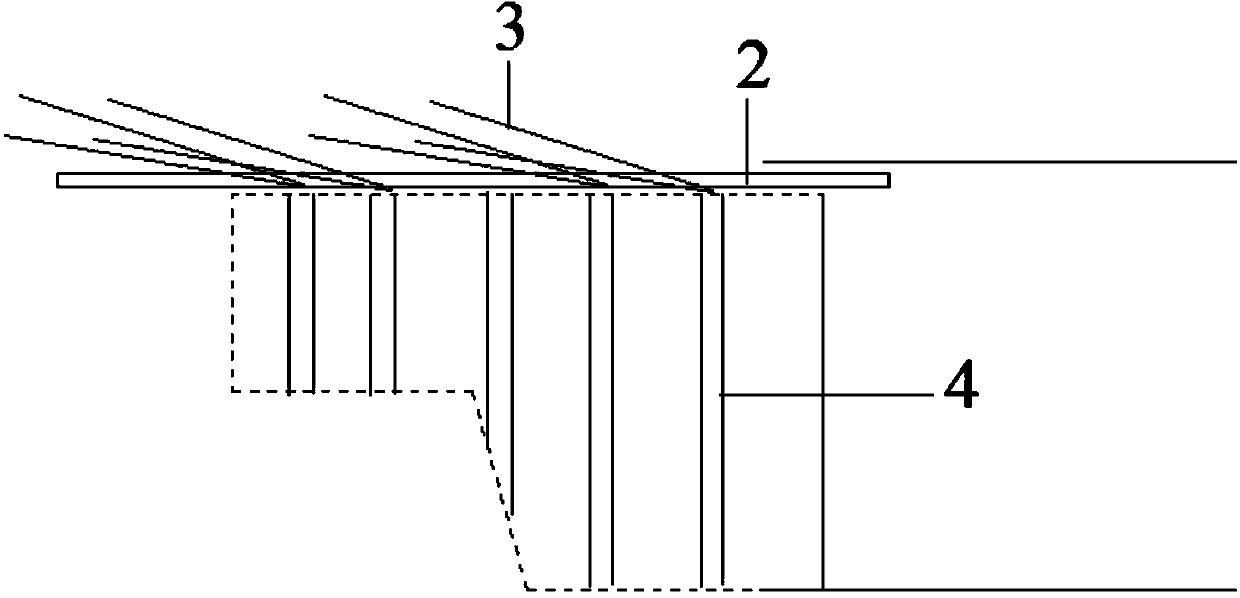

Supporting method for soft broken nonuniform stratum tunnel construction

InactiveCN103993892AImprove self-stabilityReduce construction difficultyUnderground chambersMine roof capsEngineeringSelf-stabilization

The invention discloses a supporting method for soft broken nonuniform stratum tunnel construction. The supporting method includes the steps that firstly, an arch support is erected in a bottom layer tunnel through steel pipes, and the portion, on the top of the arch support, of the bottom layer tunnel is drilled; secondly, a small pipe roof is constructed on the drilled portion of the arch crown of the arch support; thirdly, during construction of the small pipe roof for supporting, advanced reinforcement treatment is conducted on a top arch of the tunnel through advanced small pipes in a floor staggered mode; fourthly, the tunnel is excavated; fifthly, after the tunnel is excavated, preliminary supporting construction is conducted in time each cycle; sixthly, after excavation and supporting of a tunnel trunk of the tunnel, an inverted arch is constructed and sealed into a loop; and then secondary lining following operation is conducted. The method has the advantages that deformation of tunnel surrounding rocks can be effectively reduced, self-stabilization and seepage prevention capacity of the tunnel is permanently improved, a multifunctional surrounding rock reinforcement region is formed, and safety of tunnel constructors and equipment is guaranteed.

Owner:SHANDONG UNIV

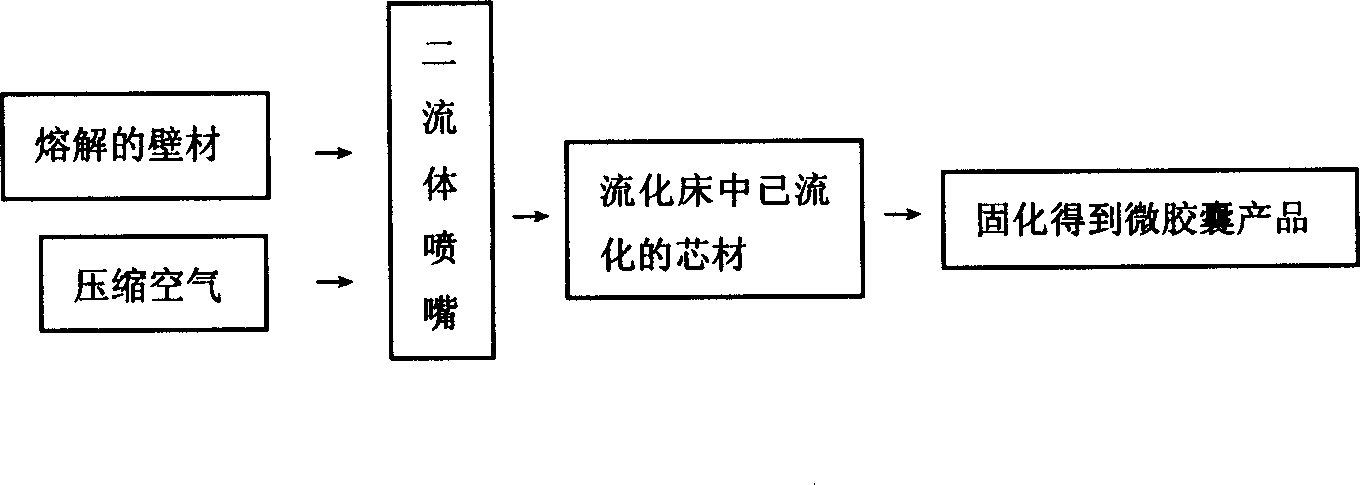

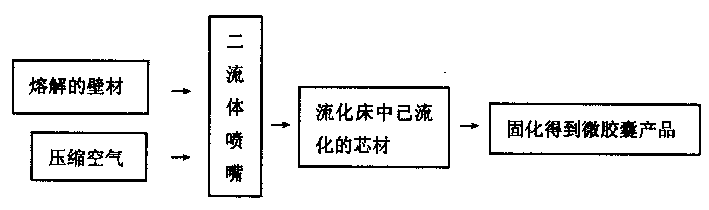

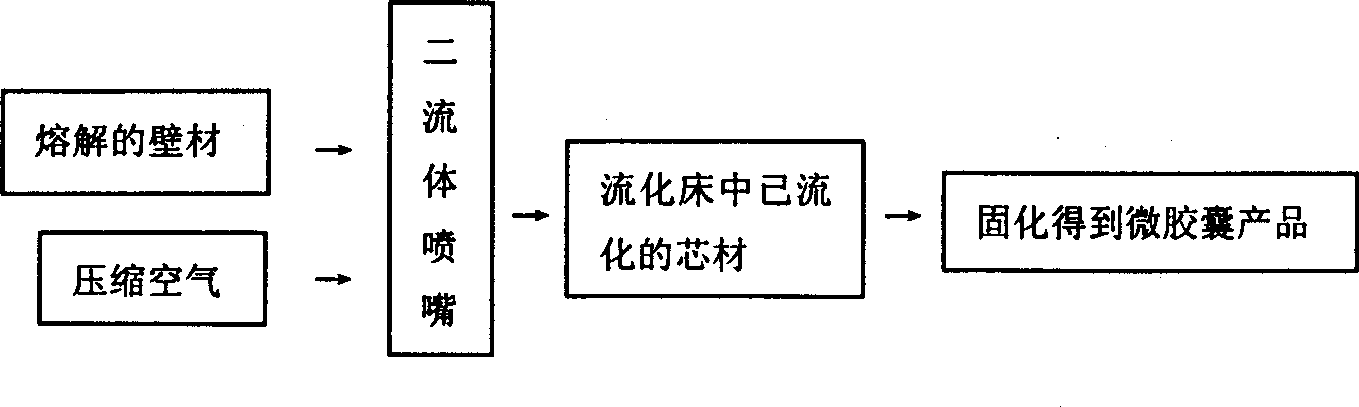

High-hydroscopicity polymer resin microcapsule and its production process

InactiveCN1486782AReduce dosageGood blocking effectSealing/packingMicroballoon preparationAmount of substancePolymer chemistry

The present invention belongs to the field of microcapsule preparing technology. The high-hydroscopicity polymer resin microcapsule has wall material of hardened oil with smelting point higher than 40 deg.c and core material of acrylic acid and acrylamide polymer. The preparation process includes smelting the wall material, fluidizing the core material, air suspension spraying, solidifying and other stages. The present invention solves the problem of high-hydroscopicity polymer to absorb water to denature, makes it possess excellent flowability and prepares microcapsule with targeting release feature. The wrapping material separates the high-hydroscopicity matter from targeting release feature. The wrapping material separates the high-hydroscopicity matter from outer environment, and under certain environment condition, the core material may be released fast to absorb water and to expand. The said process of the present invention is suitable for forming microcapsule with solid core material, and is simple, practical, good in filming performance and homogeneous in embedding.

Owner:DALIAN UNIV OF TECH

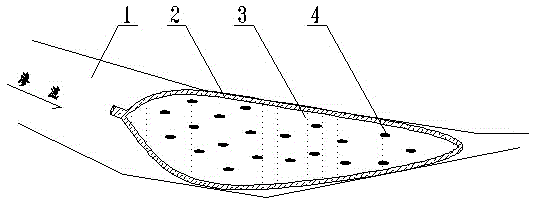

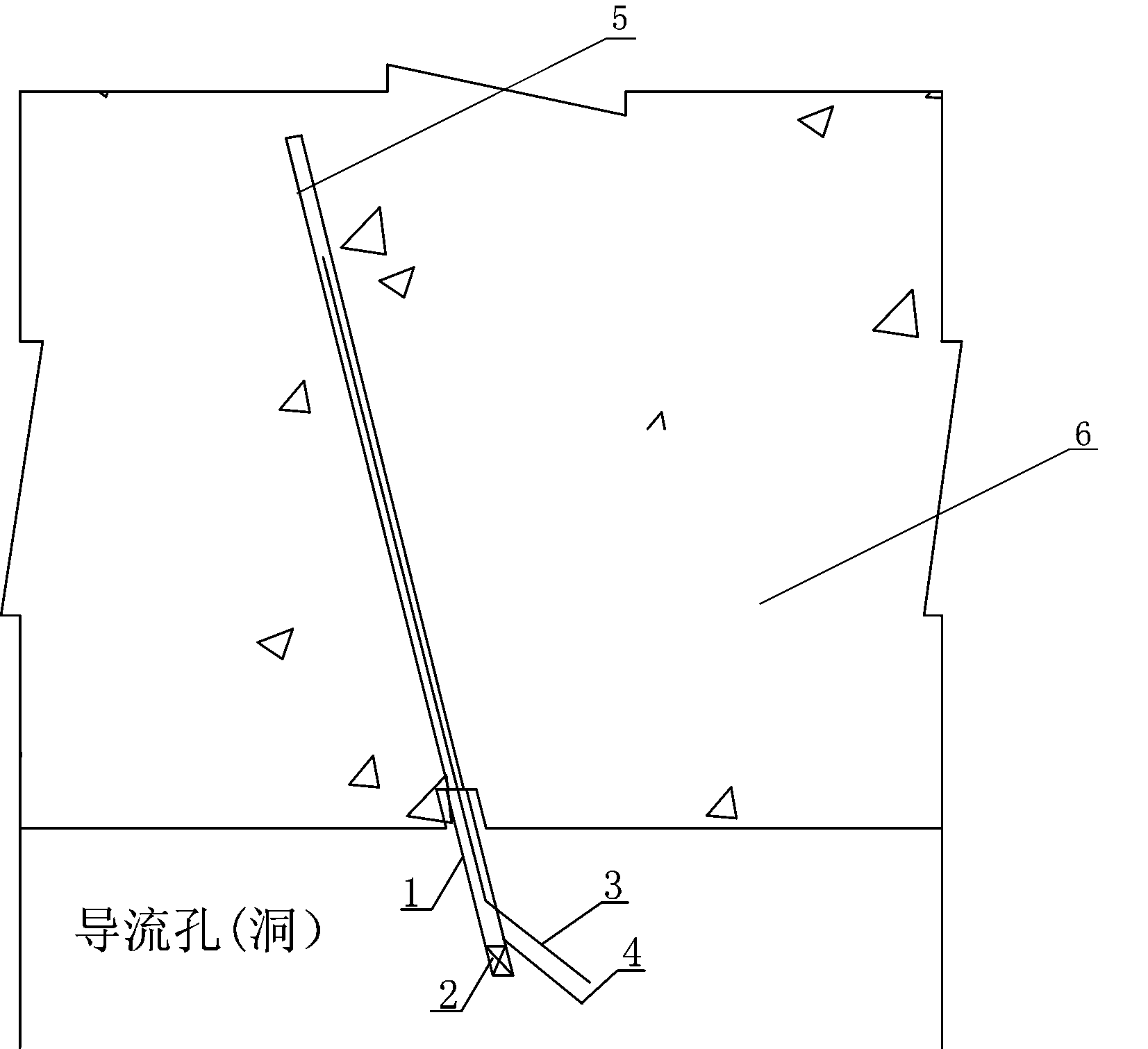

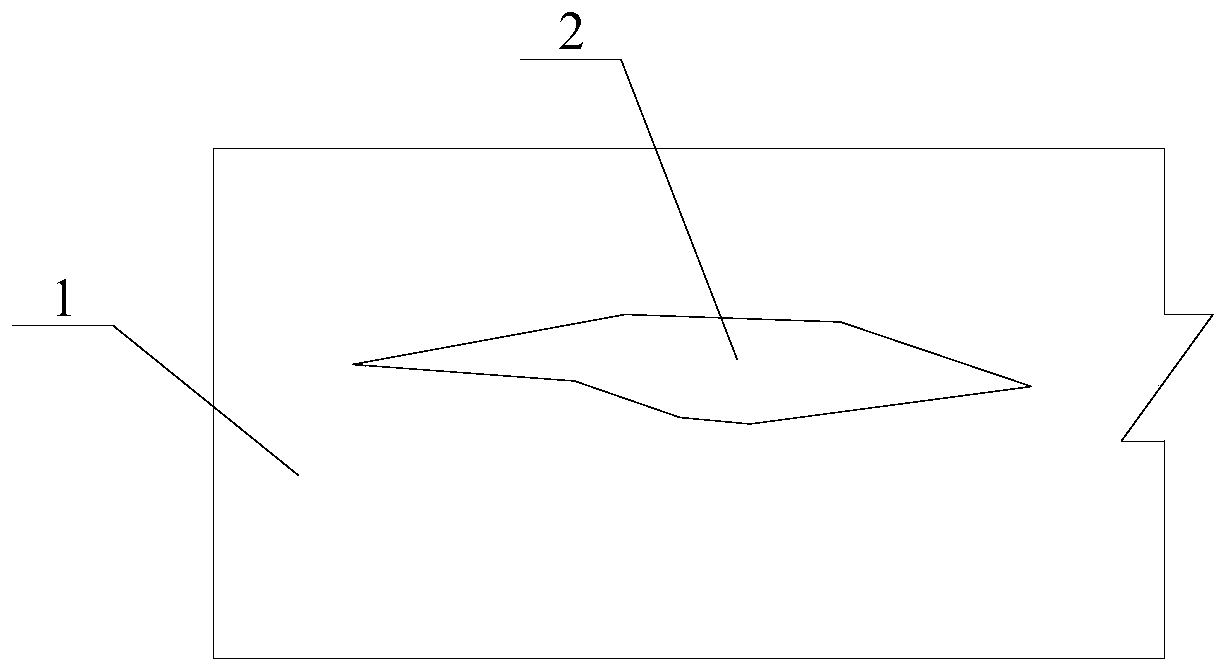

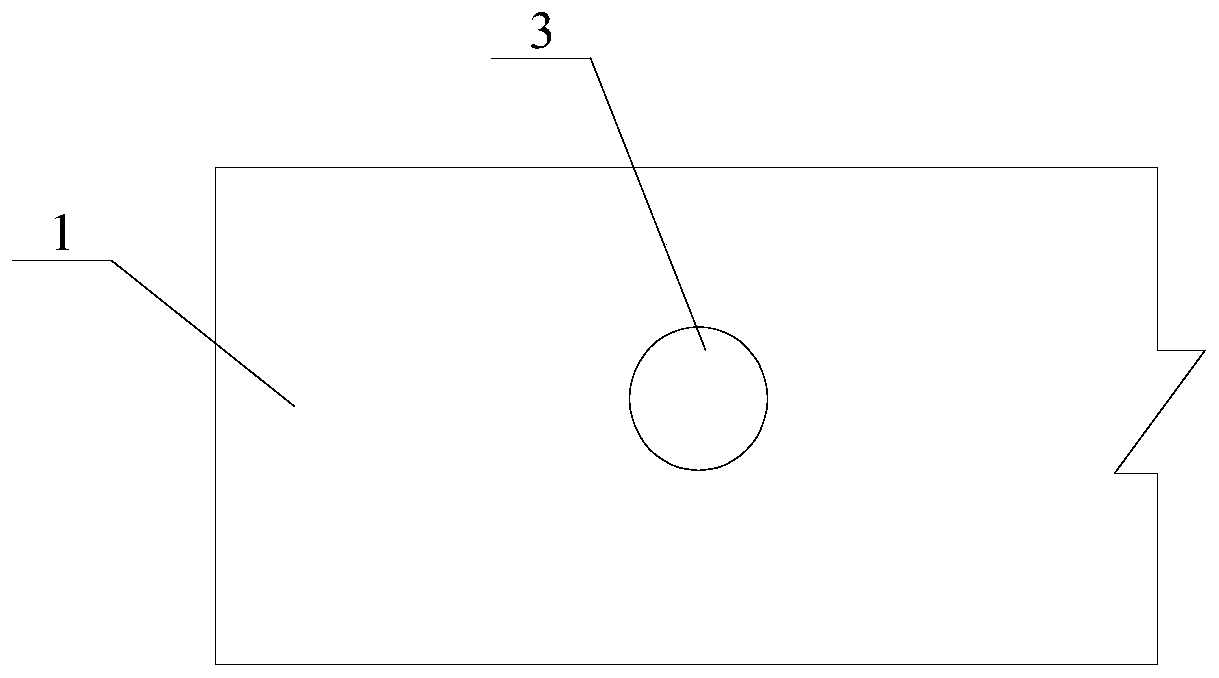

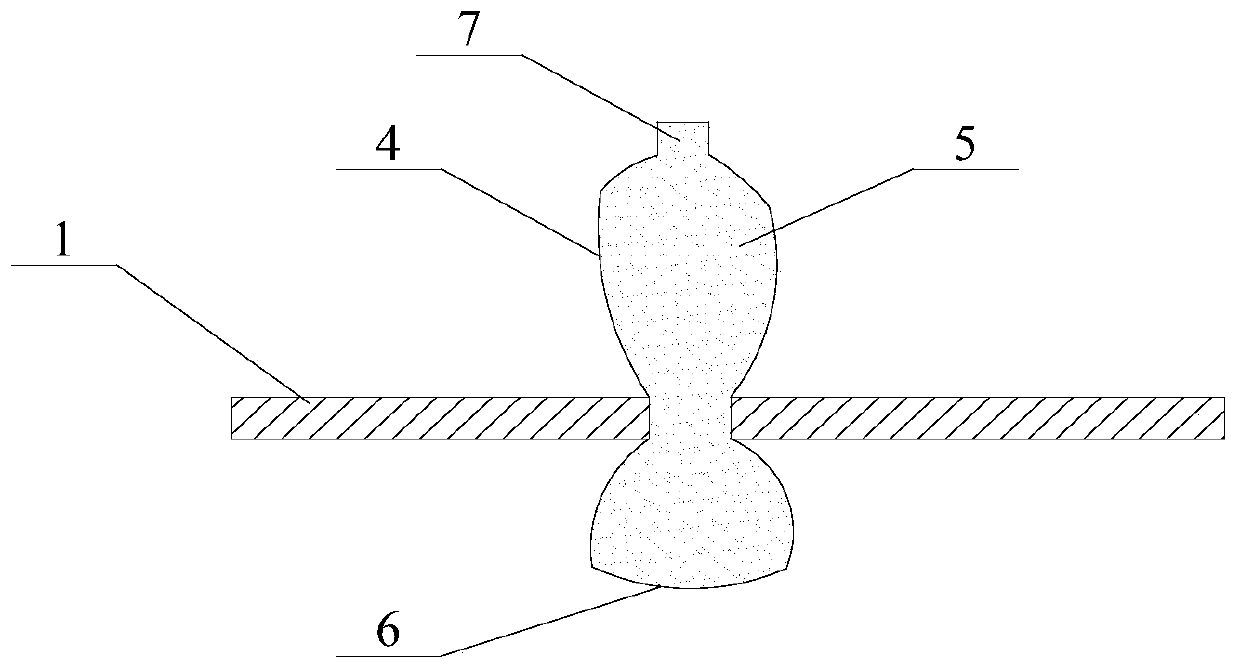

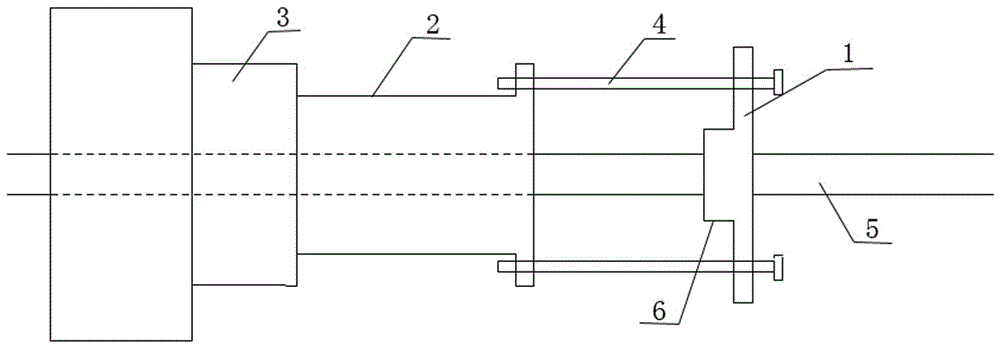

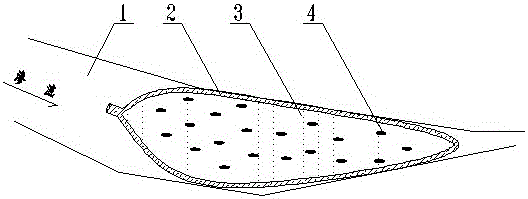

Leaking stoppage method and structure for karst pipeline

ActiveCN104131532AImprove liquidityGood flexibilityMarine site engineeringMechanical engineeringWater resource management

The invention discloses a leaking stoppage method and structure for a karst pipeline. According to the method and structure, soybeans (4) and quick-setting mortar (3) are mixed, stirred, wrapped in a film bag (2) and then placed in an inlet of a leakage point of the karst pipeline (1); the soybeans (4) make volume in the film bag (2) be expanded by utilizing the expansibility of itself before solidification of the quick-setting mortar (3); the quick-setting mortar (3) quickly solidifies while the volume of the film bag (2) is expanded; after the quick-setting mortar (3) solidifies, the film bag (2) is tightly attached to the periphery of the karst pipeline (1) to produce friction and stops flowing, and therefore the leakage stoppage purpose for the karst pipeline (1) is achieved. The leaking stoppage method and structure are low in construction technical difficulty, simple in construction procedure, low in investment and capable of achieving a good leakage stoppage effect and being widely applied and popularized in the technical field of leakage stoppage of the karst pipelines.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

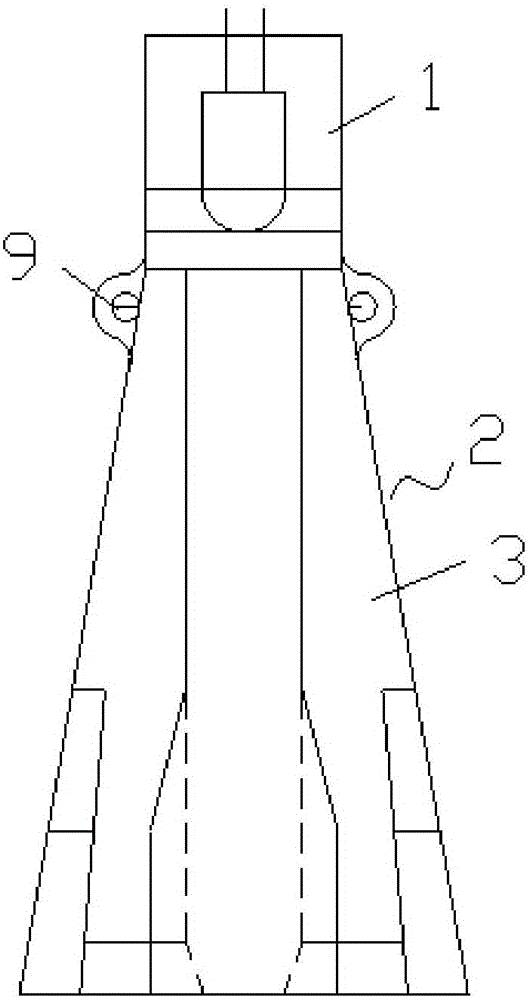

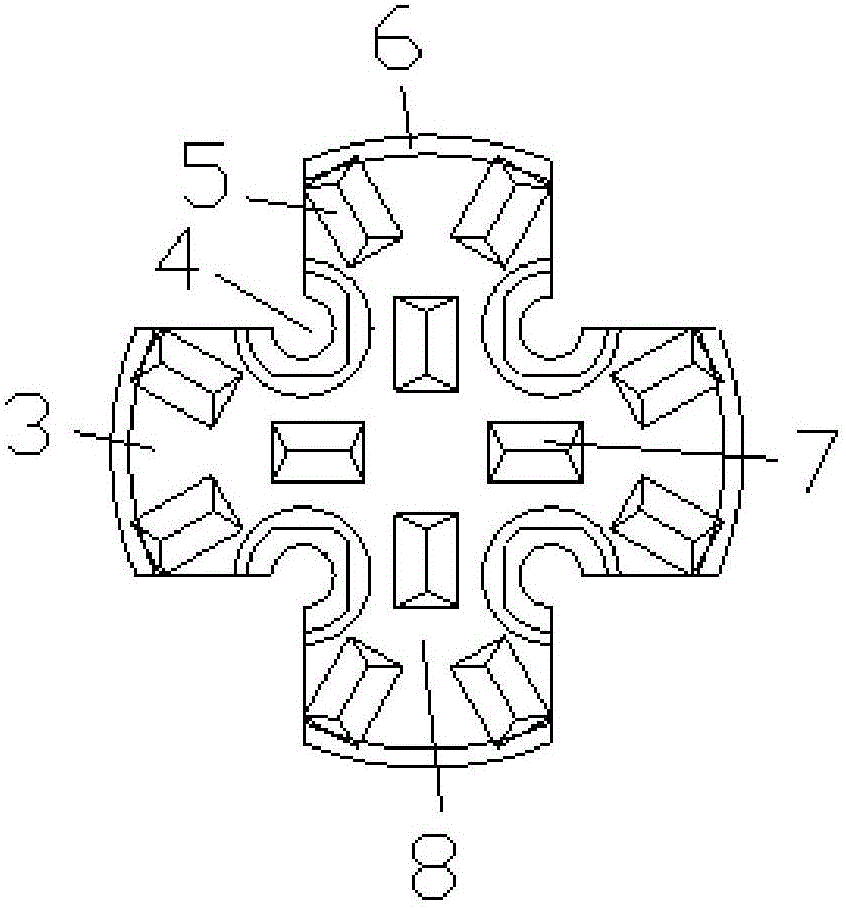

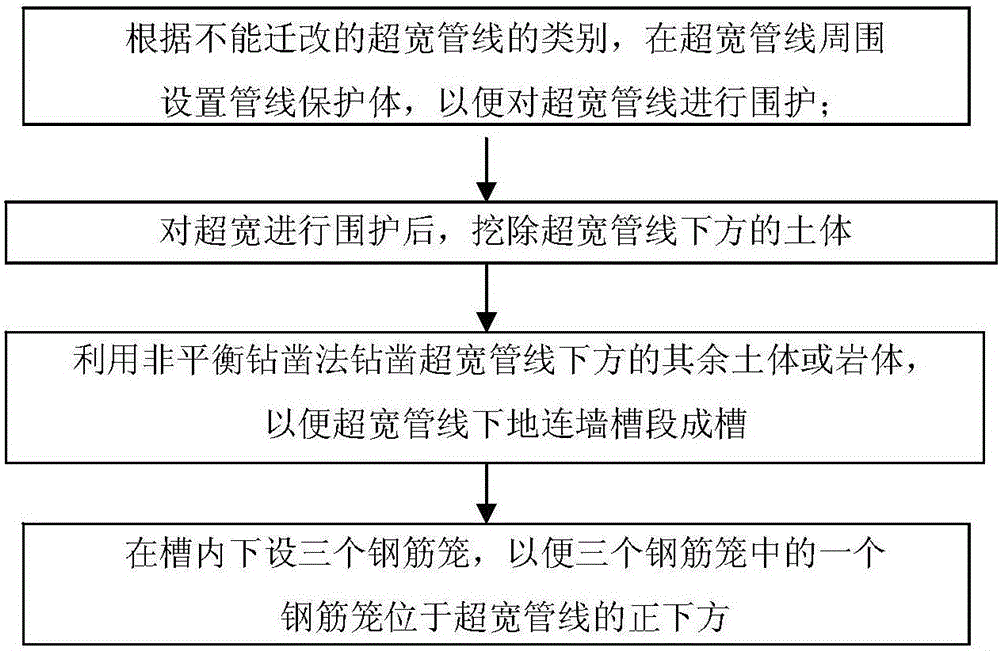

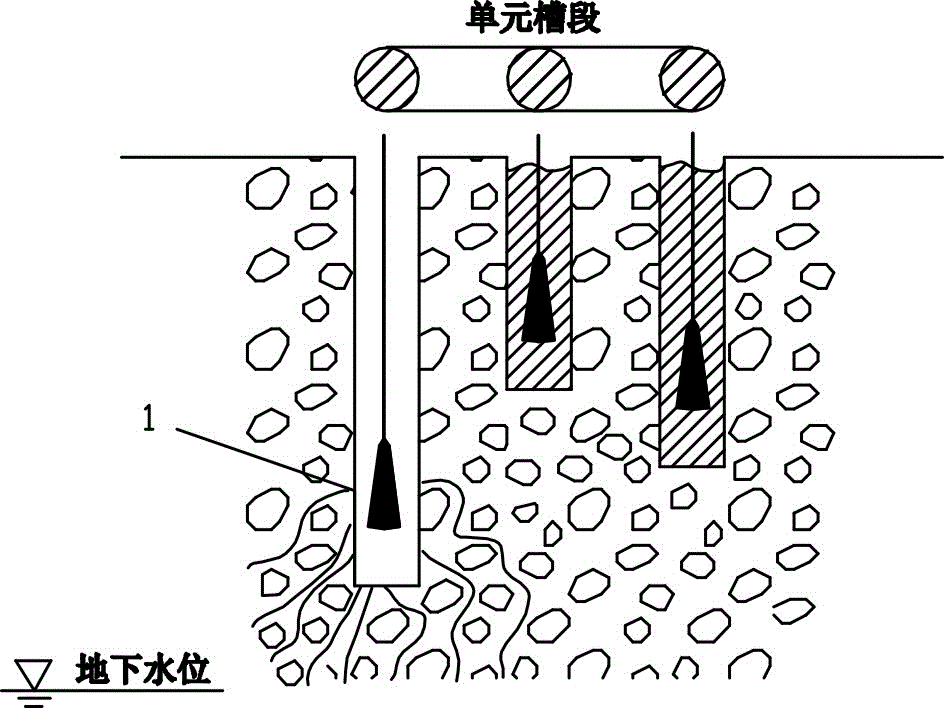

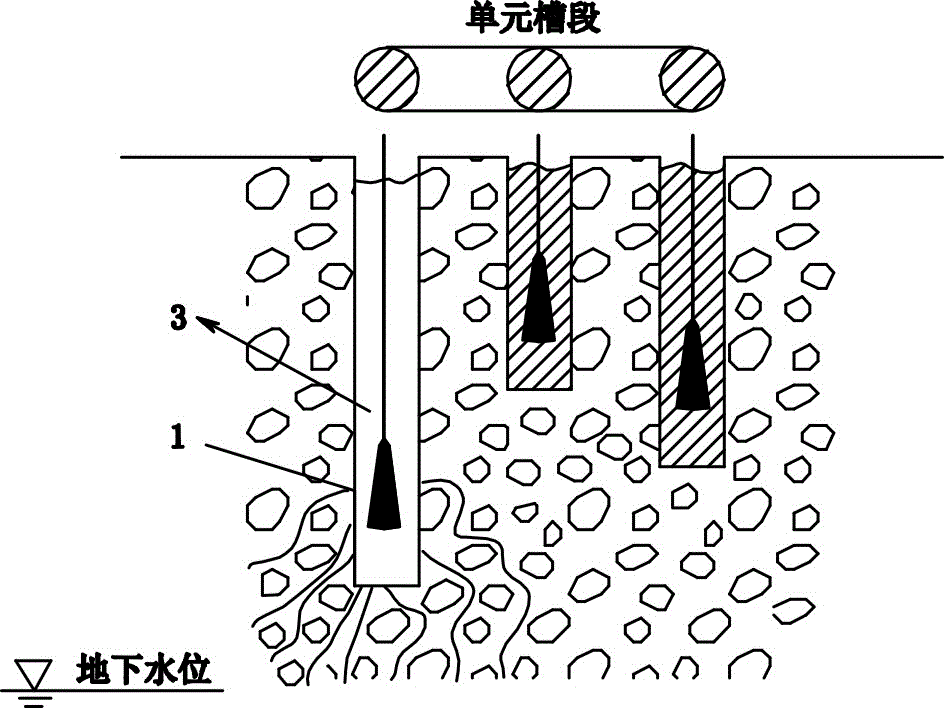

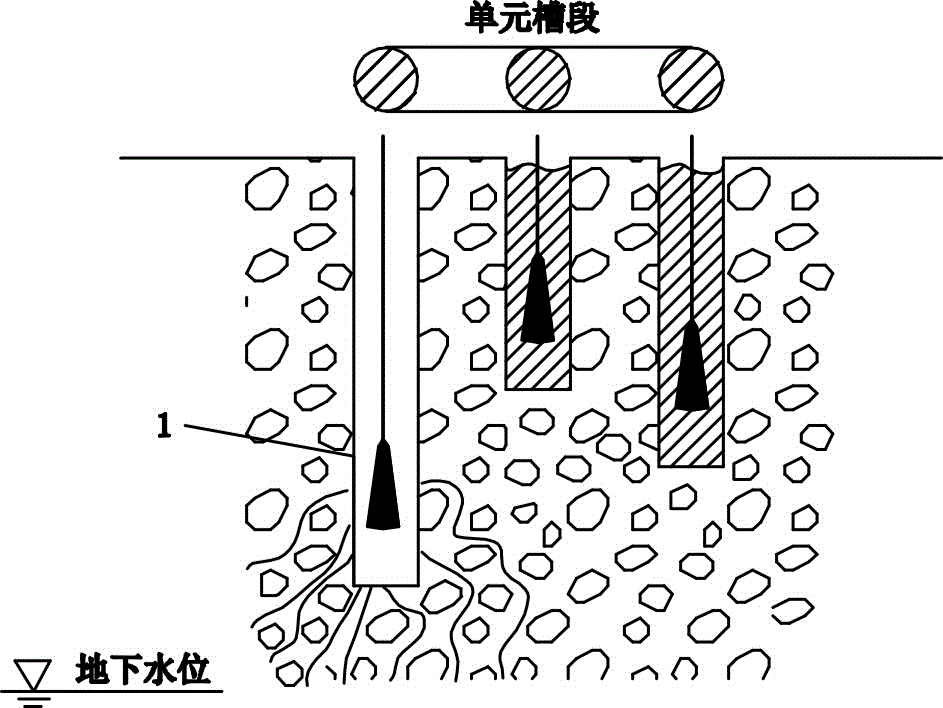

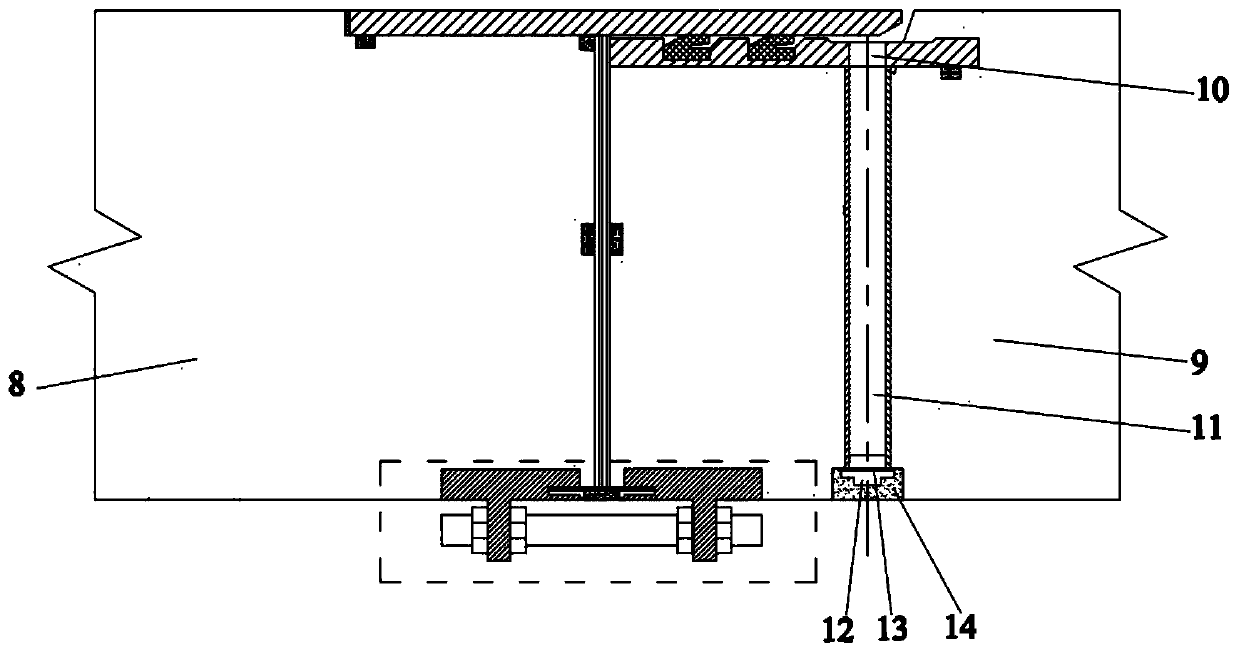

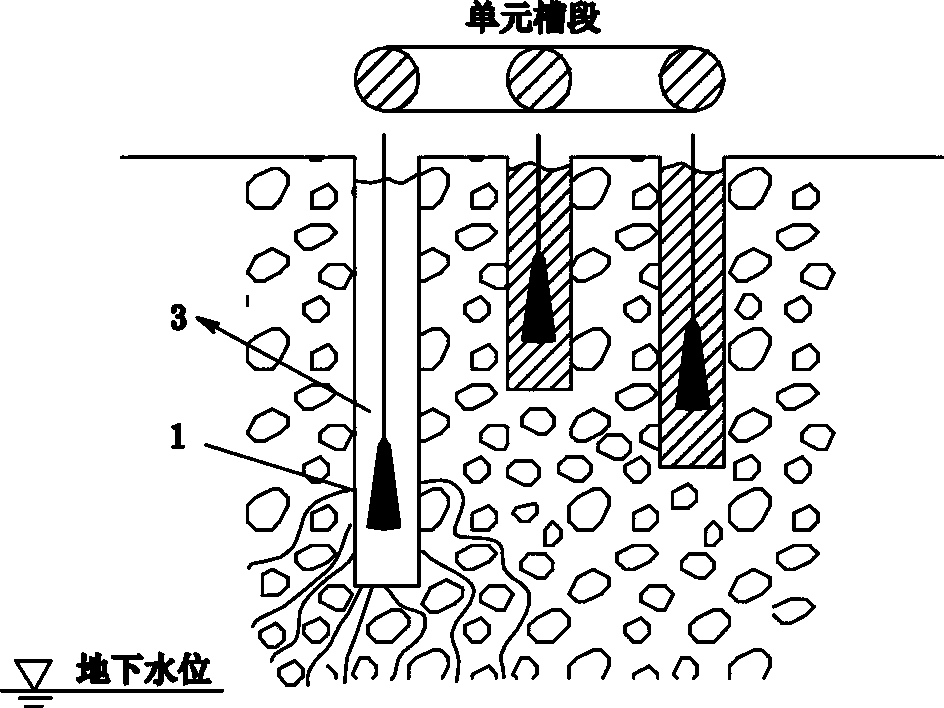

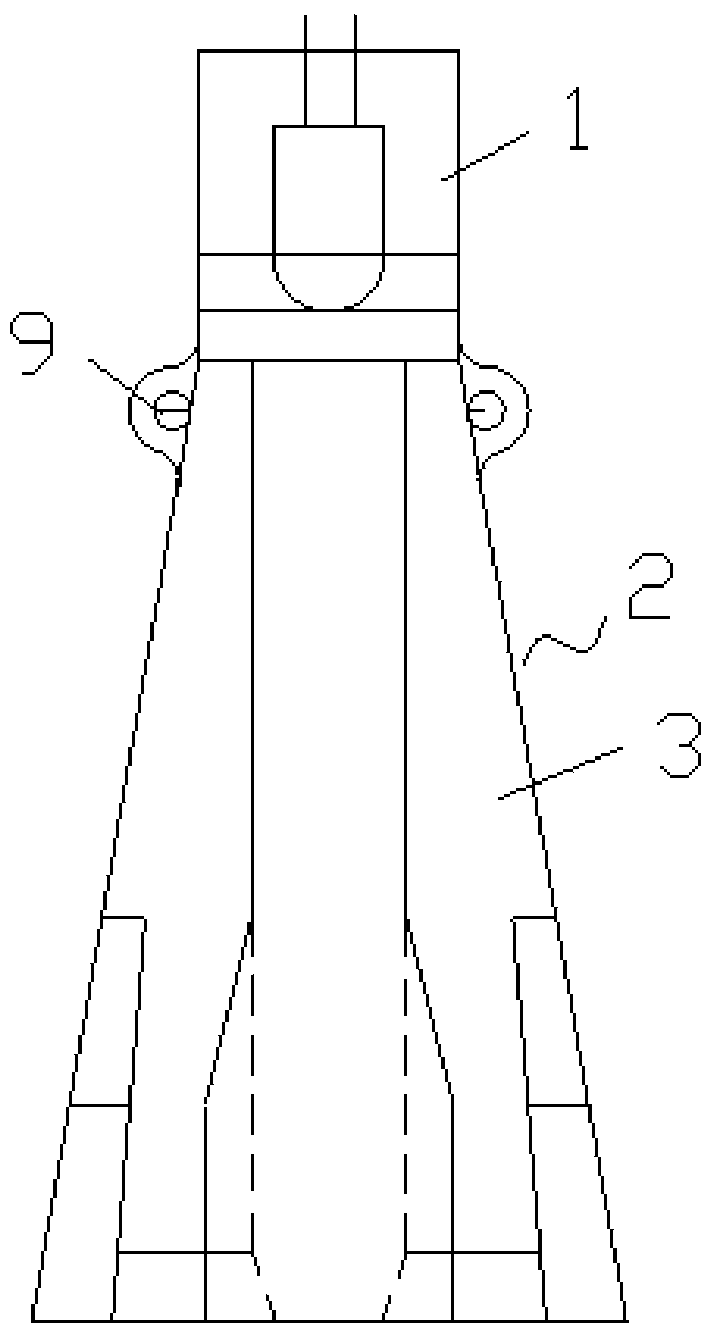

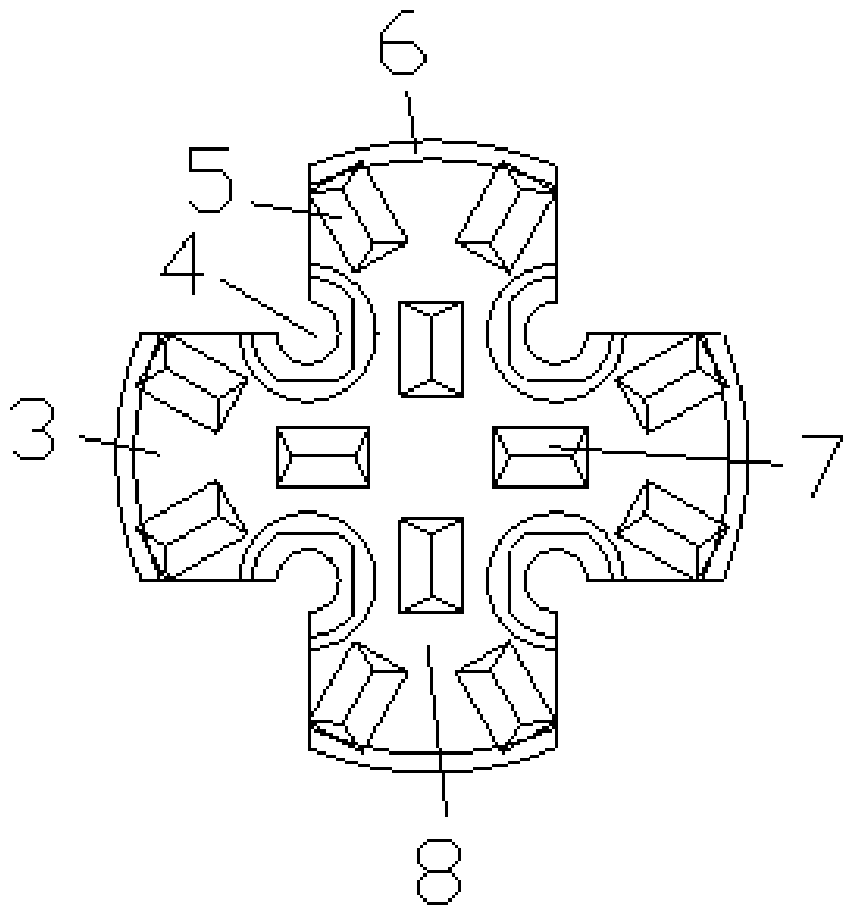

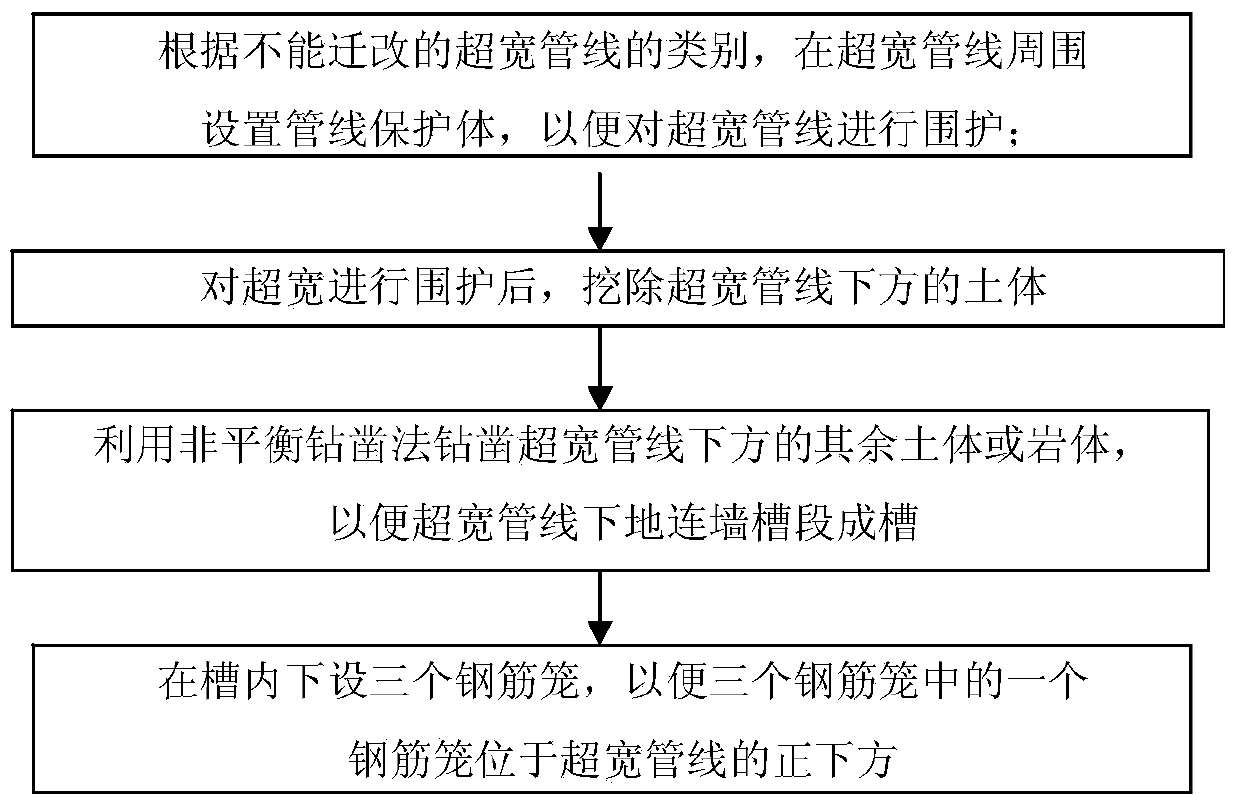

Construction method for concrete diaphragm wall of deep bedrock

ActiveCN105804057AAdvantages of construction methodSolve the problem that the reinforcement cage cannot be translated accuratelyDrill bitsProtective foundationBedrockSlurry

The invention discloses a construction method for a concrete diaphragm wall of a deep bedrock. The construction method for the concrete diaphragm wall of the deep bedrock comprises the step that when an ultra-wide pipeline incapable of being moved or modified exists, trough-forming construction is conducted on the trough section of the concrete diaphragm wall below the ultra-wide pipeline, specially, pipeline protectors are arranged around the ultra-wide pipeline so that the ultra-wide pipeline can be protected in a surrounded mode; soil below the ultra-wide pipeline is excavated out by a long-boom excavator; the rest of soil or rock below the ultra-wide pipeline is drilled through a nonequilibrium drilling method so that a trough can be formed in the concrete diaphragm wall below the ultra-wide pipeline; and three steel reinforcement cages are arranged in the trough, and one of the three steel reinforcement cages can be located under the ultra-wide pipeline. According to the construction method, the ultra-wide pipeline does not need to be moved or modified, the moving and modification cost is omitted, and the project progress is accelerated; a frictional drill bit is adopted for drilling hard bedrock, especially large-dip-angle steep rock, jamming of the drill bit during pore-forming is controlled, and the drilling efficiency is improved; and an intra-trough slurry circulating method is applied in the drilling process, the construction efficiency in the environment of deep hard rock is improved, and the trough forming quality is ensured.

Owner:SINOHYDRO FOUND ENG

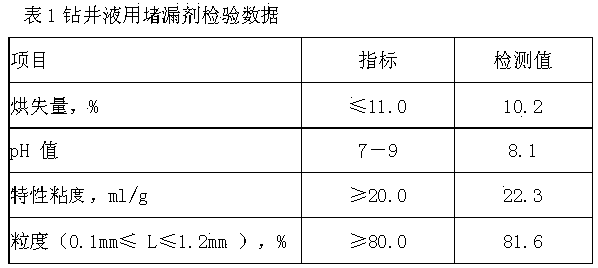

Self-cementing chemical leak-stopping agent for drilling and its preparation process

InactiveCN100556979CPlugging speed is fastTo achieve the purpose of pluggingDrilling compositionWell drillingMixing ratio

The invention relates to a self-cementing chemical plugging agent for well drilling and a preparation method thereof. Using bauxite, limestone and gypsum as raw materials, according to the mass ratio of 20-40 parts of bauxite, 30-60 parts of limestone, and 10-30 parts of gypsum, the intermediate product is fired at 1000-1500 °C, and the intermediate product is Grind, then mix with gypsum, limestone and quartz sand according to the mass ratio of 60-90 parts of intermediate products, 5-15 parts of gypsum, 5-20 parts of limestone, and 5-15 parts of quartz sand to obtain cemented chemical plugging agent products. The plugging agent has rich raw materials, low cost, simple preparation method and easy implementation, and its plugging effect is better than that of existing chemical plugging agents. It has wide applicable temperature range, fast plugging speed, strong pressure bearing capacity and is suitable Advantages of oil layer plugging.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

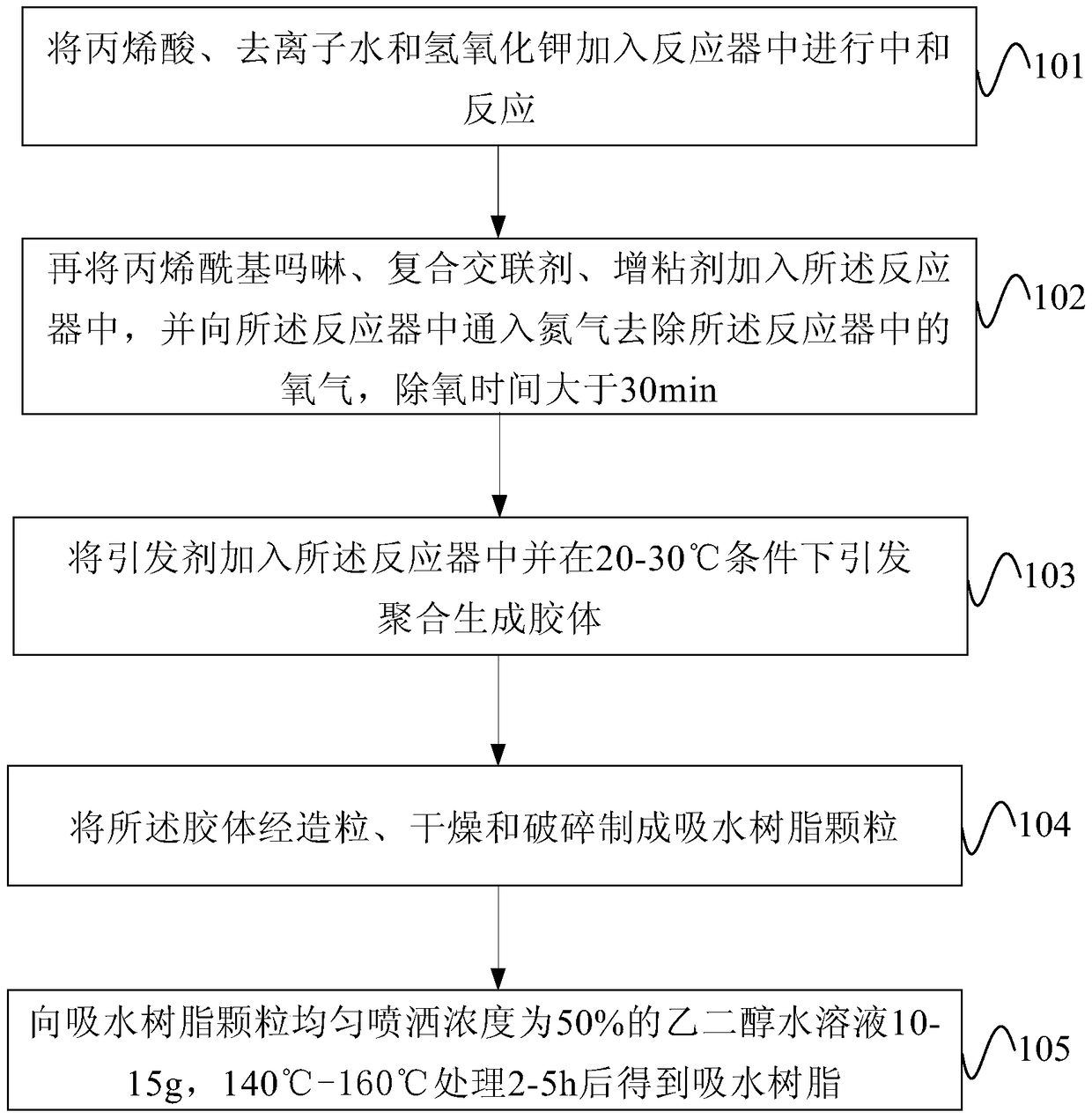

Water-absorbent material and preparation method and application thereof

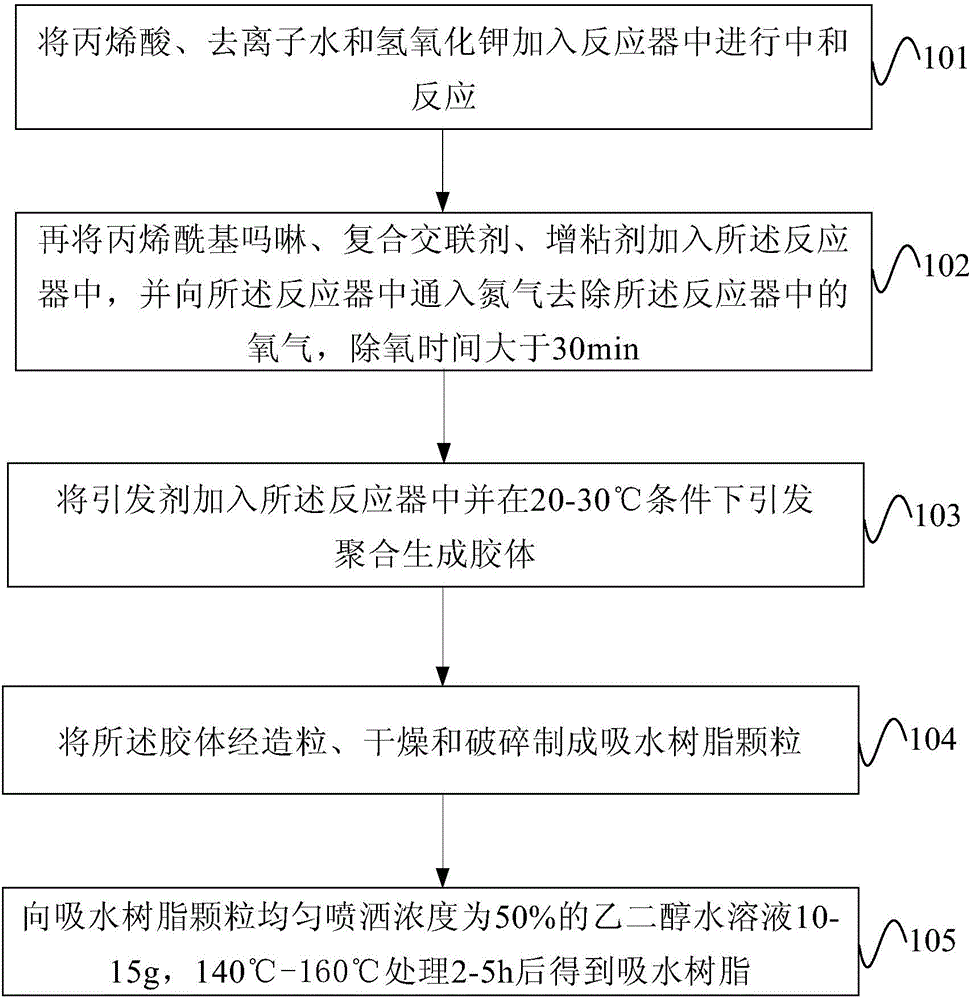

ActiveCN105837758AAvoid degradationUniform crosslinkingDrilling compositionMorpholinePotassium hydroxide

The invention provides a water-absorbent material and a preparation method and an application thereof. The water-absorbent material comprises, by mass percentage, 27-33% of acrylic acid, 17-21% of potassium hydroxide, 1-2% of acryloyl morpholine, 1-2% of a composite cross-linking agent, 0.2-0.3% of silica, 0.04-0.06% of a tackifier, 0.2-0.3% of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 41-54% of deionized water, and 0.1-0.3% of an initiator, wherein the mass ratio of acrylic acid to potassium hydroxide is 50:31. Through the provided water-absorbent material, the technical problem that a strong water-absorbent material added in a conventional kill fluid cannot resist salt, is prone to degrade, and is poor in temperature resistance is solved, and the water-absorbent material has a certain viscosity and a compression shielding function after water absorbance, thereby achieving the purpose of leakage protection. The effect of leakage protection is improved, when the water-absorbent material is applied to the kill fluid.

Owner:PETROCHINA CO LTD

Leaking stoppage material used for geological core drilling

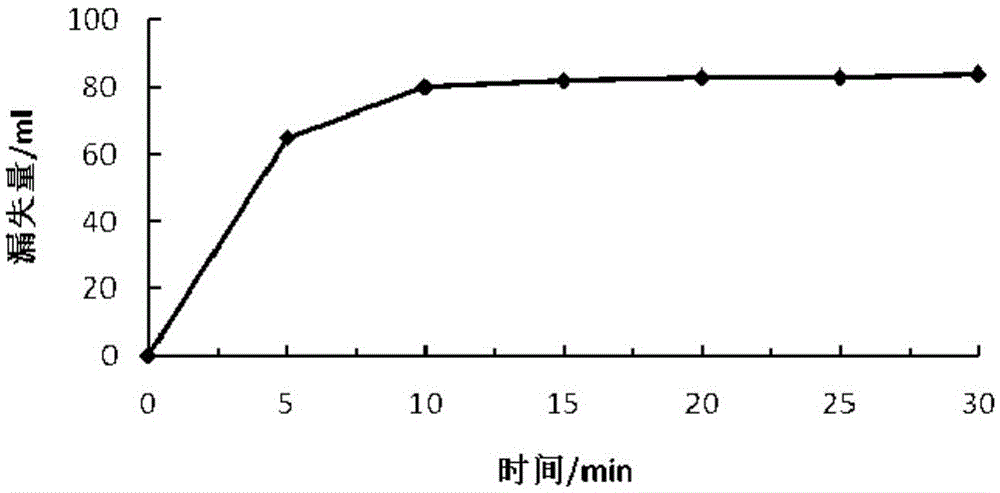

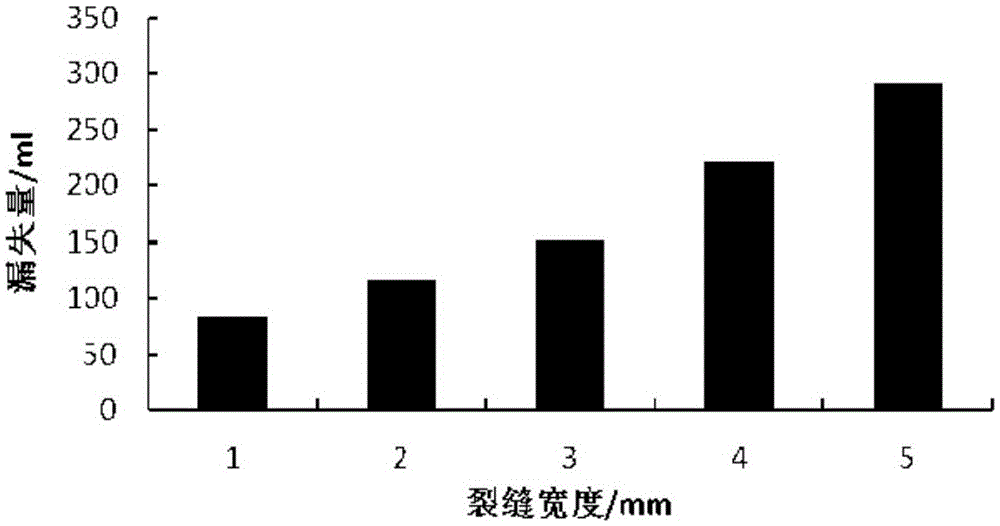

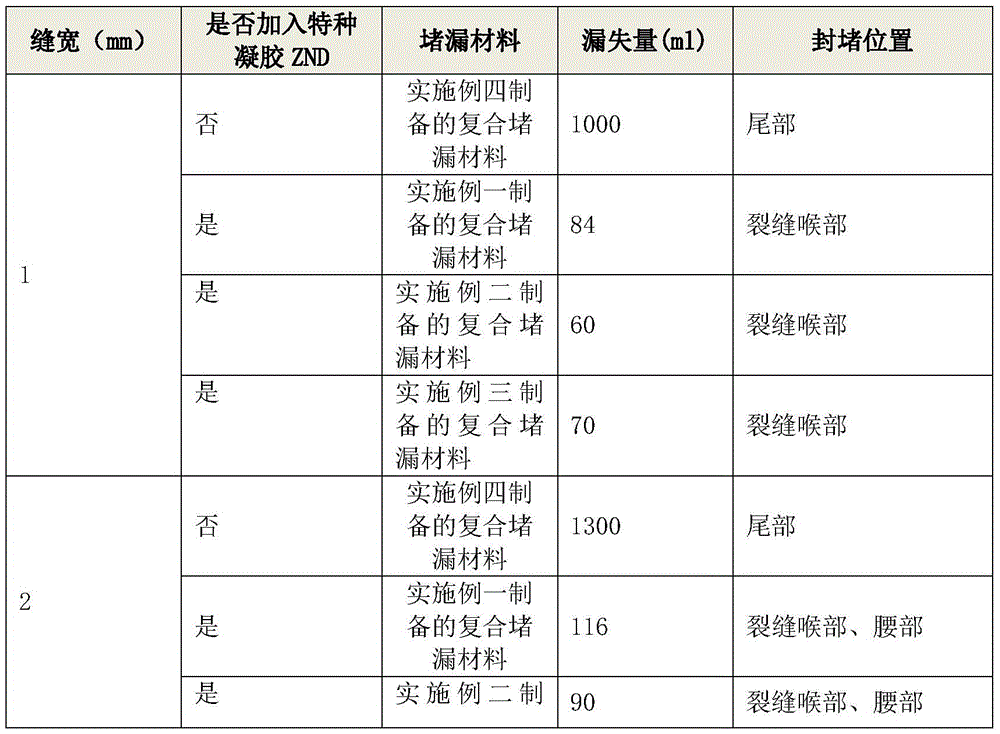

InactiveCN105647495AIncrease flow resistanceEffective blockingDrilling compositionFilling materialsPolymer

The invention provides a composite leaking stoppage material capable of adapting to geological core drilling characteristics. The composite leaking stoppage material is prepared from 3-5 parts of special gel ZND polymers, 45-47 parts of a bridge plugging material and 47-50 parts of a filling material. Under the condition of an existing geological core drilling technology, the composite leaking stoppage material overcomes the defects that when a special gel leaking stoppage technology is used for geological drilling engineering, the leaking stoppage success rate is low, and even the technology cannot be applied, and the success rate of stoppage of malignant leakage in geological core drilling can be increased.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

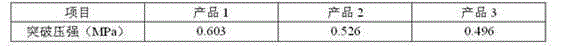

Plugging resin system and application thereof

InactiveCN111793480AImprove liquidityImprove mechanical propertiesDrilling compositionPolymer scienceFirming agent

The invention provides a plugging resin system and application thereof. The plugging resin system is obtained by a reaction of a component A and a component B, the mass ratio of the component A to thecomponent B is 1: 1 to 3: 2, the component A at least comprises epoxy resin, and the component B at least comprises an epoxy resin curing agent. Epoxy resin and a curing agent are mixed and stirred according to different proportions, the mixture is pumped into a casing leakage breaking section, the resin and the curing agent are subjected to addition polymerization reaction within specified timeand under the condition of proper formation temperature to generate a cured product of a net structure, and the purpose of plugging is achieved. And the gelling time can be controlled by the dosages of the components A and B. The compressive strength is greater than 80 MPa, and the chemical plugging construction requirements of the casing damage well are met. According to the plugging resin system, the compressive strength is met, meanwhile, the resin hardness is reduced, the resin toughness is improved, and the resin drillability is improved. And the plug drilling speed can reach 2.5 m / h under the same condition of the plug drilling process, so that the plug drilling time is greatly saved.

Owner:PETROCHINA CO LTD

Self-cementing chemical leak-stopping agent for drilling and its prepn process

InactiveCN101089115APlugging speed is fastTo achieve the purpose of pluggingDrilling compositionHigh pressureGypsum

The present invention relates to self-cementing chemical leak-stopping agent for drilling well and its preparation process. The self-cementing chemical leak-stopping agent is prepared through mixing bauxite, lime stone and gypsum in the weight proportion of 20-40 to 30-60 to 10-30; baking the mixture at 1000-1500 deg.c to obtain intermediate product; grinding the intermediate product; and mixing the intermediate product, gypsum and lime stone and quartz sand in the weight proportion of 60-90 to 5-15 to 5-20 to 5-15 to obtain the chemical leak-stopping agent. The present invention has the advantages of rich material, low cost, simple preparation process, wide applicable temperature range, fast leak-stopping speed, high pressure bearing capacity and being suitable for stopping leak in oil reservoir.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

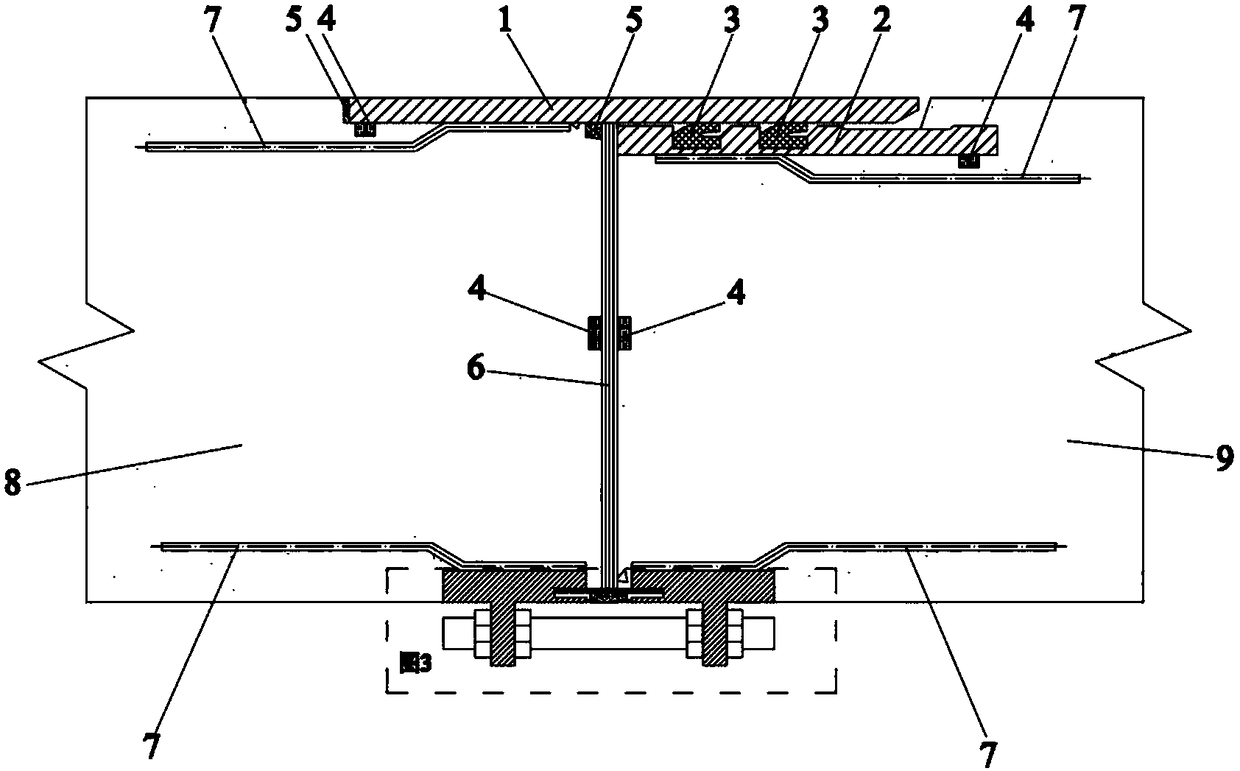

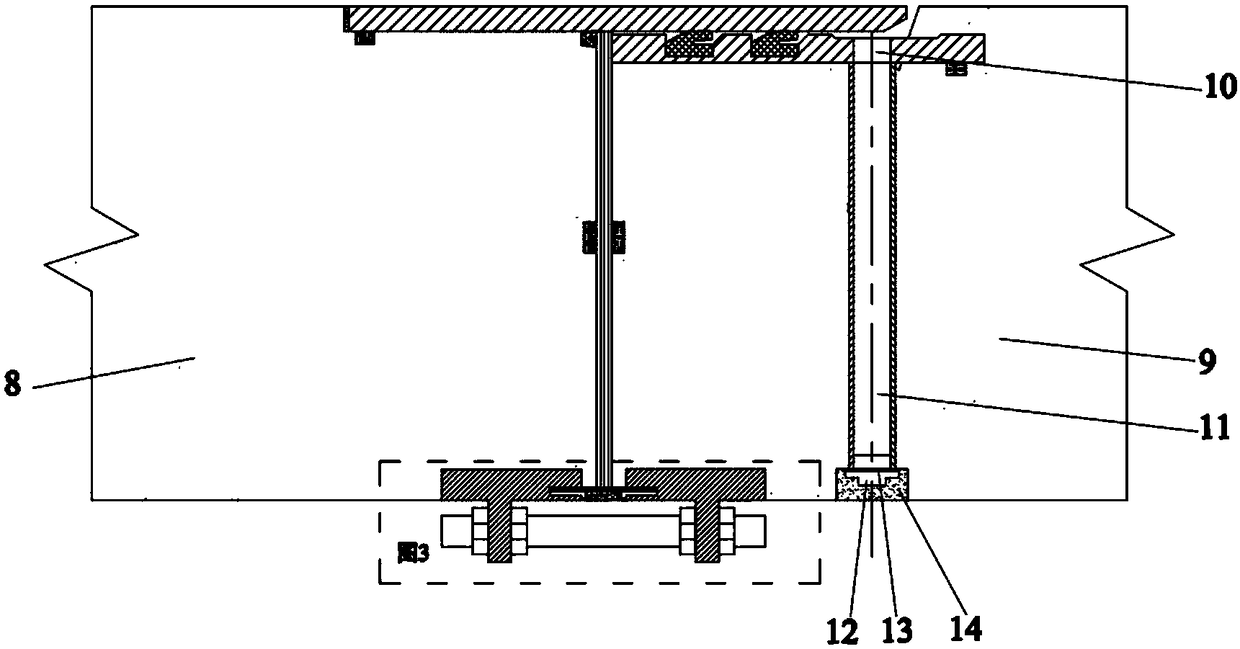

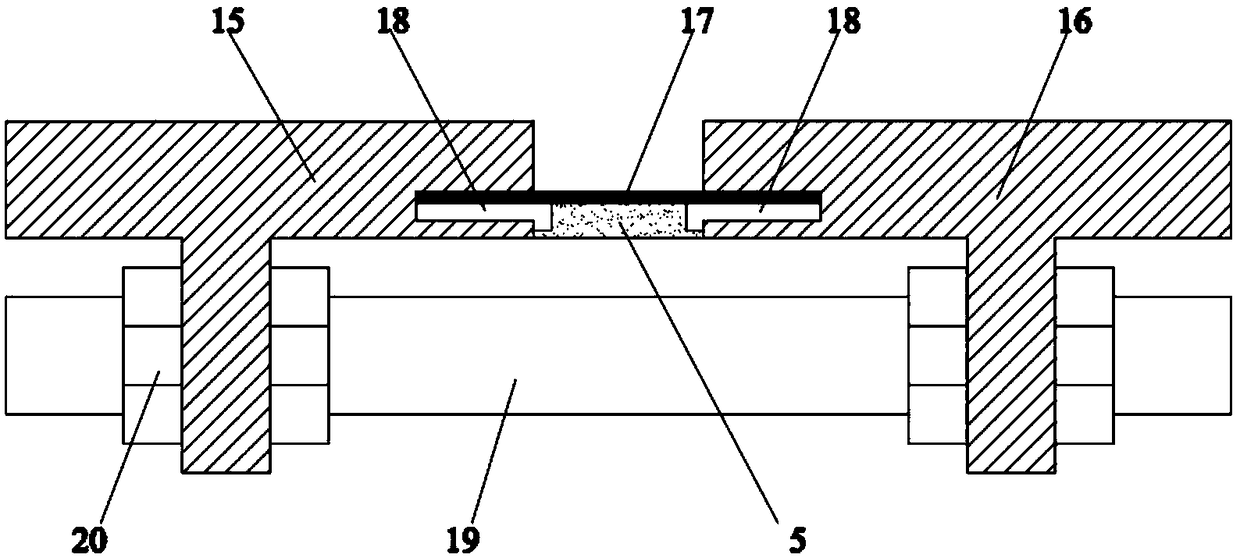

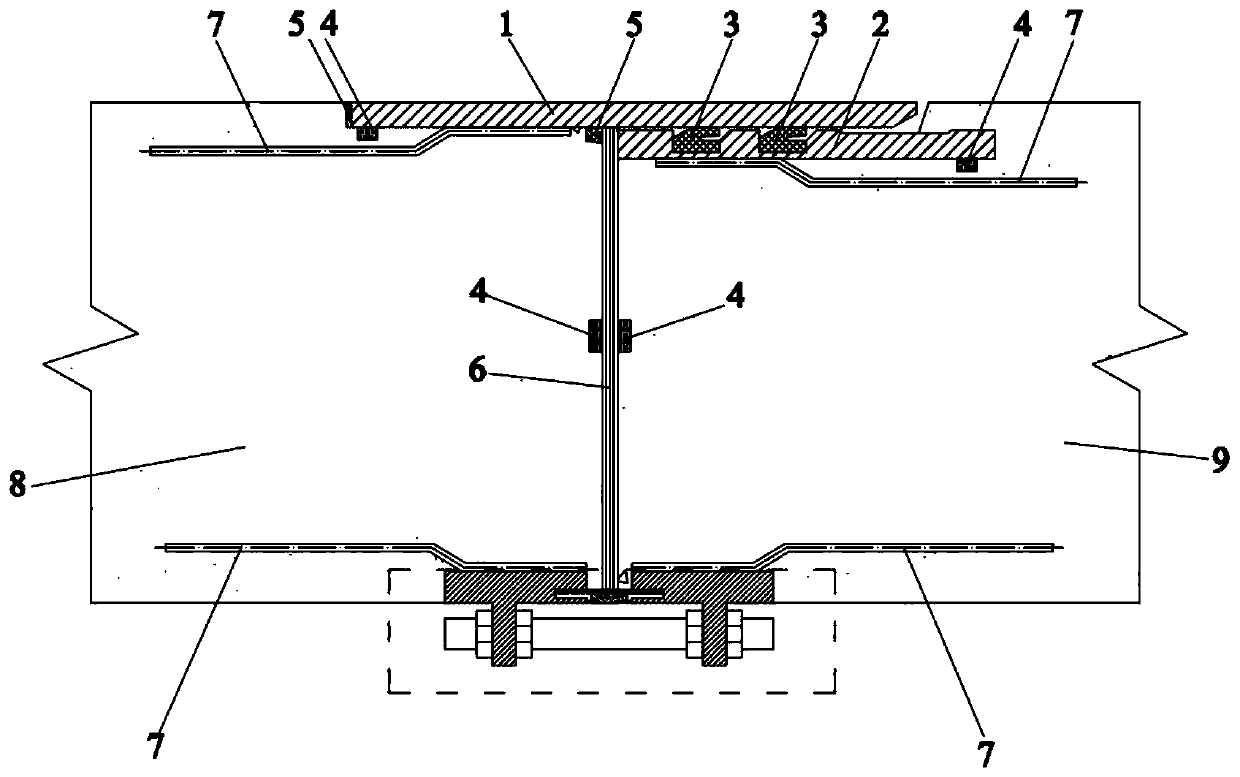

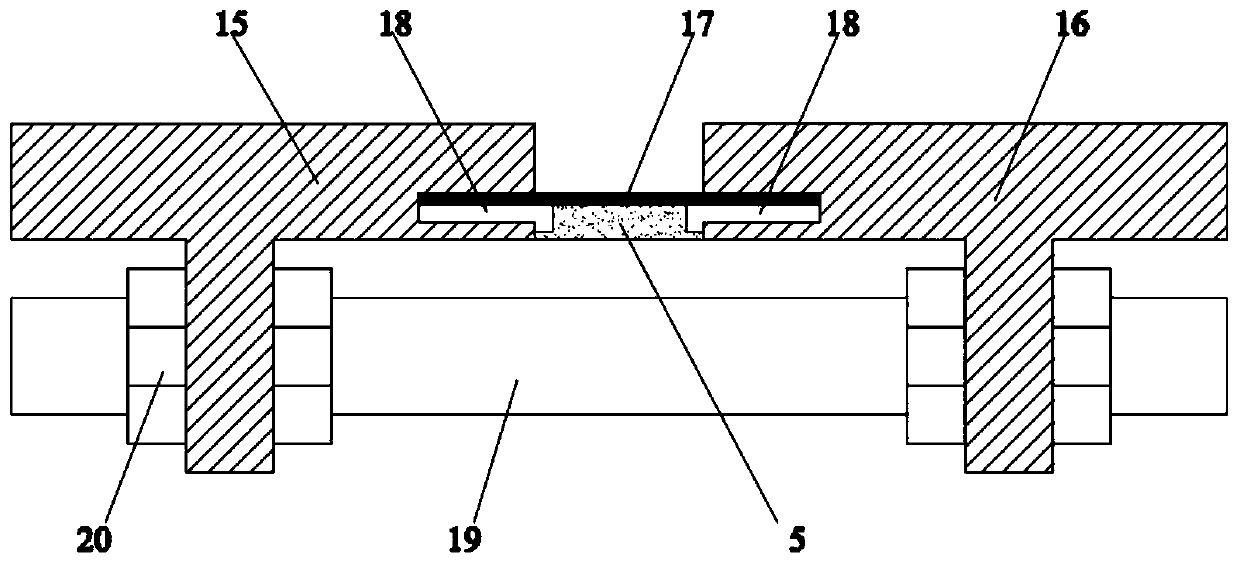

Reinforced concrete ejection pipe joint connector

ActiveCN108443612AAvoid destructionPrevent water seepageSleeve/socket jointsReinforced concreteEngineering

The invention relates to the technical field of ejection pipes of non-excavation works, in particular to a reinforced concrete ejection pipe joint connector. The connector is positioned at a connection between a front pipe joint and a rear pipe joint which are adjacent. The connection part of the connector at least comprises a pipe joint outer wall sealing connecting part and a pipe joint inner wall sealing connecting part. The pipe joint outer wall sealing connecting part at least comprises a socket steel bushing ring positioned at the rear end of the front pipe joint and a socket steel ringpositioned at the front end of the rear pipe joint. The pipe joint inner wall sealing connecting part at least comprises the structure that steel bushing rings separately arranged on the front pipe joint inner wall and the rear pipe joint inner wall. Each steel bushing ring at least comprises an annular steel ring and an annular slab. Ribbed plates and bolted holes are uniformly distributed on thefront side and the rear side of the slab. The ribbed plate and the bolted holes are staggered mutually in position. The bolted holes in the front pipe joint slab are corresponding to those of the rear pipe joint slab. The bolted holes corresponding to one another are connected by bolts and nuts. The pipe joint connector adopting the technical scheme can completely meet the need of projects with high waterproof requirements, and can adapt to complex construction environments such as high water pressure and soft ground.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID +2

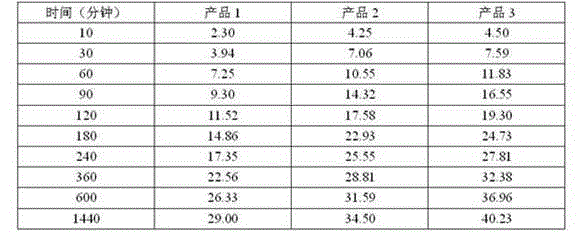

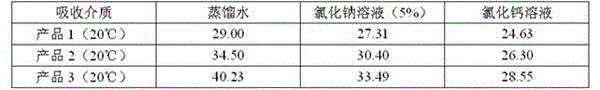

Pre-crosslinking expansion-particle leakage-stopping agent for drilling and preparation method of pre-crosslinking expansion-particle leakage-stopping agent

InactiveCN104592961AIncreased crush strengthImprove toughnessDrilling compositionTemperature resistanceToughness

The invention relates to a pre-crosslinking expansion-particle leakage-stopping agent for drilling. The pre-crosslinking expansion-particle leakage-stopping agent is formed by polymerizing materials and comprises the following materials in parts by weight: 200-280 parts of acrylamide, 4-6 parts of 2-acrylamide-2-methyl propane sulfonic acid, 20-26 parts of acryloyl-oxy-ethyl-trimethyl ammonium chloride, 4-6 parts of delaying-crosslinking agent and 4-6 parts of initiating agent. The invention also relates to a preparation method of the pre-crosslinking expansion-particle leakage-stopping agent. The pre-crosslinking expansion-particle leakage-stopping agent has high anti-extrusion strength, good toughness, good temperature resistance and slower water-absorbing expansion rate, and has certain delaying and expanding characteristics; and the preparation method is mild in reaction, is easy in operation and control and is safe and reliable.

Owner:HEBEI GUANGDA PETROCHEM

Hole filling method by blasting

The invention relates to a hole filling method by blasting. The materials used comprises two parts, i.e., a hole filling material and hole filling cartridge bags. A blast hole is sealed by using a common hole filling material; the hole filling cartridge bags are alternately arranged inside the hole filling material along the direction of the blast hole. A time-delayed detonating method is employed for allowing the cartridge bags to be detonated firstly inside the blast hole. The energy generated by the explosion of the explosive inside the hole filling cartridge bags allows the common hole filling material above and below the explosive to be compacted, thereby increasing the frictional force between the hole filling material and the wall surface of the blast hole. Meanwhile, the delayed time between a hole filling cartridge bag and a main charge of a charge section is designed, thereby achieving that the detonation gas generated by the hole filling cartridge bags inside the filling section is not escaped upon detonating the main charge, and accordingly generating a high pressure environment inside the filling section, and increasing the hole filling effect.

Owner:UNIV OF SCI & TECH OF CHINA +1

Quick processing device for large-flow water leakage hole in concrete body

InactiveCN103774619AEasy to make and installEasy to operateMarine site engineeringBall valveStreamflow

A quick processing device for a large-flow water leakage hole in a concrete body comprises a water drainage pipe installed at an opening of the water leakage hole, a ball valve installed at an outlet of the water drainage pipe, a long grouting pipe and a short grouting pipe, wherein the long grouting pipe and the short grouting pipe are welded to the inside of the water drainage pipe, the unwelded end, of a certain length, of the long grouting pipe extends into the water leakage hole, and the unwelded end of the short grouting pipe extends into the water drainage pipe. According to the quick processing device for the large-flow water leakage hole in the concrete body, the ball valve on the water drainage pipe is quickly closed, grouting is carried out through the short grouting pipe, the long grouting pipe is used for draining water, when slurry comes out from the long grouting pipe, the long grouting pipe and the short grouting pipe are simultaneously used for grouting, the two pipes are in parallel connection for grouting, and the anti-leakage aim is achieved. In the early stage of grouting, the long grouting pipe can be used for draining water all the time so that pressure of water in the water leakage hole cannot be excessively high and grouting cannot be influenced; according to the quick processing device, the processing principle that plugging is carried out during drainage and drainage is carried out during plugging is adopted, and the aim of quickly plugging the water leakage hole is achieved; the quick processing device is easy to manufacture and install and convenient to operate; the device is simple, practical and good in effect when the large-flow water leakage hole is processed.

Owner:CHINA GEZHOUBA GRP INT ENG

Flexible quick emergency plugging method

InactiveCN110844015AQuickly blockedTo achieve the purpose of pluggingEngine sealsVessel safetyLeaking waterFoaming agent

The invention discloses a flexible quick emergency plugging method, and belongs to the technical field of plugging methods. The flexible quick emergency plugging method comprises the steps that a plugging bag is made, and a plugging gun and a plugging agent are prepared; the plugging bag is put into the plugging gun rod in a sleeving mode and sent into the side of a ship plate loophole together; the plugging agent is injected into the plugging bag; and fourthly, the plugging bag is swelled after the plugging agent swells, thus the plugging agent and the plugging bag fill the loophole to make the loophole be no longer leaking water, and plugging is completed. According to the flexible quick emergency plugging method, a flexible material or an umbrella-shaped flexible material is adopted asthe plugging bag, the plugging bag is filled with a foaming agent, the volume of the foaming agent can rapidly swell and enlarge, fast solidifying and forming are achieved, and thus the purpose of plugging is achieved; but the diameter of the plugging bag needs to be greater than the diameter of the loophole, when filling, the two ends of the plugging bag become larger, the middle is small, the purpose of fixing and plugging is achieved, and thus the loophole is quickly plugged in a short time; and due to the flexible function of the plugging bag material and the liquid nature of a filler, theplugging bag can be deformed at will, and thus can be suitable for plugging loopholes with a variety of regular or irregular shapes.

Owner:刘效锋 +1

Oil gas productive layer plugging-type oil well cement being acidifyingly soluble

InactiveCN105131919ATo achieve the purpose of pluggingImprove pollutionDrilling compositionCement slurryUltimate tensile strength

The invention discloses oil gas productive layer plugging-type oil well cement being acidifyingly soluble and belongs to the field of oil well cement of well cementation of petroleum and natural gas. The oil well cement comprises following components, by weight, 100 parts of oil well cement, 50-200 parts of carbonates, 15-30 parts of silicon powder, 2-10 parts of micro silicon, 0-5 parts of a flow-type regulation agent, 0-5 parts of a fluid loss agent and 0-5 parts of a retarder. When the cement slurry is injected into an oil gas leakage zone, static gelatinization strength is quickly generated in the cement slurry, and then the cement slurry is thickened and condensed to form low-strength cement stone for plugging gaps and throat channels in the oil gas bed, thereby achieving plugging in a well. After well completion, through acidification operation, the carbonates in the cement in the pores and gaps in the strata is acidified and dissolved, thereby penetrating an oil gas channel in a productive layer and further recovering oil gas productivity. The oil well cement solves the problem that common oil well cement causes serious pollution to the productive layer, and has a significant effect of recovering the oil gas productivity for an oil gas channel which is plugged by cement, and is beneficial to development and production increase of an oil gas well in later period.

Owner:CNPC BOHAI DRILLING ENG

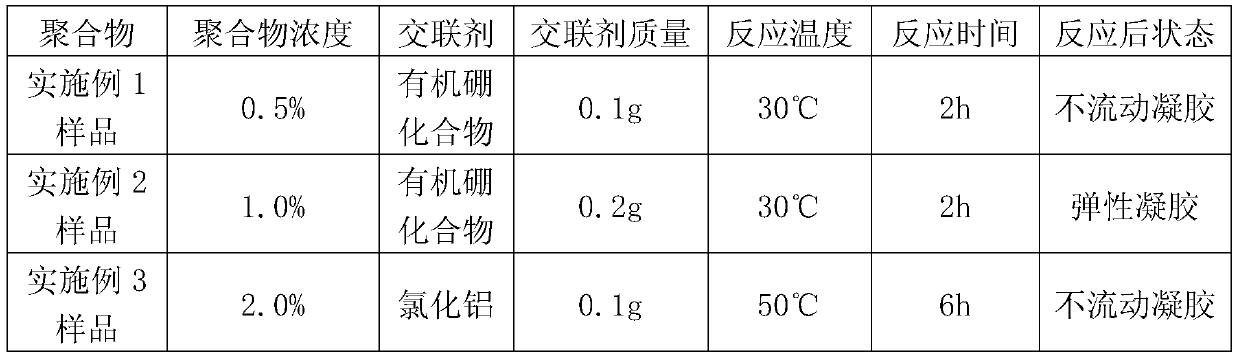

Reactive polymer for well drilling plugging and preparation method thereof

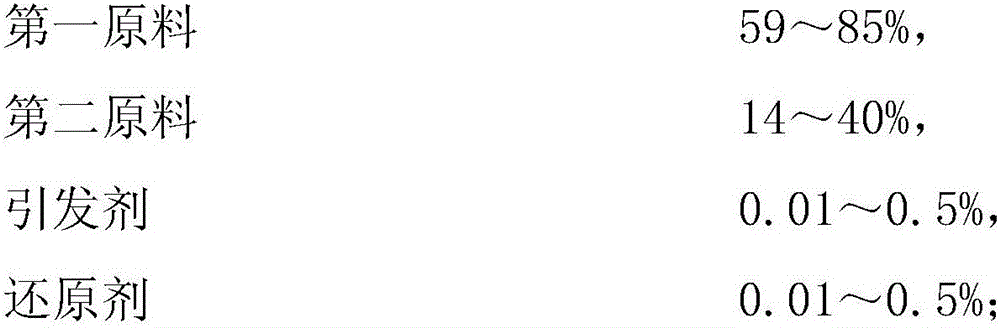

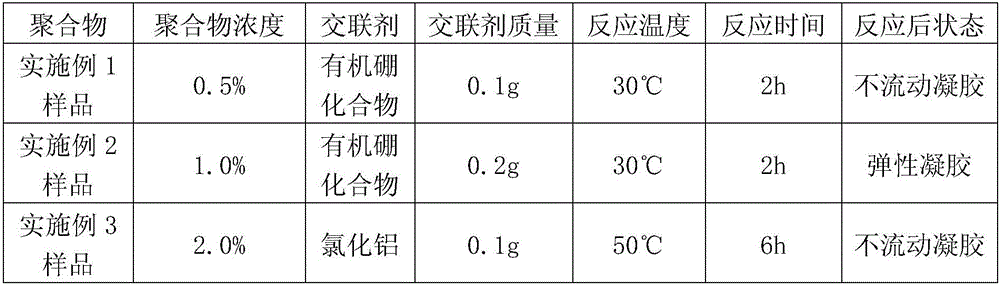

ActiveCN106046250AImprove performanceAvoid popping and gelationDrilling compositionNitrogen atmosphereNitrogen gas

The invention discloses a reactive polymer for well drilling plugging and a preparation method thereof. The polymer is mainly prepared by polymerizing the following raw materials in percentage by mass: 59-85% of first raw material, 14-40% of second raw material, 0.01-0.5% of initiator and 0.01-0.5% of reducer. The first raw material is one or mixture of more than two of acrylamide, acrylic acid and sodium acrylate. The second raw material is one or mixture of more than two of vinyl acetate, hydroxyethyl methacrylate and 2-hydroxyethyl acrylate. The method comprises the following steps: 1. preparing the raw materials and a solvent water; 2. after dissolving the first raw material, adding the second raw material; 3. adding the initiator, and continuously introducing nitrogen into the mixed solution to remove oxygen in the mixed solution; 4. in a nitrogen atmosphere, adding a reducer, heating the mixed solution to 20-40 DEG C, and carrying out polymerization reaction to obtain a jelly; and 5. drying the jelly, and pulverizing to obtain the polymer.

Owner:CHINA PETROCHEMICAL CORP +2

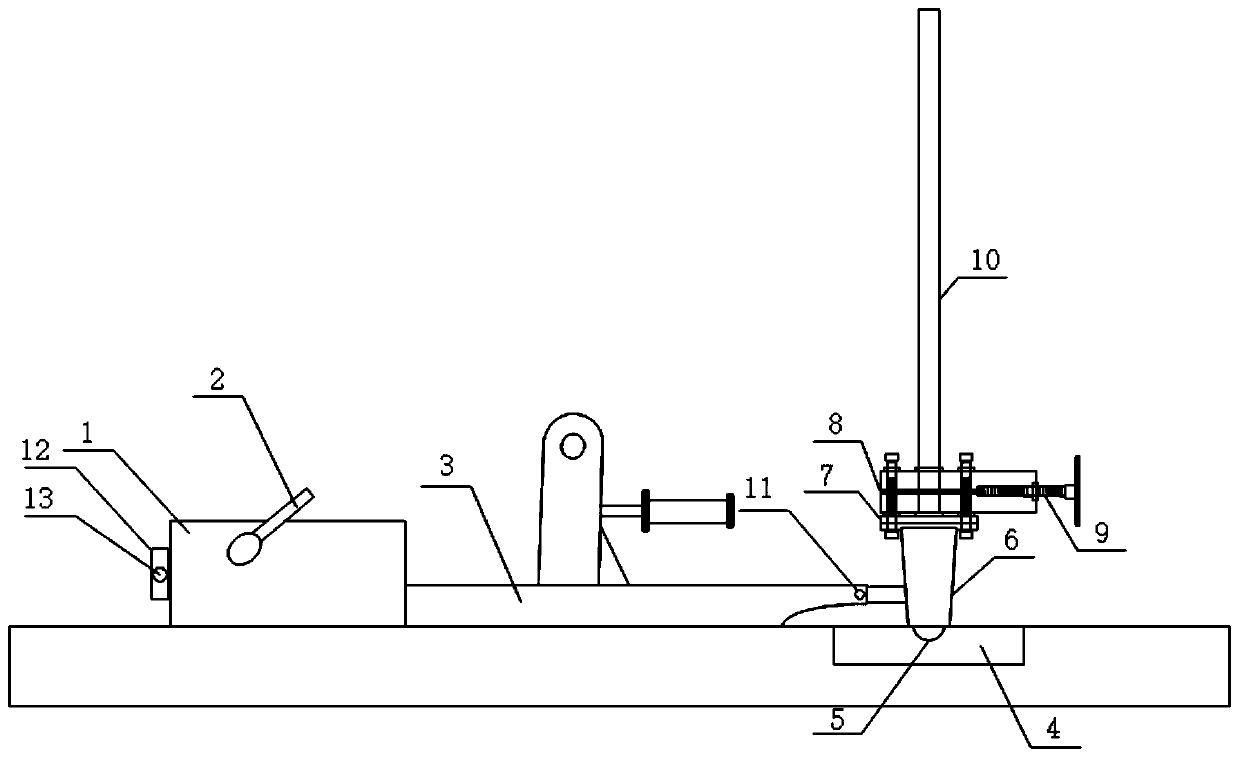

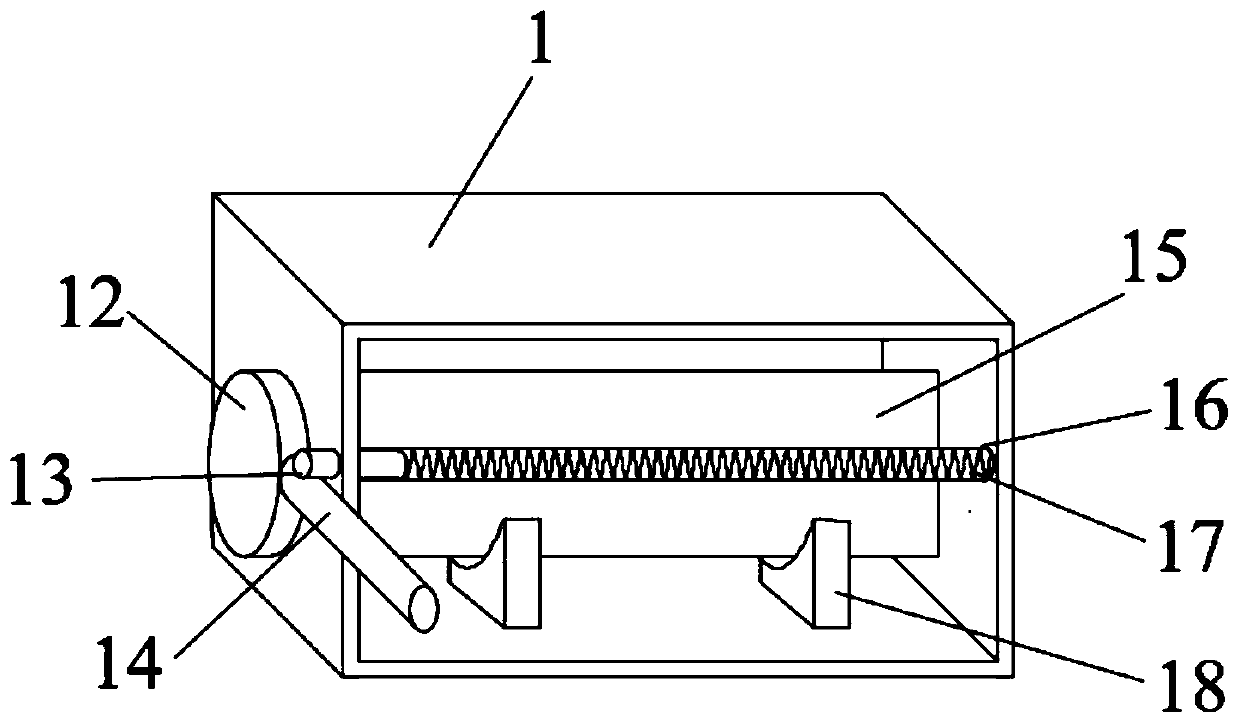

Gas pipe network high-pressure magnetic repair device

InactiveCN110319297AAvoid harmTo achieve the purpose of pluggingPipe elementsMagnetic tension forceSuction force

The invention discloses a gas pipe network high-pressure magnetic repair device. The device comprises a magnetic portion, a lever portion and a diffusion drainage portion, wherein the magnetic portionis a driving force source of the whole repair device, the diffusion drainage portion can diffuse leaked natural gas to a safety area so as to avoid damage to repair persons due to large concentrationof natural gas, meanwhile, the pipeline plugging operation can be carried out, the action of the lever portion is to connect the magnetic portion and the diffusion drainage portion, so that the diffusion drainage portion is provided with strong magnet attraction force. The device has the beneficial effects that during gas leakage repair of a paramagnetic pipeline, the super-strong suction force of a magnet is used for resisting the impact force generated by the high-pressure air flow, so that leakage of a high-pressure pipe network is realized.

Owner:TIANJIN CHENGJIAN UNIV

Water-absorbing material and its preparation method and application

ActiveCN105837758BHigh absorption rateHas the ability to resist degradationDrilling compositionHeat resistanceSalt water

The invention provides a water-absorbing material and its preparation method and application. The mass percentage of the water-absorbing material is composed of: 27%-33% of acrylic acid, 17%-21% of potassium hydroxide, 1%-2% of acryloylmorpholine, Composite crosslinking agent 1%‑2%, silica 0.2%‑0.3%, tackifier 0.04%‑0.06%, 2‑acrylamide‑2‑methylpropanesulfonic acid AMPS 0.2%‑0.3%, deionized water 41%-54%, initiator 0.1%-0.3%, and the mass ratio of the acrylic acid to the potassium hydroxide is 50:31, the water-absorbing material provided by the present invention solves the problem of adding in the existing killing fluid The strong water-absorbent material has technical problems of not being able to withstand salt, is easy to degrade, and has poor temperature resistance. At the same time, the water-absorbing material has a certain viscosity and compression shielding effect after absorbing water, and realizes the purpose of plugging, thereby improving plugging when used in well killing fluid. leaking effect.

Owner:PETROCHINA CO LTD

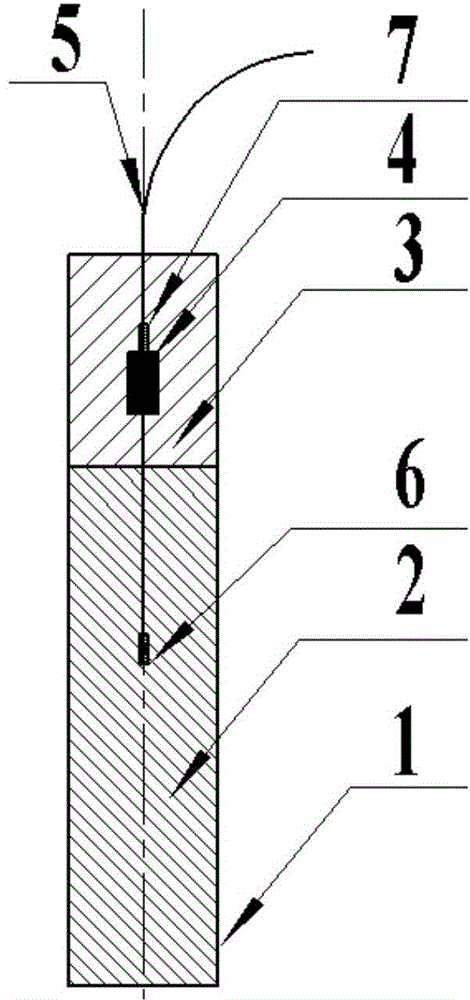

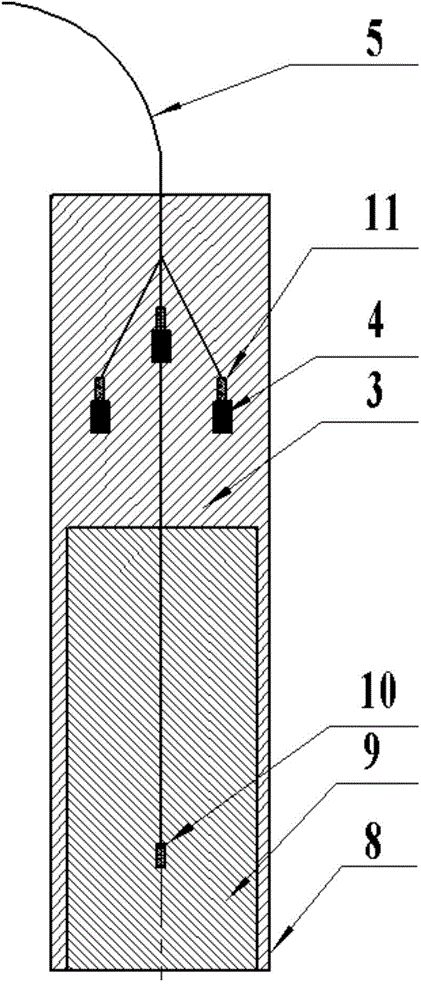

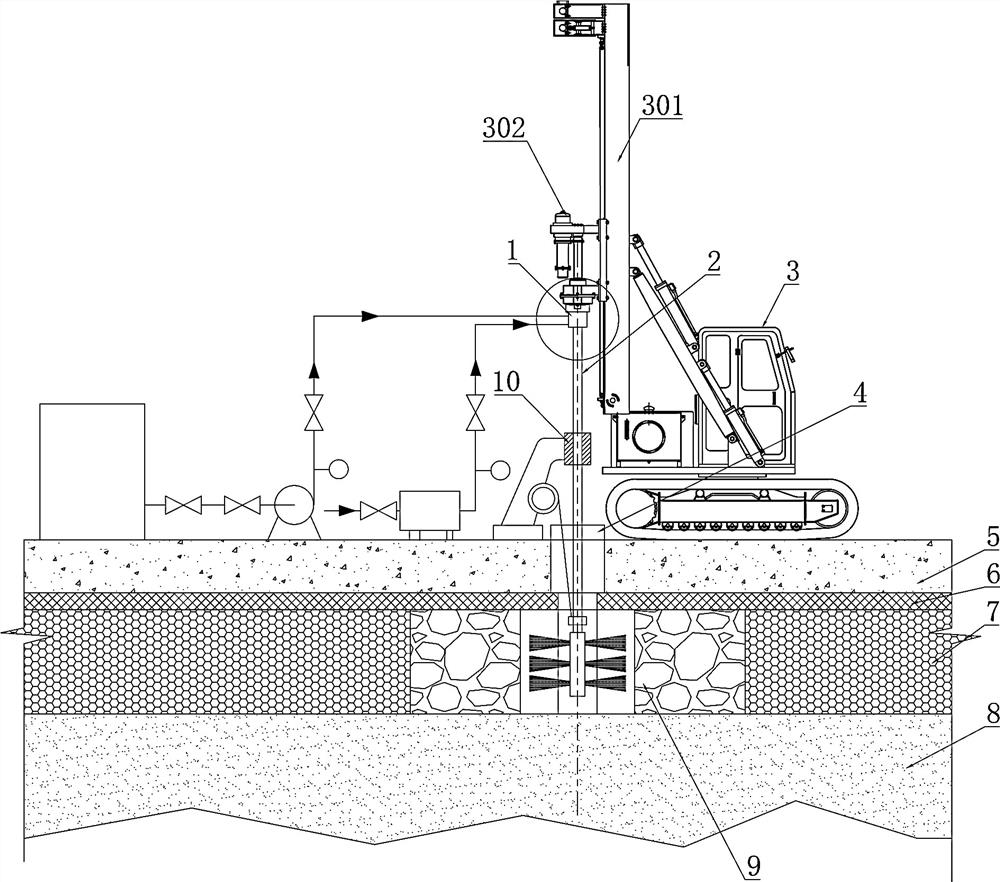

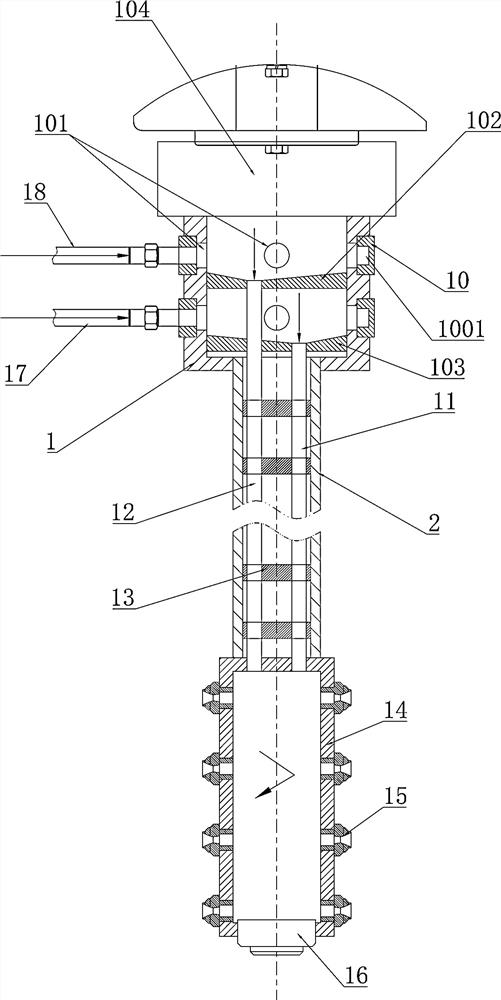

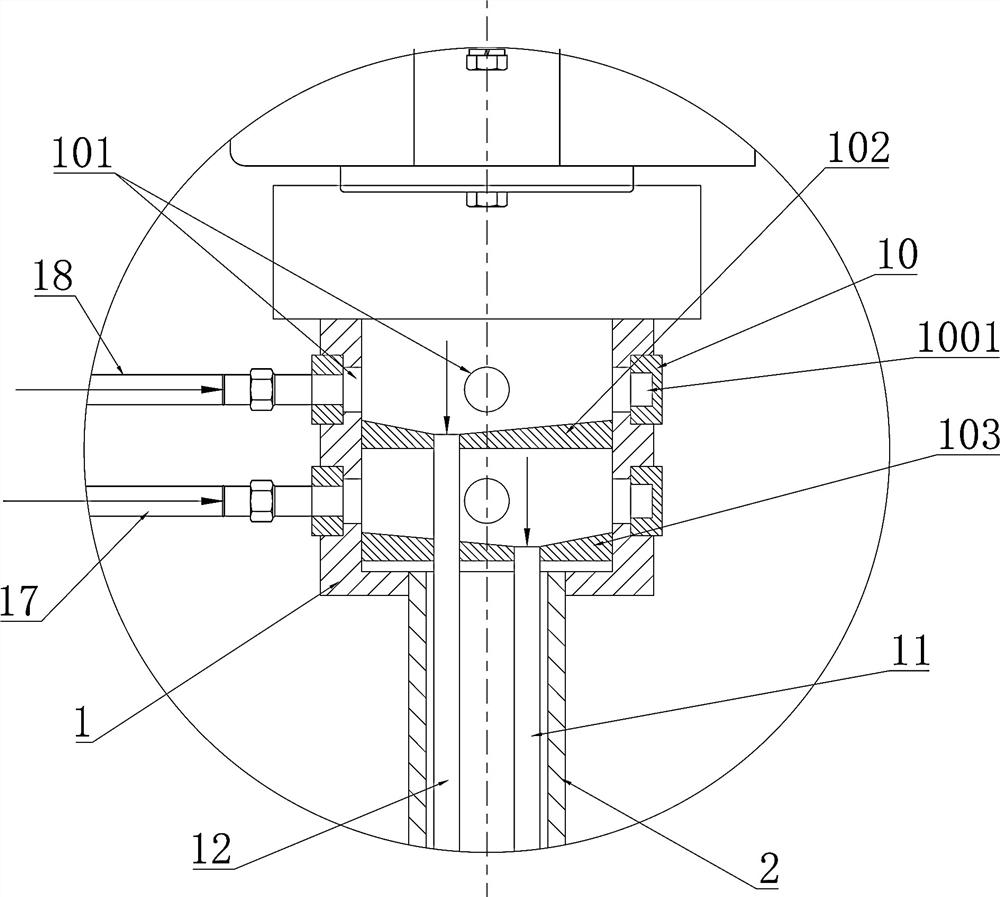

Leakage repairing rod for stopping slurry leakage of cast-in-situ bored pile on riprap embankment in complex sea area

PendingCN114808931AEasy to operatePrecise leak stopBulkheads/pilesSoil scienceStructural engineering

The invention provides a leak repairing rod for stopping slurry leakage of a cast-in-situ bored pile on a riprap embankment in a complex sea area, a grouting rotating ring is arranged at one end of the leak repairing rod, a spraying seat is arranged at the other end of the leak repairing rod, a plurality of spraying heads are arranged on the spraying seat, and the grouting rotating ring at the upper end of the leak repairing rod is connected with a driving rotating seat of a jumbolter. The air pressure pipeline and the grouting pipeline are communicated with the grouting rotating ring respectively and are rotatably and hermetically communicated with the grouting rotating ring, an air pressure vertical pipe and a solution vertical pipe are arranged in the leak repairing rod, the air pressure vertical pipe is communicated with the air pressure pipeline, and the solution vertical pipe is communicated with the grouting pipeline. Air and leaking stoppage slurry are accurately sprayed to the leakage position through the parallel pipelines, the leaking stoppage slurry forms a strong and hard hole wall through chemical reaction, and therefore the purpose of leaking stoppage is achieved. The equipment for quickly stopping the leakage of the cast-in-situ bored pile slurry on the riprap embankment in the complex sea area is simple to operate and accurate in leakage repairing.

Owner:中交二航局第一工程有限公司 +1

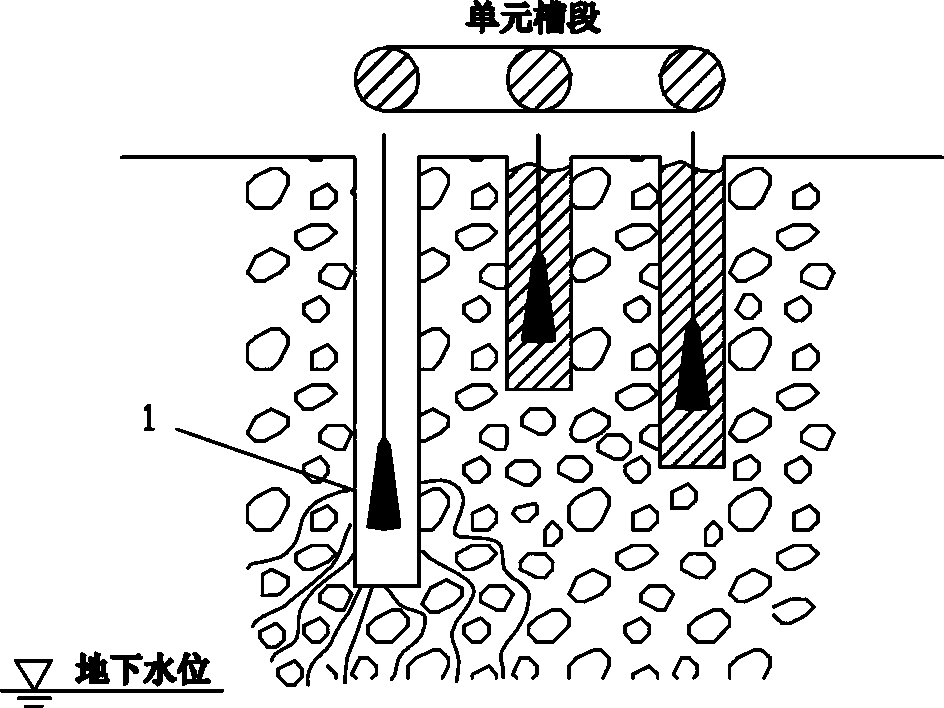

A kind of treatment method for leakage of slurry from slot hole of anti-seepage wall

The invention provides a handling method for diaphragm wall slotted hole slurry leakage. The method comprises the steps that (1) neat cement grout is poured into a slotted hole to reach an aperture; (2) a percussion drill conducts drilling; (3) after the surface of the neat cement grout in the slotted hole descends to the hole bottom, cement mortar is poured into the hole to reach the aperture; (4) the percussion drill is continuously adopted for drilling, and the cement mortar and the cement grout form a stone body surrounding the hole wall; (5) in the drilling process conducted in the step (4), when the surface of the cement mortar in the slotted hole descends, cement mortar is continuously supplemented into the hole; (6) when the cement mortar inside the slotted hole approximately reaches initial setting, the cement mortar inside the hole is replaced with drilling mud; (7) after setting is kept for 24 to 48 hours, diaphragm wall slotted hole slurry leakage handling is completed. The handling method for diaphragm wall slotted hole slurry leakage can solve the problem that slotted hole slurry leakage of a deep and thick covering layer diaphragm wall which is low in underground water level, loose in structure and seriously overhead is difficult to handle, and is good in leakage blocking effect and easy to implement.

Owner:GEZHOUBA GROUP FOUND ENG

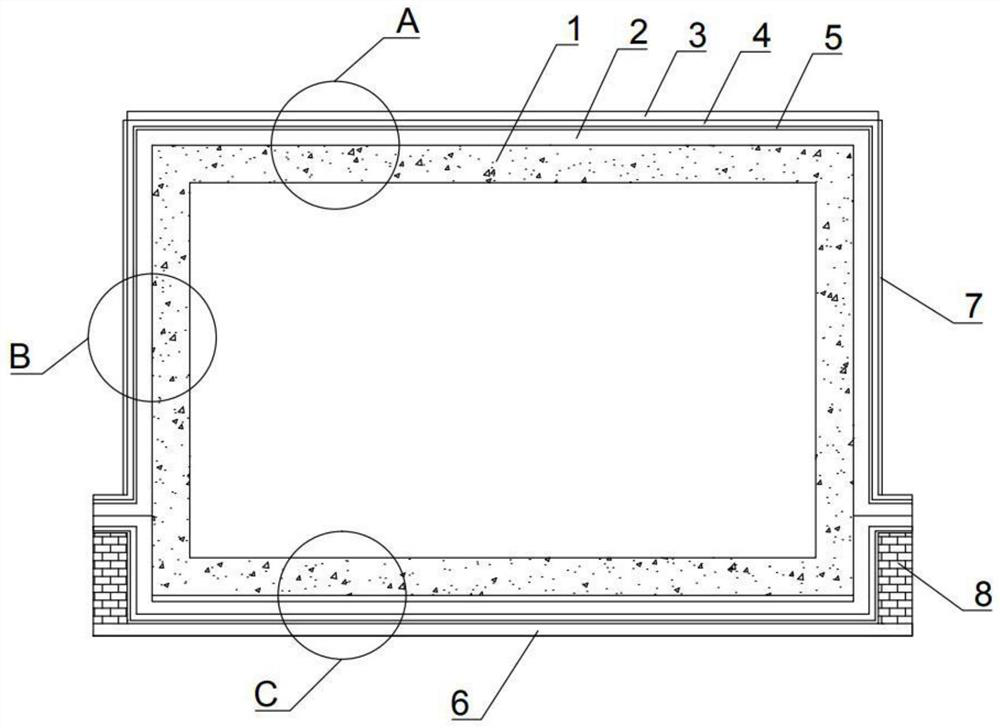

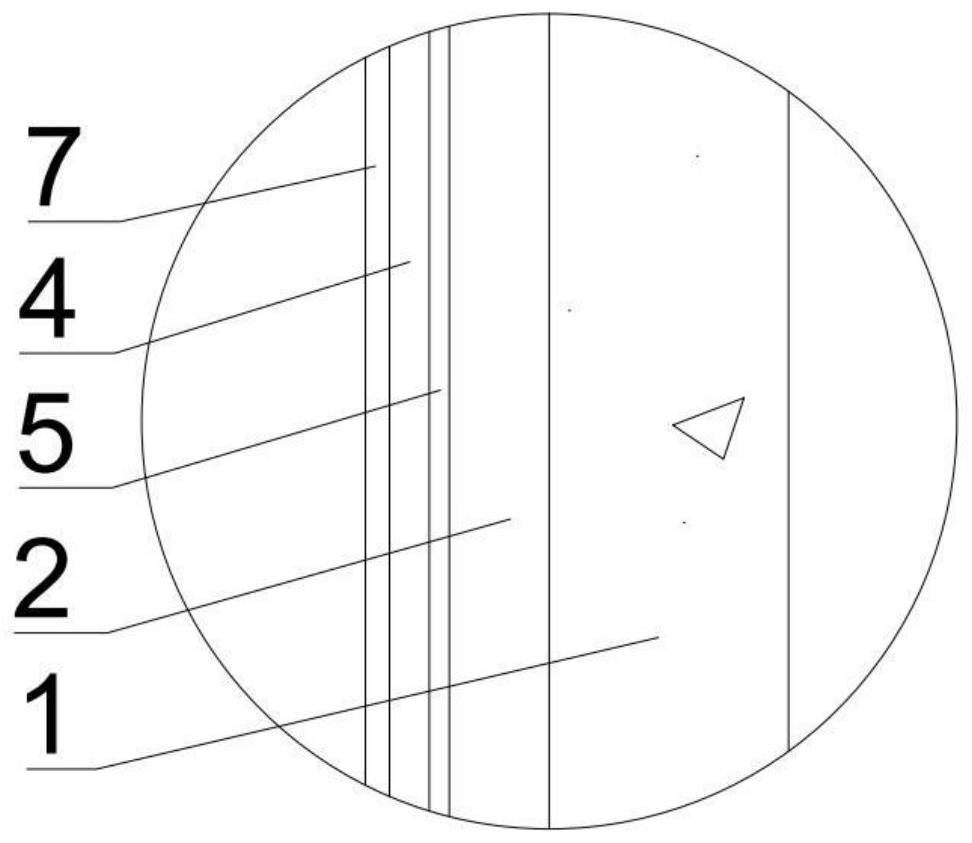

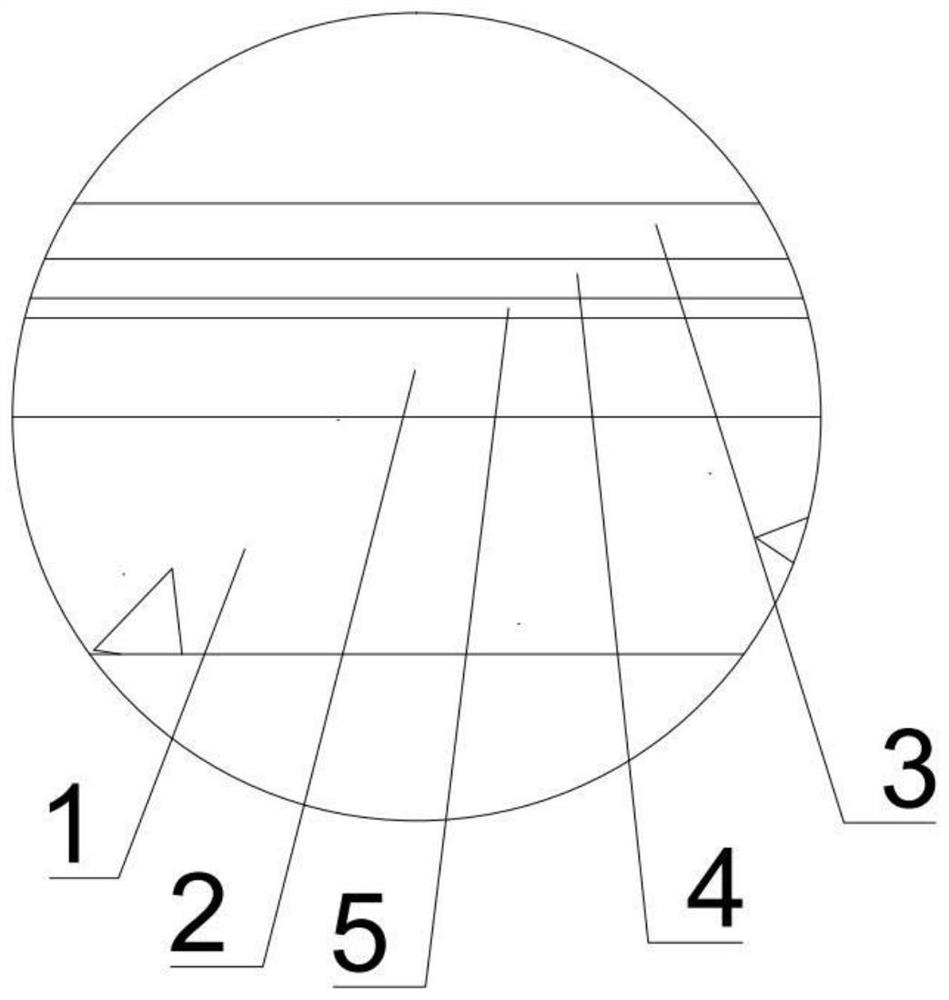

JS waterproof coating repairing and reinforcing structure and construction method

ActiveCN114197540AAvoid damageGuaranteed stabilityRoof improvementClimate change adaptationCalcium hydroxideCrazing

The invention relates to the technical field of building waterproof construction, in particular to a JS waterproof coating repairing and reinforcing structure and a construction method. The JS waterproof coating repairing and reinforcing structure comprises a top plate waterproof structure, a bottom plate waterproof structure and a wall waterproof structure, the top plate waterproof structure comprises a JS waterproof layer, a waterproof protection layer, a repairing and maintaining layer and a repairing and reinforcing layer, and the bottom plate waterproof structure comprises a JS waterproof layer, a waterproof protection layer, a repairing and maintaining layer, a repairing and reinforcing layer and a cushion layer. The wall waterproof structure comprises a JS waterproof layer, a repairing and maintaining layer, a repairing and reinforcing layer and a waterproof isolating layer, the repairing and reinforcing layer is a calcium salt coating, and the repairing and maintaining layer is a geotechnical cloth laying layer. The calcium hydroxide coating is additionally arranged, so that the structure has sufficient calcium ions, the requirement for the surrounding environment is lowered, and when cracks occur, calcium salt promotes the waterproof layer to form solid colloid linkage and accumulation to block a water inlet channel, and the leaking stoppage purpose is achieved.

Owner:CHINA CONSTR EIGHTH ENG DIV

Reinforced Concrete Pipe Jacking Joints

ActiveCN108443612BAvoid destructionPrevent water seepageSleeve/socket jointsReinforced concreteEngineering

The invention relates to the technical field of ejection pipes of non-excavation works, in particular to a reinforced concrete ejection pipe joint connector. The connector is positioned at a connection between a front pipe joint and a rear pipe joint which are adjacent. The connection part of the connector at least comprises a pipe joint outer wall sealing connecting part and a pipe joint inner wall sealing connecting part. The pipe joint outer wall sealing connecting part at least comprises a socket steel bushing ring positioned at the rear end of the front pipe joint and a socket steel ringpositioned at the front end of the rear pipe joint. The pipe joint inner wall sealing connecting part at least comprises the structure that steel bushing rings separately arranged on the front pipe joint inner wall and the rear pipe joint inner wall. Each steel bushing ring at least comprises an annular steel ring and an annular slab. Ribbed plates and bolted holes are uniformly distributed on thefront side and the rear side of the slab. The ribbed plate and the bolted holes are staggered mutually in position. The bolted holes in the front pipe joint slab are corresponding to those of the rear pipe joint slab. The bolted holes corresponding to one another are connected by bolts and nuts. The pipe joint connector adopting the technical scheme can completely meet the need of projects with high waterproof requirements, and can adapt to complex construction environments such as high water pressure and soft ground.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID +2

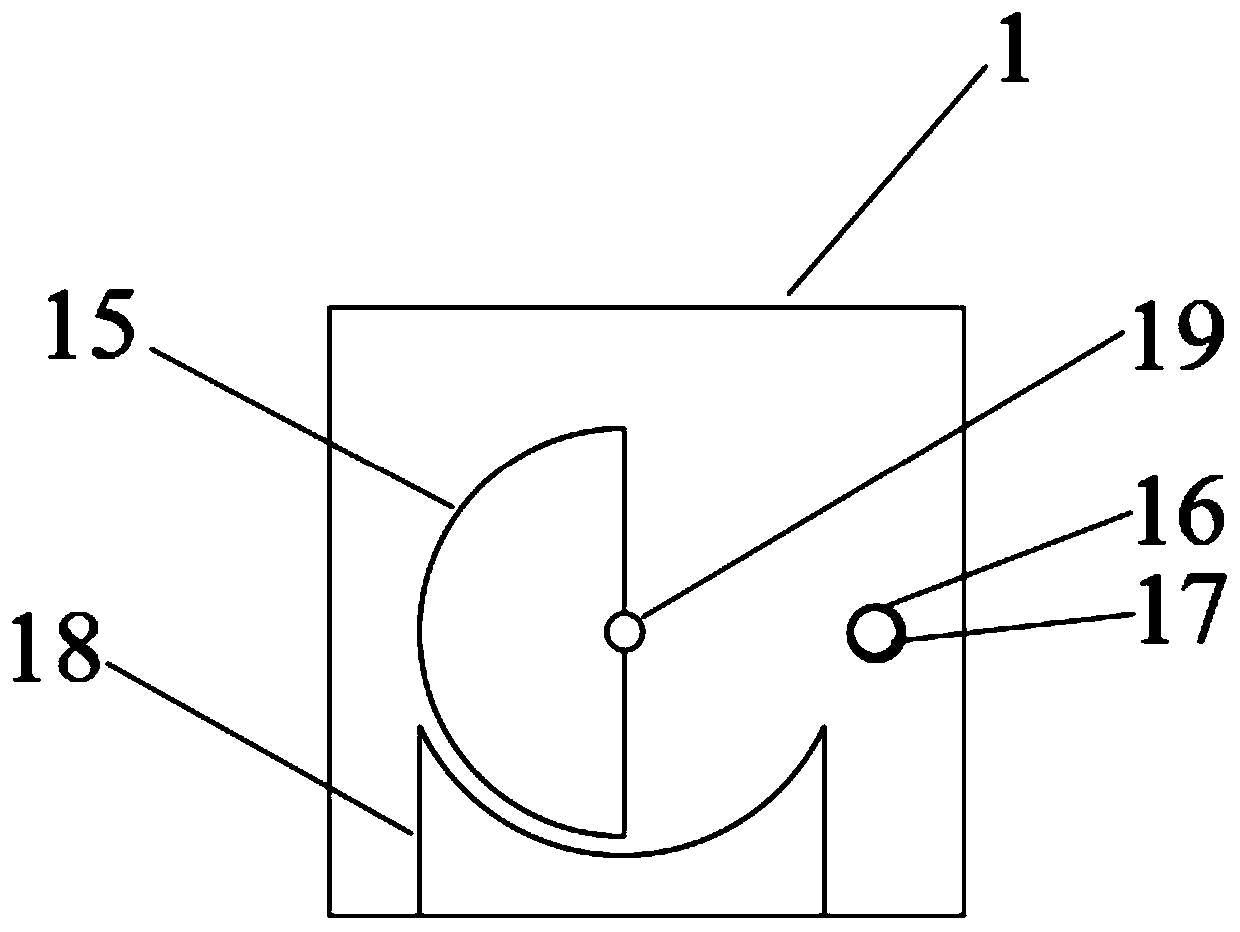

Stirring machine mechanical seal shaft sleeve leakage elimination device

PendingCN107524808ATo achieve the purpose of pluggingEngine sealsTransportation and packagingEngineeringMachining

The invention relates to a mechanical seal shaft sleeve leakage stoppage tool, in particular to a stirring machine mechanical seal shaft sleeve leakage elimination device. The stirring machine mechanical seal shaft sleeve leakage elimination device comprises a disc and a pipe body, wherein the disc center machining diameter is larger than a round hole of a stirring machine shaft; a bolt hole located at the same circle is further machined in the disc; a boss is further machined on the disc; and the boss center machining diameter is larger than a through hole of the stirring machine shaft. By means of the stirring machine mechanical seal shaft sleeve leakage elimination device, when the leakage problem of a mechanical seal shaft sleeve is solved, a pipe body is added outside the mechanical seal shaft sleeve and filled with padding, the padding is compacted and sealed through the disc at the tail, and the purpose of leakage stoppage is achieved.

Owner:SHANXI JINFENG COAL CHEM IND

Handling method for diaphragm wall slotted hole cement grout leakage

The invention provides a handling method for diaphragm wall slotted hole slurry leakage. The method comprises the steps that (1) neat cement grout is poured into a slotted hole to reach an aperture; (2) a percussion drill conducts drilling; (3) after the surface of the neat cement grout in the slotted hole descends to the hole bottom, cement mortar is poured into the hole to reach the aperture; (4) the percussion drill is continuously adopted for drilling, and the cement mortar and the cement grout form a stone body surrounding the hole wall; (5) in the drilling process conducted in the step (4), when the surface of the cement mortar in the slotted hole descends, cement mortar is continuously supplemented into the hole; (6) when the cement mortar inside the slotted hole approximately reaches initial setting, the cement mortar inside the hole is replaced with drilling mud; (7) after setting is kept for 24 to 48 hours, diaphragm wall slotted hole slurry leakage handling is completed. The handling method for diaphragm wall slotted hole slurry leakage can solve the problem that slotted hole slurry leakage of a deep and thick covering layer diaphragm wall which is low in underground water level, loose in structure and seriously overhead is difficult to handle, and is good in leakage blocking effect and easy to implement.

Owner:GEZHOUBA GROUP FOUND ENG

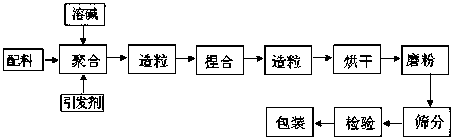

A kind of plugging agent for drilling fluid and preparation method thereof

The invention relates to a plugging agent for drilling fluid and a preparation method thereof. The components of the treatment agent include: 20-25 acrylamide, 0.4-0.5 2-acrylamide-2-methylpropanesulfonic acid, and 0.4-0.5 acrylamide Oxyethyltrimethylammonium chloride 2.0-2.5, soda ash 0.8-1.0, high viscoelastic modifier 6.3-7.5 and cross-linking agent 0.001‑0.003, the rest is deionized water. Acrylamide, soda ash and water are polymerized and hydrolyzed into polyacrylamide in a polymerization tank, and then polyacrylamide and other additives are placed in a kneader for modification. The preparation of the plugging agent includes batching, polymerization-hydrolysis reaction, kneading modification, drying, granulation, milling, screening, inspection and packaging processes. In the invention, the multi-component copolymerized high molecular organic matter is modified by using a high viscoelastic modifier to make it have good viscosity, elasticity and plugging effect. The preparation condition of the present invention is moderate, has no pollution to the environment, less equipment investment and low production cost.

Owner:HEBEI GUANGDA PETROCHEM

Reactive polymer for drilling plugging and preparation method thereof

ActiveCN106046250BImprove performanceTo achieve the purpose of pluggingDrilling compositionPolymer science(Hydroxyethyl)methacrylate

Owner:CHINA PETROCHEMICAL CORP +2

Construction Method of Connecting Wall in Deep and Thick Bedrock

ActiveCN105804057BSolve the problem that the reinforcement cage cannot be translated accuratelyGuarantee the quality of the projectDrill bitsProtective foundationBedrockSlurry

The invention discloses a construction method for a concrete diaphragm wall of a deep bedrock. The construction method for the concrete diaphragm wall of the deep bedrock comprises the step that when an ultra-wide pipeline incapable of being moved or modified exists, trough-forming construction is conducted on the trough section of the concrete diaphragm wall below the ultra-wide pipeline, specially, pipeline protectors are arranged around the ultra-wide pipeline so that the ultra-wide pipeline can be protected in a surrounded mode; soil below the ultra-wide pipeline is excavated out by a long-boom excavator; the rest of soil or rock below the ultra-wide pipeline is drilled through a nonequilibrium drilling method so that a trough can be formed in the concrete diaphragm wall below the ultra-wide pipeline; and three steel reinforcement cages are arranged in the trough, and one of the three steel reinforcement cages can be located under the ultra-wide pipeline. According to the construction method, the ultra-wide pipeline does not need to be moved or modified, the moving and modification cost is omitted, and the project progress is accelerated; a frictional drill bit is adopted for drilling hard bedrock, especially large-dip-angle steep rock, jamming of the drill bit during pore-forming is controlled, and the drilling efficiency is improved; and an intra-trough slurry circulating method is applied in the drilling process, the construction efficiency in the environment of deep hard rock is improved, and the trough forming quality is ensured.

Owner:SINOHYDRO FOUND ENG

A kind of plugging method and structure for karst pipeline

ActiveCN104131532BImprove liquidityGood flexibilityMarine site engineeringMechanical engineeringWater resource management

The invention discloses a leaking stoppage method and structure for a karst pipeline. According to the method and structure, soybeans (4) and quick-setting mortar (3) are mixed, stirred, wrapped in a film bag (2) and then placed in an inlet of a leakage point of the karst pipeline (1); the soybeans (4) make volume in the film bag (2) be expanded by utilizing the expansibility of itself before solidification of the quick-setting mortar (3); the quick-setting mortar (3) quickly solidifies while the volume of the film bag (2) is expanded; after the quick-setting mortar (3) solidifies, the film bag (2) is tightly attached to the periphery of the karst pipeline (1) to produce friction and stops flowing, and therefore the leakage stoppage purpose for the karst pipeline (1) is achieved. The leaking stoppage method and structure are low in construction technical difficulty, simple in construction procedure, low in investment and capable of achieving a good leakage stoppage effect and being widely applied and popularized in the technical field of leakage stoppage of the karst pipelines.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

High-hydroscopicity polymer resin microcapsule and its production process

InactiveCN1264602CPromote water swellingReduce dosageDrilling compositionSealing/packingPolymer resinPolymer chemistry

The present invention belongs to the field of microcapsule preparing technology. The high-hydroscopicity polymer resin microcapsule has wall material of hardened oil with smelting point higher than 40 deg.c and core material of acrylic acid and acrylamide polymer. The preparation process includes smelting the wall material, fluidizing the core material, air suspension spraying, solidifying and other stages. The present invention solves the problem of high-hydroscopicity polymer to absorb water to denature, makes it possess excellent flowability and prepares microcapsule with targeting release feature. The wrapping material separates the high-hydroscopicity matter from targeting release feature. The wrapping material separates the high-hydroscopicity matter from outer environment, and under certain environment condition, the core material may be released fast to absorb water and to expand. The said process of the present invention is suitable for forming microcapsule with solid core material, and is simple, practical, good in filming performance and homogeneous in embedding.

Owner:DALIAN UNIV OF TECH

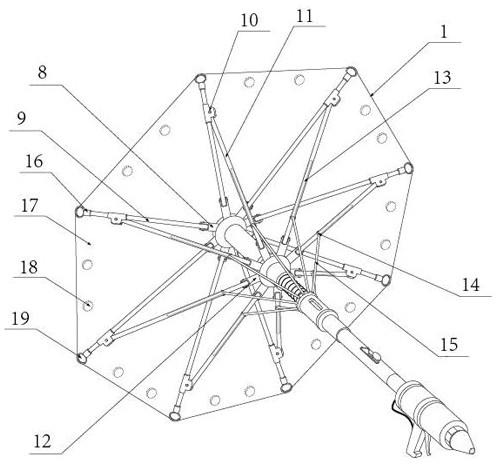

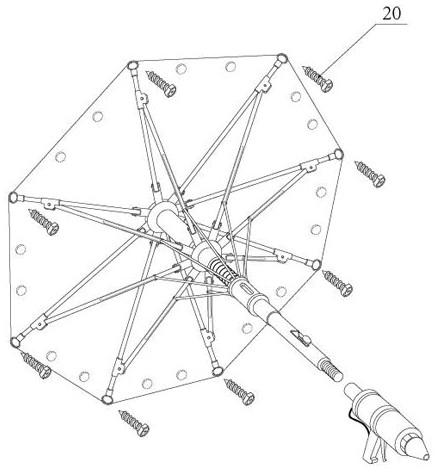

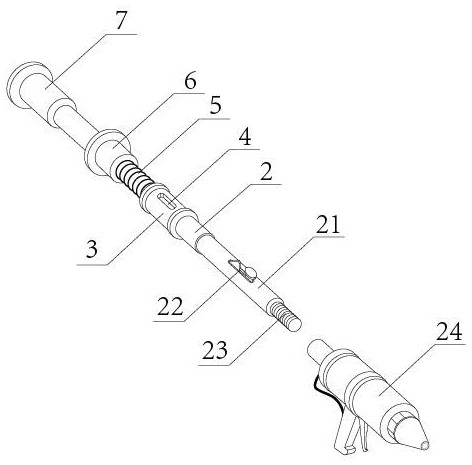

Multifunctional leaking stoppage device

A multifunctional leaking stoppage device comprises a leaking stoppage umbrella body, an umbrella handle, a lower sliding pipe, a clamping groove, a spring, an upper sliding pipe, an upper pipe, a first rotating shaft, a main framework, a second rotating shaft, an auxiliary framework, a third rotating shaft, a groove, a fourth rotating shaft, a supporting framework, an umbrella buckle, umbrella cloth, a powerful magnetic disc, a connecting hole, a screw, a telescopic rod, a buckle, a thread, a glue gun and super glue. The marine leaking stoppage umbrella has the advantages that by means of the shape of a traditional umbrella, after the leaking stoppage umbrella is unfolded, a leaking hole can be plugged, and operation is convenient and effective; the leaking stoppage umbrella is supported by three layers of frameworks, so that the supporting force of the leaking stoppage umbrella is improved; the composite umbrella cloth is used, so that the waterproof and tear-resistant capabilities are improved, and the purpose of leaking stoppage is effectively achieved; the edge of the umbrella cloth is fixed on the ship body through a powerful magnetic disk and screws and sealed through super glue to prevent water leakage of the edge of the umbrella cloth; and the tail end of the umbrella handle is connected with the glue gun, so that the use is convenient, the working efficiency is effectively improved, and sailors can finish the leaking stoppage work in the first time.

Owner:浙江铭品海工智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com