JS waterproof coating repairing and reinforcing structure and construction method

A waterproof structure and waterproof coating technology, which is applied in the direction of basic structure engineering, building construction, protective devices, etc., can solve the problems of difficult control of the impact of waterproof coating repair process, complex surrounding environment of underground structures, and inability to meet engineering waterproof requirements, etc., to achieve The technical level of workers is limited, the construction quality is easy to guarantee, and the effect of prolonging the water curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

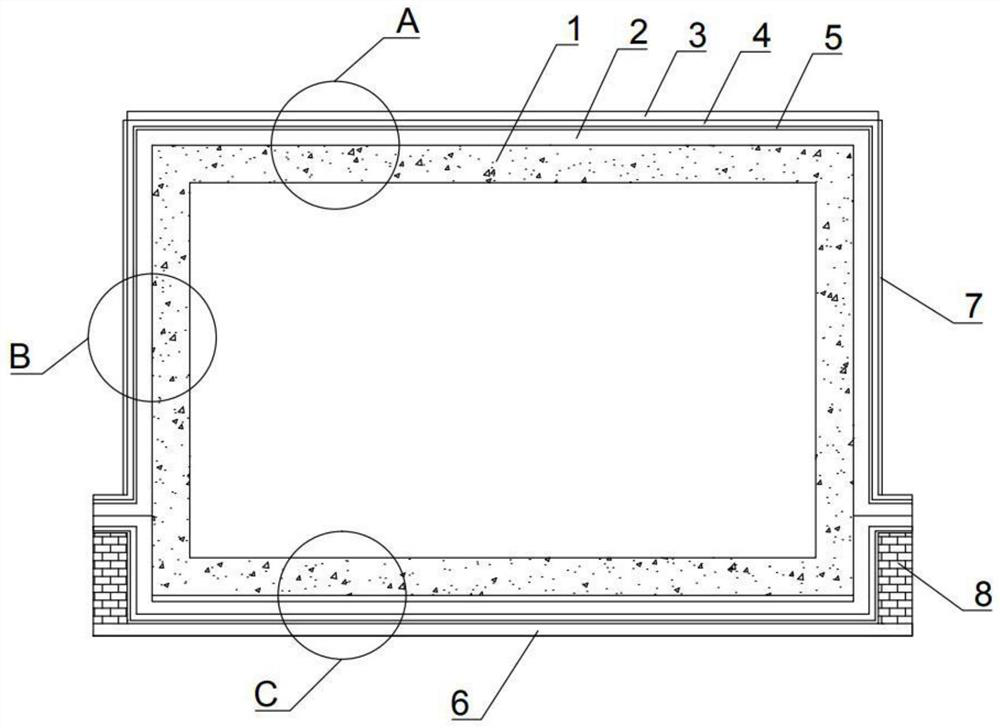

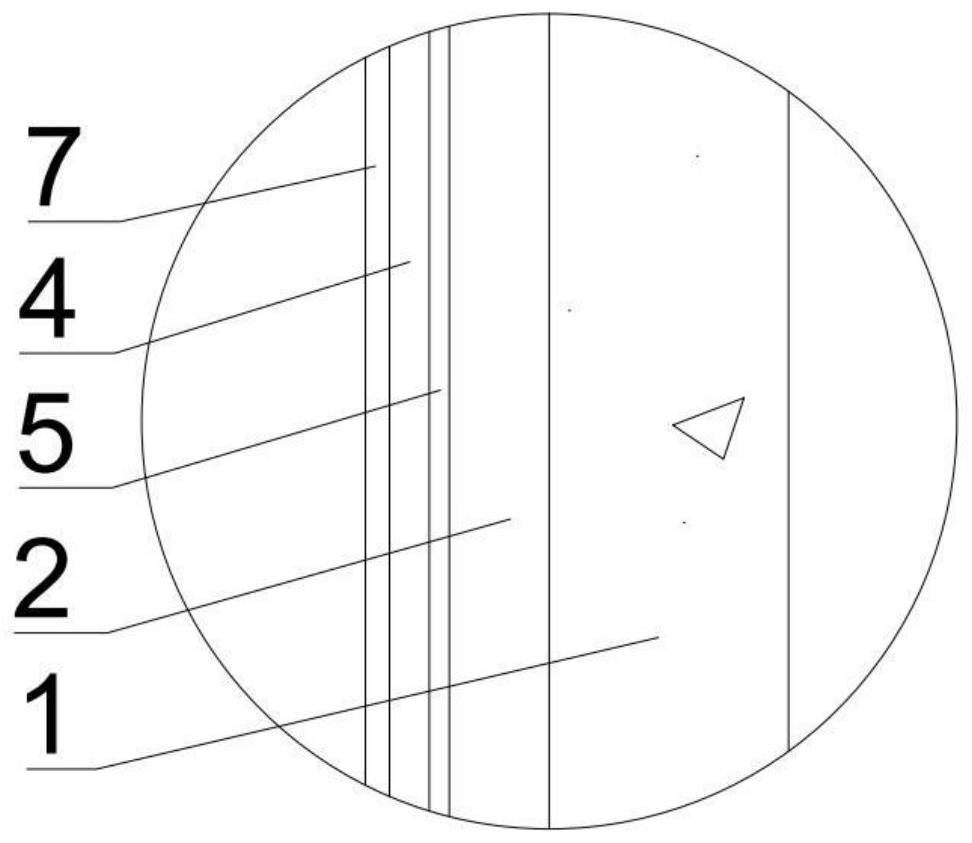

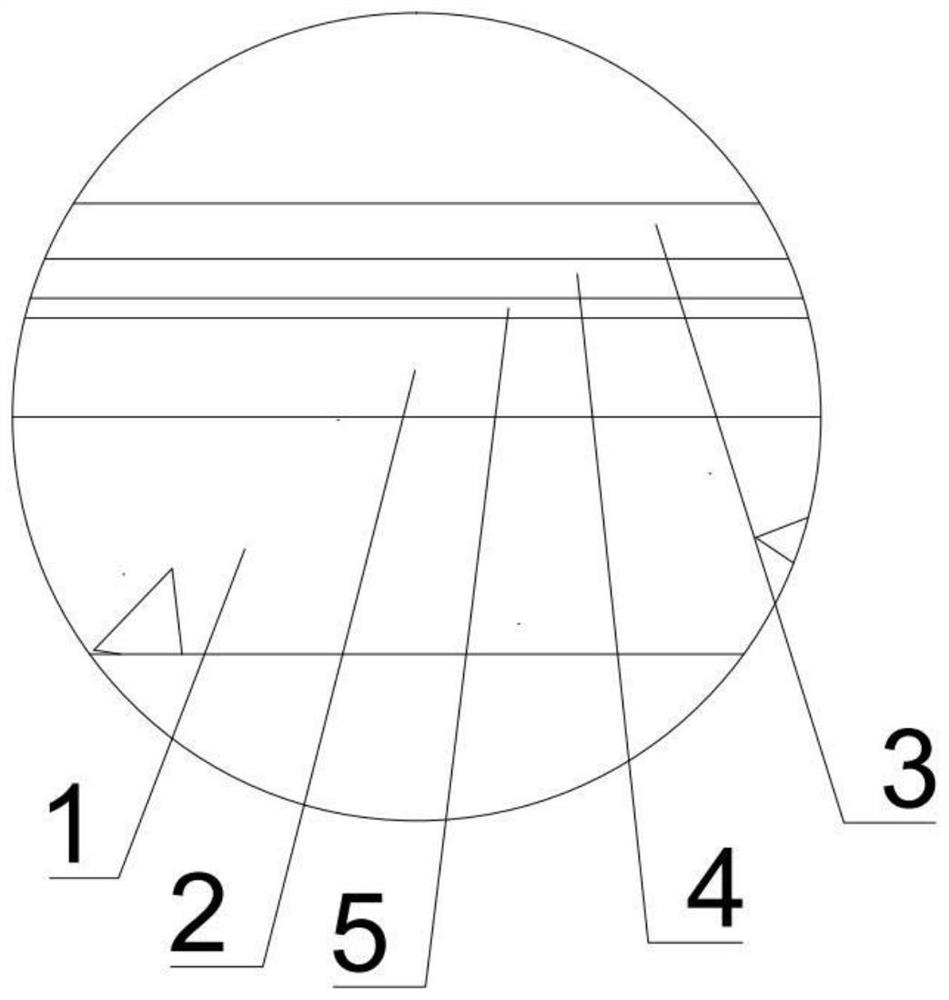

[0043] Embodiments of the present invention disclose a JS waterproof coating repair and enhancement structure, reference Figure 1-4 However, including the top plate waterproof structure, the bottom plate waterproof structure and wall waterproof structure, the top plate waterproof structure includes a JS waterproof layer 2, a waterproof protective layer 3, a repair maintenance layer 4, and a repair reinforcing layer 5, and the bottom plate waterproof structure comprises JS waterproof layers. 2, the waterproof protective layer 3, the repair maintenance layer 4, repair the reinforcing layer 5 and the pad layer 6, the wall waterproof structure includes JS waterproof layer 2, repair the maintenance layer 4, repair the reinforcing layer 5 and the waterproof isolation layer 7, the The reinforcing layer 5 is a calcium salt coating, and the repair maintenance layer 4 is a geotextile laying layer.

[0044] A JS waterproof coating repair and enhancement construction method, including the fol...

Embodiment 2

[0052] Added on the basis of Example 1:

[0053] Refer Figure 2-4 The top plate waterproof structure is disposed on the top floor of the underground building, and the structure from the concrete layer 1 is sequentially the JS waterproof layer 2, the reinforcing layer 5, the repair maintenance layer 4 and the waterproof protective layer 3, the bottom plate waterproof structure setting Under the underground building floor, the structure from the concrete layer 1 is sequentially the waterproof protective layer 3, the JS waterproof layer 2, the repair maintenance layer 4, the reinforcing layer 5, and the pad layer 6, the wall waterproof structure is disposed underground. In addition to the construction wall, the structure from the concrete layer 1 is sequentially the JS waterproof layer 2, the reinforcing layer 5, the repair layer 4, and the waterproof isolation layer 7 are repaired.

[0054] The underground buildings include underground warehouses, underground parking lots, undergrou...

Embodiment 3

[0062] The increase in Embodiment 1 or Example 2 is increased:

[0063] The temperature change difference between the construction ambient temperature is controlled within 5 ° C through the blower and sprinkler operation during the spray construction.

[0064] The premise of controlling temperature is to choose the most uniform moment of temperature in the day. When the temperature is too high, the water and the blast treatment are used or the spray ice is lowered. When the temperature is too low, the warm water is sprayed or passed through the heater. Treatment, maintain the humidity of the construction surface in a reasonable range during cooling and temperature rise treatment.

[0065] The repair reinforcing layer 5 is sprayed with a high pressure sprayer during spraying, wherein the ratio of calcium hydroxide and water in the calcium hydraulic calcium hydroxide coating is 1: 2, and when the wall is sprayed, the angle is sprayed, and the pre-buried line is encountered. Spray ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com