Water-absorbent material and preparation method and application thereof

A technology of water-absorbing materials and reactors, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of strong water-absorbing materials that are not resistant to salt, easy to degrade and temperature resistance, etc., to increase salt resistance and prevent resin The effect of degradation and molecular cross-linking uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the raw material composition of the water-absorbing material and the weight percentage of each component are as follows:

[0034] Acrylic acid: 27% to 33%;

[0035] Potassium hydroxide: 17% to 21%;

[0036] Acryloylmorpholine: 1% to 2%;

[0037] Composite crosslinking agent: 1% to 2%;

[0038] Silicon dioxide: 0.2% to 0.3%;

[0039] Tackifier: 0.04% to 0.06%;

[0040] Deionized water: 41% to 54%;

[0041] Initiator: 0.1% to 0.3%;

[0042] And the mass ratio of the acrylic acid to the potassium hydroxide is 50:31.

[0043] Concrete preparation process is as follows:

[0044] First, the tackifier is prepared;

[0045] Add 300g of acrylamide to 500g of deionized water, then add 30g of AMPS, adjust the temperature to 25°C, add 5g of initiator, after the reaction is completed, granulate and dry and crush at 70°C to obtain a tackifier.

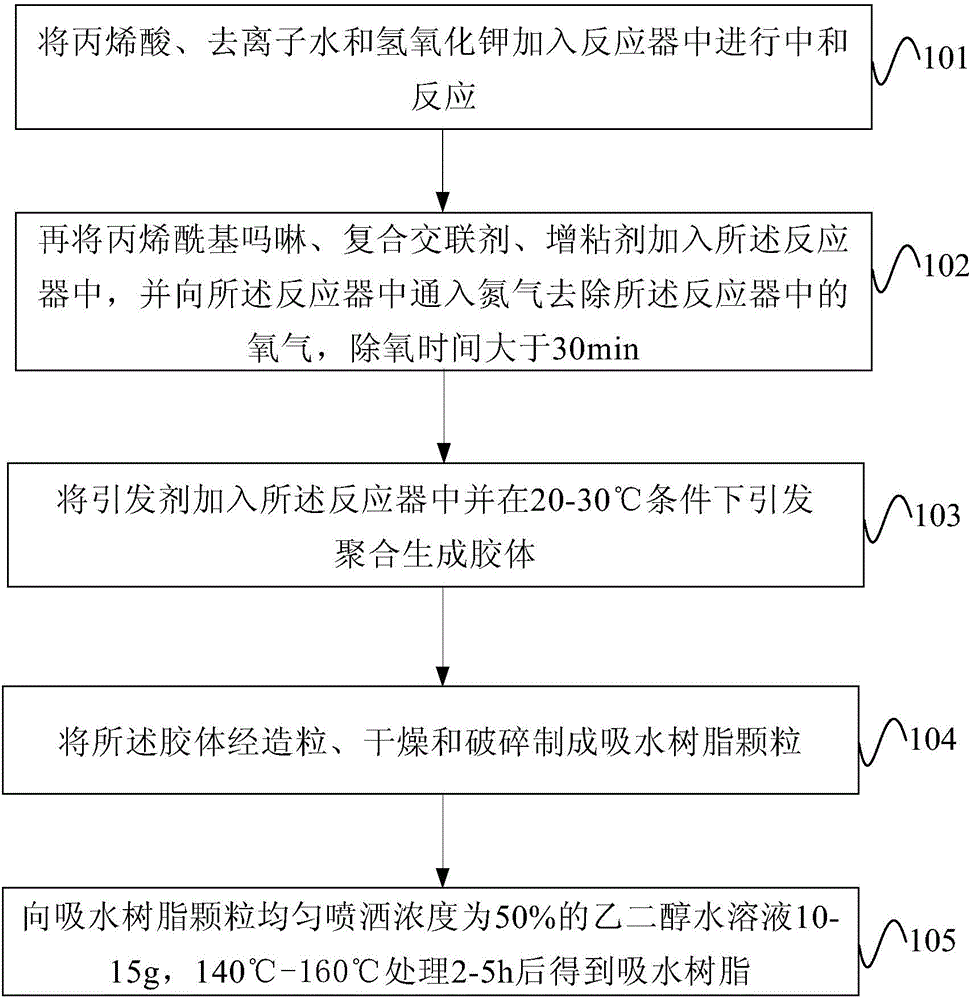

[0046] Then, figure 1 It is a schematic flow chart of the preparation method of the water-absorbing material o...

Embodiment 2

[0056] In this embodiment, the raw material composition and the weight of each component of the water-absorbing material are as follows:

[0057] Acrylic acid: 100g;

[0058] Potassium hydroxide: 62g;

[0059] Acryloylmorpholine: 5g;

[0060] Composite crosslinking agent: 5g;

[0061] Silicon dioxide: 1g;

[0062] Viscosifier: 0.2g;

[0063] Deionized water: 190g;

[0064] Initiator: 0.5g;

[0065] Specifically, the preparation process is as follows:

[0066] First, the tackifier is prepared;

[0067] Add 300g of acrylamide to 500g of deionized water, then add 30g of AMPS, adjust the temperature to 25°C, add 5g of initiator, after the reaction is completed, granulate and dry and crush at 70°C to obtain a tackifier.

[0068] Then, add 100g of acrylic acid, 190g of deionized water into the reactor, and then add 62g of potassium hydroxide for neutralization reaction, then add 5g of acryloyl morpholine, 5g of composite crosslinking agent, 1g of silicon dioxide, the above-m...

Embodiment 3

[0074] In this embodiment, the raw material composition and the weight of each component of the water-absorbing material are as follows:

[0075] Acrylic acid: 150g;

[0076] Potassium hydroxide: 93g;

[0077] Acryloylmorpholine: 7g;

[0078]Composite crosslinking agent: 7g;

[0079] Silicon dioxide: 1.5g;

[0080] Viscosifier: 0.4g;

[0081] Deionized water: 280g;

[0082] Initiator: 1g;

[0083] Specifically, the preparation process is as follows:

[0084] First, the tackifier is prepared;

[0085] Add 300g of acrylamide to 500g of deionized water, then add 30g of AMPS, adjust the temperature to 25°C, add 5g of initiator, after the reaction is completed, granulate and dry and crush at 70°C to obtain a tackifier.

[0086] Then, add 150g of acrylic acid, 280g of deionized water into the reactor, then add 93g of potassium hydroxide for neutralization reaction, then add 7g of acryloyl morpholine, 7g of composite crosslinking agent, 1.5g of silicon dioxide, 0.4g of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com