High-hydroscopicity polymer resin microcapsule and its production process

A high water absorption, production process technology, applied in microcapsule preparation, drilling composition, microsphere preparation and other directions, to achieve the effect of good blocking effect, convenient use and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

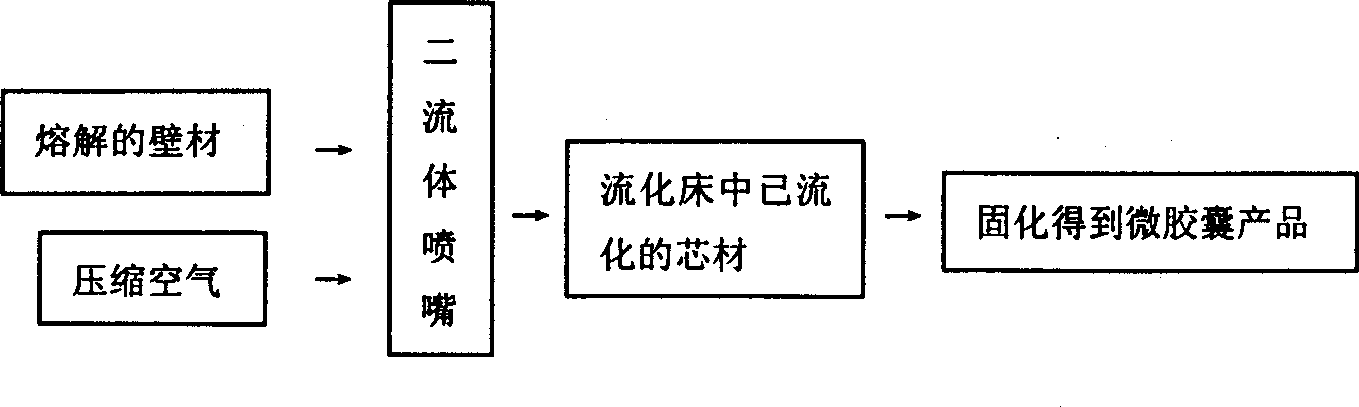

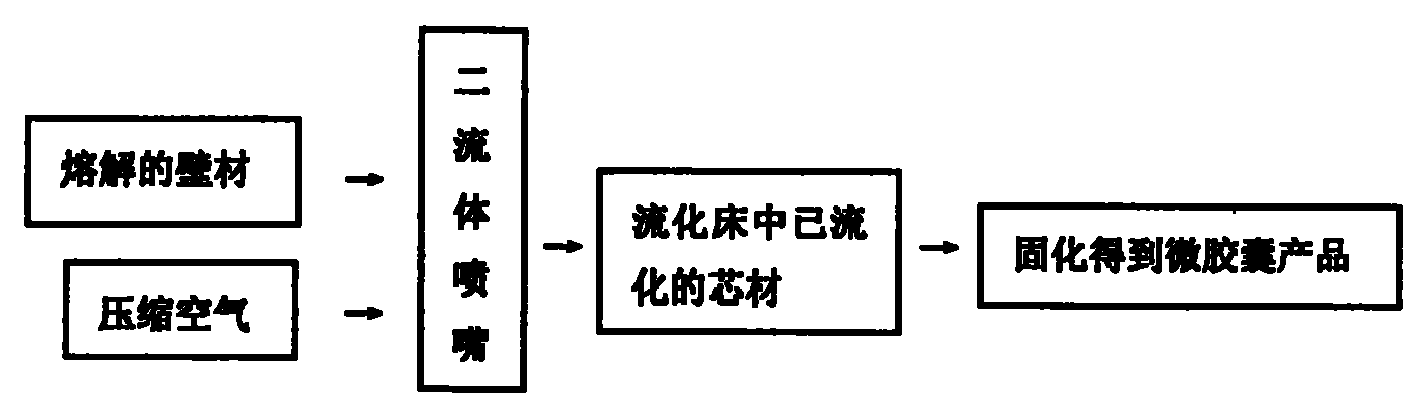

[0008] 1. Pass the core material through a standard sieve of 28 mesh to 38 mesh, and use the particles within this particle size range as the core material.

[0009] 2. Weigh a certain amount of hardened lard with a melting point of 56°C and melt it, take 400ml in a beaker, and place it in a constant temperature water bath at 90°C.

[0010] 3. Take 900g of sieved core material and put it in the fluidized bed. The fluidized air volume is 200m 3 / h under the condition of fluidization.

[0011] 4. The volume of compressed air is 0.64m 3 / h, the feed rate is 124ml / h, under the condition that the feed liquid is sprayed onto the surface of the core material through the two-fluid nozzle.

[0012] 5. The bed temperature was kept at 34°C and operated continuously for 2.5 hours. Remove the solidified microcapsule particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com