A method for reusing bamboo and wood clothes hanger production tailings

A technology for tailings and hangers, which is applied in the field of reusing tailings in the production of bamboo and wood hangers, can solve the problems of non-durability, high requirements for solid wood, and low prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

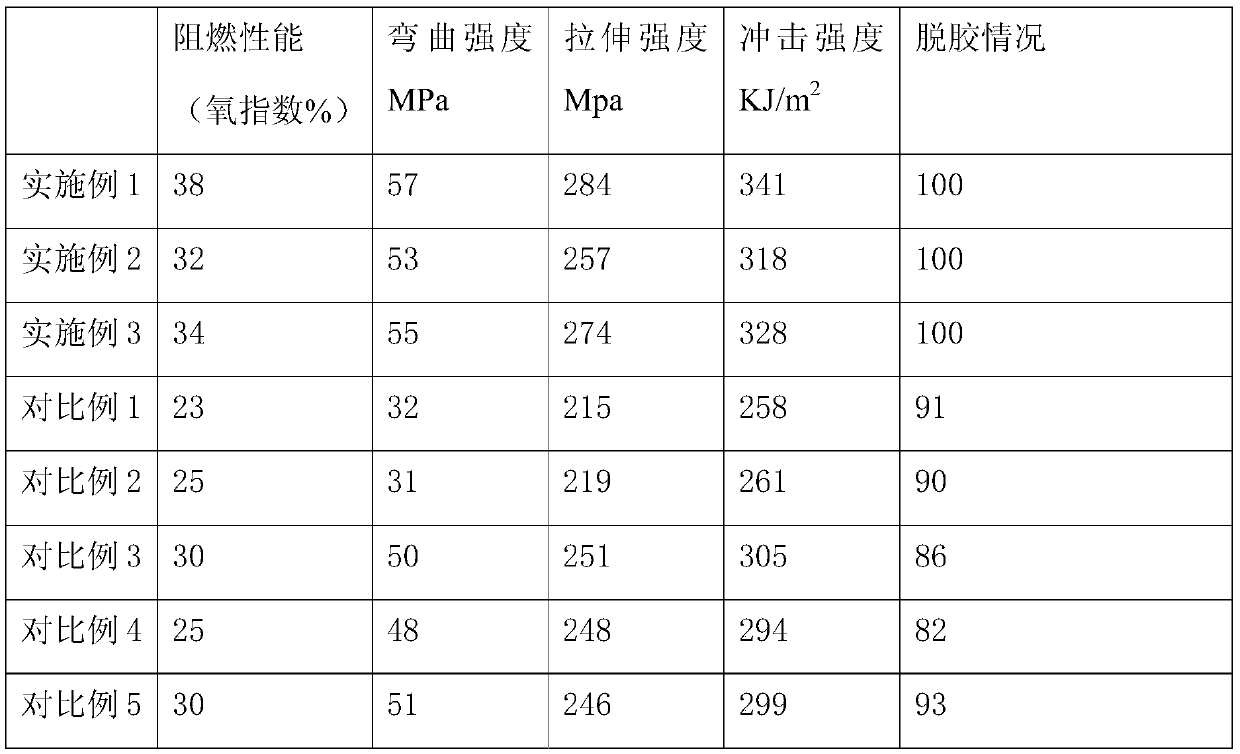

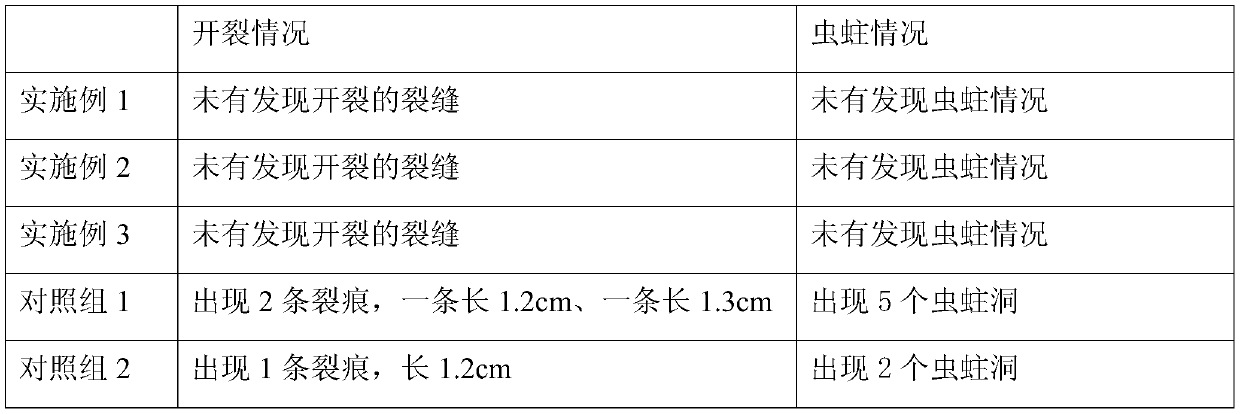

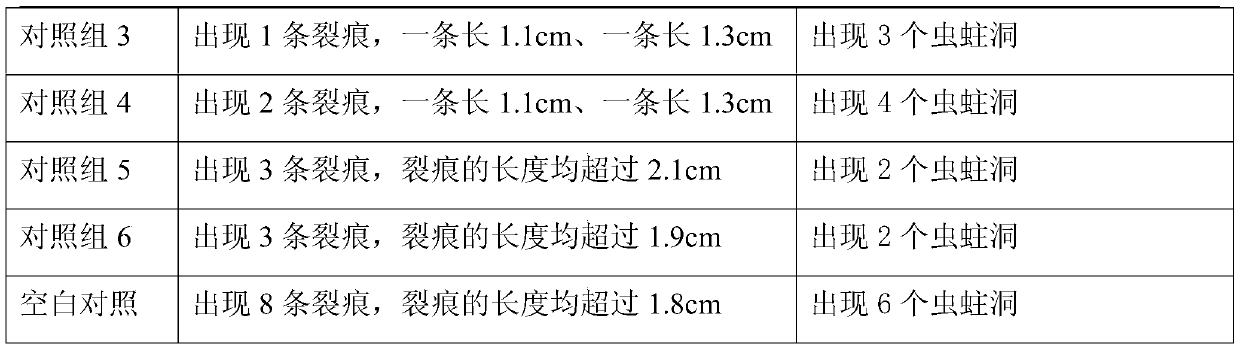

Examples

Embodiment 1

[0029] 1. Raw material preparation: The paint includes in parts by weight: 5 parts of marigold, 3 parts of tarragon, 2 parts of Lycoris, 10 parts of turpentine, 8 parts of wood wax oil, 6 parts of perilla oil, 8 parts of orange oil, bee 10 parts of wax, 8 parts of palm wax, 5 parts of isoethyl alcohol, 8 parts of polyester resin;

[0030]The coating is prepared by the following specific method: after weighing the raw materials in parts by weight, the whole plants of marigold, tarragon and Lycoris are collected, washed, dried naturally, chopped, and added 5 times the volume of Carry out alcohol extraction with ethanol solution for 10 hours, filter and get the filtrate for later use;

[0031] Mix turpentine oil, wood wax oil, perilla oil, and orange oil into the reaction kettle, and under the protection of nitrogen, rapidly raise the temperature to 200°C at 30MPa, react for 3 hours, then cool down to 150°C and keep warm for 2 minutes, then Cool down to 100°C and keep warm for 3...

Embodiment 2

[0045] 1. Raw material preparation: The paint includes in parts by weight: 8 parts of marigold, 5 parts of tarragon, 5 parts of Lycoris, 15 parts of turpentine, 13 parts of wood wax oil, 10 parts of perilla oil, 12 parts of orange oil, bee 15 parts of wax, 12 parts of palm wax, 8 parts of isoethyl alcohol, 10 parts of polyester resin;

[0046] The coating is prepared by the following specific method: after weighing the raw materials in parts by weight, the whole plants of marigold, tarragon and Lycoris are collected, washed, dried naturally, chopped, and added 10 times the volume of Carry out alcohol extraction with ethanol solution for 12 hours, filter and get the filtrate for later use;

[0047] Put turpentine oil, wood wax oil, perilla oil, and orange oil into the reaction kettle, and under the protection of nitrogen, the temperature is rapidly raised to 250°C at 30MPa, and the reaction is for 5 hours, then the temperature is lowered to 180°C and kept for 3 minutes, then C...

Embodiment 3

[0060] 1. Raw material preparation: The paint includes in parts by weight: 6 parts of marigold, 4 parts of tarragon, 3 parts of Lycoris, 12 parts of turpentine oil, 11 parts of wood wax oil, 8 parts of perilla oil, 10 parts of orange oil, bee 12 parts of wax, 10 parts of palm wax, 6 parts of isoethyl alcohol, 9 parts of polyester resin;

[0061] The coating is prepared by the following specific method: after weighing the raw materials in parts by weight, the whole plants of marigold, tarragon and Lycoris are collected, washed, dried naturally, chopped, and 8 times the volume of Carry out alcohol extraction with ethanol solution for 11 hours, filter and get the filtrate for later use;

[0062] Mix turpentine oil, wood wax oil, perilla oil, and orange oil into the reaction kettle, and under the protection of nitrogen, the temperature is rapidly raised to 220°C at 30MPa, reacted for 4 hours, then cooled to 160°C and kept for 2.5 minutes, then Cool down to 110°C and keep it warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com