Leaking stoppage material used for geological core drilling

A technology of plugging materials and filling materials, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of inability to seal the orifice, low gel strength, and low success rate of plugging, and achieves a high success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

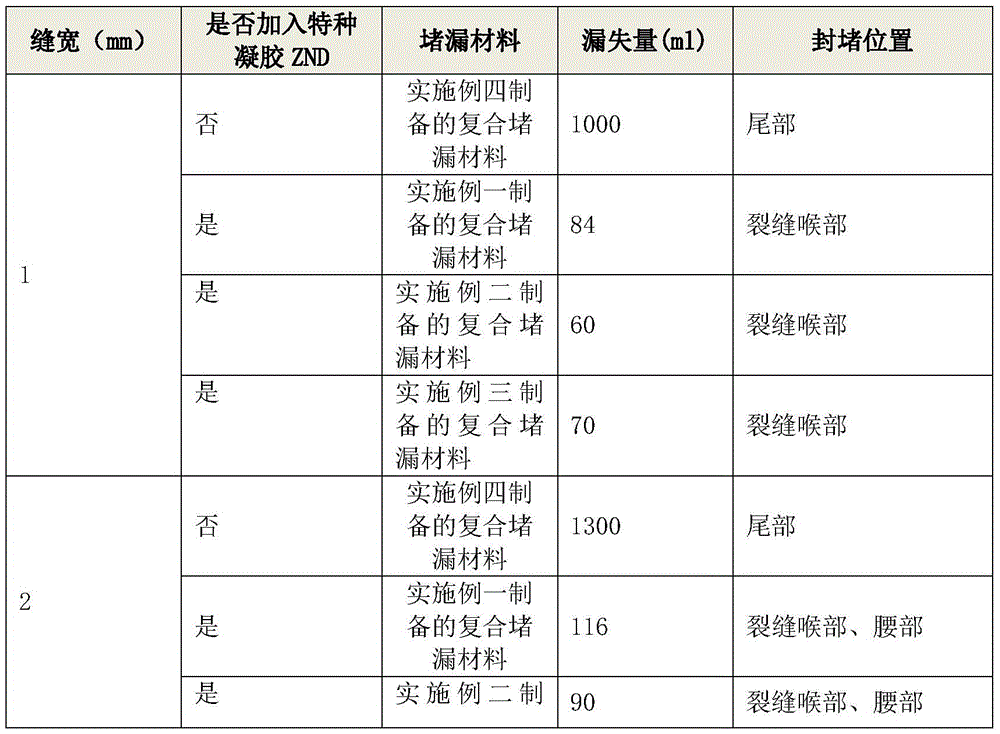

[0035] Embodiment 1, preparation of composite plugging material

[0036] 1. According to the calculation of plugging slurry prepared with 10 liters of clean water, take 80g of polymer, 1200g of bridge plug material, and 1253g of filling material in parts by mass;

[0037] The polymer is: special gel ZND; the bridge plug material is: calcium carbonate particles (calcium carbonate particles with a particle size of 2-0.85 mm in mass ratio: calcium carbonate particles with a particle size of <0.85 mm = 9:7) and walnuts Shells (in terms of mass ratio, walnut shells with a particle size of 4 to 3 mm: walnut shells with a particle size of 3 to 2 mm = 7:8) are compounded at a ratio of parts by mass of 3: 2; the filling material is: high water loss plugging material DTR

[0038] 2. At room temperature, first mix the bridge plug material with the filling material, then put in the polymer, and mix evenly to obtain a composite plugging material.

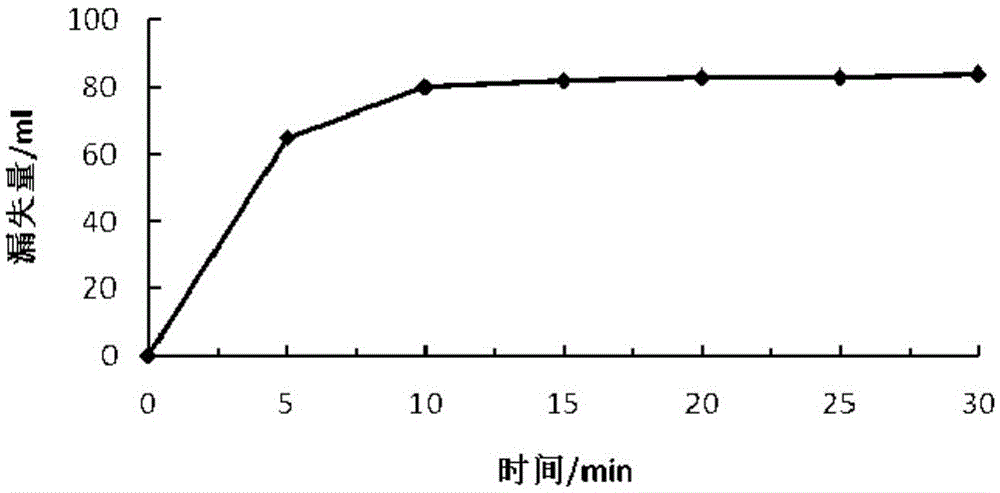

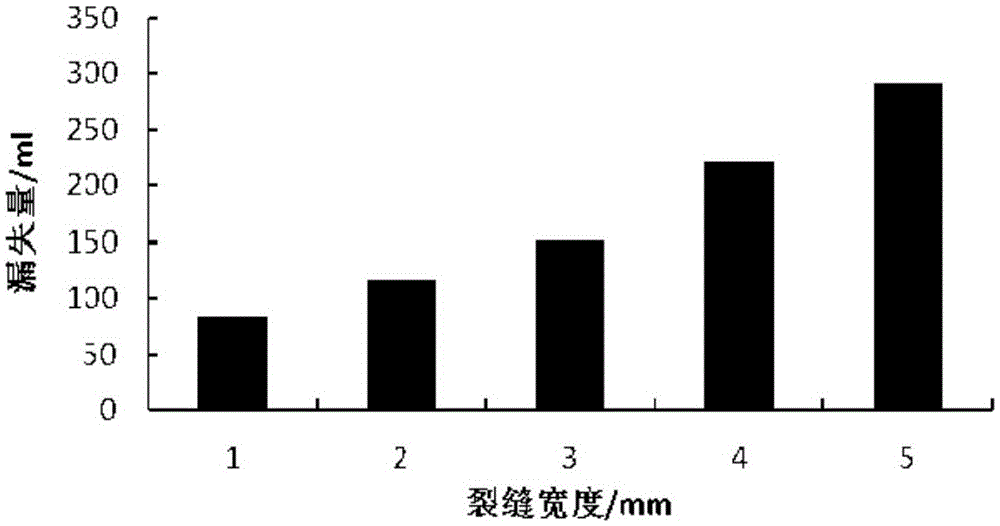

[0039] 3. Under stirring conditions, sl...

Embodiment 2

[0040] Embodiment two, the preparation of composite plugging material

[0041] 1. According to the calculation of plugging slurry prepared with 10 liters of clean water, take 120g of polymer, 1080g of bridge plug material and 1200g of filling material in parts by mass;

[0042] The polymer is: special gel ZND; the bridge plug material is: calcium carbonate particles (calcium carbonate particles with a particle size of 2-0.85 mm in mass ratio: calcium carbonate particles with a particle size of <0.85 mm = 9:7) and walnuts Shells (in terms of mass ratio, walnut shells with a particle size of 4 to 3 mm: walnut shells with a particle size of 3 to 2 mm = 7:8) are compounded at a ratio of parts by mass of 3: 2; the filling material is: high water loss plugging material DTR2. At room temperature, first mix the bridge plug material with the filling material, then put in the special gel ZND, mix evenly, and get the composite plugging material.

[0043] 3. Under stirring conditions, sl...

Embodiment 3

[0044] Embodiment three, the preparation of composite plugging material

[0045] 1. According to the calculation of plugging slurry prepared with 10 liters of water, take 100g of polymer, 1175g of bridge plug material and 1225g of filling material in parts by mass;

[0046] The polymer is: special gel ZND; the bridge plug material is: calcium carbonate particles (calcium carbonate particles with a particle size of 2-0.85 mm in mass ratio: calcium carbonate particles with a particle size of <0.85 mm = 9:7) and walnuts Shells (in terms of mass ratio, walnut shells with a particle size of 4 to 3 mm: walnut shells with a particle size of 3 to 2 mm = 7:8) are compounded at a ratio of parts by mass of 3: 2; the filling material is: high water loss plugging material DTR2. At room temperature, first mix the bridge plug material with the filling material, then put in the polymer, and mix evenly to obtain a composite plugging material.

[0047] 3. Under stirring conditions, slowly add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com