Leaking stoppage method and structure for karst pipeline

A plugging method and pipeline technology, applied in water conservancy projects, sea area engineering, construction, etc., can solve problems such as complex construction procedures, high safety risks, and difficulty in plugging, and achieve low construction technical difficulty, simple construction procedures, and good performance. The effect of plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

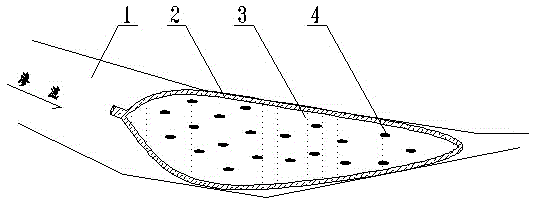

[0012] The present invention is implemented like this: figure 1 As shown, the present invention mainly adopts a film bag type plugging structure, and the outside of this film bag type plugging structure is a film bag 2, and the film bag 2 has a soft texture, and has good stretch resistance and sufficient The strength must be high, and it must also be waterproof, so the selection of materials is more important, and it is usually sewn with a film processed from natural rubber. Put mixed soybeans 4 and quick-setting mortar 3 into the film bag 2, then seal the film bag 2 and place it on the leaking port of the karst pipeline 1, so that the soybeans 4 can use their own expansion before the quick-setting mortar 3 solidifies The inner volume of the membrane bag 2 expands due to the property of membrane bag 2, and the membrane bag 2 will continue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com