Handling method for diaphragm wall slotted hole cement grout leakage

A treatment method and anti-seepage wall technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve the problems of loose structure and difficulty in handling slurry leakage in the slots of the anti-seepage wall, and achieve plugging good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

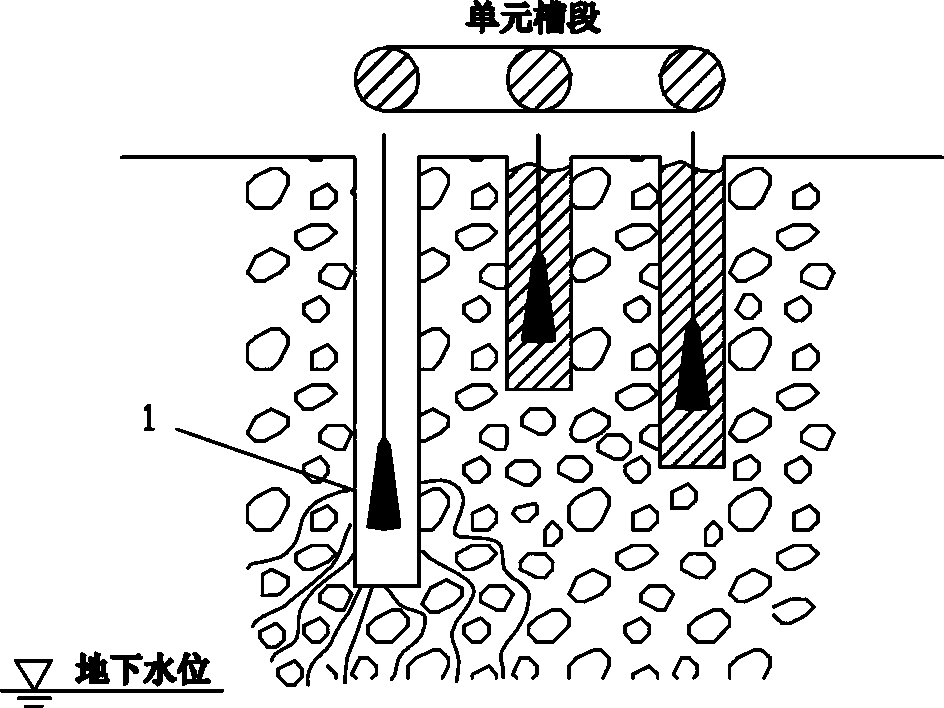

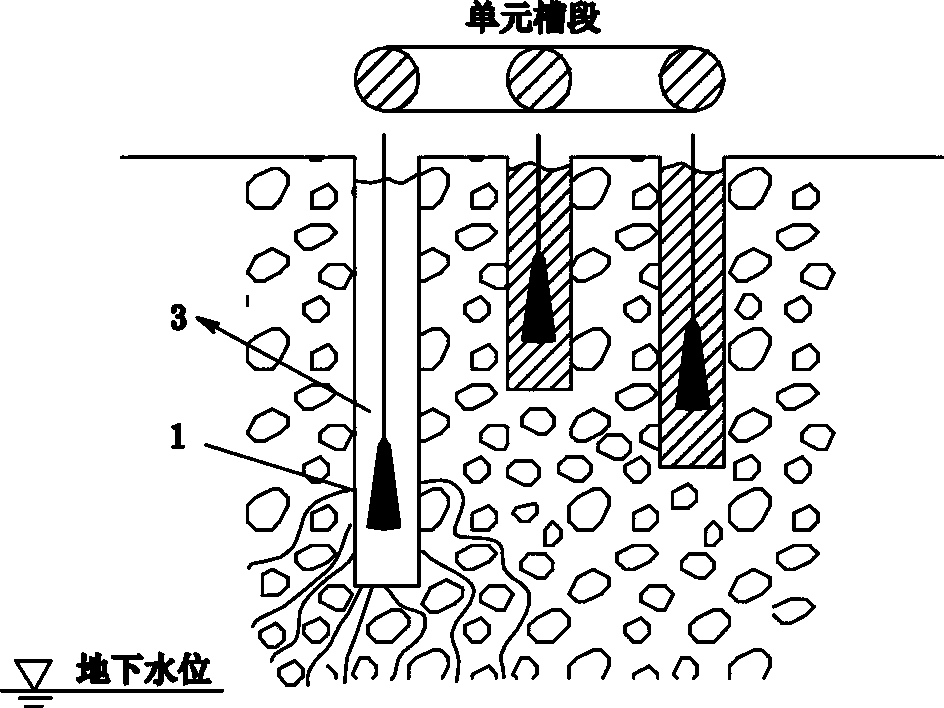

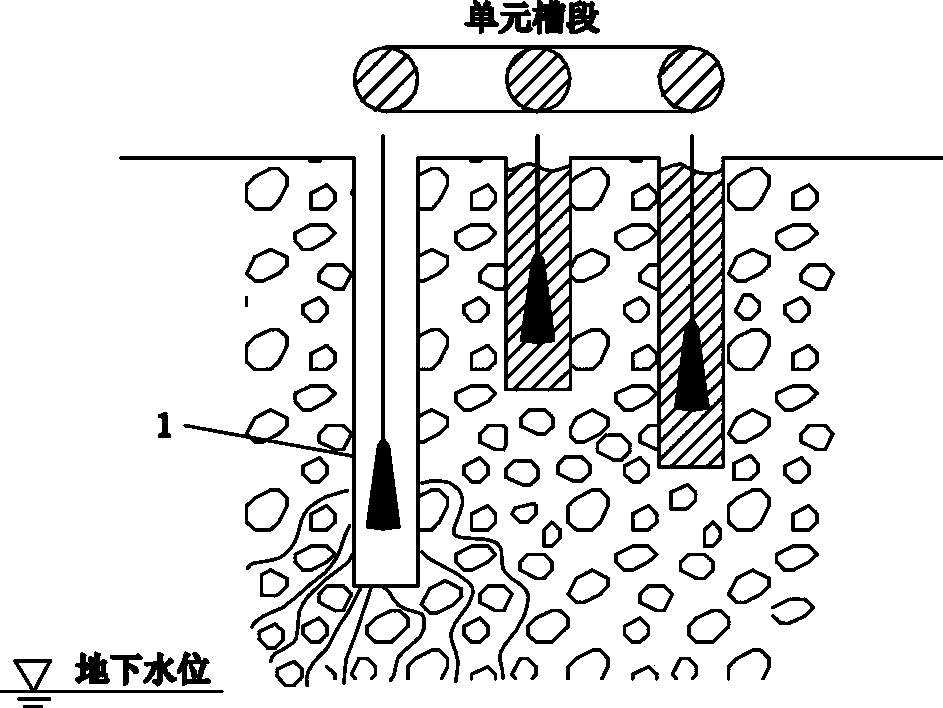

[0025] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a treatment method for grout leakage in cut-off wall slots, the method comprises the following steps:

[0026] 1) During the construction of the anti-seepage wall, inject pure cement slurry 3 into the hole 1 of the slot 1 that cannot be plugged by conventional methods to ensure the stability of the hole wall and prevent the slot from collapsing;

[0027] 2) Under the condition of cement slurry solidifying the wall, the percussion drilling rig is used for drilling. Since the density of pure cement slurry is greater than that of mud, the pressure of the slurry column formed is also greater than the pressure of the slurry column formed by the mud. During the drilling process, the pure cement slurry 3 Penetrate into the soil layer around the hole wall of slot 1, and fill the overhead layer around the hole wall;

[0028] 3) When the pure cement slurry surface in the slot hole 1 drops to the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com