Gas pipe network high-pressure magnetic repair device

A technology of gas pipes and emergency repair devices, which is applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., which can solve the problems of unsealable material operations, etc., and achieve the effect of preventing chemical corrosion and static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

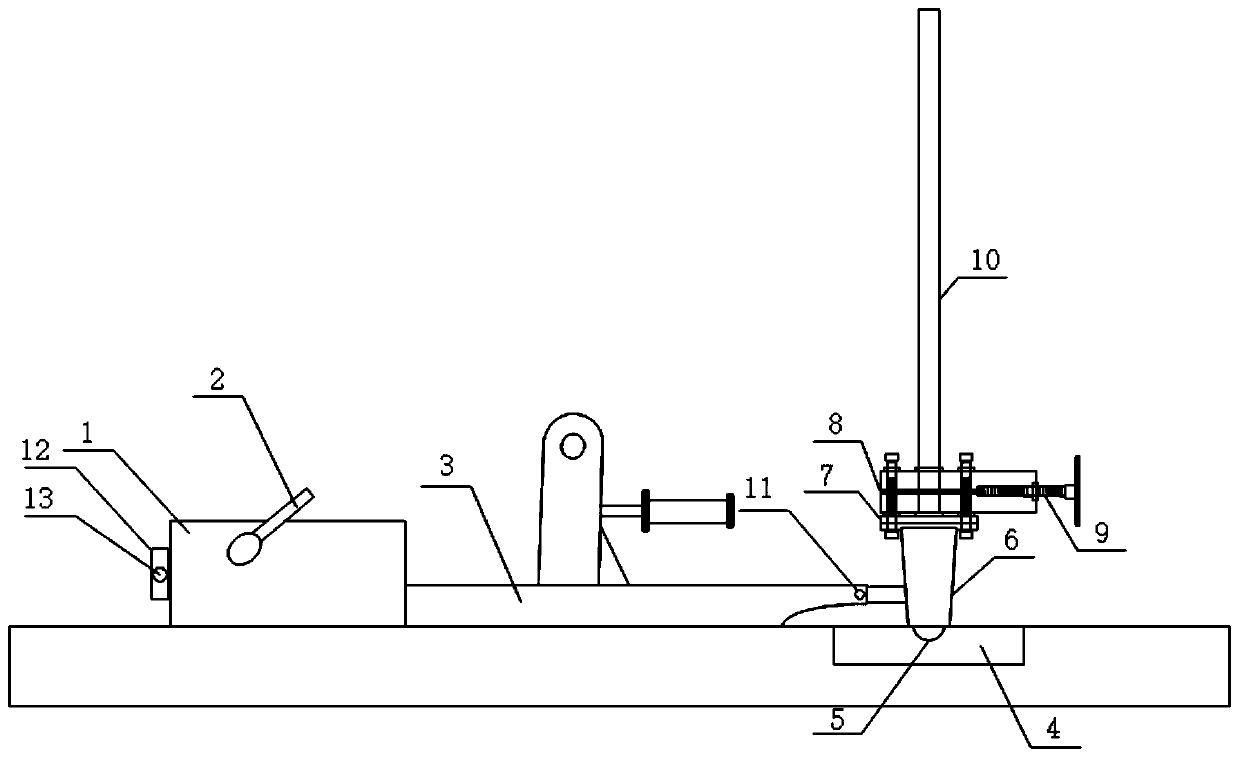

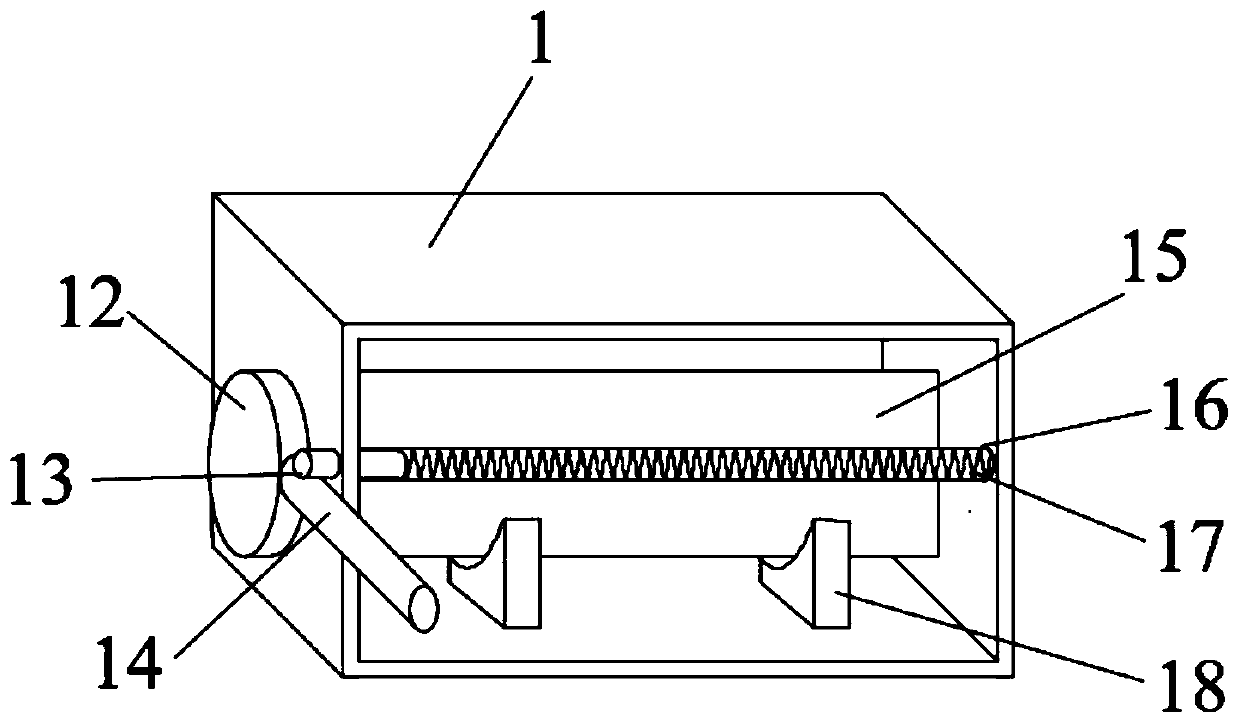

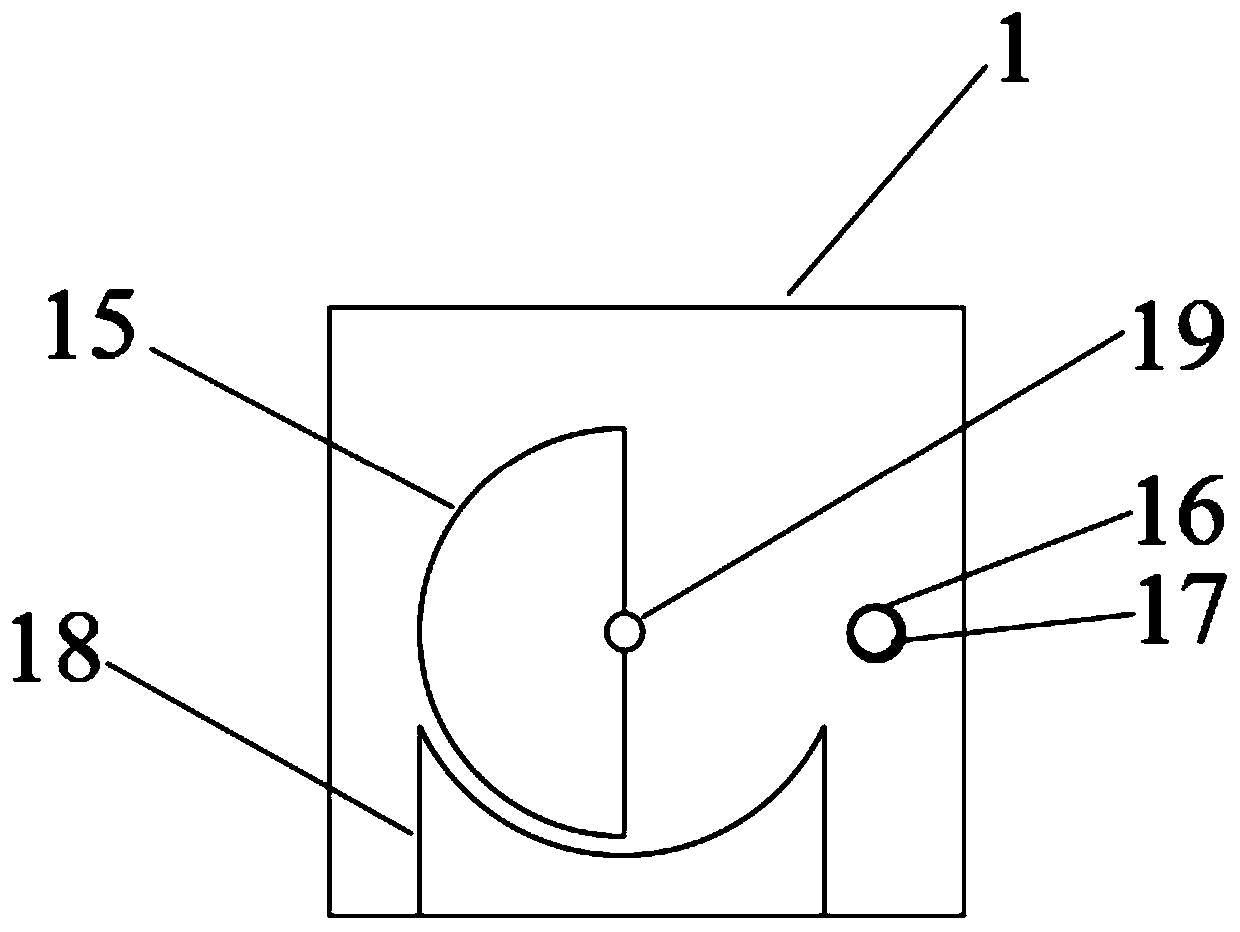

[0025] The gas pipe network high-voltage magnetic emergency repair device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as Figures 1 to 3 As shown, a gas pipeline network high-voltage magnetic emergency repair device of the present invention includes: a magnetic part, a lever part and a drainage and drainage part. Wherein the magnetic force part is made up of magnetic base box body 1, handle 2, strong magnetic shell 12, rotating handle 14, button 13, and the inside of magnetic base box body 1 is made up of strong magnet 15, spring 17, spring shell 16, bottom bracket 18 , bearing 19, wherein the bearing 19 is fixed inside the magnetic box 1 and can rotate, the powerful magnet 15 is fixed on the bearing so that it can rotate with the bearing 19, the button 13 is fixed in the spring housing 16 by the spring 17, and can be used The spring stretches, and the strong magnetic casing 12 and the rotary handle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com