Supporting method for soft broken nonuniform stratum tunnel construction

A tunnel construction and uniform technology, applied in tunnels, tunnel linings, roof beams supporting mine roofs, etc., can solve problems such as limited self-stabilization ability of tunnel surrounding rock, uneven grouting effect, general water-stop effect, etc., to achieve Improve the self-stabilization ability of surrounding rock, excellent support effect, reduce construction cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the accompanying drawings and embodiments.

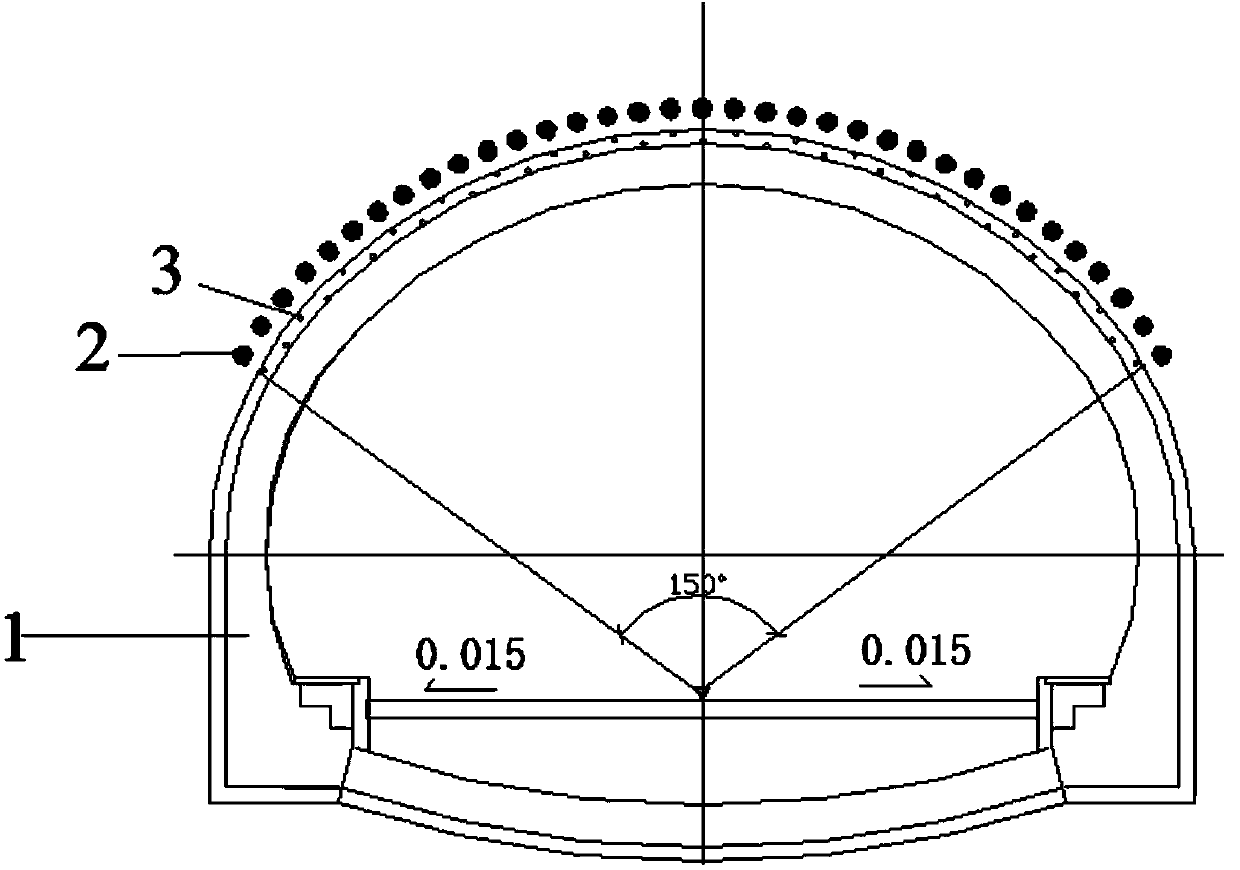

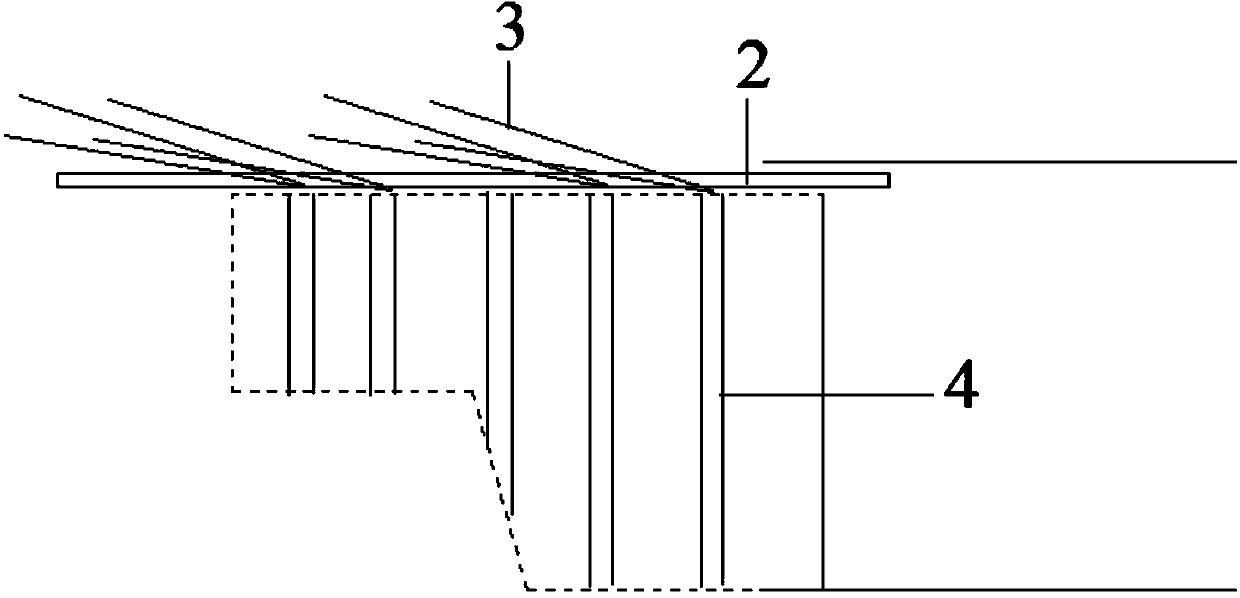

[0039] like figure 1 , figure 2 As shown, a support method for tunnel construction in weak and broken uneven stratum includes steel arches 4, steel pipes 2, and advanced small conduits 3 set in the tunnel lining 1, and the tunnel surrounding rock support steps are as follows:

[0040] (1) Small tube shed support

[0041] The outer diameter of 70mm and the length of 10m are seamless steel pipes, the longitudinal spacing is 7m, and the lap length is 3m. The small pipe shed is set up in the range of 150° of the dome, the circumferential spacing is 30cm, and the outside angle is 3° to 5°; the construction error of the steel pipe Controlled to be no more than 20cm in the radial direction and no more than 10cm along the direction of the adjacent steel pipe; the size of the small tube shed studio is 0.3m*1.4m.

[0042] Before drilling, positioning is carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com