Supporting structure formed on high-ground-stress weak surrounding rock tunnel by using ultralong extended head anchor cable

A technology of supporting structure and high in-situ stress, applied in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of long in-situ stress release period, low work efficiency, cracking of secondary lining, etc. Economic benefits and the effect of saving engineering materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

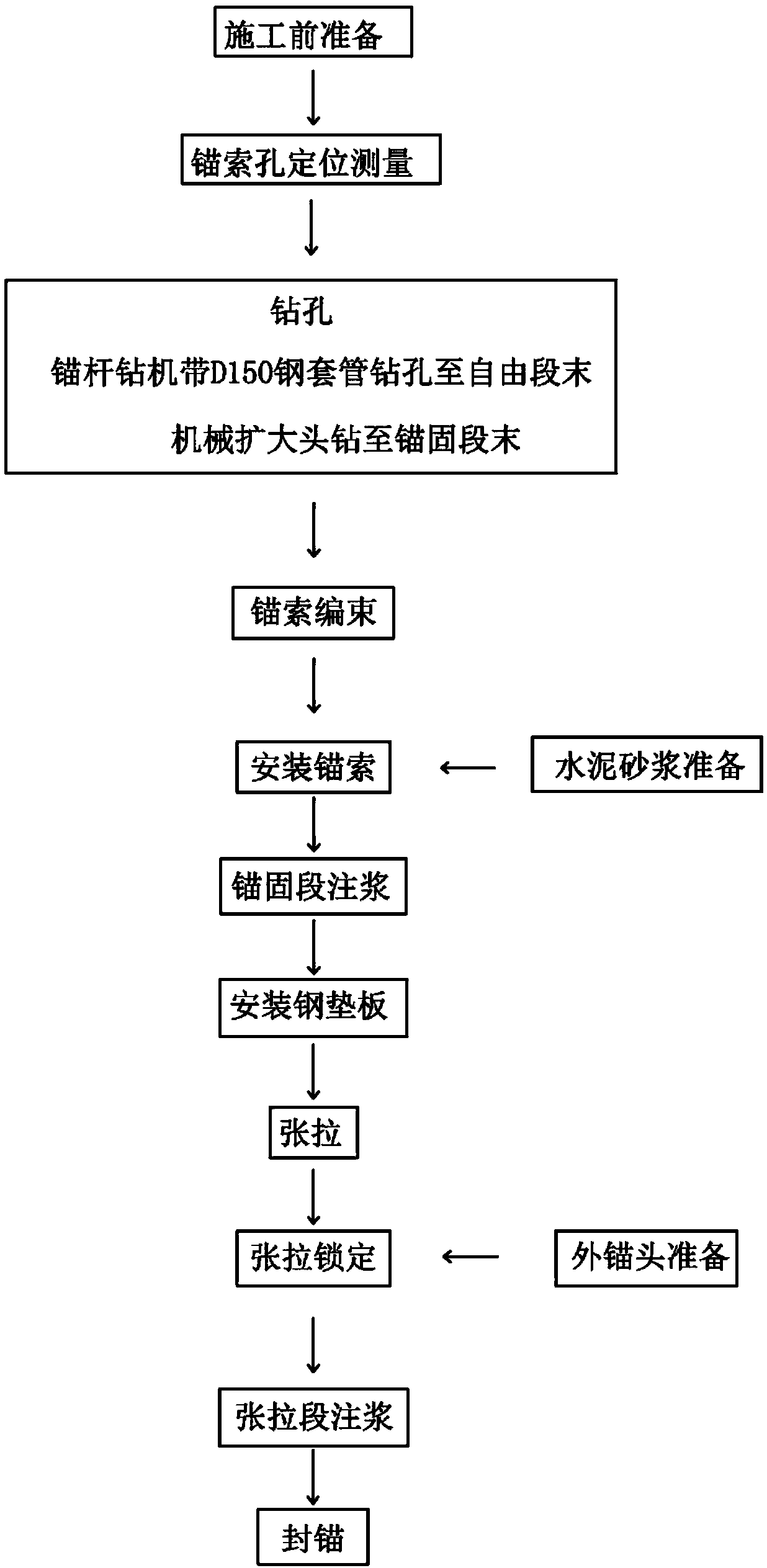

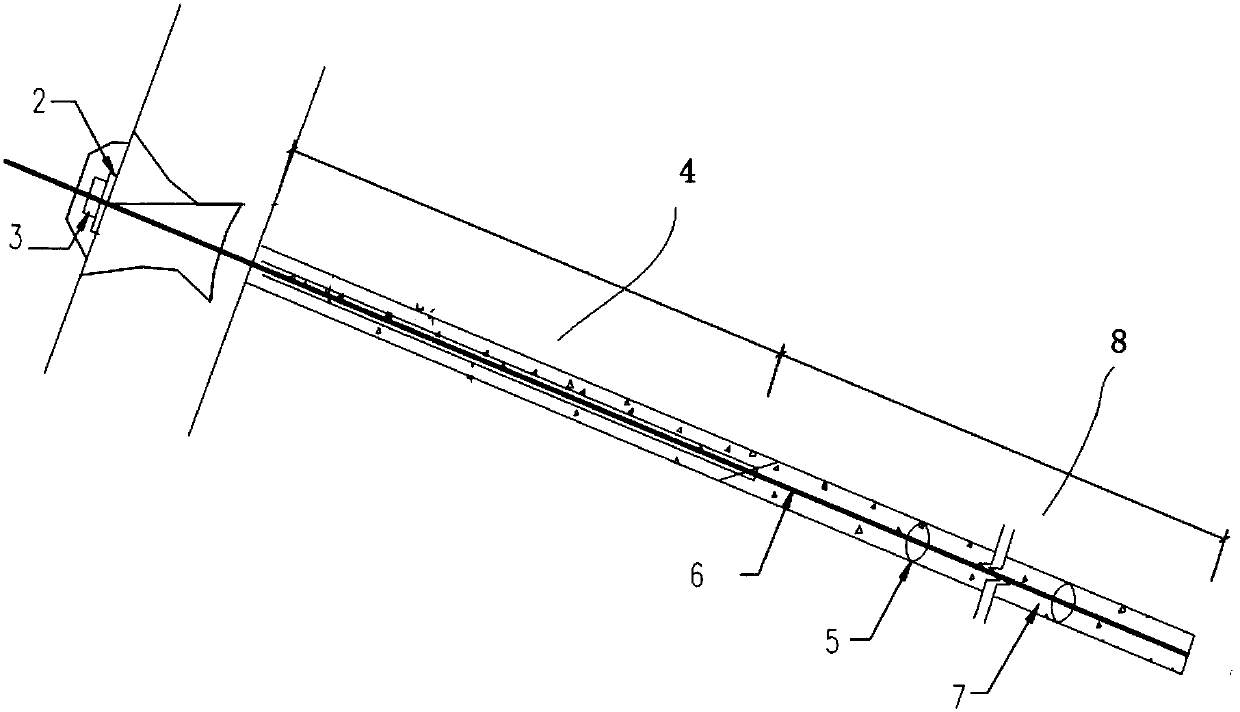

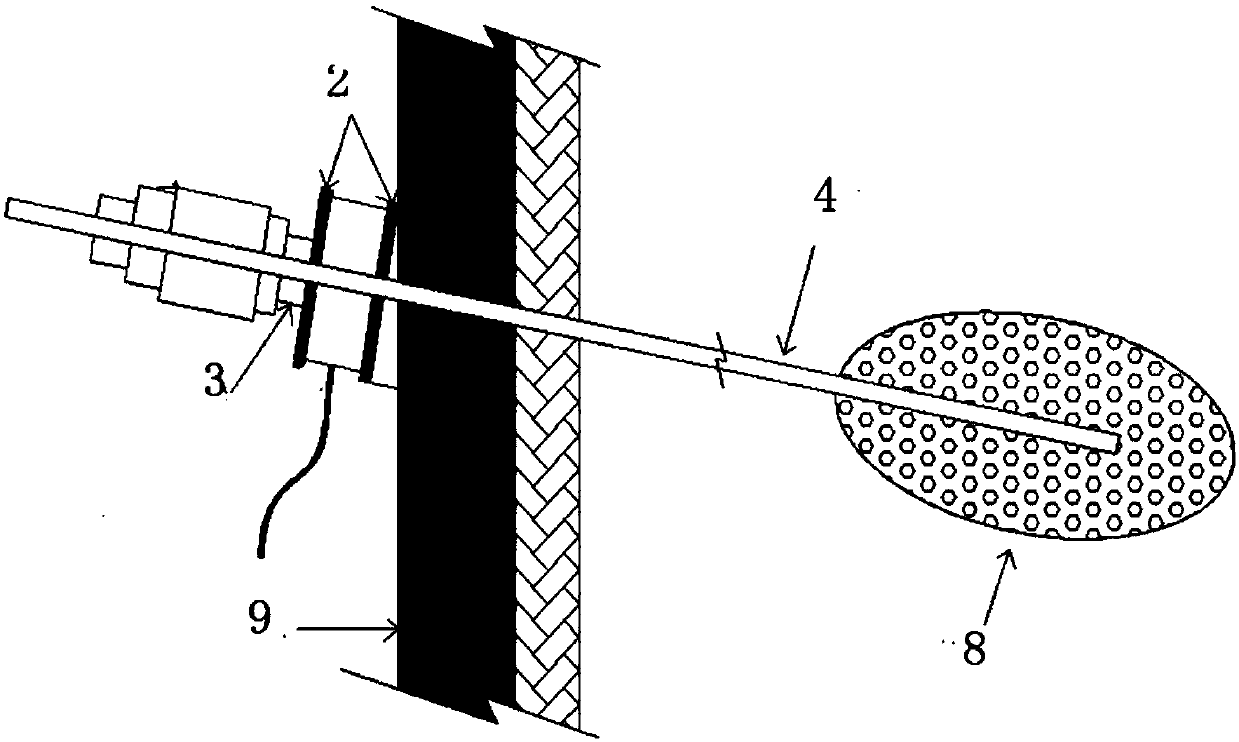

[0034] Such as figure 2 , image 3 As shown, a support structure formed by super-long expansion-head anchor cables for tunnels with high ground stress and weak surrounding rocks includes a support structure formed by anchor cables and an initial support structure. The support structure includes According to the different functions of the anchor cable, it can be divided into the anchor section located in the deep stable rock formation, the anchor section located in the anchor section and the primary support The tension section between the structures, the outer anchor head located outside the surrounding rock, the section size of the anchor cable head in the anchor section is larger than the other parts of the anchor cable, the anchor cable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com