Construction method for advance grouting and supporting for tunnel partial collapse

A technology of advanced grouting and construction method, applied in tunnels, tunnel linings, earthwork drilling and other directions, can solve problems such as deformation of unilateral primary support and landslide, and achieve the effect of strong adaptability, simple measures, and good control and restraint effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

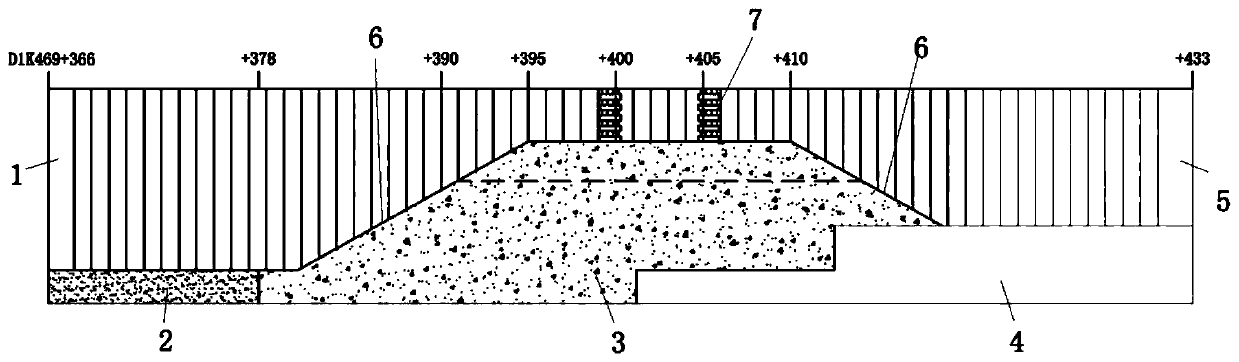

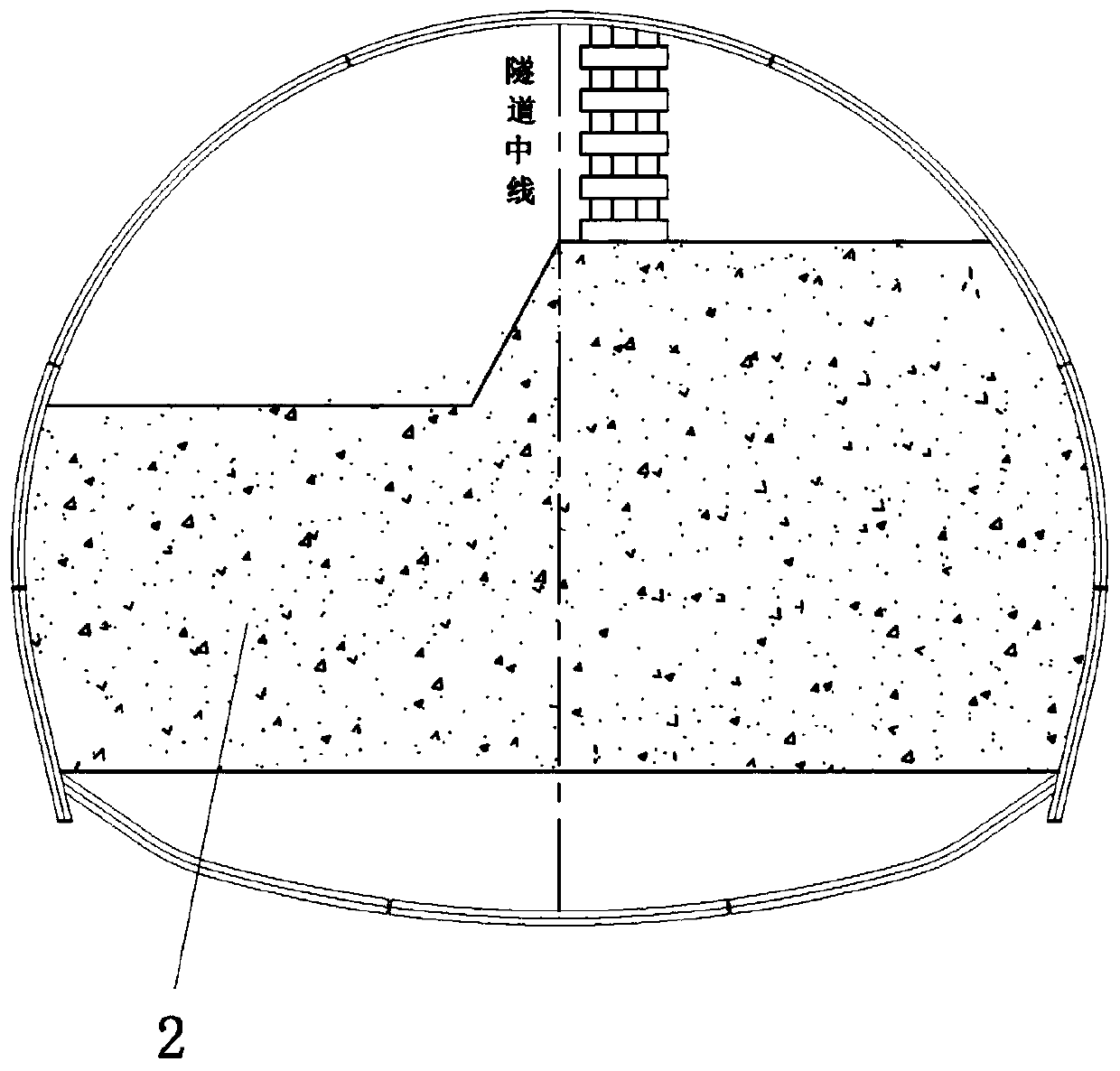

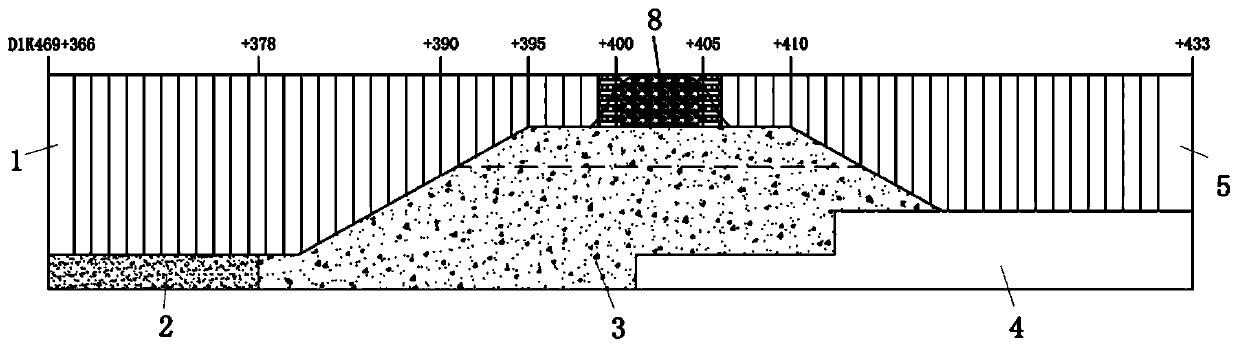

[0048] Such as Figure 1-9 As shown, this embodiment provides a construction method for advance grouting and support for partial tunnel collapse, which mainly includes the following steps:

[0049] ⑴ Backfill backpressure in the deformed section.

[0050]① Use ballast to backfill the deformed section under back pressure. When backfilling, fill in layers and control the thickness of the layers not to exceed 1m, and compact them layer by layer with loaders and excavators. The backfill range extends from the end mileage D1K469+405 of the deformation section to D1K469+410 by 5m toward the face 5 to facilitate construction operations. The backfill height is about 3m from the vault. The top of the platform is 15m long, and the gradient of the slope 6 is suitable for on-site mechanical construction.

[0051] ② At D1K469+400 and D1K469+405 with the largest amount of deformation, set up a sleeper pile 7 to support the initial support. Sleepers are 1.2-1.5m long and 20-30cm wide. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com