Patents

Literature

66results about How to "Save engineering materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

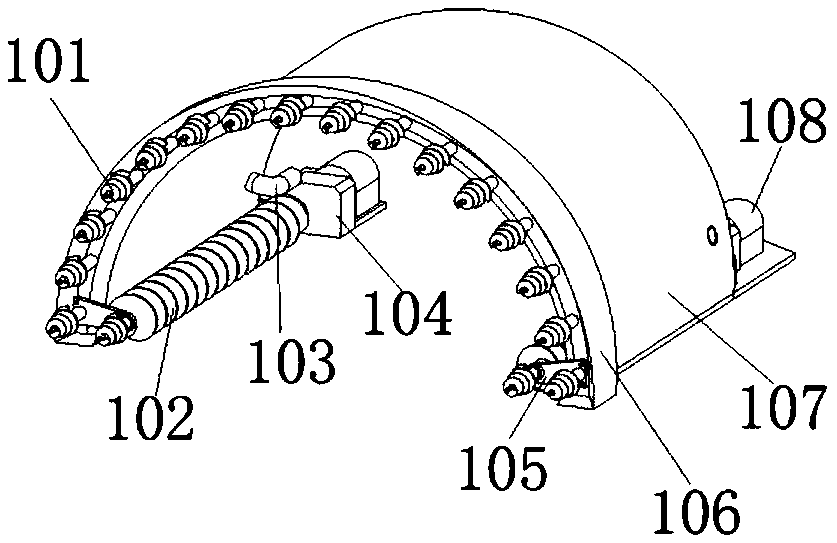

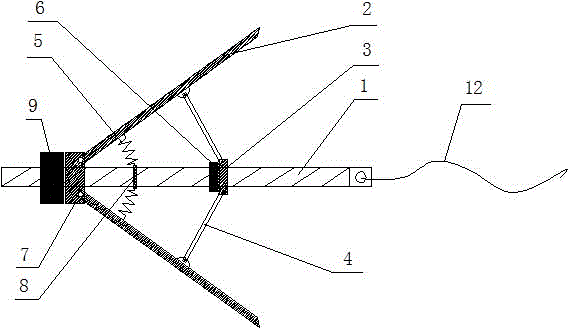

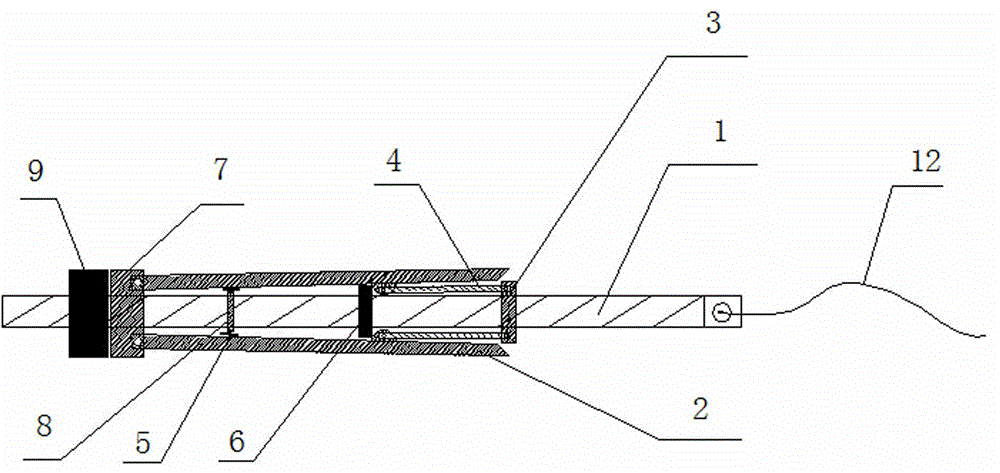

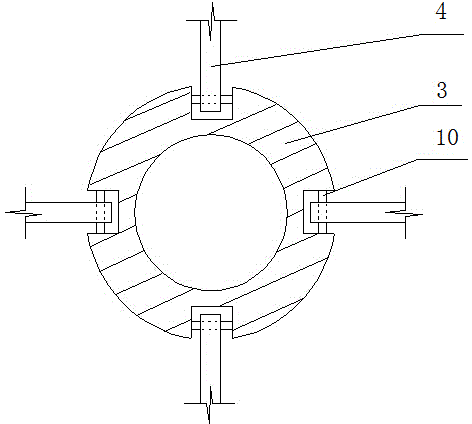

Flexible umbrella supporting anchor bolt and method for supporting soil slope thereby

ActiveCN104179178AIncrease anchoring forceConstruction quality is easy to ensureExcavationsBulkheads/pilesGeogridRock bolt

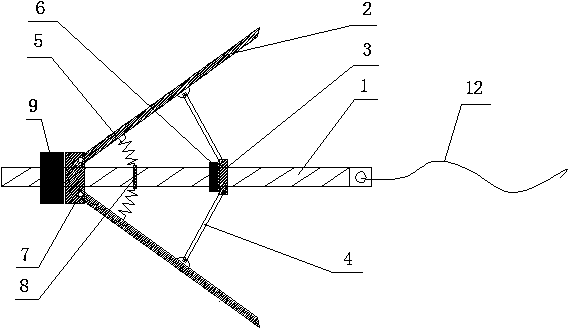

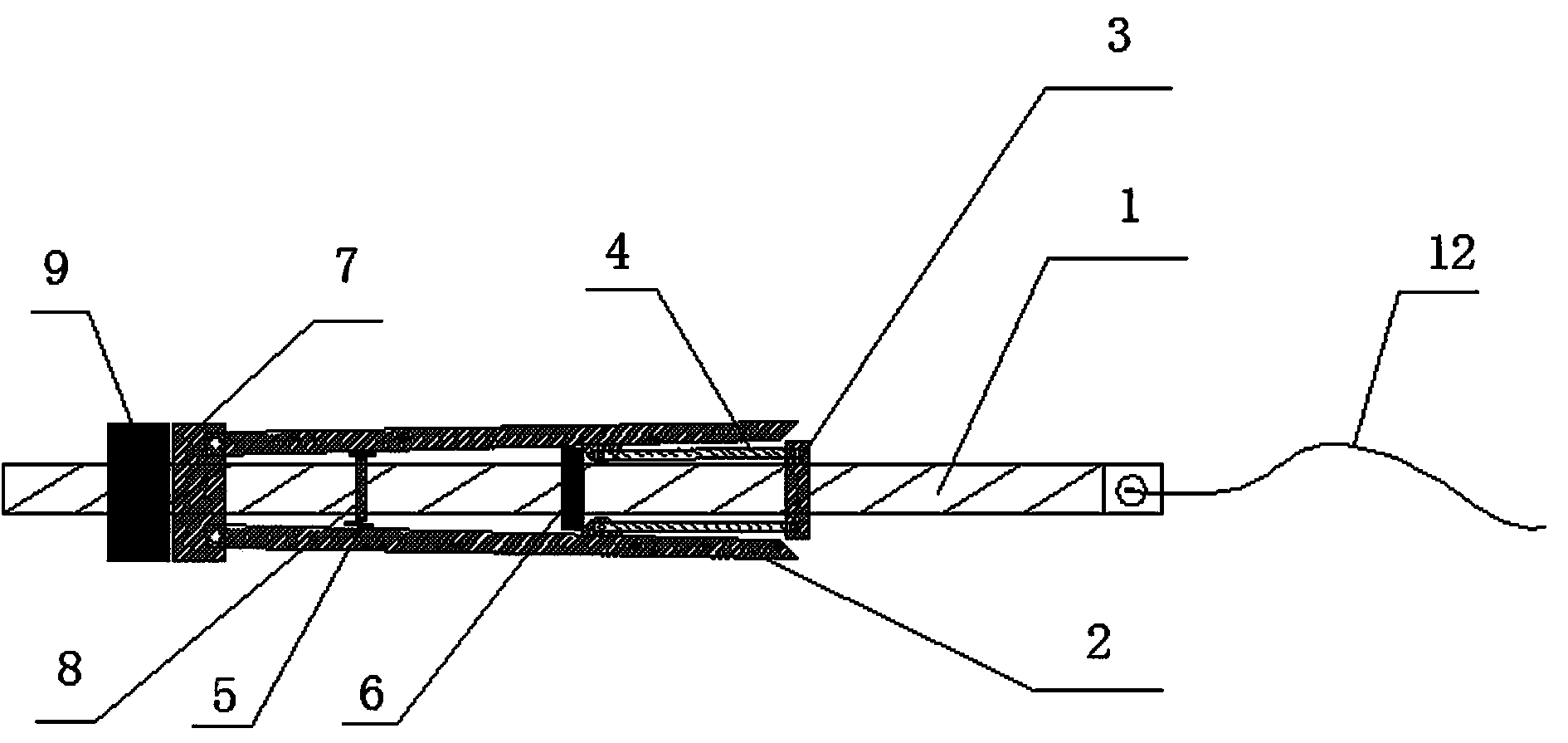

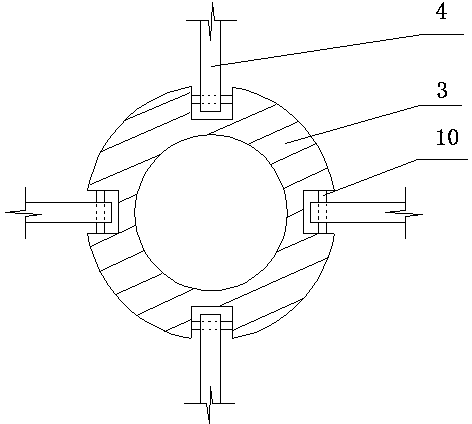

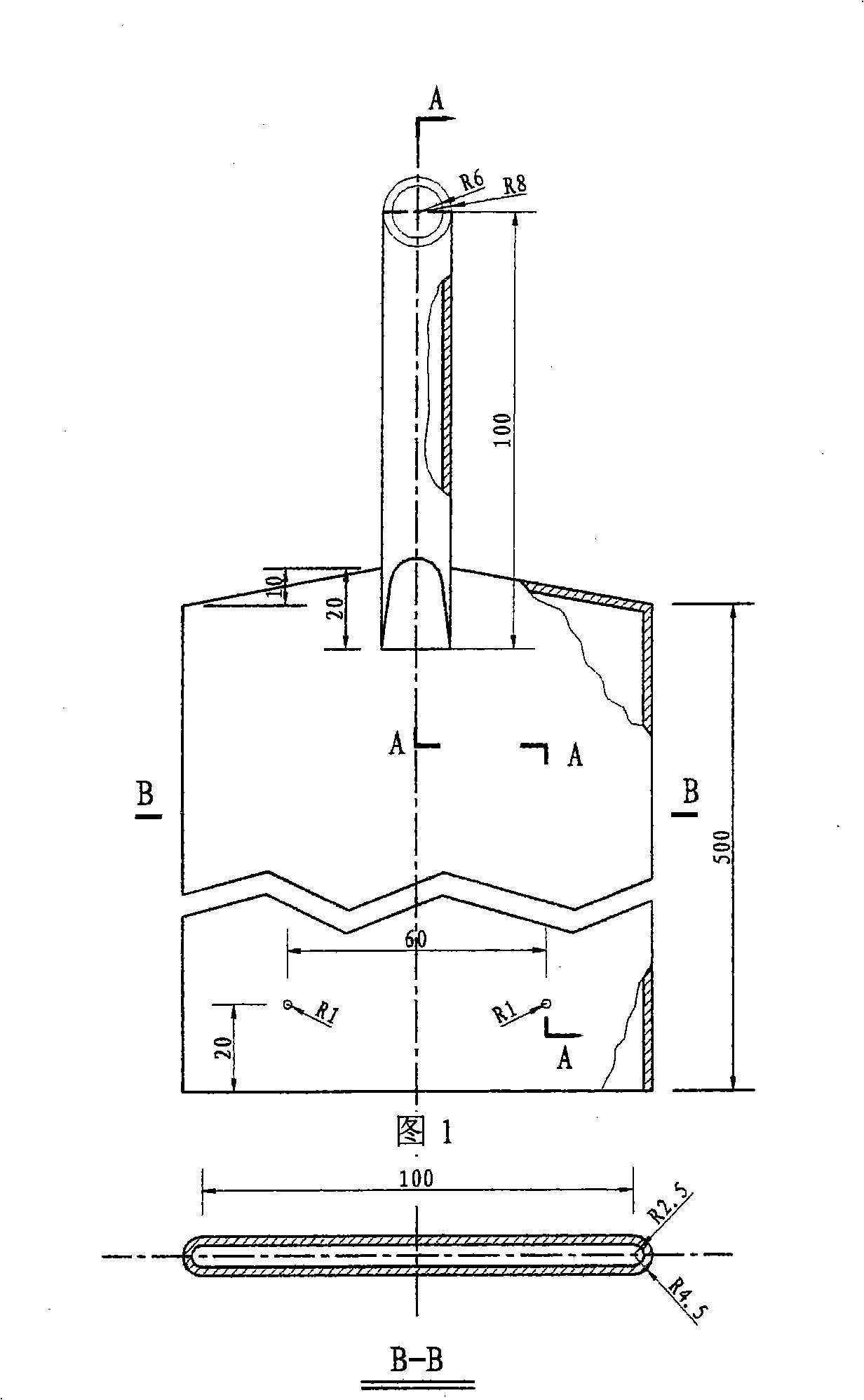

The invention relates to a flexible umbrella supporting anchor bolt and a method for supporting a soil slope thereby. An end ring and an end circular connector are fixedly disposed at one end of a round anchor bolt. A spring circular connector and a middle ring are fixedly disposed in the middle of the round anchor bolt. A lower circular connector adjacent to the right side of the middle ring movably sleeves the round anchor bolt. A drag umbrella surrounding the round anchor bolt comprises reacting plates evenly arranged, pull rods and compression springs. One end of a flexible pull rope is fixed to a round hole arranged in the other end of the round anchor bolt. More than one flexible umbrella supporting anchor bolt is connected with a soil high slope protective structure, composed of a geogrid mesh, a vegetation protective layer and a retaining wall, through the flexible pull ropes, and a whole for firmly and reliably anchoring and protecting the soil high slope is formed. The umbrella reacting plates are connected with the protective structural mesh through the flexible pull rope, anchoring force is greatly higher than that of a traditional anchor bolt, anchoring effect is more reliable, and engineering cost can be decreased by 50-60%.

Owner:NANCHANG INST OF TECH

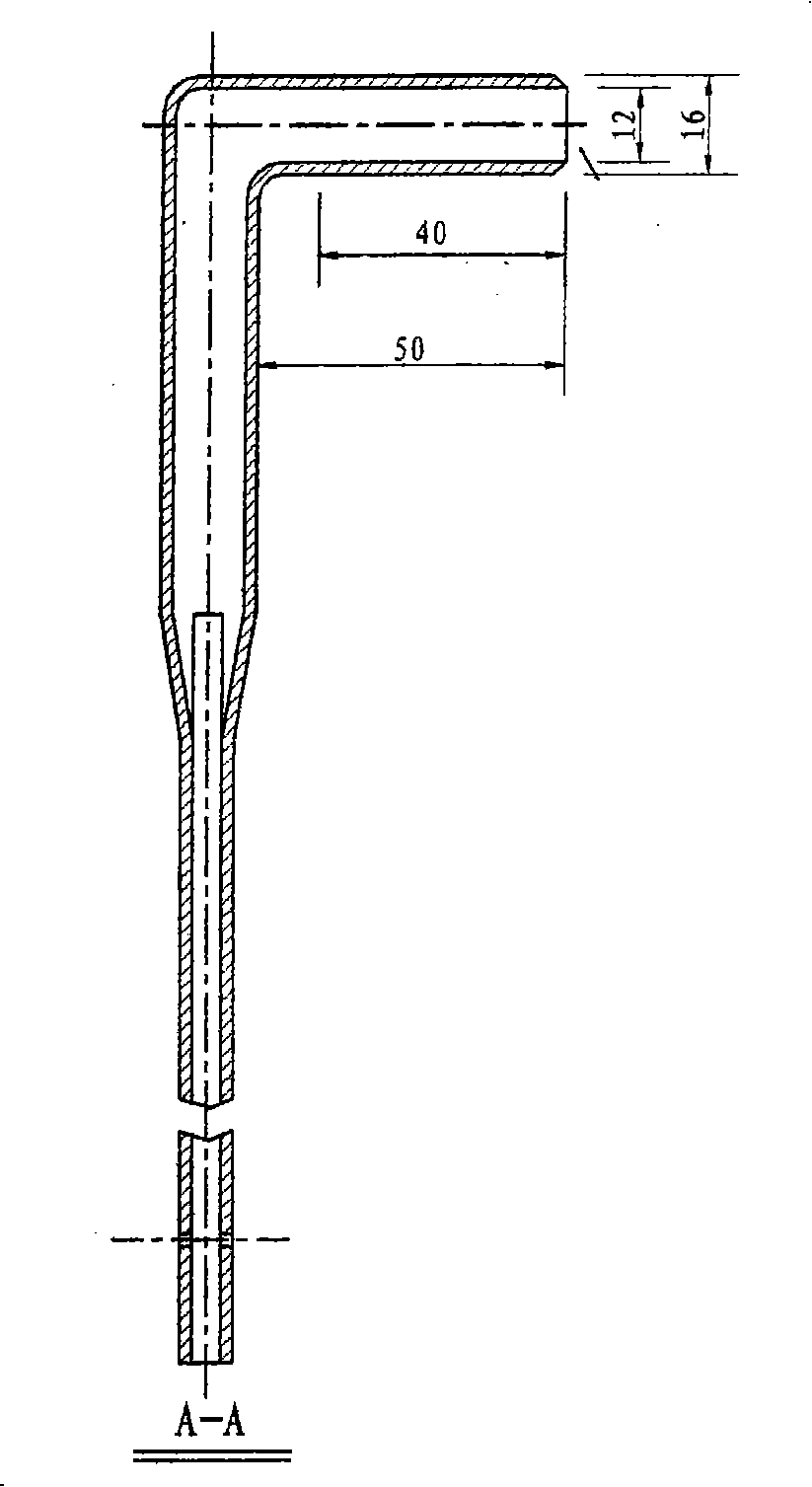

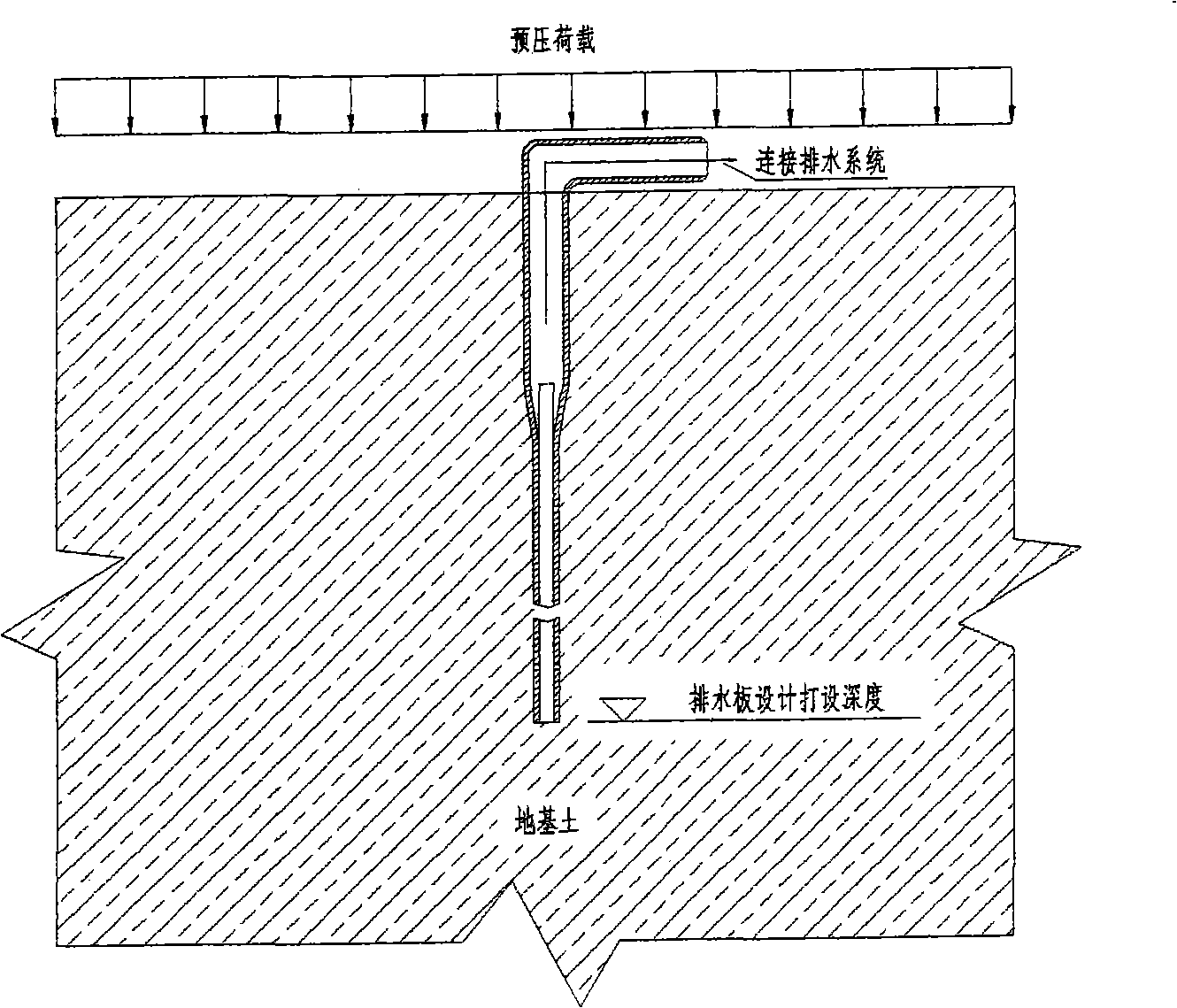

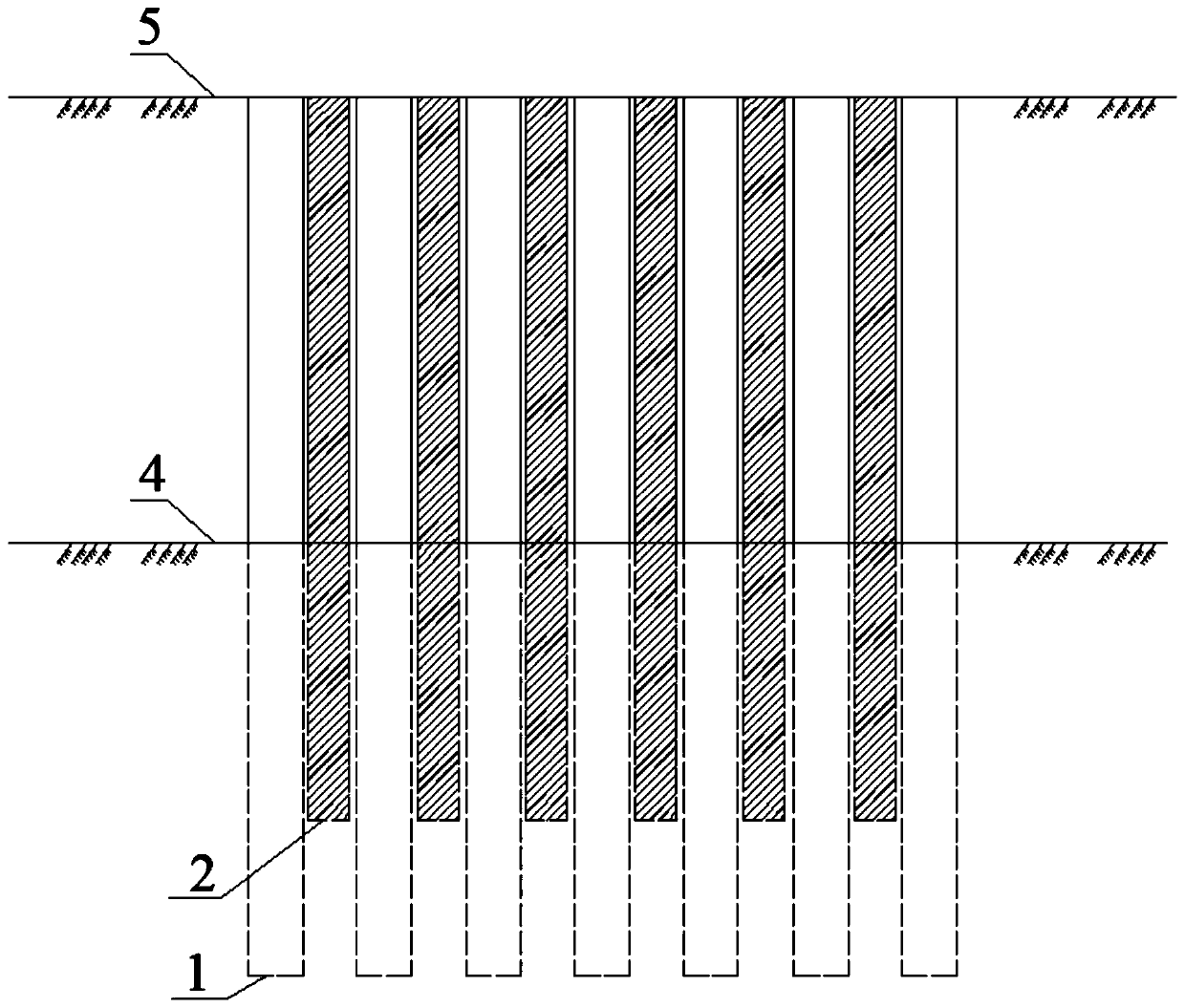

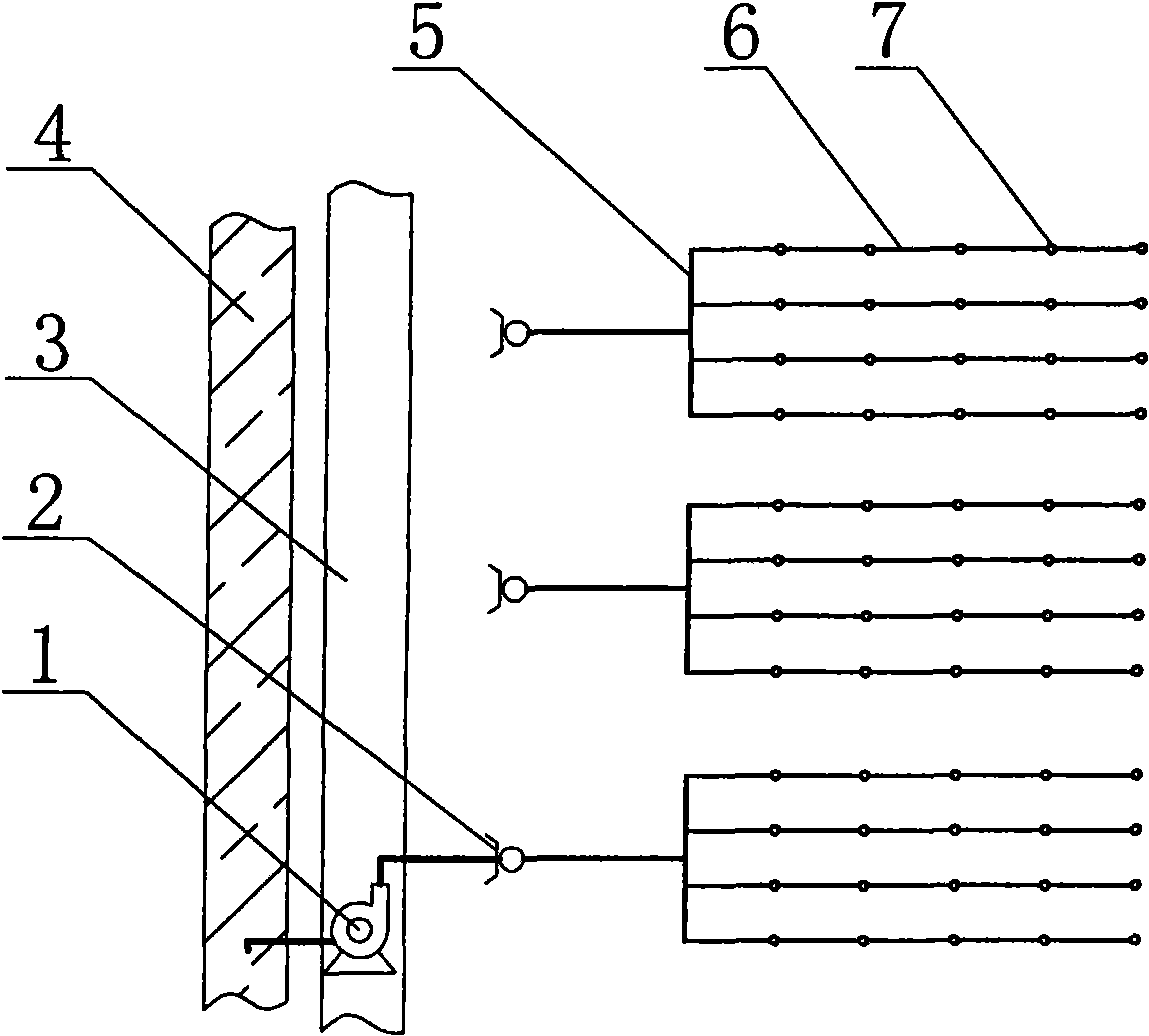

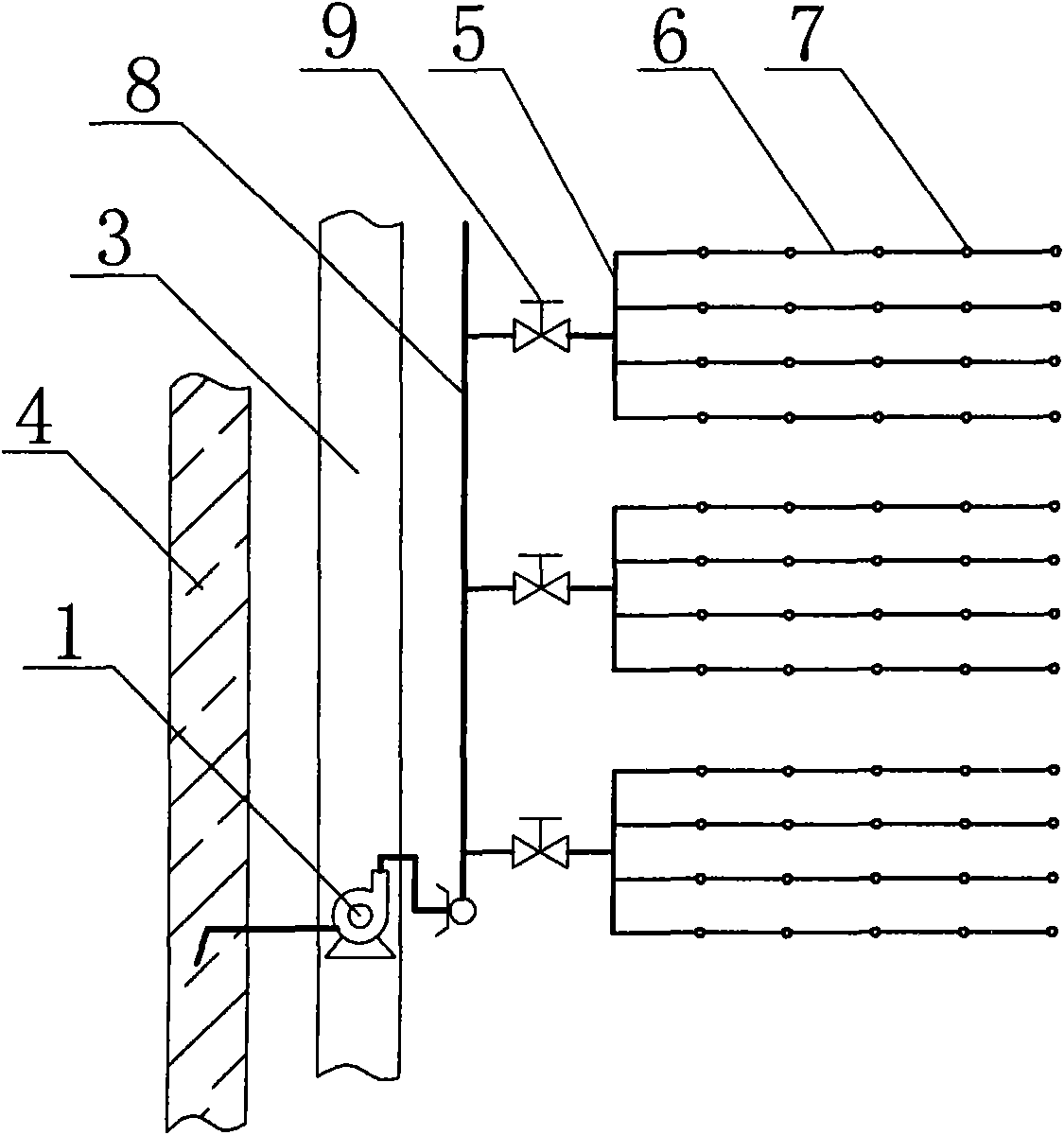

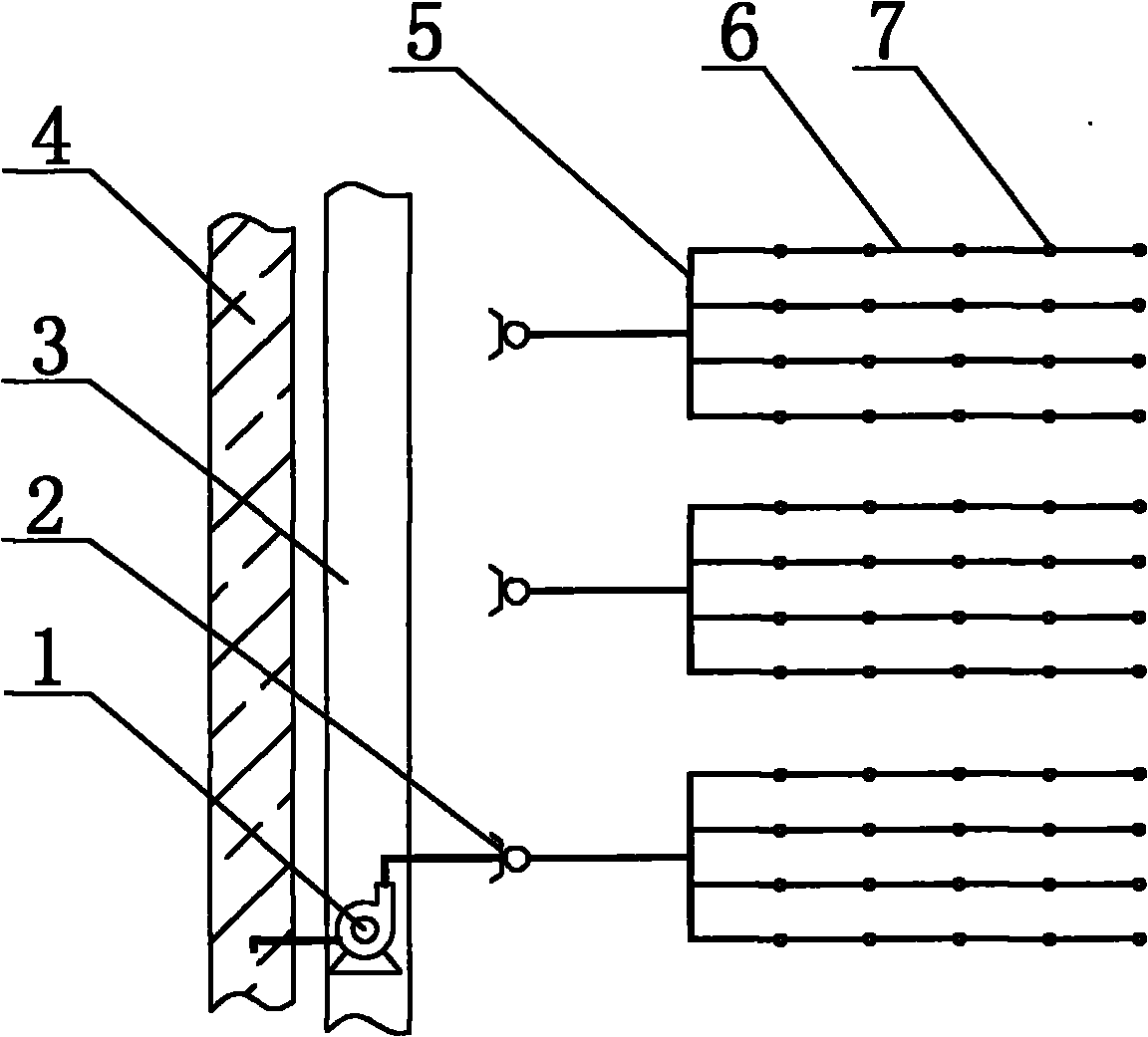

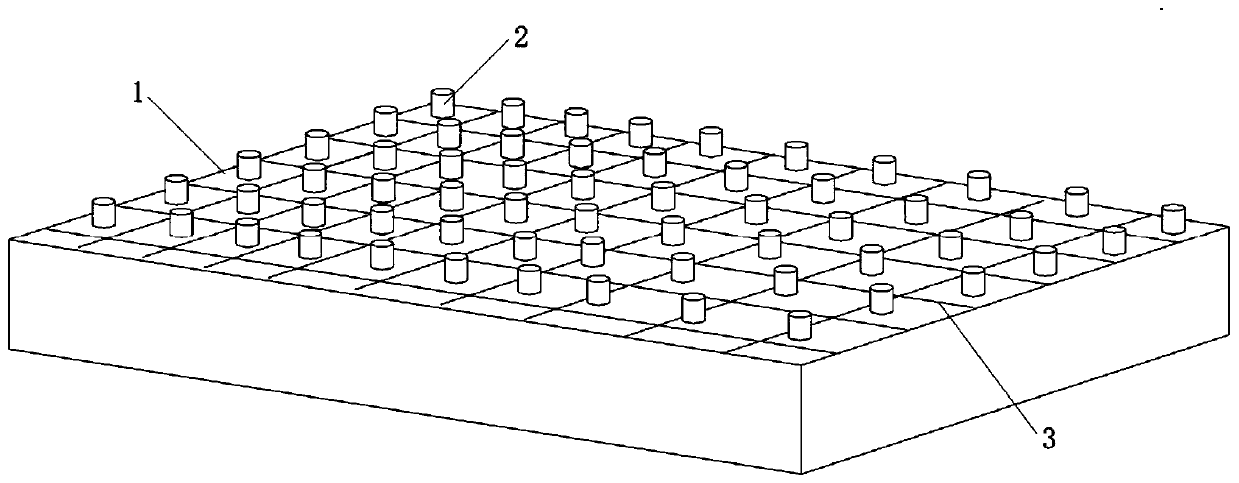

Self-seal vacuum pre-press reinforcing foundation technical method

InactiveCN101349054ASimplify construction proceduresEasy constructionSoil preservationEarth surfaceVacuum pump

The invention relates to a technical method for reinforcing foundation by self-sealing and vacuum prepressing, which adopts a mode of mounting a drainage plate self-sealing device and connecting an air suction and drainage connecting pipe system to discharge pore water in soft soil foundation for reinforcing the foundation; drainage plates and the drainage plate self-sealing device are driven into the foundation needing drainage and reinforcement in rank; and the drainage plate self-sealing device is connected to the air suction and drainage connecting pipe system and then a vacuum pump. The drainage plates and the drainage plate self-sealing device are arrayed according to a matrix and driven to the foundation; the vacuum pump is connected with a main pipe of the air suction and drainage connecting pipe system; the main pipe is connected with a plurality of rows of parallel branched pipes; two sides of the branched pipes are connected with a plurality of connecting branched pipes which are connected with a water and air suction pipe of the air suction and drainage plate self-sealing device. The method saves a plastic sealed film for reinforcing the ground surface, a horizontal drainage undercourse, total filter pipes, a film outgoing device and a film pressing sealed ditch in the common vacuum prepressing, simplifies the construction procedure, has convenient and rapid construction, shortens the construction period, saves mass engineering material, manpower and engineering investment.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG

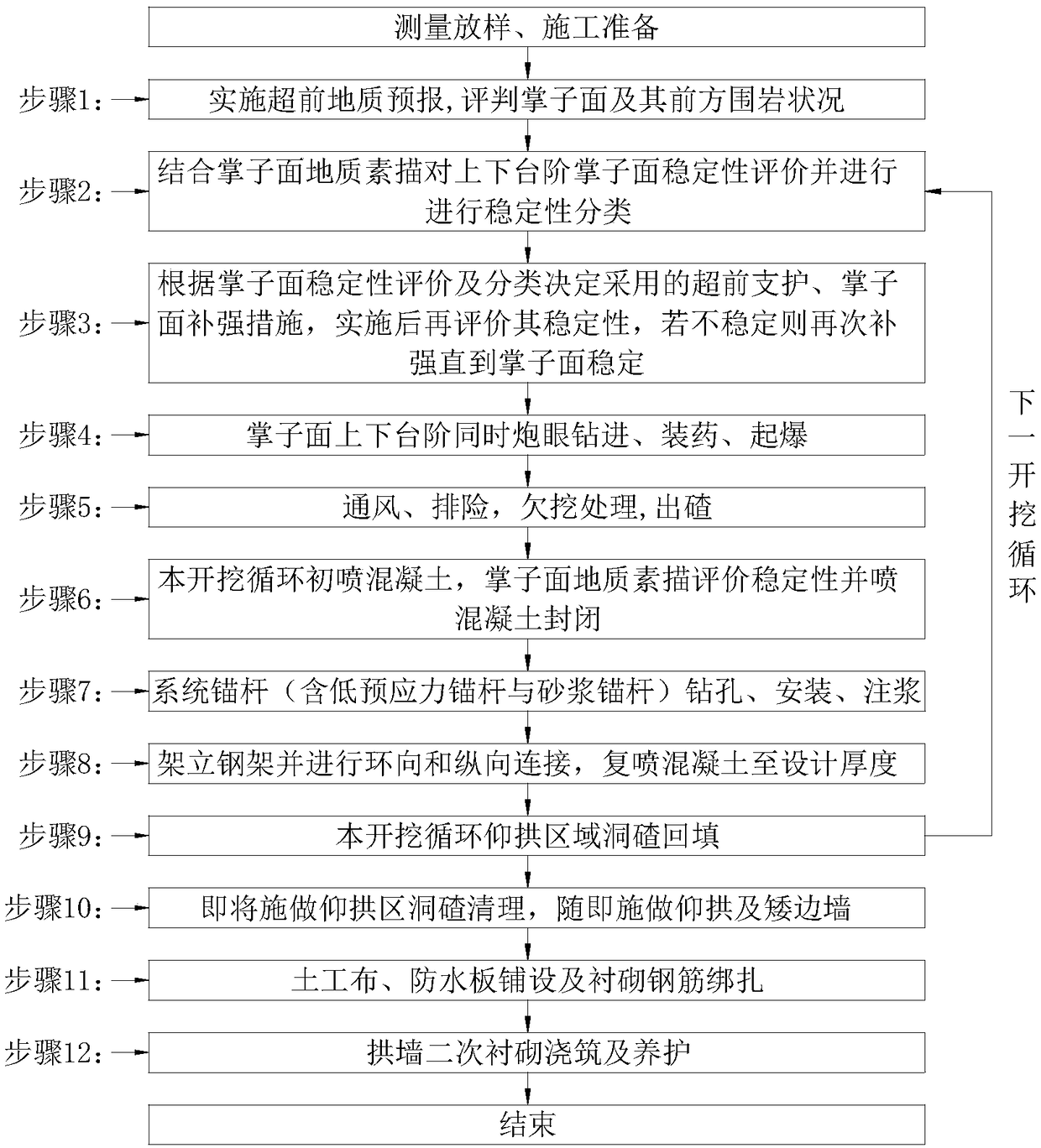

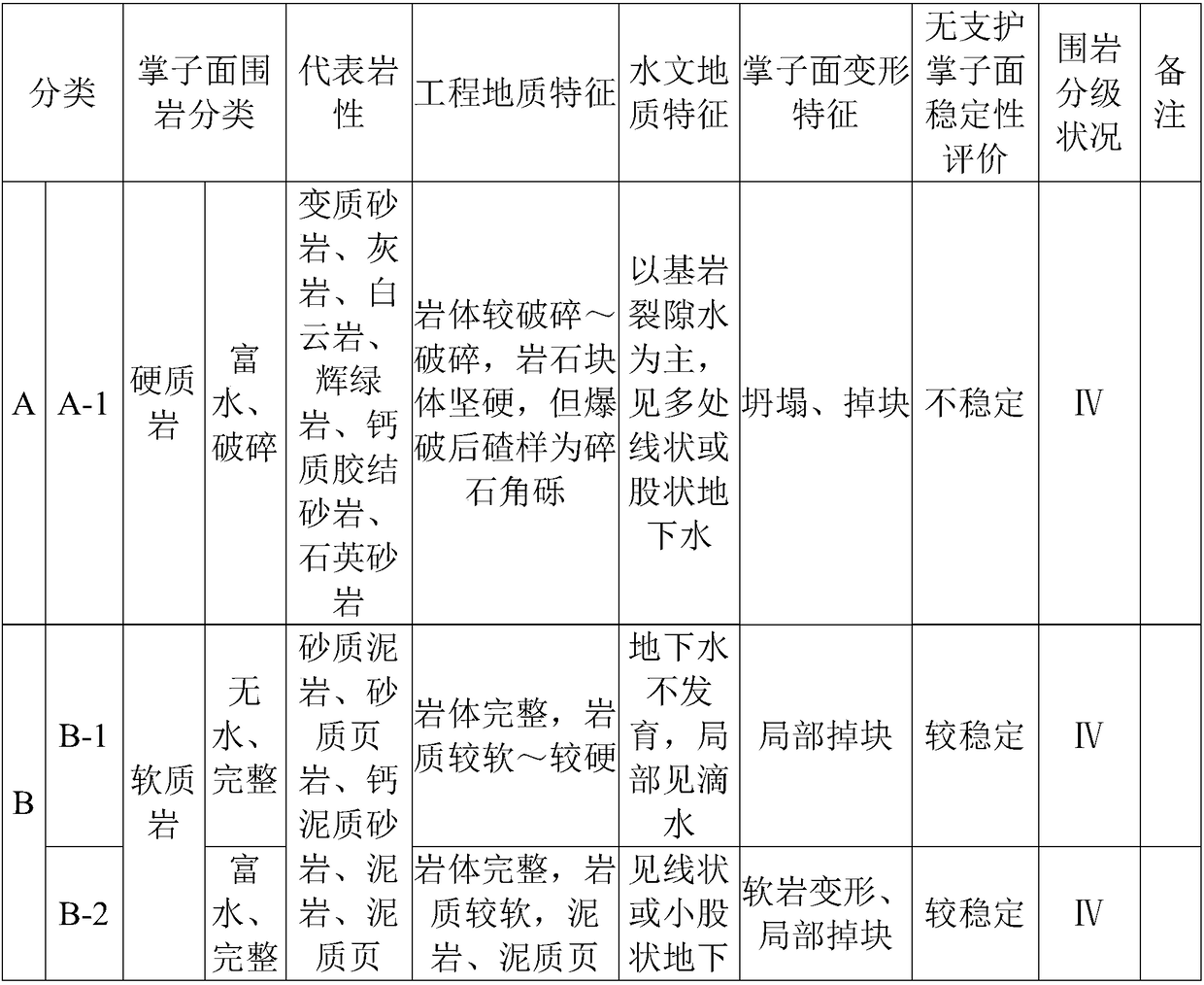

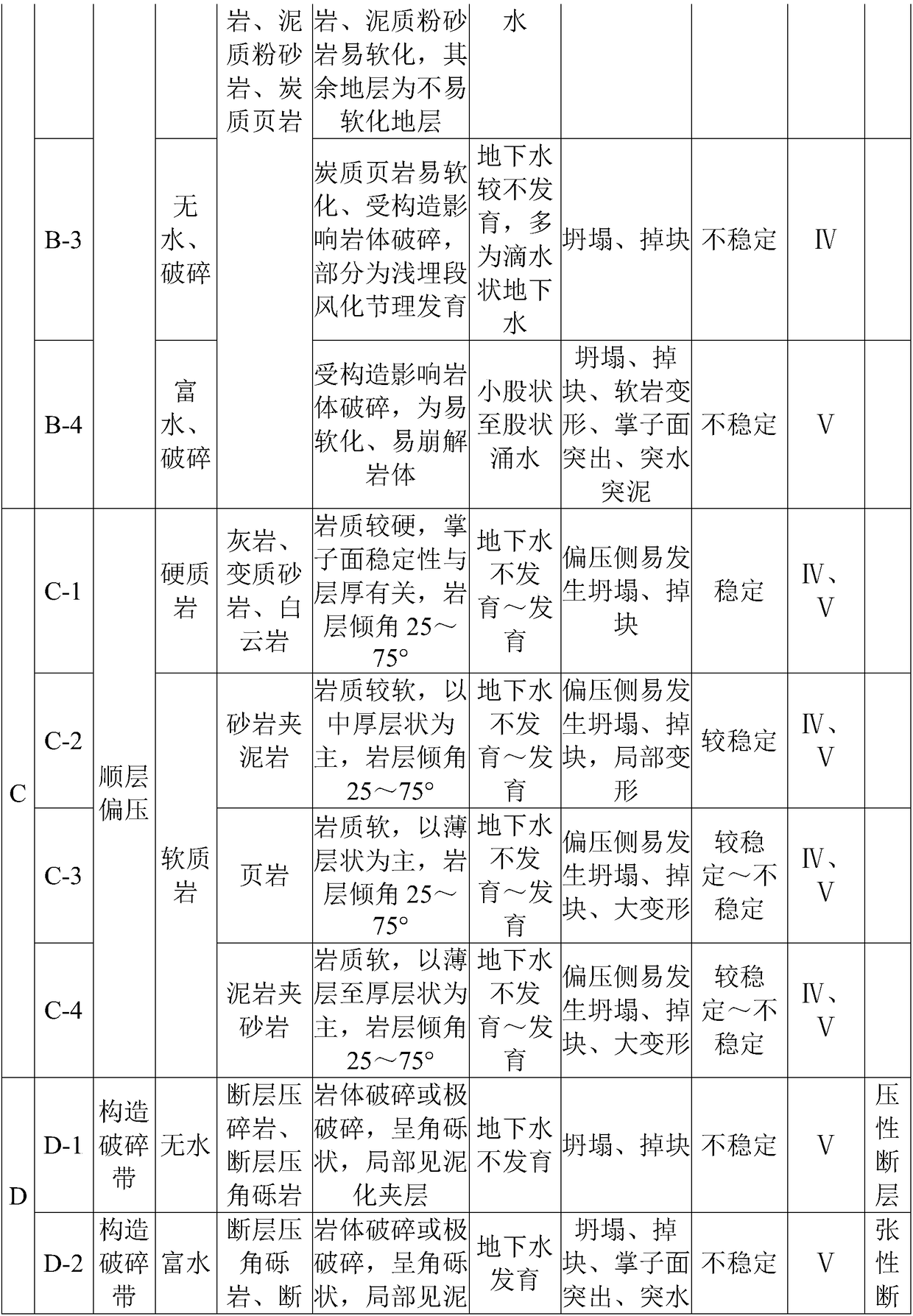

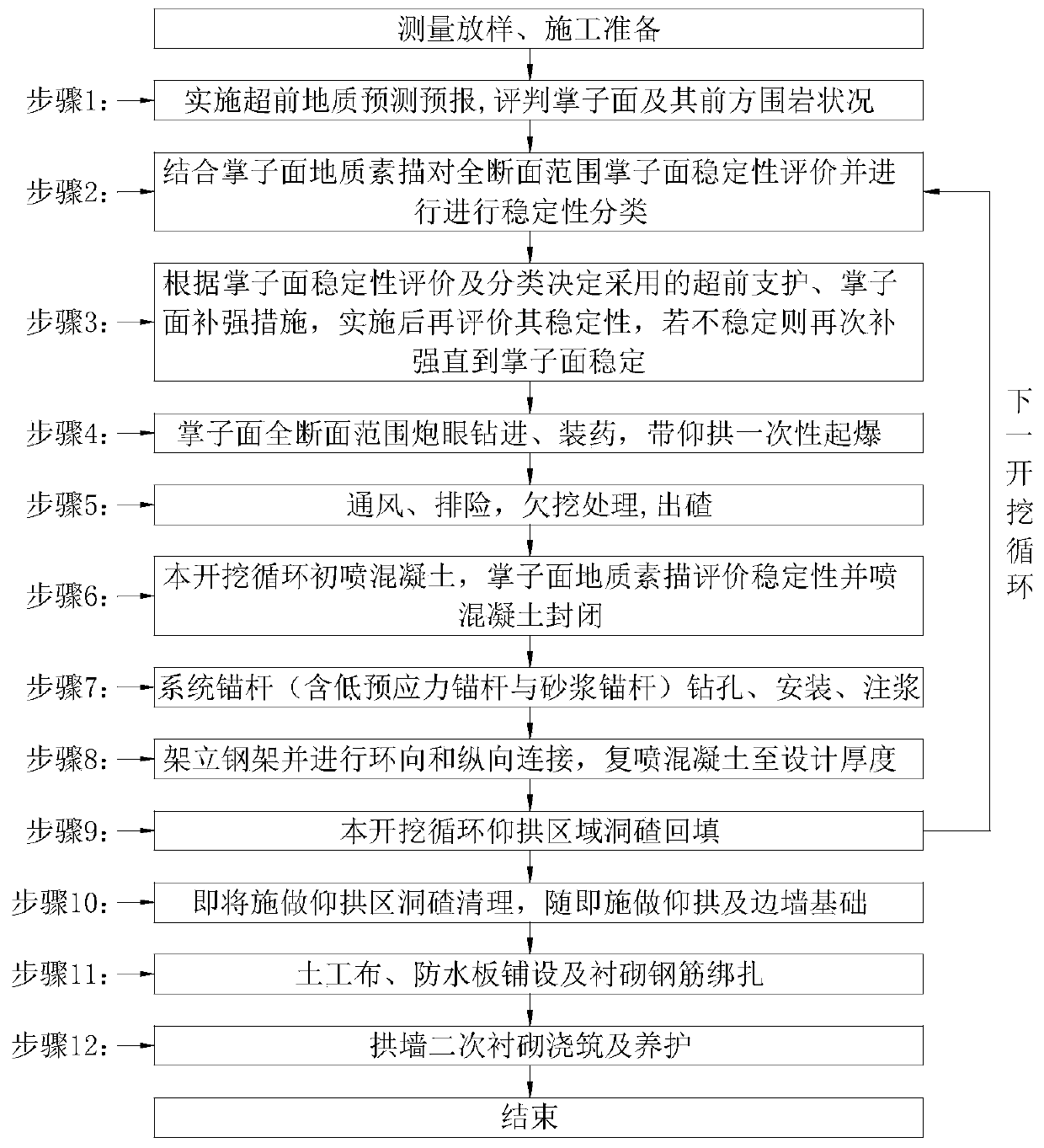

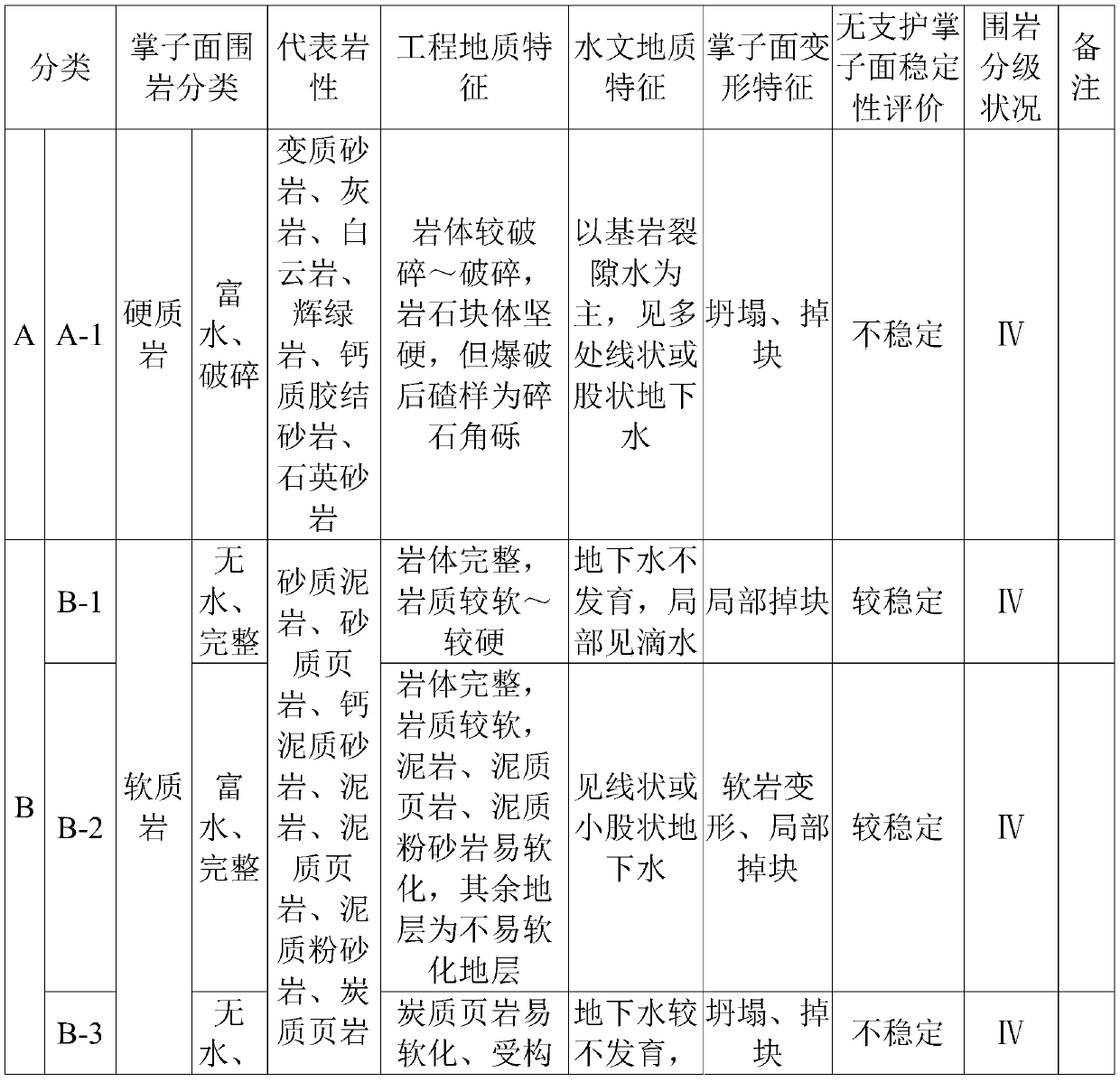

Mini step excavation method suitable for IV-V level of surrounding rocks of large-section tunnel

The invention discloses a mini step excavation method suitable for IV-V level of surrounding rocks of a large-section tunnel. A tunnel face is divided into upper and lower steps, the height of the lower step ranges from 5m to 8m, and advanced geologic prediction is implemented; the tunnel face stability is evaluated and classified; whether to implement advanced support and tunnel face reinforcement is decided, and a processing method is used till the tunnel face is stable; a drill jumbo drills blast holes and fill an explosive in the full section of the tunnel face, whole detonation is carriedout, and the vertical length difference between the upper and lower steps ranges from 3m to 5m; ventilation, danger removing, under-excavation handling and slag removing are carried out on the tunnelface; the tunnel face after excavation is sketched geologically, the stability of the tunnel face is determined, a wet spraying manipulator sprays an early high-strength concrete preliminarily, and the tunnel face is enclosed; an arc centering installation trolley erects a steel frame and implements annular and vertical connection, and concrete is sprayed again to reach a design thickness; an inverted arc area of a present excavation cycle is back filled with hole slag, and work of next cycle is carried out; a movable inverted arch trestle is used to pour the inverted arc and sidewall with basic concrete; earthwork cloths and waterproof boards are laid, and lining steel bars of an arch wall are lashed; and the lining of the arch wall is poured and maintained.

Owner:武九铁路客运专线湖北有限责任公司 +4

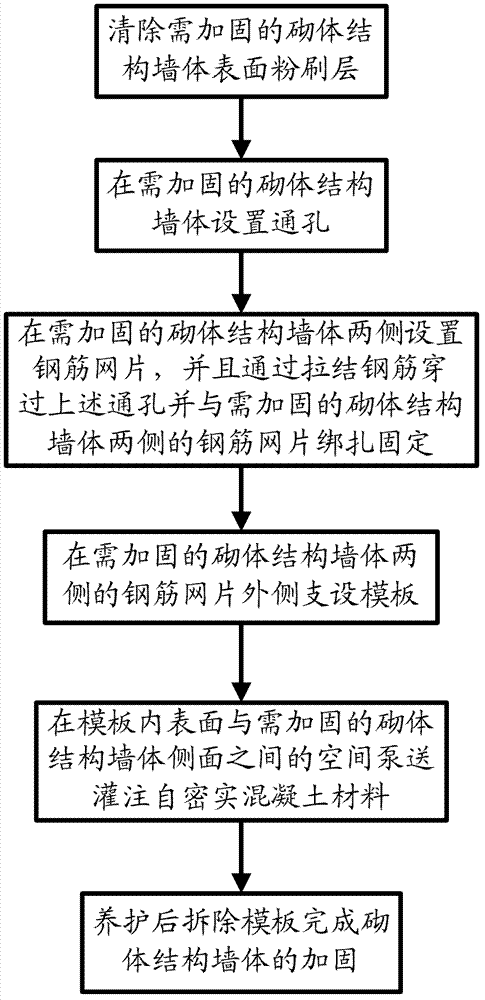

Seismic reinforcement method of masonry structure wall

InactiveCN103089022AImprove adhesionSmall shrinkageBuilding repairsBuilding material handlingRebarLow shrinkage

The invention discloses a seismic reinforcement method of a masonry structure wall. A through hole is arranged on the masonry structure wall required to be reinforced, then steel bar meshes are disposed on two sides of the wall, binding steel bars penetrate through the through hole to bound and fixed with the steel bar meshes on the two sides of the wall, formworks are disposed on the outer sides of the steel bar meshes on the two sides of the wall in a supporting mode, self-compacting concrete materials are pumped and filled between inner surfaces of the formworks and side surfaces of the wall, and the concrete materials have advantages of high cohesiveness, low shrinkage, self-compaction and non-vibration. Accordingly, vibration processes are omitted, construction speeds are improved, the maintaining time is short, a pumping filling technology is utilized, so that the problem of slow manual pouring by traditional methods is solved, and the construction speed is greatly improved.

Owner:SHANGHAI MEICHUANG CONSTR REINFORCEMENT ENG

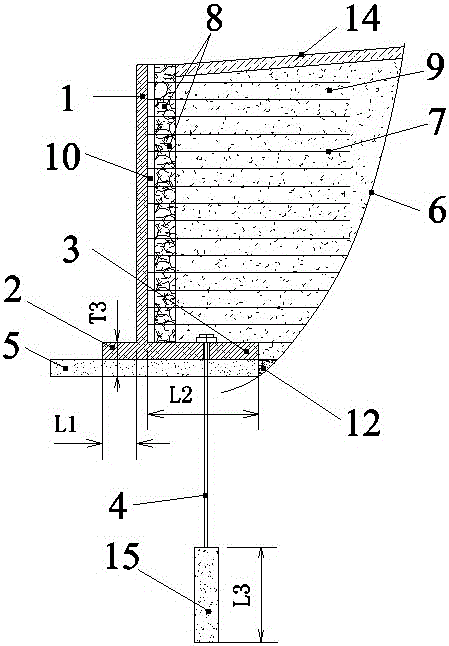

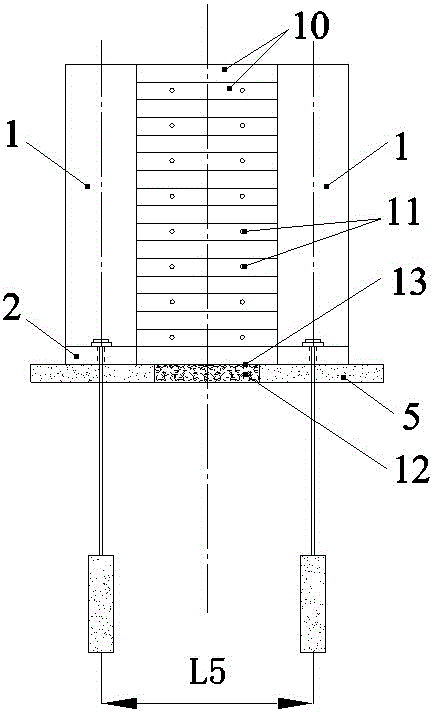

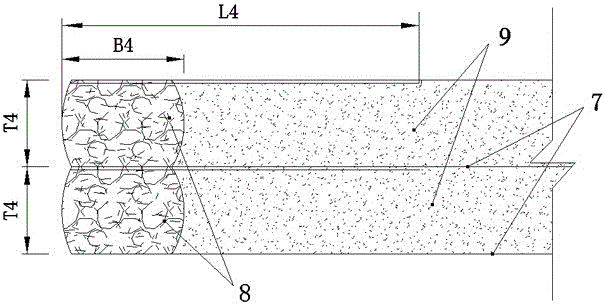

Construction method of combined supporting and retaining structure

ActiveCN106638673AReduce excavationReduce lateral deformationArtificial islandsUnderwater structuresReinforced concretePre stress

The invention discloses a construction method of a combined supporting and retaining structure, and relates to the technical field of civil construction. The method includes the steps of surveying and setting-out, mountain slope treatment, manufacturing of prefabricated reinforced concrete breast boards, foundation surface cleaning and replacement filling, construction of a cast-in-place concrete foundation, construction of a cantilever type structure, construction of pre-stressed anchor cables, masonry installation of the prefabricated reinforced concrete breast boards, and construction of a wrapped face reinforced soil structure and a covering layer. By using the vertical pre-stressed anchor cables, the workload can be reduced, the construction period can be shortened, the anti-overturning capacity and anti-slippage capacity of the combined supporting and retaining structure can be improved, and the overall stability and anti-lateral-deformation capacity of the whole combined supporting and retaining structure can be improved; by adopting the prefabricated reinforced concrete breast boards, the construction progress can be accelerated, and the project quality can be ensured; by using the wrapped face reinforced soil structure, the strength and integrity of a filling part can be improved, and the lateral soil pressure on the panel of the supporting and retaining structure can be reduced. By means of the method, the overall stability is improved, occupation of land is reduced, construction is simplified, and the construction cost is reduced; the method is especially suitable for roadbed construction in mountainous and hilly regions.

Owner:SOUTHWEST JIAOTONG UNIV +4

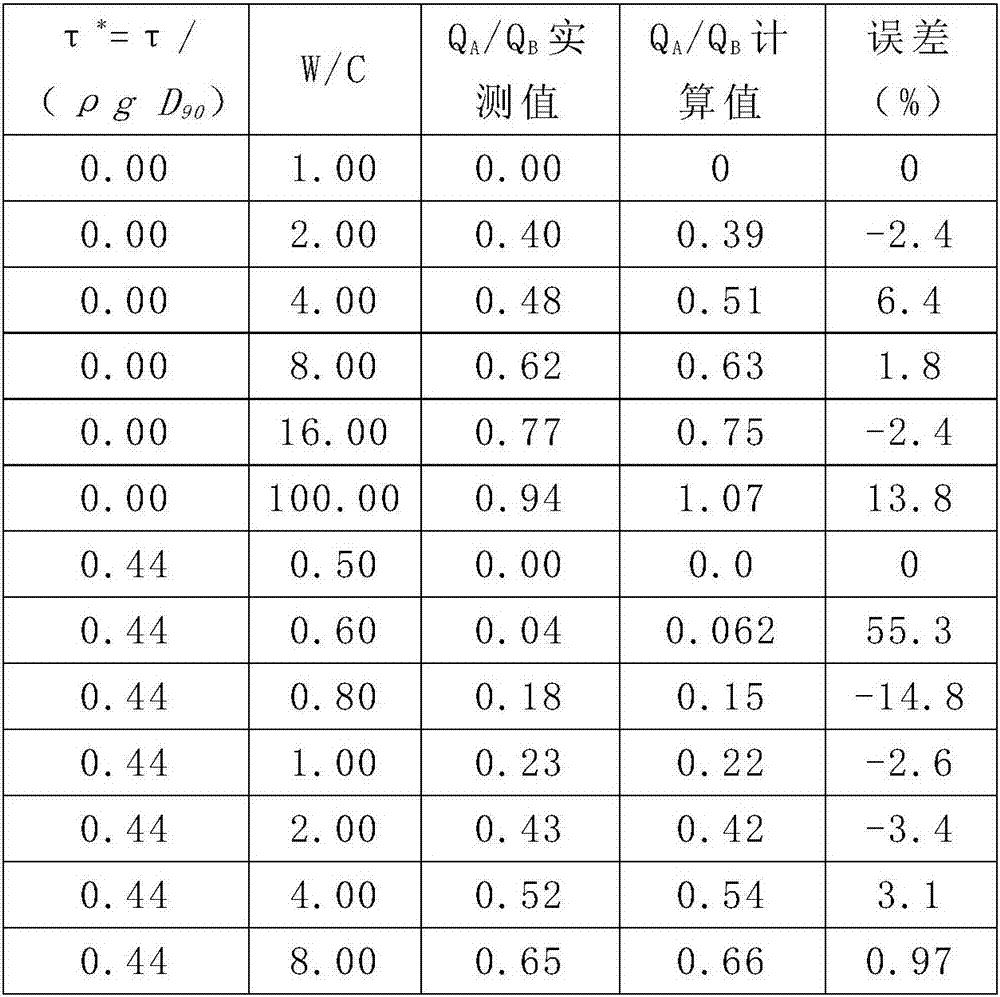

Method for calculating flow of mudslide behind dam and application thereof

ActiveCN107423484AGuarantee the effect of disaster prevention and mitigationAccurate calculationGeometric CADClimate change adaptationStress factorComputer science

The invention discloses a method for calculating flow of mudslide behind a dam and application thereof, belonging to the field of mudslide prevention and control projects. The method comprises the following steps of a. obtaining incoming mudslide total W and mudslide peak flow Q through hydrologic calculation, and investigating on the side to determine a storage capacity C of the dam, a yield stress Tau of the mudslide, a volume weight Rho of the mudslide and a characteristic particle size D<90> of mudslide; and b. calculating the flow Q of mudslide behind the dam according to the incoming mudslide total W, the mudslide peak flow Q, the storage capacity C of the dam, the yield stress Tau of the mudslide, the volume weight Rho of the mudslide, the characteristic particle size D<90> of mudslide, and a dimensionless yield stress factor Tau*. The method is applicable to outdoor large scale actual calculation, can calculate the flow of the mudslide behind the dam accurately, provides reliable data reference for the mudslide prevention and control project, and ensures disaster prevention and mitigation effects in mudslide regions.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

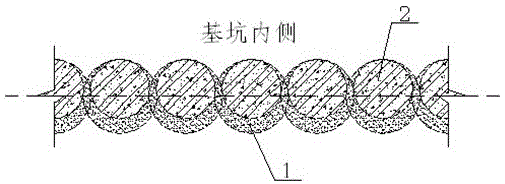

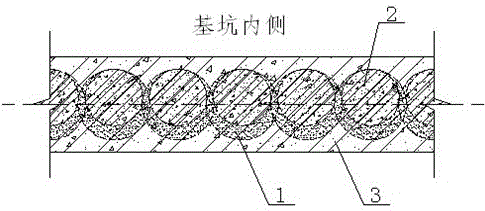

Combined type foundation pit supporting pile structure

ActiveCN105064377AEffectively play a supporting roleEffectively play the role of water stopExcavationsStructural engineeringEngineering

The invention discloses a combined type foundation pit supporting pile structure. The combined type foundation pit supporting pile structure is composed of high-pressure jet grouting piles, cast-in-situ bored piles and a top beam. The high-pressure jet grouting piles which are engaged with one another and have large diameters are taken as a foundation pit waterproof curtain. The cast-in-situ bored piles are used as foundation pit supporting piles. The high-pressure jet grouting piles are constructed firstly, so that the waterproof curtain is formed; after the quality of the high-pressure jet grouting piles is almost stable, the cast-in-situ bored piles with small diameters are constructed again at the same positions as the high-pressure jet grouting piles, and it is guaranteed that the cast-in-situ bored piles are internally tangent to the high-pressure jet grouting piles on the sides close to a foundation pit on the premise that the portions, engaged with one another, of adjacent high-pressure jet grouting piles are not occupied during construction of the cast-in-situ bored piles; and finally, the top beam is arranged at the tops of the piles, and thus the purpose of supporting the foundation pit and the waterstop purpose are achieved. By the adoption of the combined type foundation pit supporting pile structure, the construction space of the foundation pit supporting structure can be effectively reduced. The combined type foundation pit supporting pile structure is particularly suitable for a foundation pit supporting project under the land shortage condition; due to the fact that the cast-in-situ bored piles with the small diameters are internally tangent to the high-pressure jet grouting piles with the large diameters, the combined effect of the two kinds of piles can be brought into full play.

Owner:KUNMING SURVEY DESIGN & RES INST OF CREEC

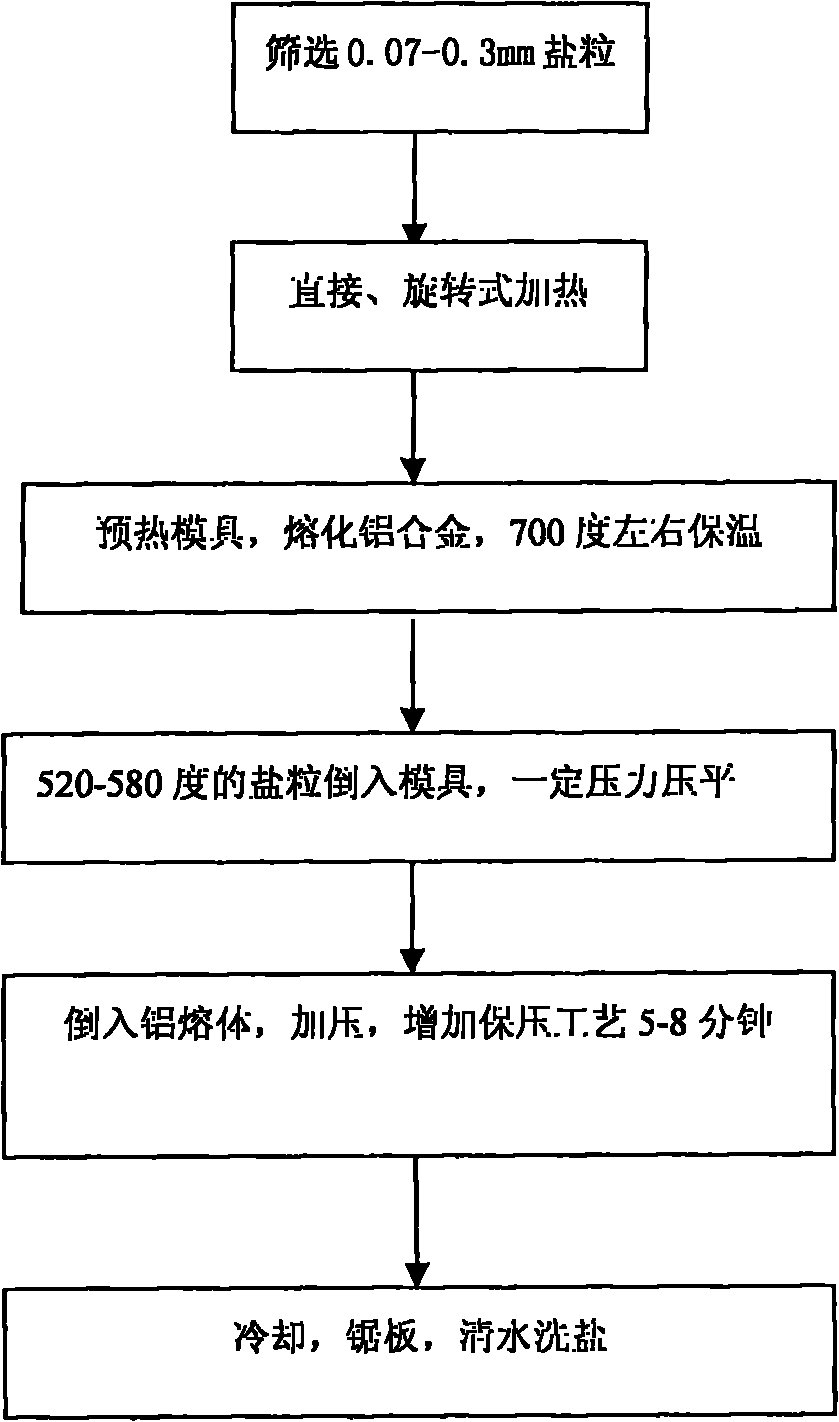

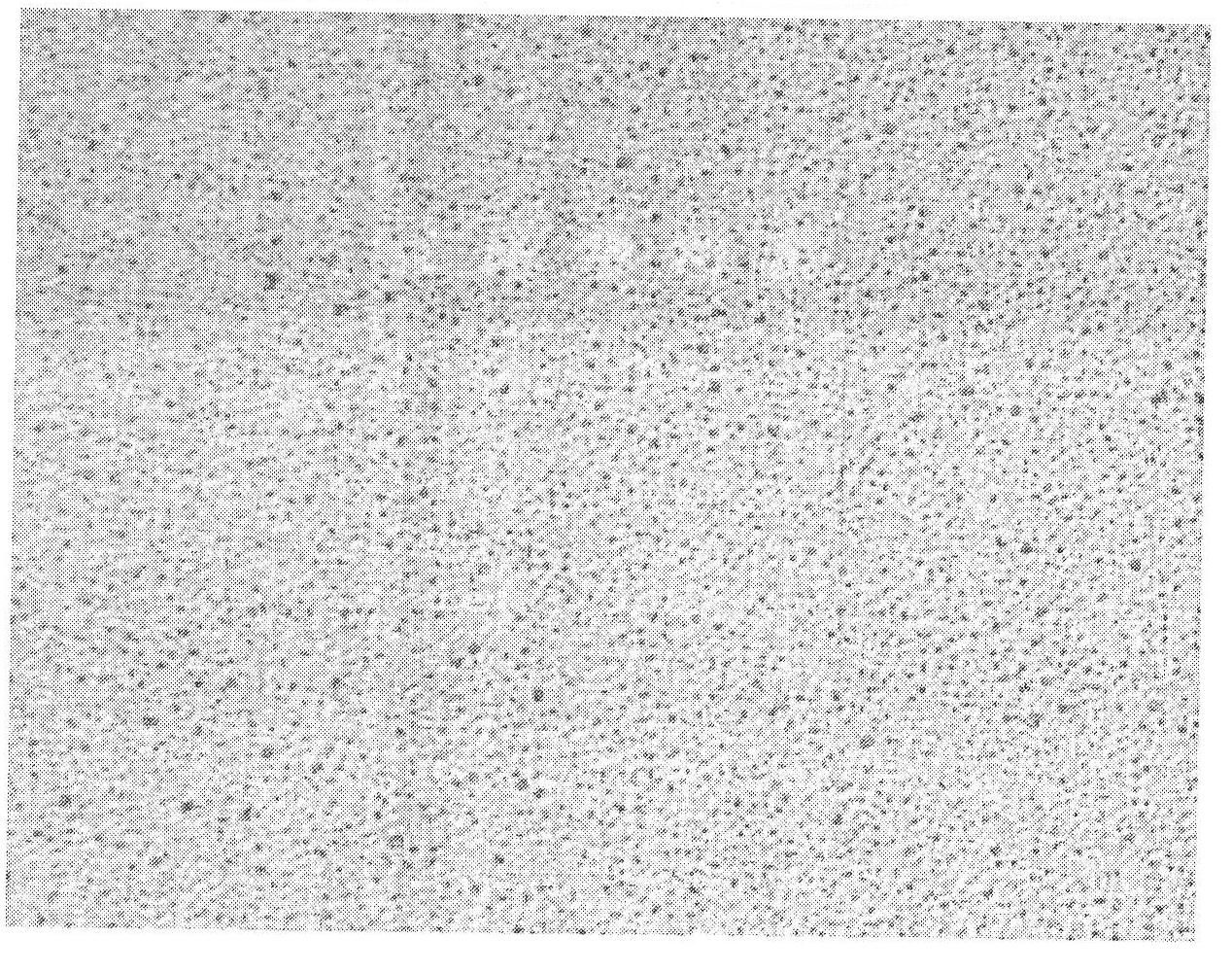

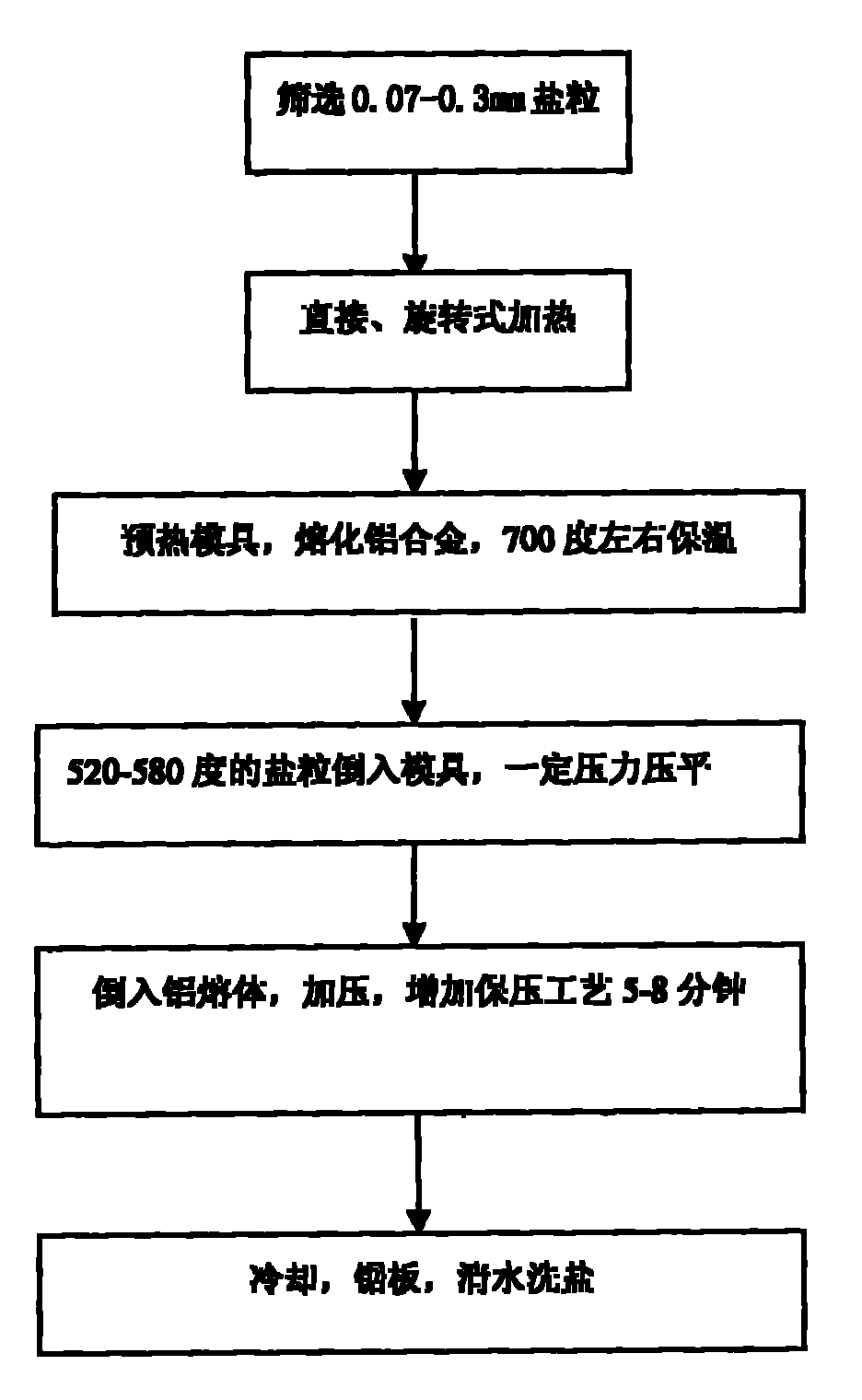

Through hole type microcellular foam aluminum sheet with 0.07 to 0.3mm aperture and preparation method

The invention discloses a through hole type microcellular foam aluminum sheet and a preparation method. The microcellular foam aluminum sheet has an aperture of 0.07 to 0.3mm, a void ratio of 45 to 70 percent, a thickness of more than 2mm and a volume weight of 0.8 to 1.5g / cm<3>. The preparation method thereof mainly comprises the following steps of: filtering salt particles, heating, melting aluminium alloy, pouring the salt particles into a mould and pressing initially, pouring into aluminum melt and pressing, cooling, rinsing salt by clean water and the like and finally obtaining the foam aluminum sheet. The invention is mainly characterized in that: in the heating processing, directly heating is adopted without preheating, a revolving heater is adopted to heat while revolving, a mixer is used for mixing and making the salt particles fully contact hot air. The invention has the technical advantages: the foam aluminum sheet having an aperture of 0.07 to 0.3mm has excellent sound absorption performance and greatly improved intensity. In the invention, revolving heating is adopted, so bonding and agglomeration of salt particles with a diameter of 0.07 to 0.7mm when the salt particle is heated to 520 to 580 DEG C are avoided and seepage is completed.

Owner:朱旭

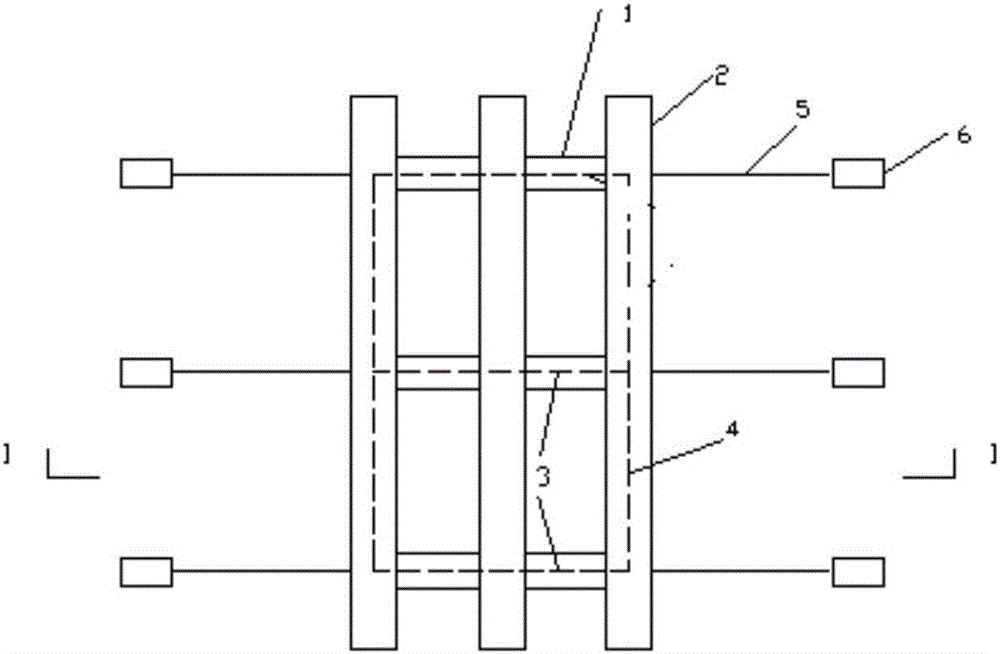

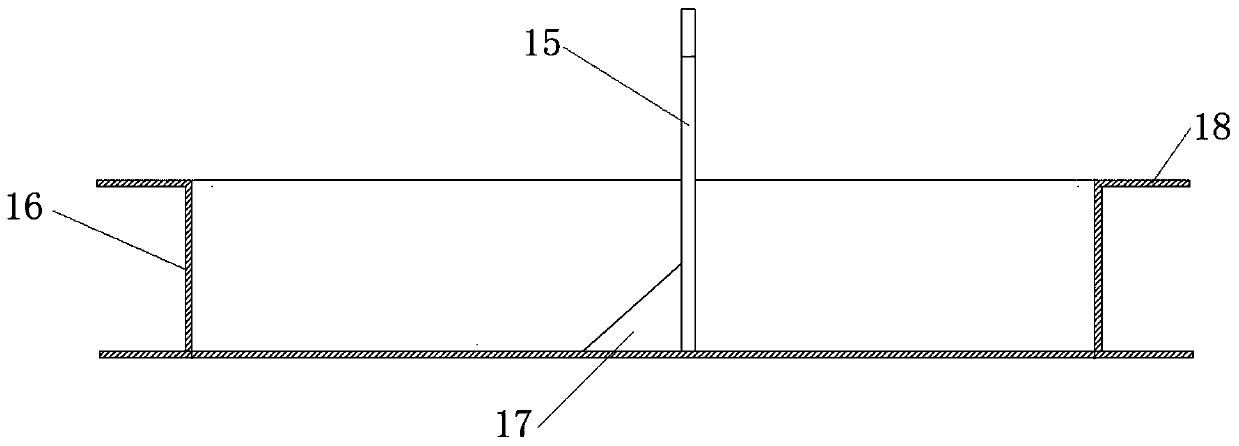

Frame type combined structure man-vehicle passage

ActiveCN1936184AGive full play to mechanical propertiesSave engineering materialsRoadwaysBridge structural detailsMarine engineeringEconomic benefits

The invention relates to a street and crossing that could realize people and vehicles passing separately. It has installable composite structure that adopts frame structure to combine steel material and concrete having strong tensile property to make full of the mechanical property of the materials. The entire capability of the street would be improved through optimizing the entire structure size. The invention has the advantages of decreasing project material, realizing industrial producing, lowering constructing cost, having good comprehensive economic benefits, etc.

Owner:钟宝驹

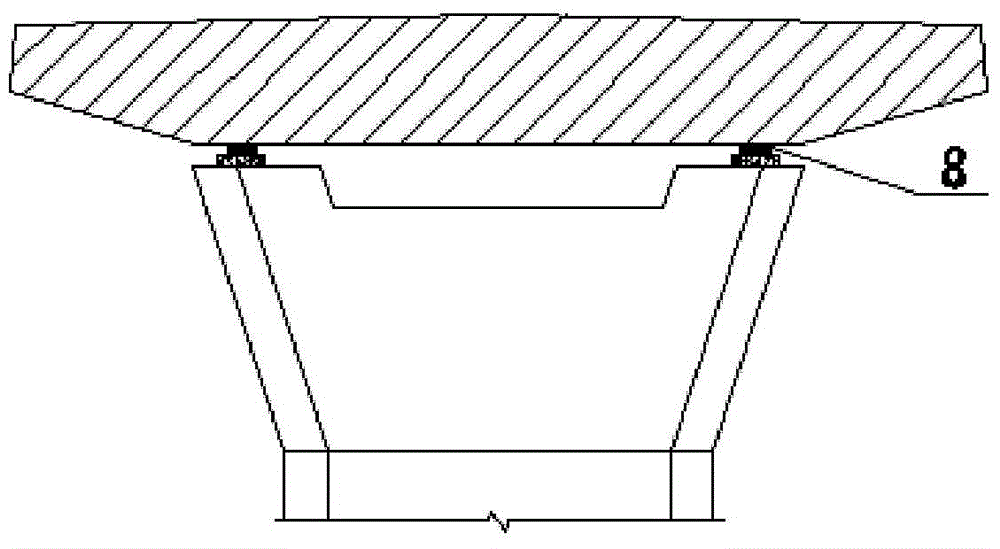

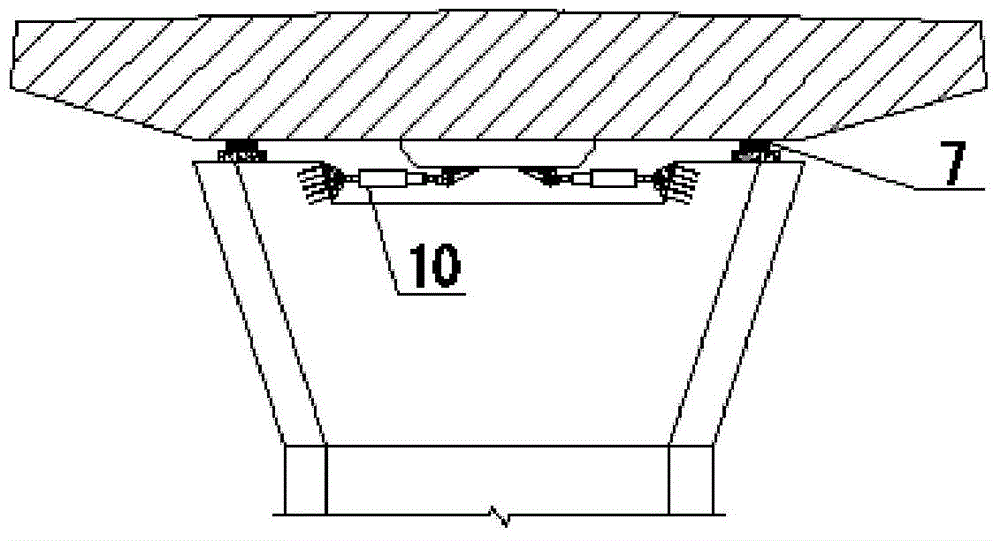

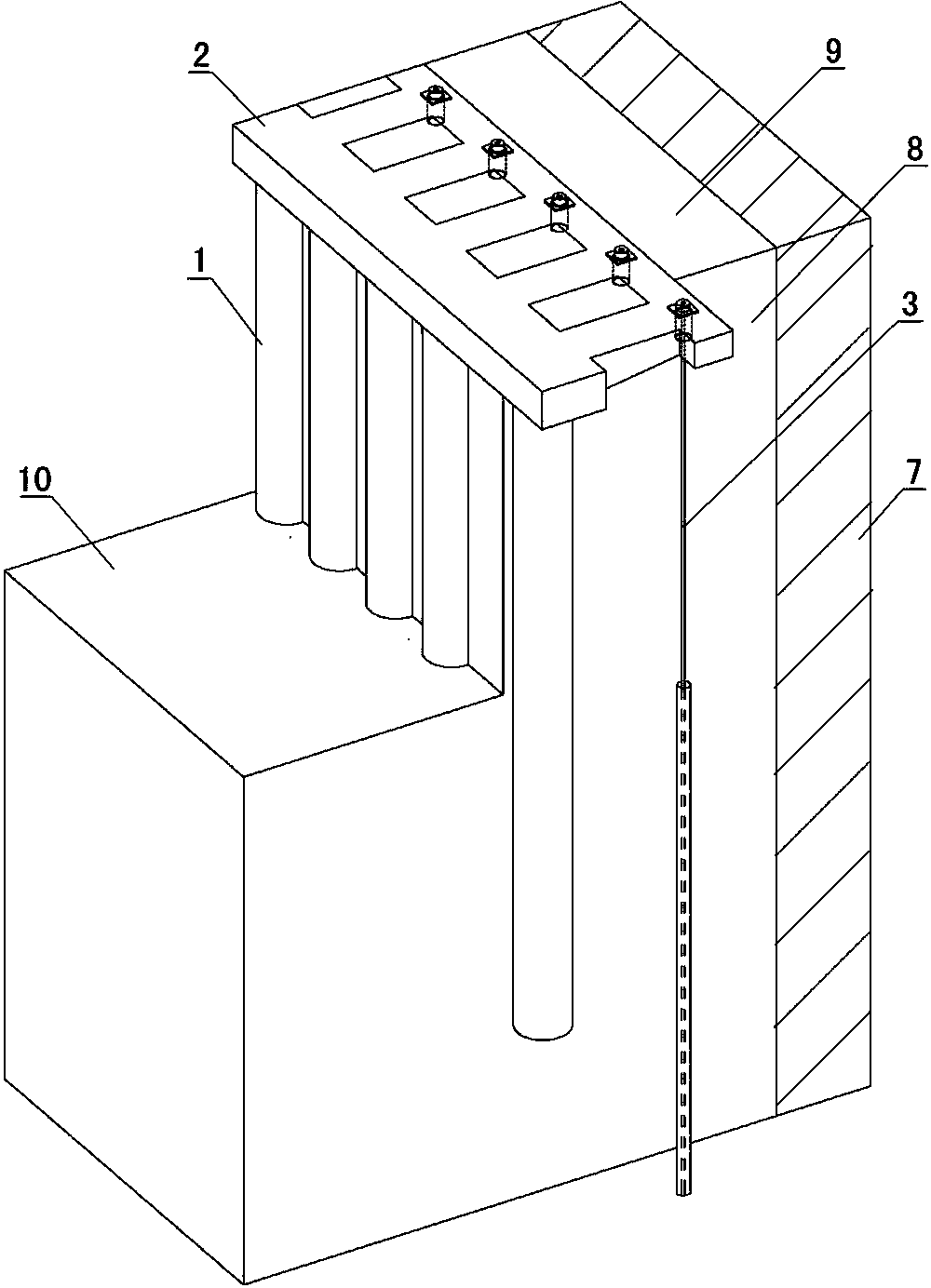

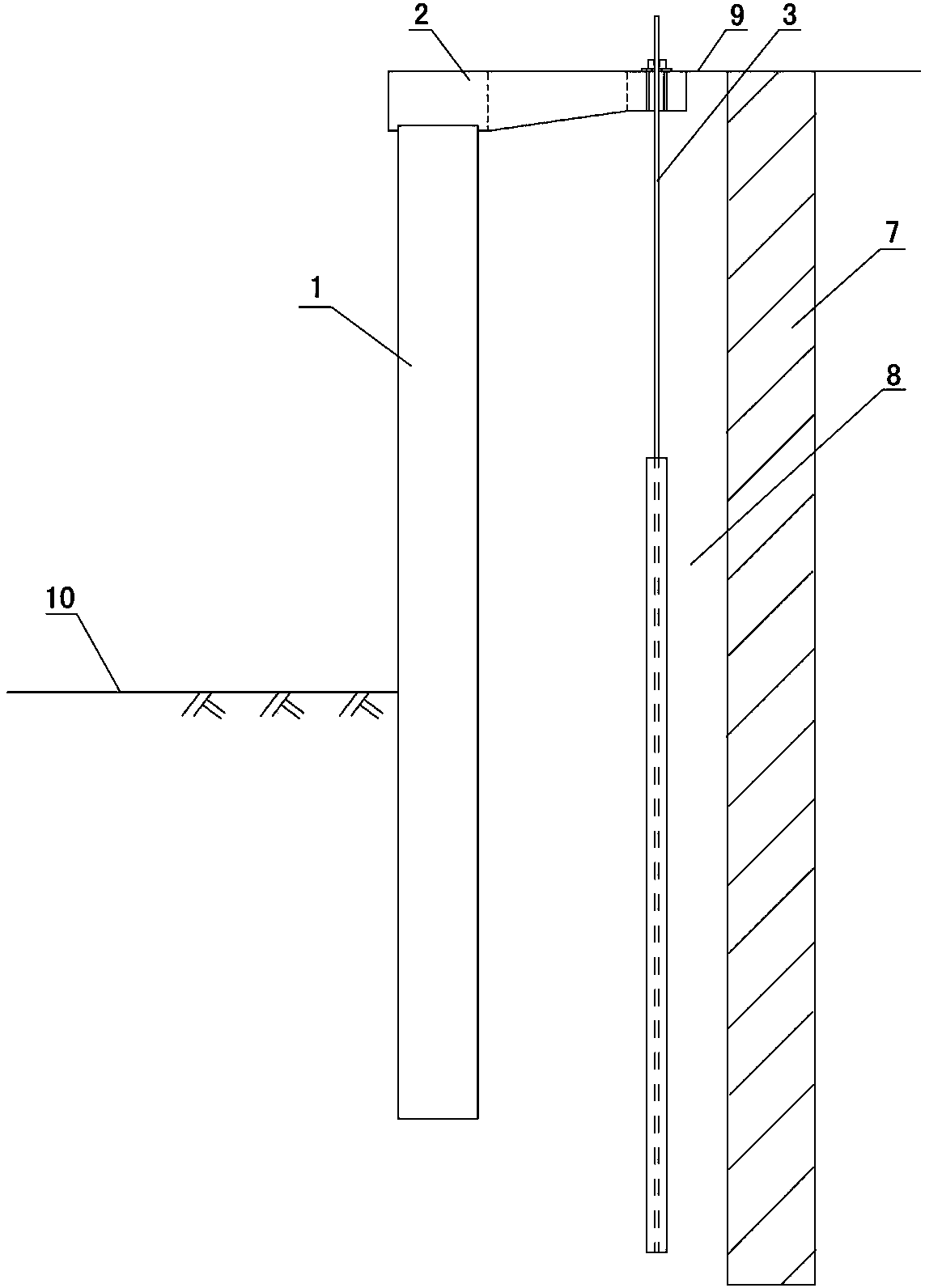

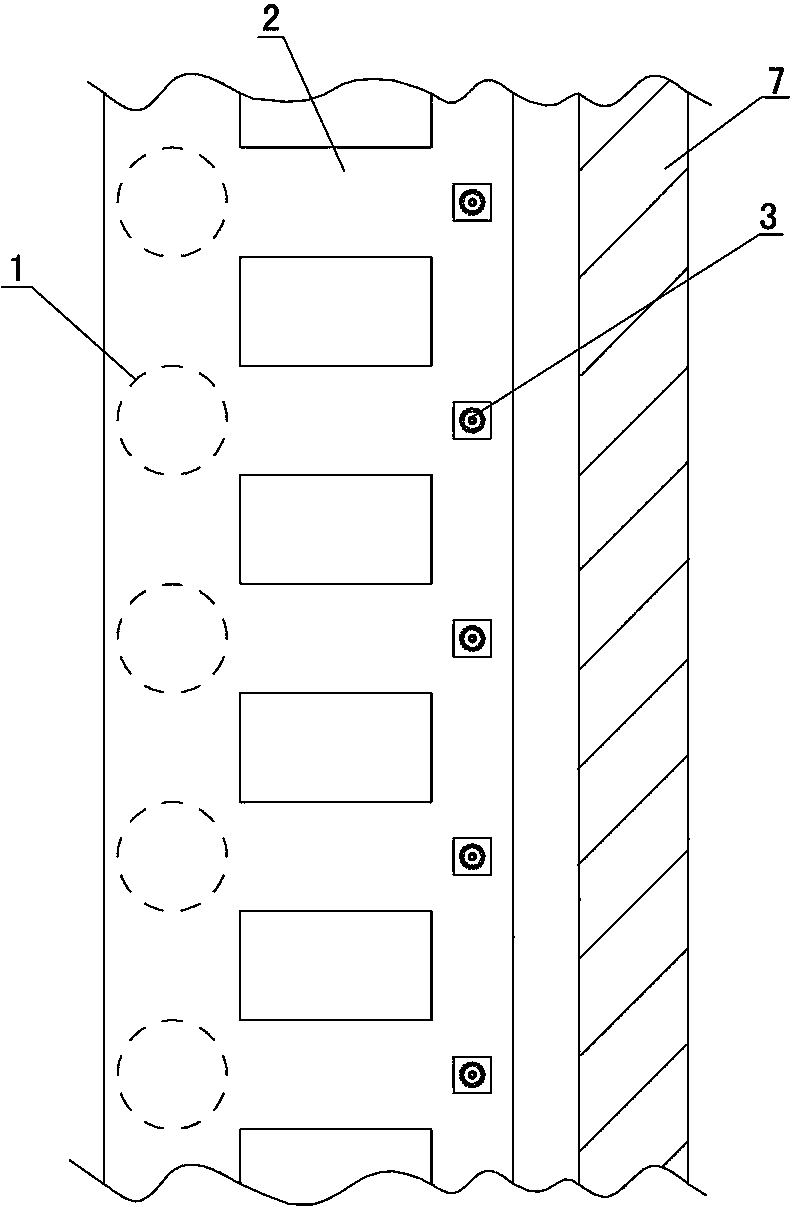

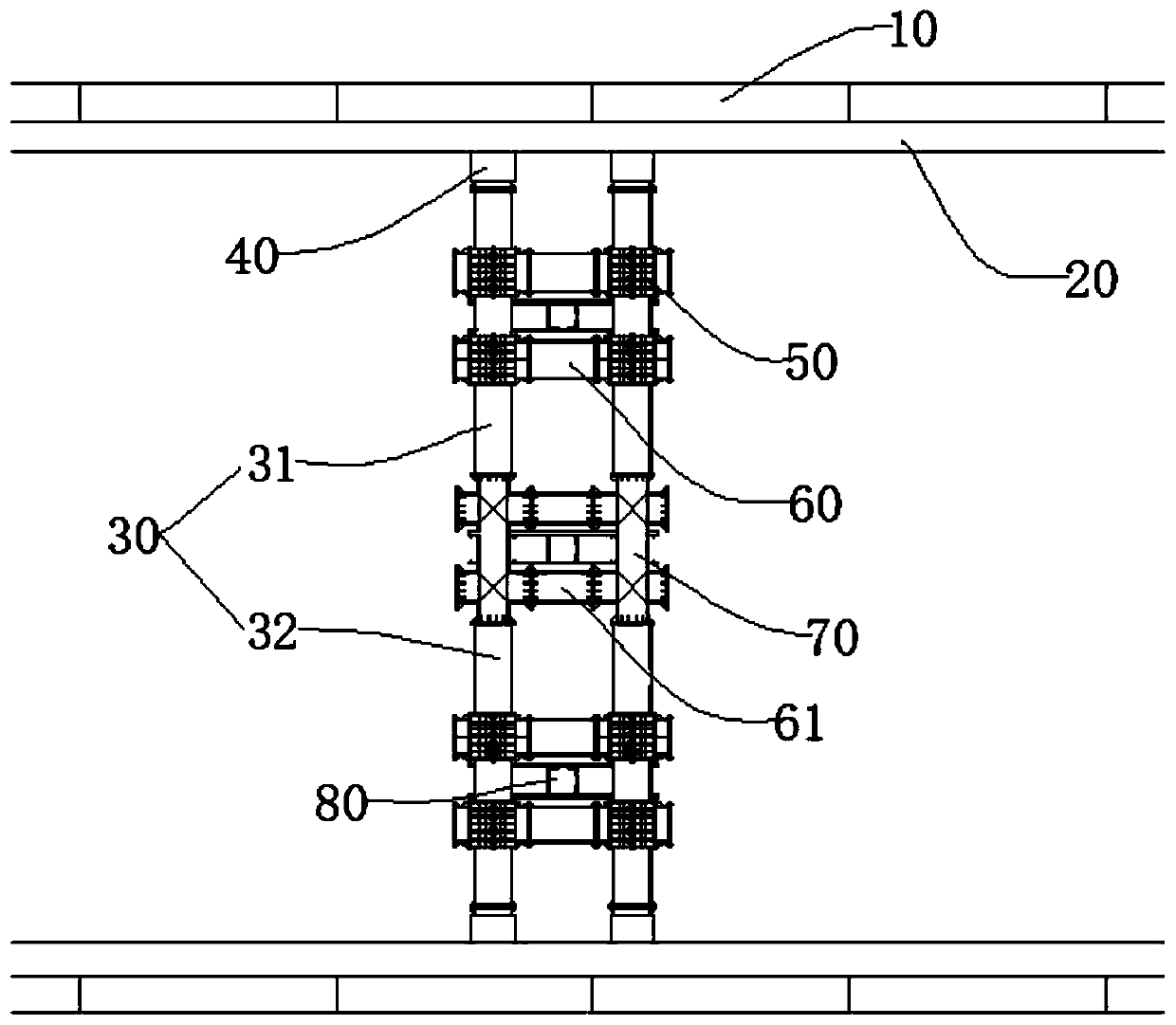

Inclined pile vertical anchor rod supporting structure for foundation pit supporting and construction method thereof

InactiveCN103485351ALow construction environment requirementsMake full use of anchoring forceExcavationsBulkheads/pilesPre stressPre stressing

The invention provides an inclined pile vertical anchor rod supporting structure for foundation pit supporting and a construction method thereof. The supporting structure comprises inclined slope protection piles, pile top beams and anchor rods. A row of the inclined slope protection piles are arranged on the edges of a foundation pit, and the bottoms of the inclined slope protection piles extend into the lower soil layer of the bottom of the foundation pit. The supporting structure is characterized in that the anchor rods comprise vertical pre-stress anchor rod bodies arranged in the stable soil layer between every two adjacent inclined slope protection piles and inserted and anchored in the stable soil layer from the ground between every two adjacent inclined slope protection piles, and the pile top beams are in rigid connection with the tops of the inclined slope protection piles and in flexible connection with the upper portions of the vertical pre-stress anchor rod bodies. The supporting structure and the construction method are particularly applied to the adjacent existing building foundation pits with limited underground space, and have the outstanding advantages of supporting the adjacent existing building deep foundation pits, and being good in supporting effect, convenient to construct, simple in working procedure and low in cost.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

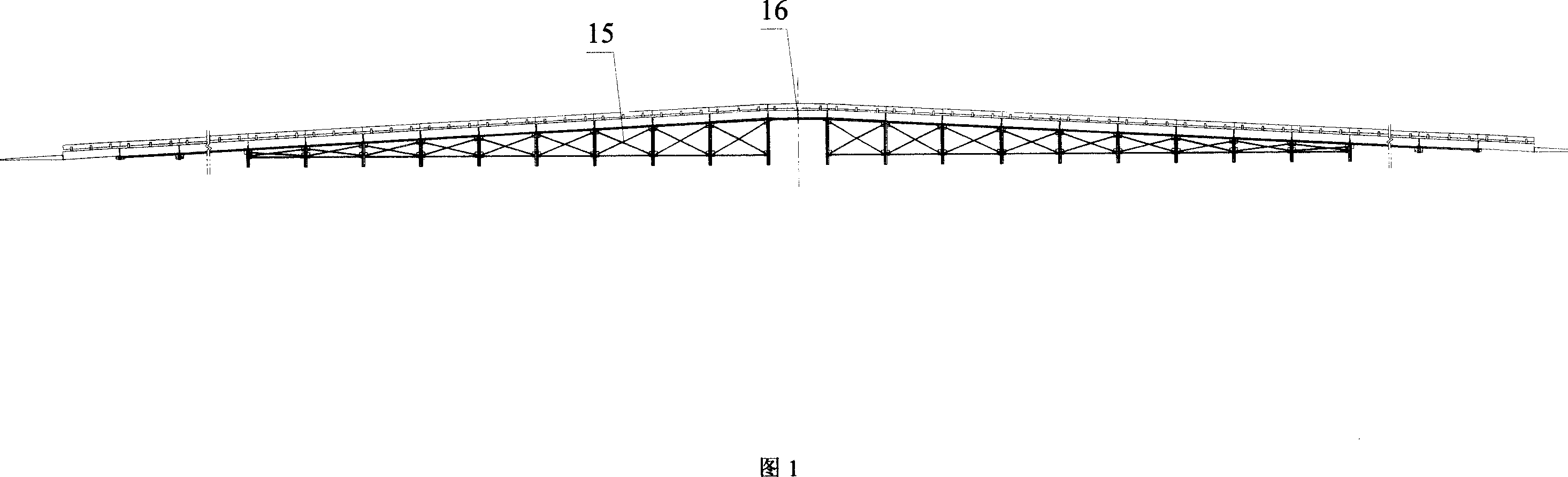

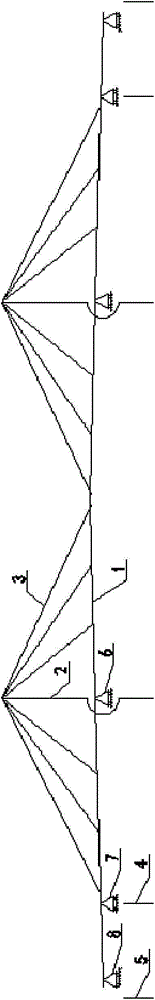

Outer-side span stay cable-free stay bridge with horizontal stress performance improved

InactiveCN104452572AReduce internal forceForce coordinationCable-stayed bridgeBridge structural detailsHorizontal stressEngineering

The invention discloses an outer-side span stay cable-free stay bridge with horizontal stress performance improved. A girder is supported by bridge towers, auxiliary piers and transition piers. The auxiliary piers are arranged on two sides of the bridge towers, and the transition piers are arranged on two sides of the auxiliary piers. The portion, between the auxiliary piers and the transition piers, of the girder is connected with columns of the bridge towers without stay cables. The girder is supported by the transition piers through first vertical support seats with horizontal unlocking functions. The auxiliary piers support the girder through second vertical support seats and are connected with the same through horizontal damping devices. Damping direction of the horizontal damping devices is the horizontal direction of the girder. Lower beams of the bridge towers support the girder through third vertical support seats. The girder is connected with the columns of the bridge towers through horizontal support seats which are horizontally distributed along the girder. According to the arrangement, stress applied to the auxiliary piers, the transition piers and the base is greatly decreased under horizontal earthquake action, the stress to the auxiliary piers and the transition piers is harmonized, and horizontal displacement occurring in case that the auxiliary piers are under the earthquake action, of the girder is under control.

Owner:CCCC HIGHWAY CONSULTANTS

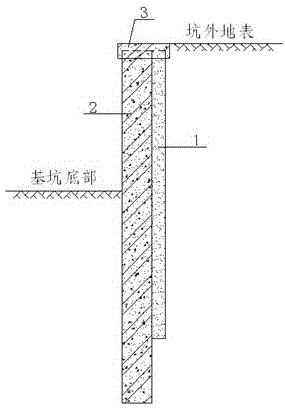

Pile beam vertical anchor support system used for supporting foundation pit and construction method of pile beam vertical anchor support system

InactiveCN103469803AOptimize the support structureImprove the support effectExcavationsSupporting systemPre stress

The invention discloses a pile beam vertical anchor support system used for supporting a foundation pit and a construction method of the pile beam vertical anchor support system. The support structure comprises slope shield piles, pile top crown beams and anchor rods, wherein a row of slope shield piles are arranged on the edge of the foundation pit; the bottoms of the slope shield piles stretch into a soil layer under a substrate; the anchor rods comprise vertical prestress anchor rods which are formed into a row at standing ground of the outer sides of the slope shield piles, are inserted from the ground at the outer sides of the slope shield piles and are anchored in the standing ground at the outer sides of the slope shield piles; the pile top crown beams are lattice girders; one sides, close to the foundation pit, of the lattice girders are in rigid connection with the tops of the slope shield piles; one sides, far away from the foundation pit, of the lattice girders are in soft connection with the upper parts of the vertical prestress anchor rods. The support system and the construction method thereof are particularly suitable for a foundation pit which is limited in underground space and is adjacent to existing buildings, have obvious advantages in the support for the foundation pit adjacent to the existing buildings, not only are good in support effect, but also have the advantages that the construction is convenient, the working procedure is simple and the cost is lower.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

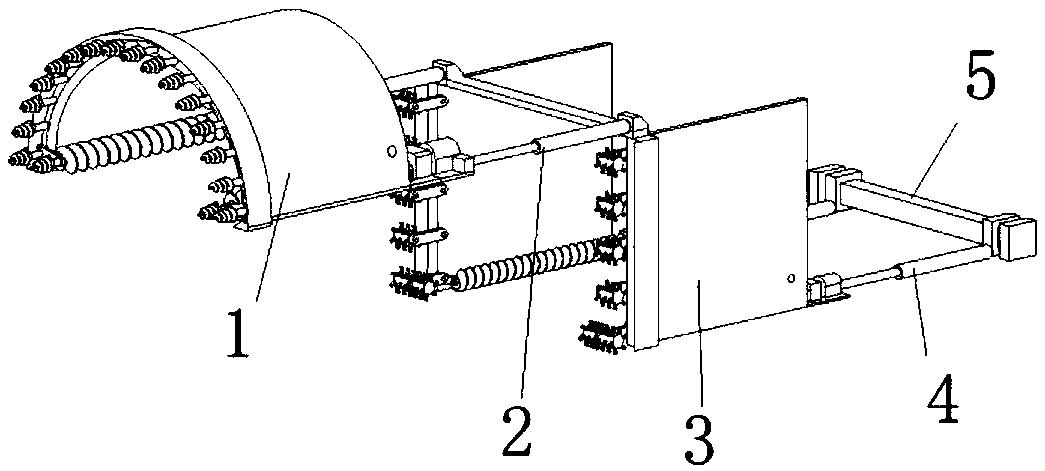

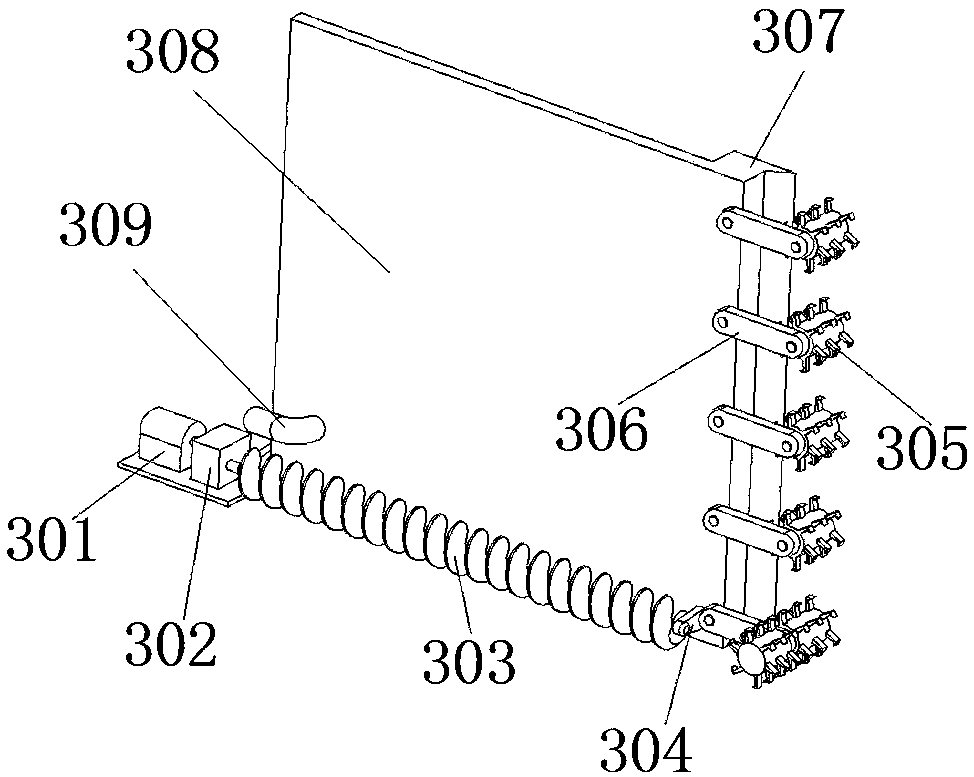

Small-pilot-tunnel advance support equipment and construction method

PendingCN109268042AControl land subsidenceFast constructionUnderground chambersTunnel liningResidual soilsSubway station

The invention provides small-pilot-tunnel advance support equipment and a construction method and belongs to the technical field of subway station pilot tunnel construction. The equipment comprises anarched cutting form board, a lateral wall cutting form board, a rear support device and two pushing devices and is characterized in that the arched cutting form board is located on an upper step at the front end of a small pilot tunnel and connected with the lateral wall cutting form board of a lower step through the pushing device A, the lateral wall cutting form board is connected with the same-level rear support device at the rear of the lateral wall cutting form board through the pushing device B. The small-pilot-tunnel advance support equipment has the advantages that conical drill bitsand soil cutting hobs are used to cut the soil of an arch and a lateral wall, spiral hobs are used to discharge soil, arched shovel blades and lateral wall shovel blades are used to remove residual soil under the jacking effect of the pushing devices, the lateral wall cutting form board and a lining structure at the rear of the lateral cutting form board form a sealed molding space, the molding space is grouted through grouting holes to form a lining structure, excavation is performed after the lining structure reaches 75% of design strength, and a bottom plate is constructed finally. By the construction method, advance support before excavation is achieved, and ground surface settlement is reduced.

Owner:SUBWAY ENG CO LTD OF CHINA RAILWAY 16TH CONSTR BUREAU +2

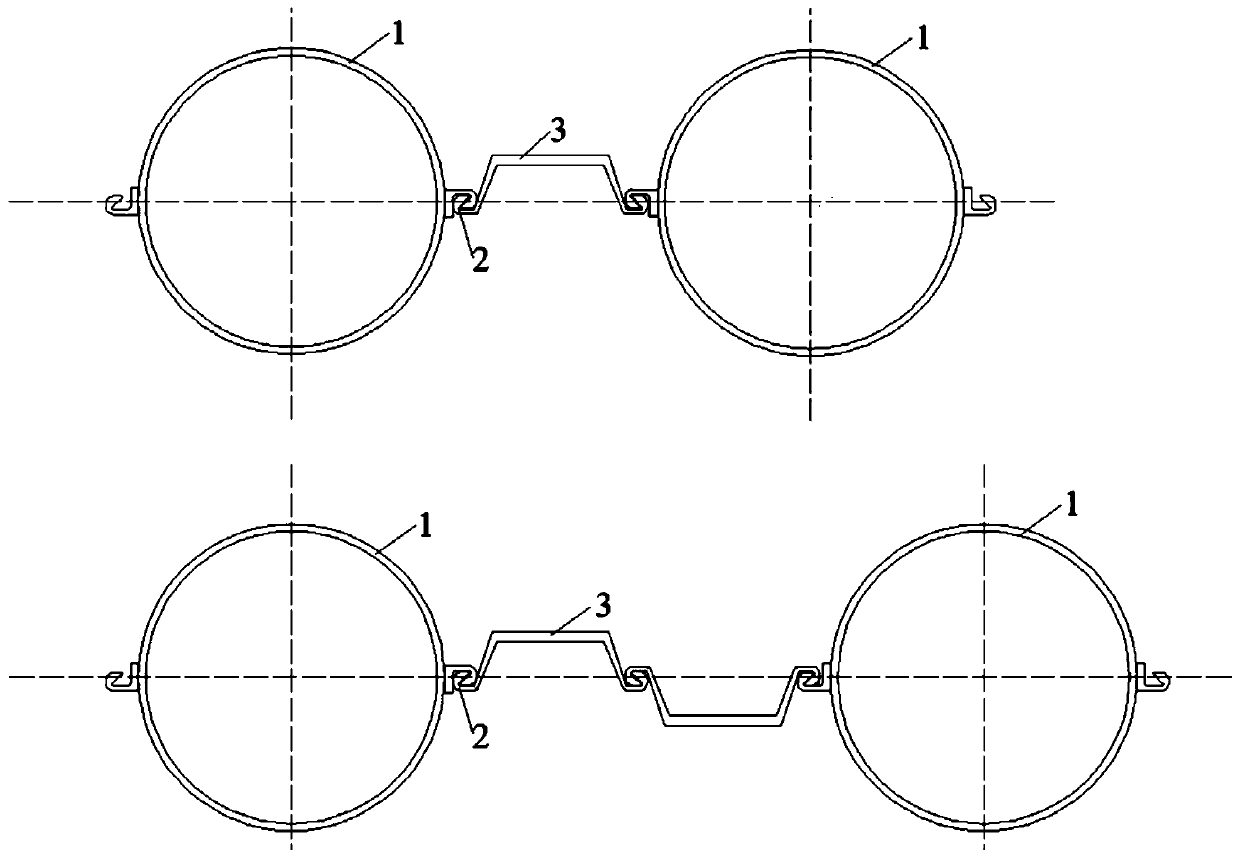

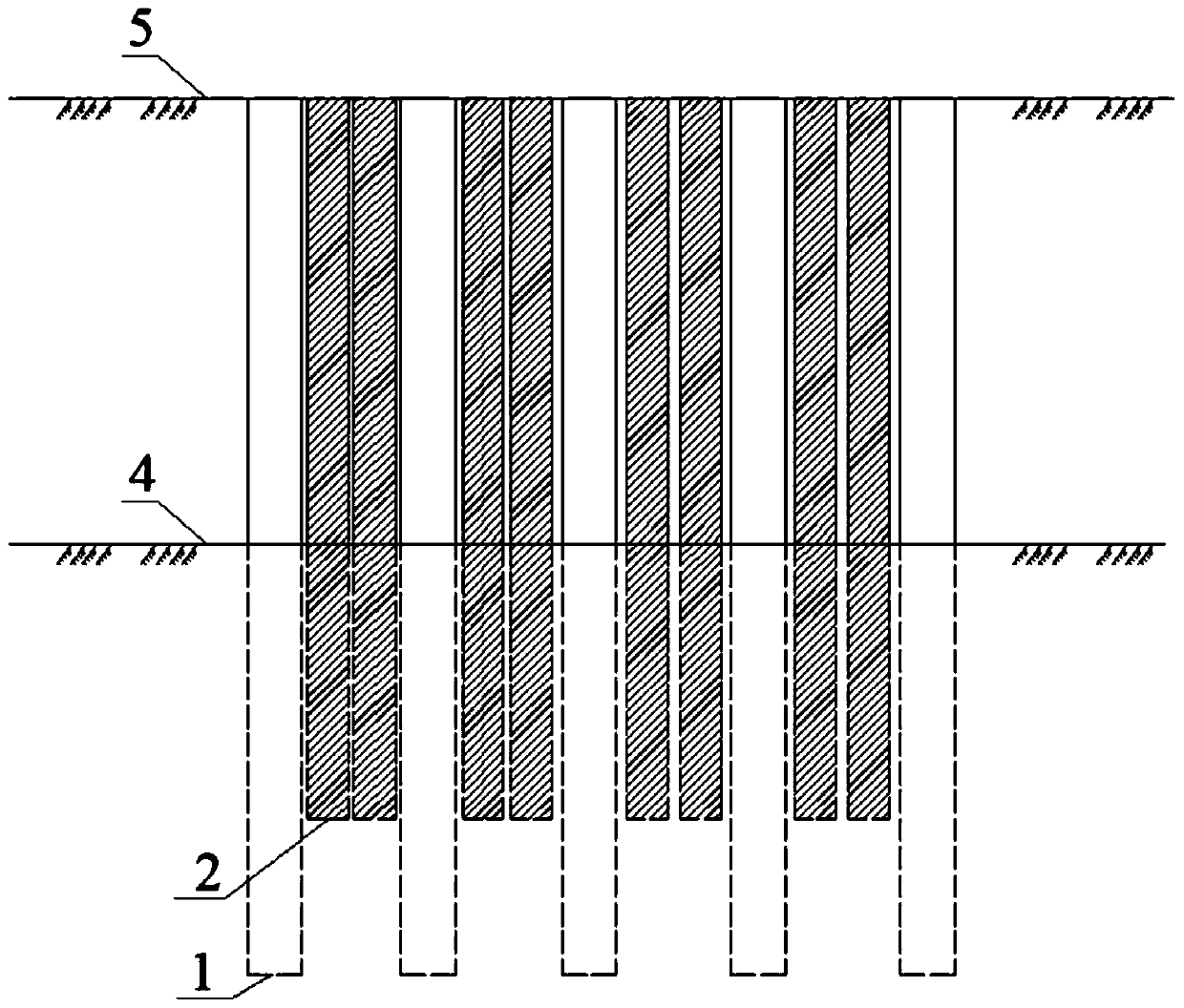

PC-method pile enclosure structure with Larssen piles of different lengths

InactiveCN110067249AHigh rigidity of the pile bodyGood water stop effectExcavationsBulkheads/pilesBuilding constructionSteel plates

The invention provides a PC-method pile enclosure structure with Larssen piles of different lengths. The PC-method pile enclosure structure comprises steel pipe piles, the Larssen steel plate piles and connecting tongues, wherein the steel pipe piles and the Larssen steel plate piles are connected together through the connecting tongues, and the steel pipe piles and the Larssen steel plate piles are connected through the connecting tongues to form the combined enclosure structure; the steel pipe piles and the Larssen steel plate piles are distributed alternately, the steel pipe piles and the Larssen steel plate piles serve as the enclosure structure with water and soil retaining functions, the Larssen steel plate piles and the steel pipe piles are unequal in length, the Larssen steel platepiles are uniformly distributed between the steel pipe piles, and the steel pipe piles and the Larssen steel plate piles are uniformly distributed in a one-to-one or one-to-many manner. The PC-methodpile enclosure structure has the advantages of being large in pile body rigidity, good in water stopping effect, short in construction period and the like, the mechanism of common action of the pilesand soil is brought into full play, engineering materials are saved, the problem that Larssen steel plate piles are difficult to insert into certain sites is solved, and the enclosure structure has good popularization and application value.

Owner:EAST CHINA JIAOTONG UNIVERSITY

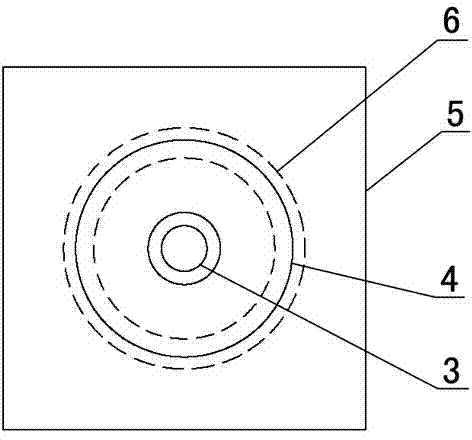

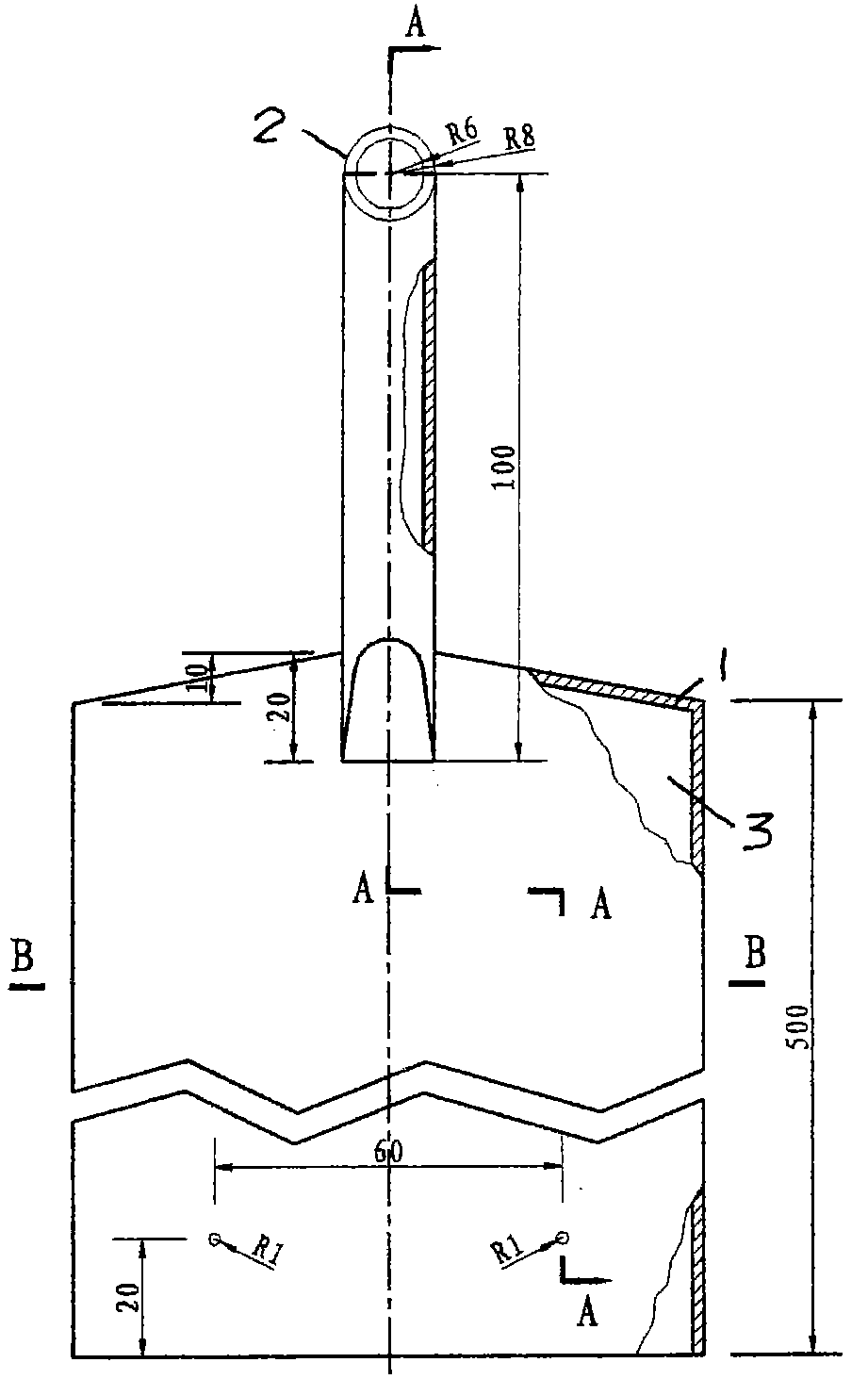

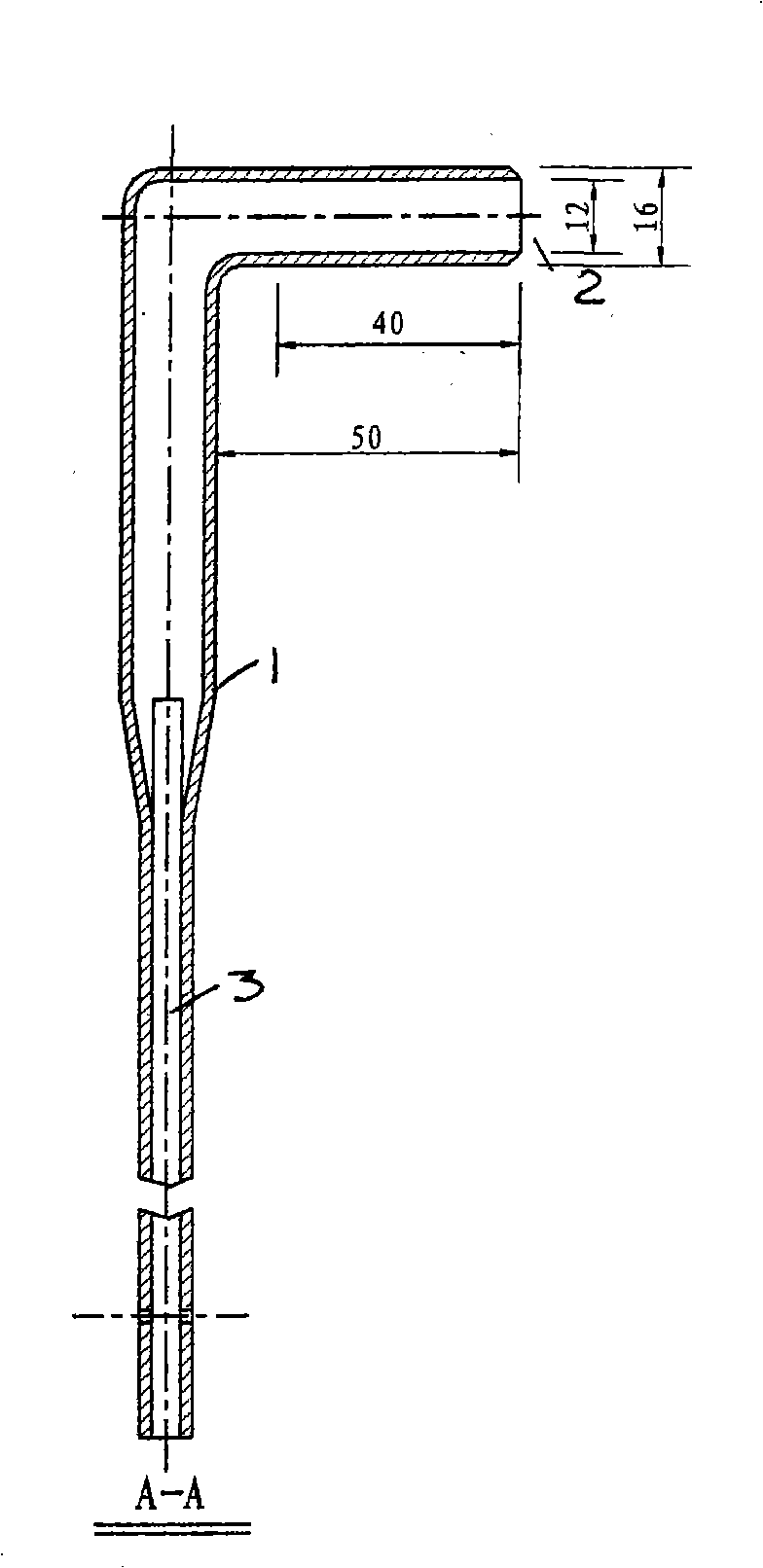

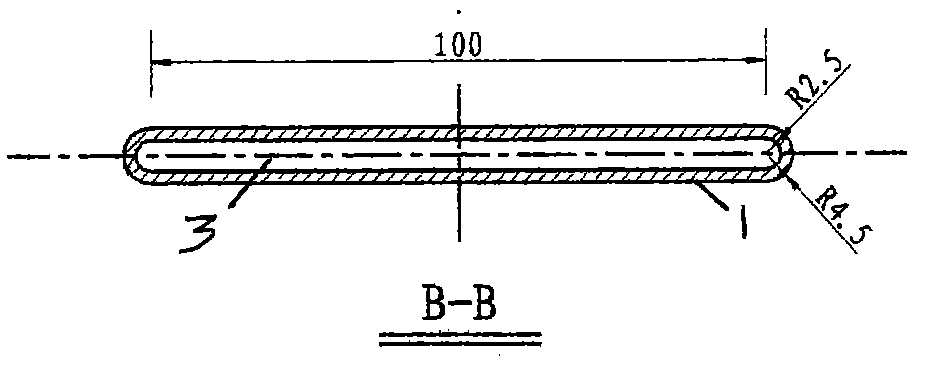

Self-seal device of water drain plate

InactiveCN101349055ASave engineering materialsSave horizontal drainage beddingSoil preservationSurface layerEarth surface

The invention relates to a drainage plate self-sealing device, which consists of a sealing body coated or stuck on the upper part of the drainage plate and a water and air suction pipe; the underside of the drainage plate is open; the superface of the drainage plate is also open and positioned in the sealing body of the self-sealing device; the periphery of the upper part of the drainage plate body is sealed; and the sealing body is coated or stuck on the periphery of the upper part of the drainage plate body. The sealing body of the upper part of the drainage plate is a box-shaped cylinder. The water and air suction pipe of the self-sealing device is a right-angle and bended-angle pipe. The device is used in the vacuum prepressing and can save a plastic sealed film for reinforcing the surface layer, a film outgoing device and a film pressing sealed ditch, a horizontal drainage undercourse and total filter pipes. The device is used in the load prepressing and can save the horizontal drainage undercourse. The device is used in the well point precipitation prepressing and can use the drainage plate and the self-sealing device to replace a lightweight well point with expensive price, shorten the construction period and improve the precipitation speed; and the device is used in the prepressing and reinforcing technology and can save manpower, engineering material and engineering investment, simplifies the construction procedure, shortens the construction period and improves the precipitation speed. The vacuum degree can reach between 80 and 95 kilopascals below zero.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG

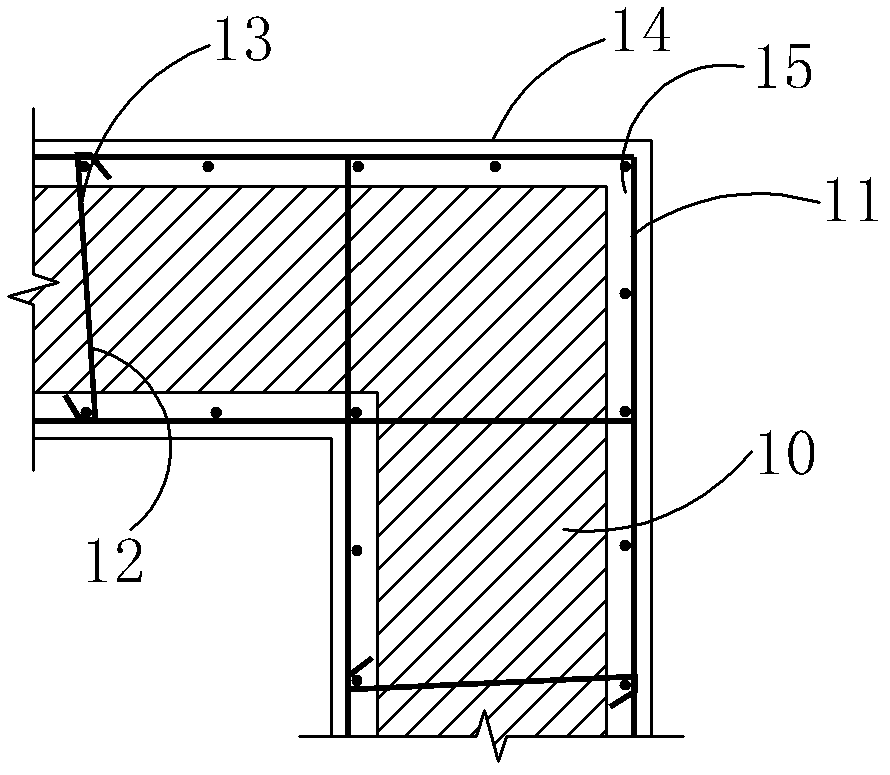

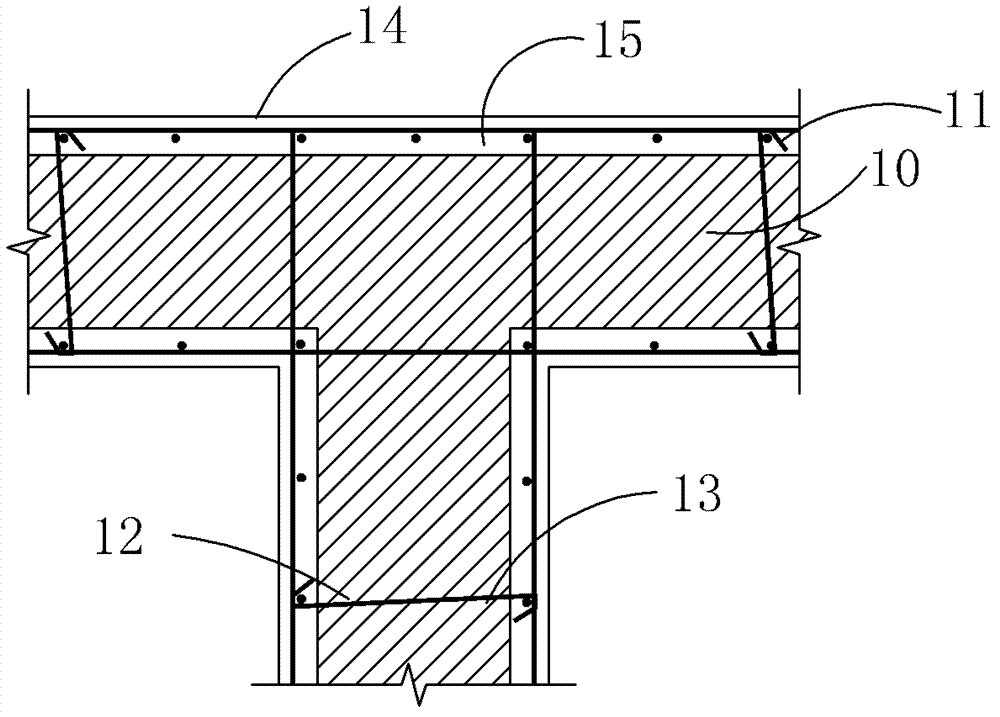

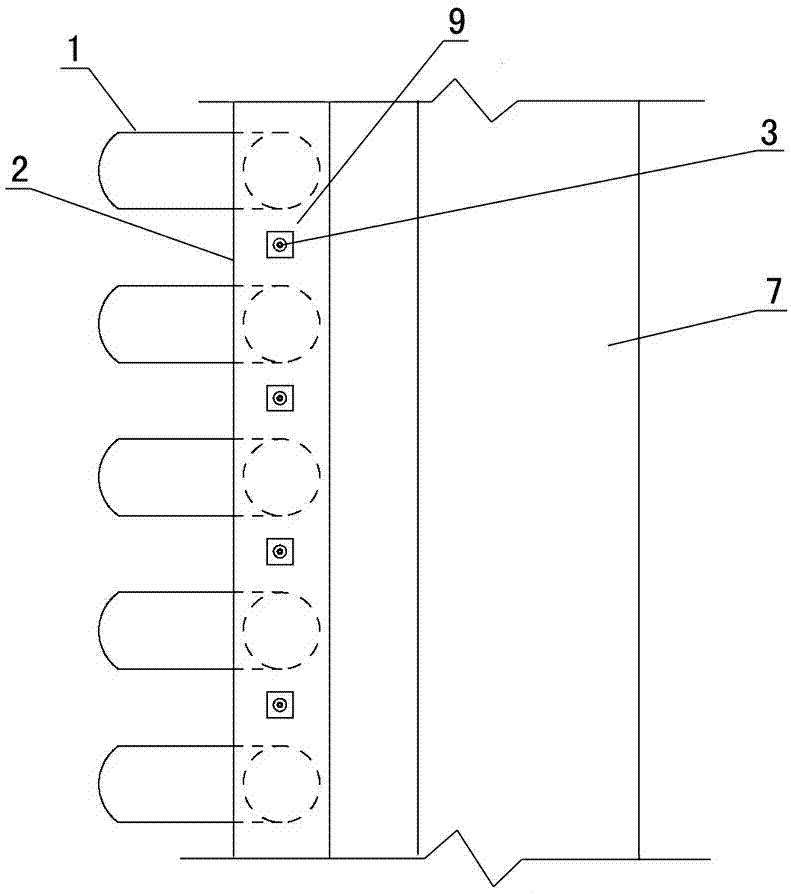

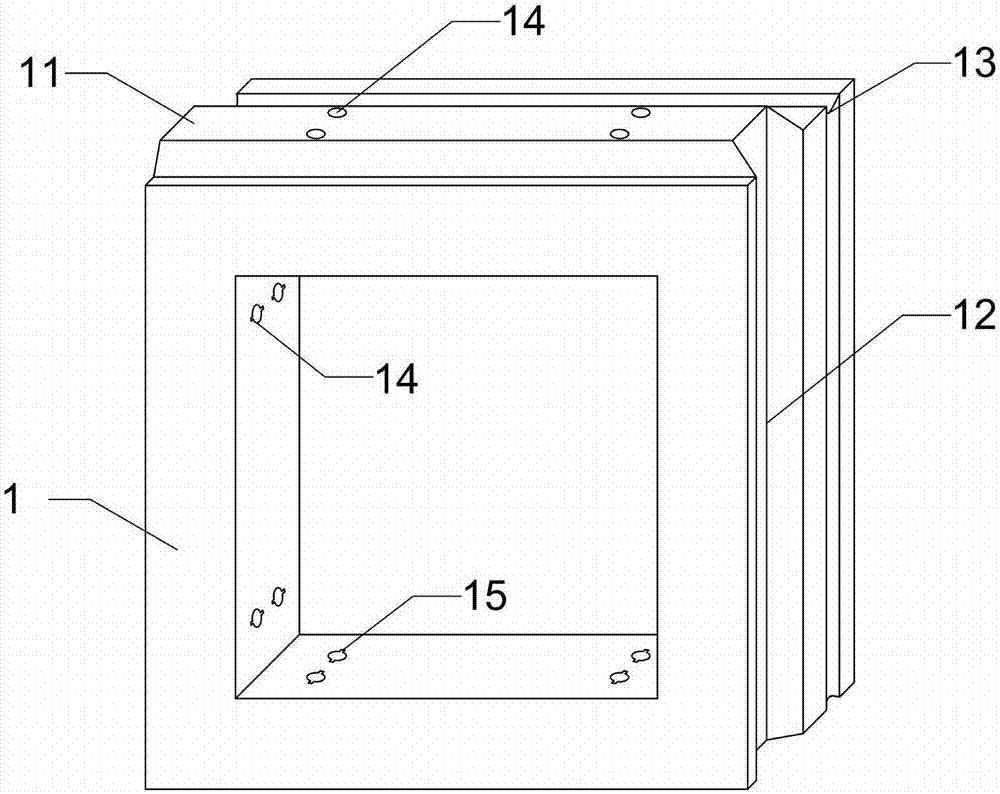

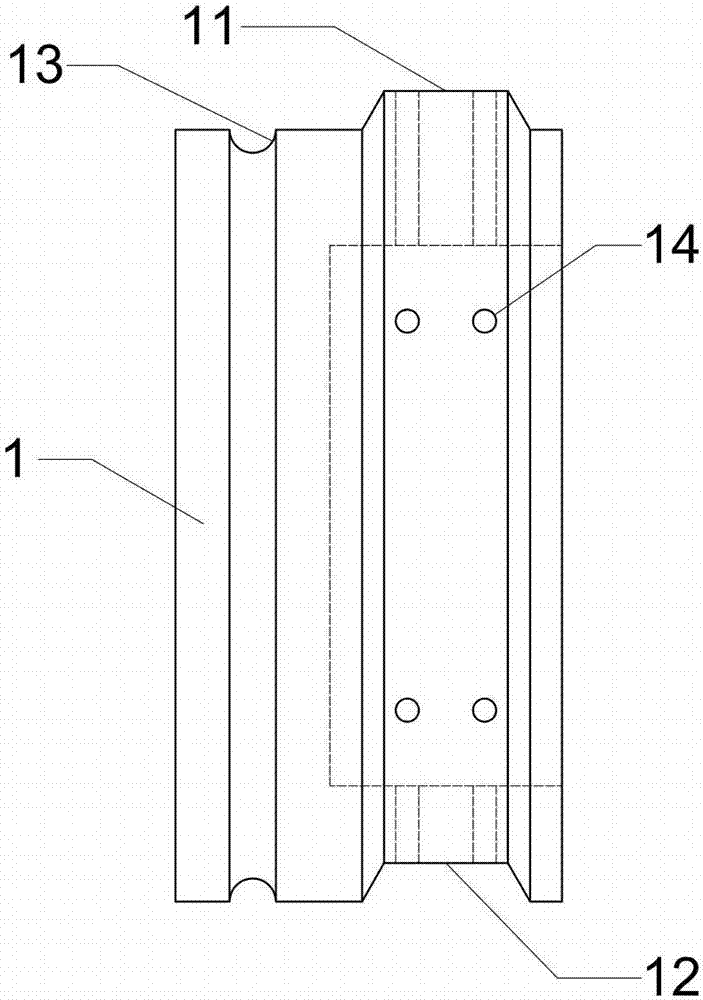

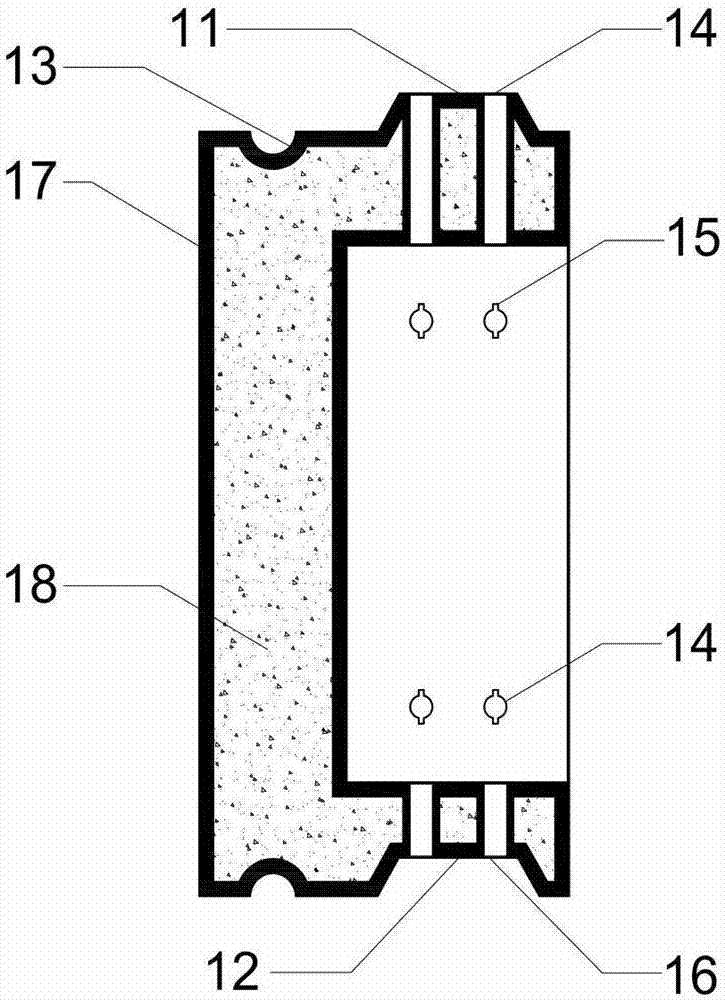

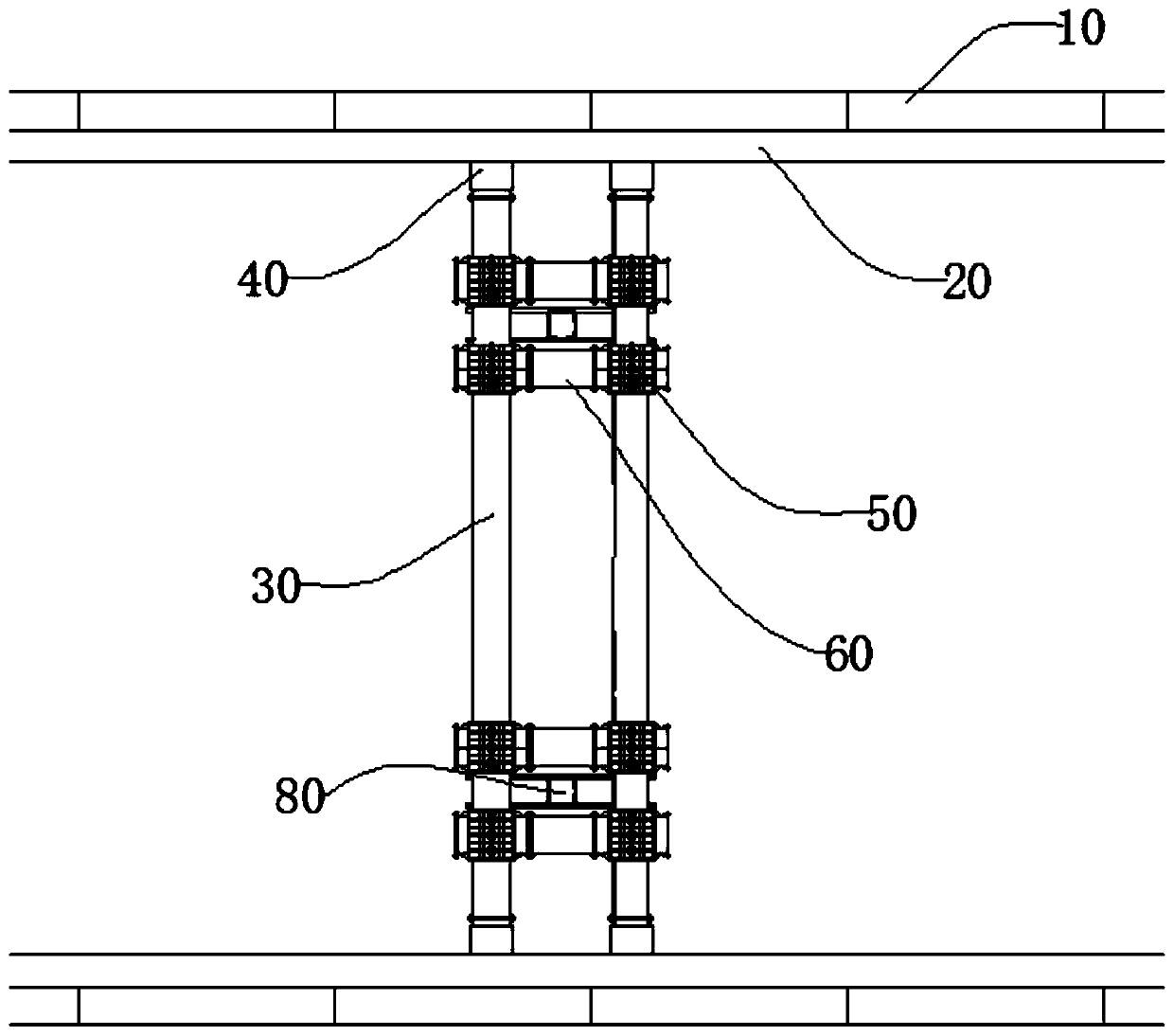

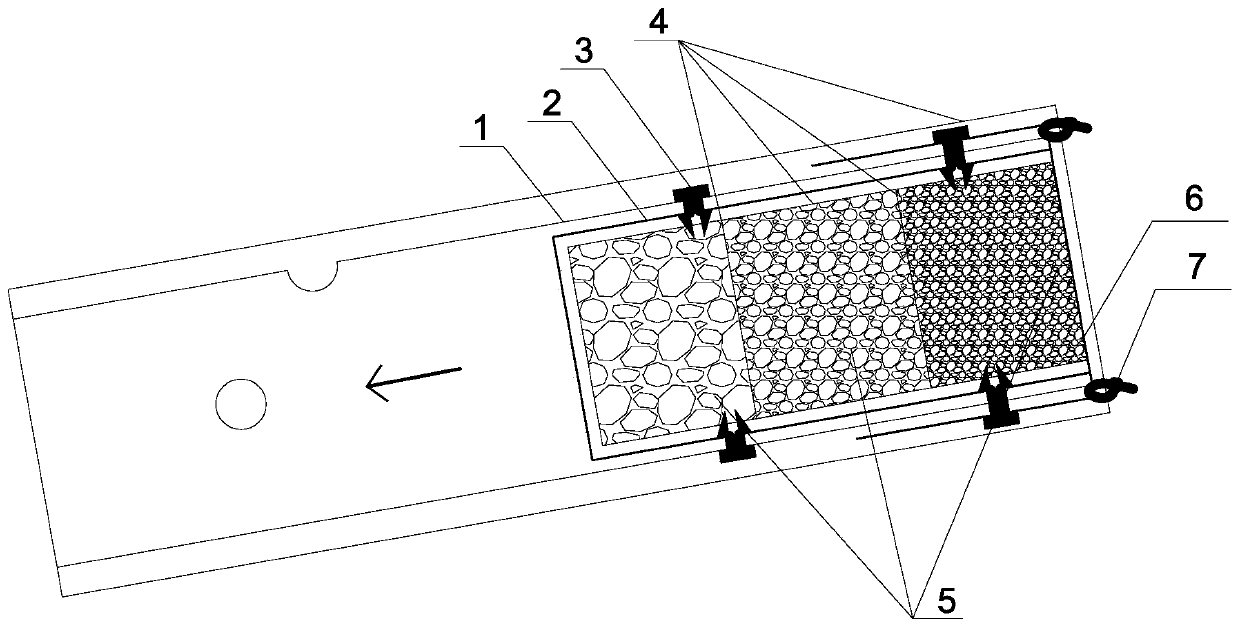

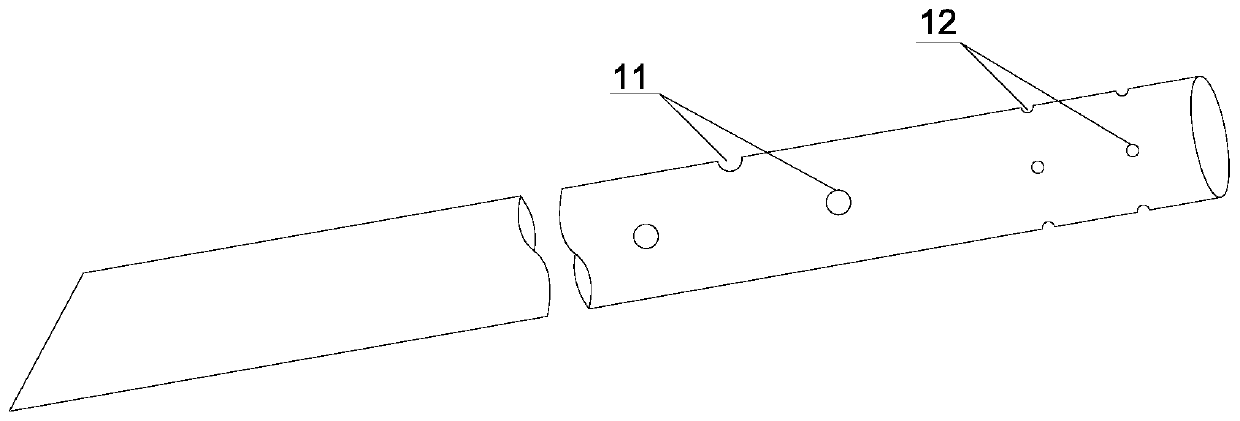

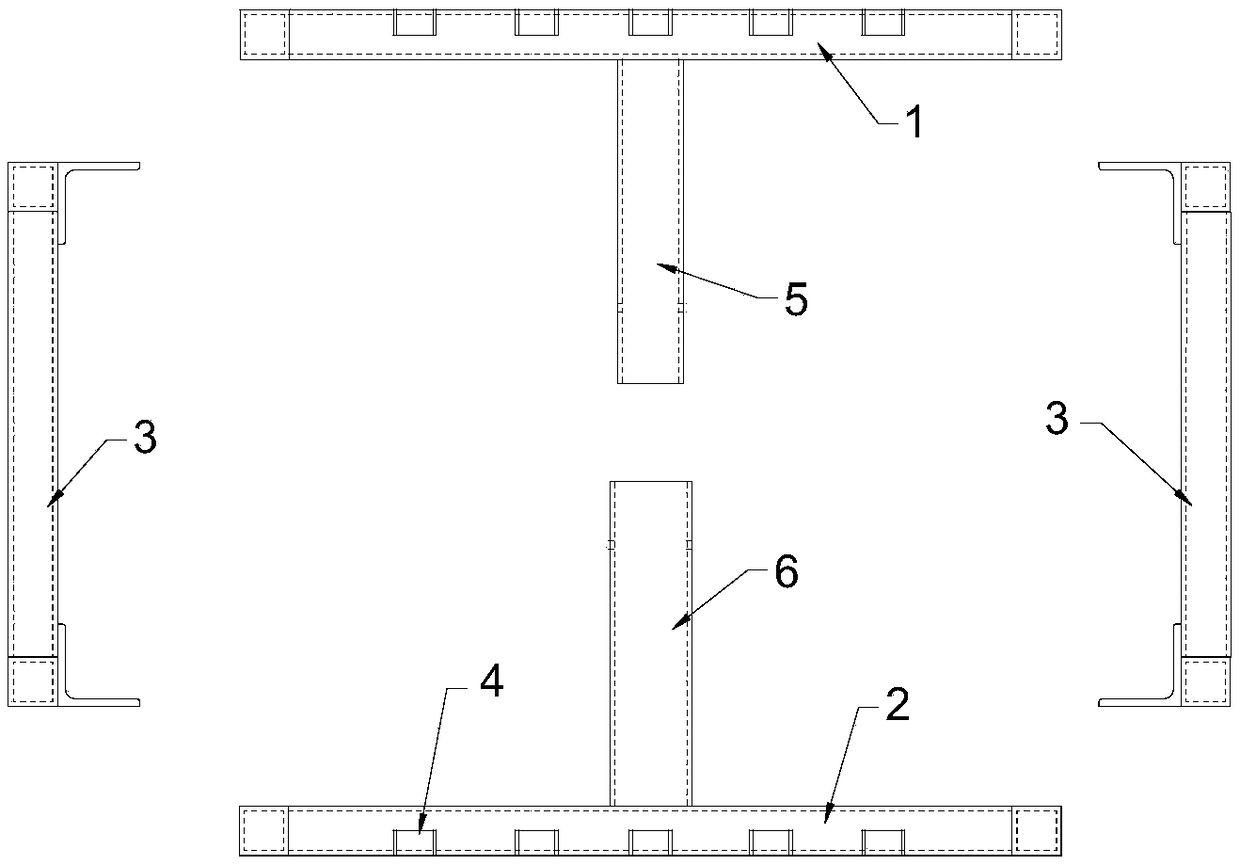

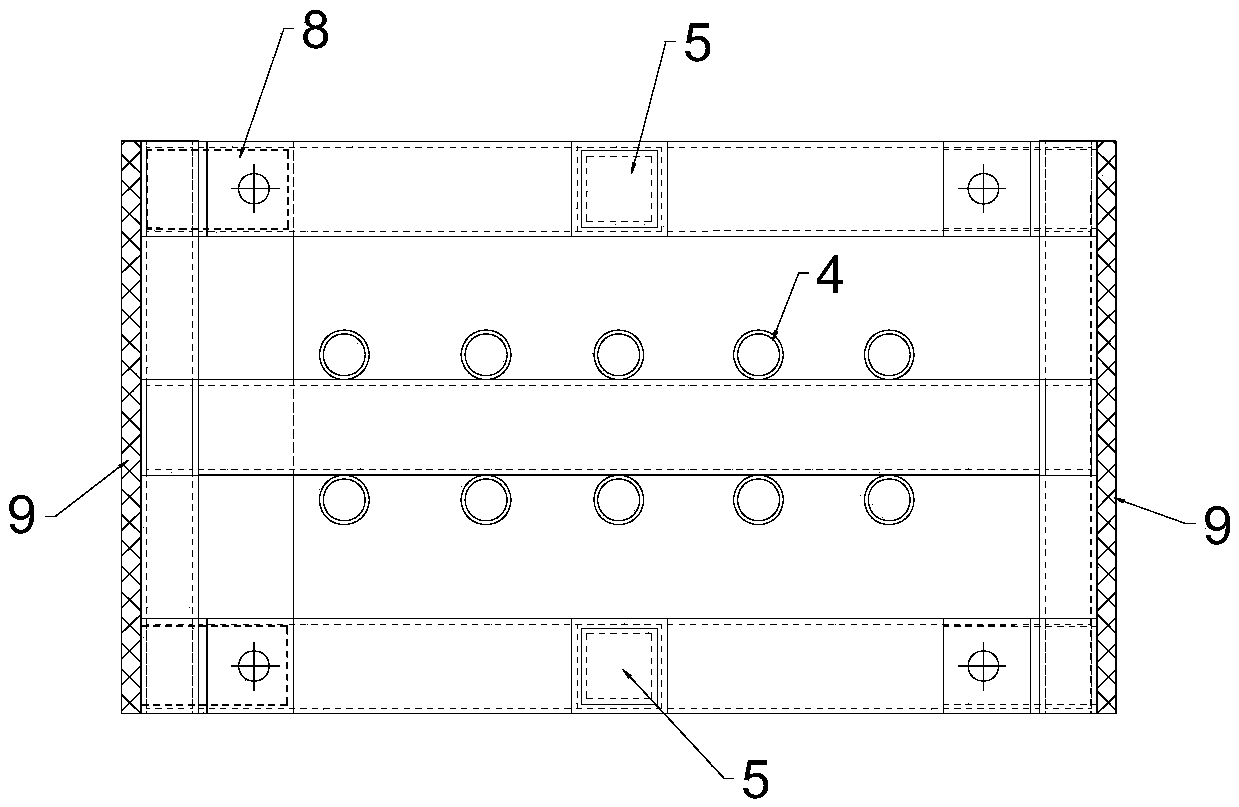

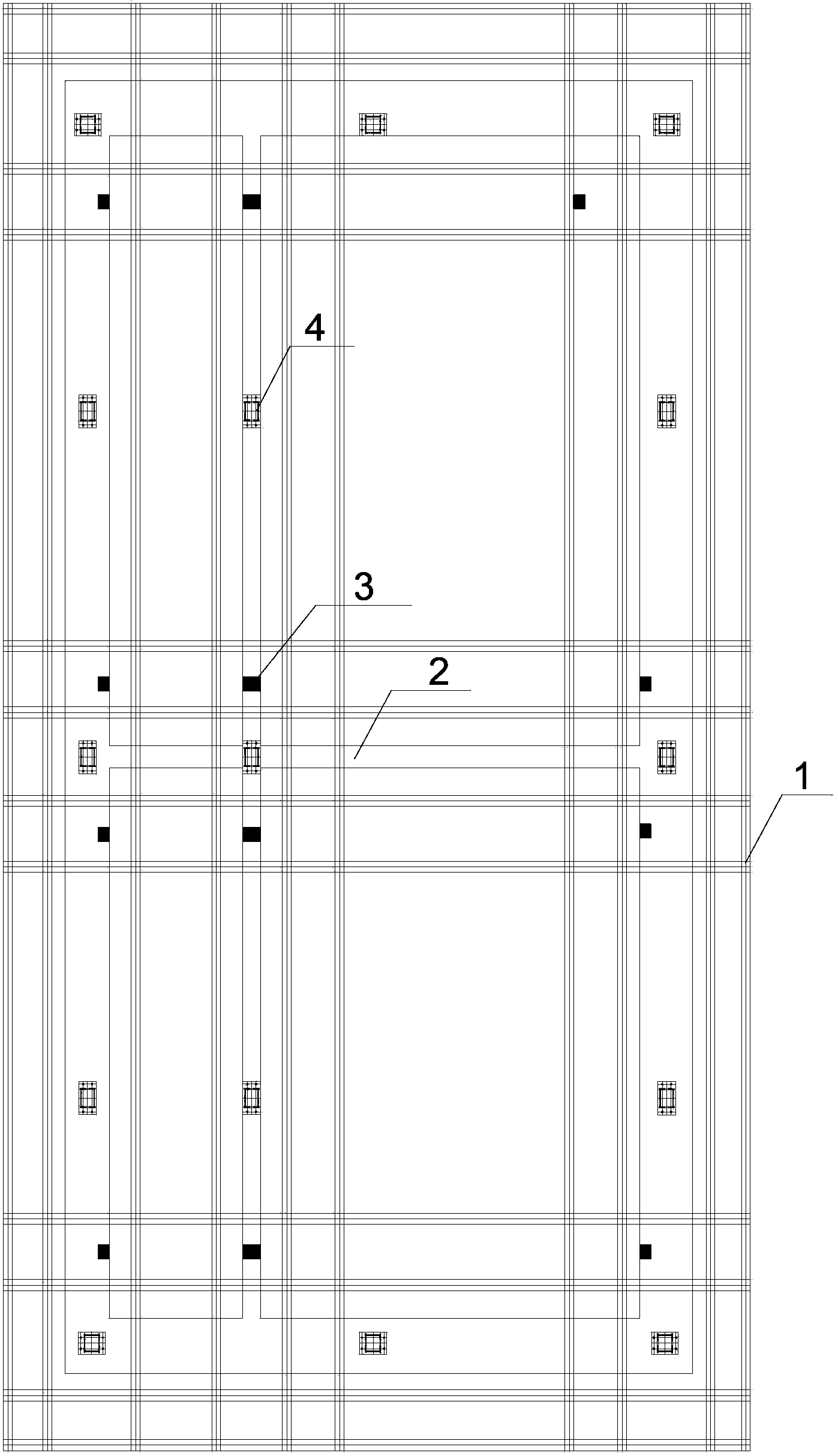

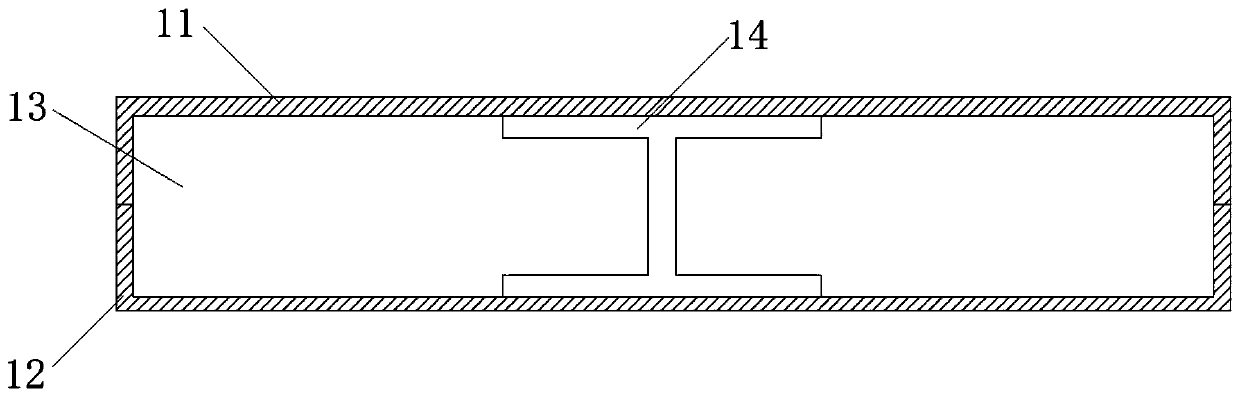

Construction method for assembled foundation pit support structure

The invention relates to a construction method for an assembled foundation pit support structure. A prefabricated reinforced concrete pile and a prefabricated box type component are mainly adopted. The prefabricated box type component comprises at least one standard piece. Trapezoid tenons 11 and trapezoid mortises 12 are formed in transverse and longitudinal connector positions of the standard pieces in a staggered manner. The prefabricated reinforced concrete pile comprises a front part 41, a rear part 42 and a pile head 43, wherein trapezoid tenons 412 and trapezoid mortises 413 are formed in the two sides of the front part in a staggered manner, and the tenons and the mortises of the prefabricated reinforced concrete pile and the tenons and the mortises of the prefabricated box type component are matched in size. A clamp support 421 used for supporting a prefabricated box type component located at the adjacent position is arranged at the position, close to the front part 41, of the rear part 42. After the whole support structure is spliced, compaction grouting is conducted on the position of a last anti-seepage grouting hole where the corresponding standard piece is arranged, and the anti-seepage grouting holes formed by the standard pieces and a pile body are fully filled with pulp from bottom to top. When it is observed that the pulp overflows out of an anti-seepage grouting hole channel of the top-layer standard piece, grouting is stopped.

Owner:TIANJIN UNIV

Ramp turn superelevation calculation method for viscose debris flow, and application

ActiveCN106245573AAvoid errorsAvoid casualtiesHydraulic engineering apparatusDatum referenceEngineering

The invention discloses a ramp turn superelevation calculation method for a viscose debris flow, and belongs to the technical field of prevention and control engineering for viscose debris flows. The ramp turn superelevation calculation method is characterized by comprising the following steps: a. obtaining an average flow speed V0 of debris flows in a place where the debris flows occur in former years, a ramp turn width B0 of the debris flows in the place where the debris flows occur in former years, and a ramp turn superelevation value Delta H0 of the debris flows in the place where the debris flows occur in former years, calculating a determination coefficient c according to a formula 1, obtaining an average flow speed V of the debris flow, and a ramp turn width B of the debris flow through field measurement, wherein the unit of the average flow speed is m / s, and the unit of the ramp turn width is m; and substituting the coefficient c obtained in the step d into a formula 2 to determine a ramp turn superelevation value Delta H of the debris flow, wherein the unit of the ramp turn superelevation value is m. The ramp turn superelevation value of the debris flow, which is obtained by the ramp turn superelevation calculation method disclosed by the invention, is more accurate, thus a better theoretic data reference can be provided for defense measures for the debris flow, higher disaster prevention applicability is achieved for disaster reduction for the debris flow, and a prevention and control effect for the debris flow is greatly improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Construction method for machine-made glass magnesium composite plate air pipes

ActiveCN108591634AWith sound insulationWith heat insulation functionPipe laying and repairRigid pipesArchitectural engineeringSmall footprint

The invention discloses a construction method for machine-made glass magnesium composite plate air pipes. The construction method comprises the following steps that (1) plates of the air pipes are cut; (2) the air pipes are spliced; (3) the air pipes are hoisted and connected; and (4) parts of the air pipes are mounted. Compared with a tradition construction method for a galvanized steel plate airpipe, the construction method for the machine-made glass magnesium composite plate air pipes has the characteristics of less construction machines, simple construction procedures, less auxiliary material using amount, small floor space, short construction period and the like. Due to the fact that the air pipes are connected without flanges, a large amount of engineering materials such as angle steel, gaskets, bolts, welding rods, rivets, oxygen and acetylene can be saved; and the average construction efficiency of the galvanized air pipe is 3 m<2> / d per person, the average construction efficiency of the machine-made glass magnesium composite plate air pipes can reach to 12.1 m<2> / d per person, and as for manufacturing and mounting of the air pipes with the same area, the construction period can be shortened obviously for the machine-made glass magnesium composite plate air pipes.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

Foundation pit supporting structure

PendingCN111424677AImprove general performanceImprove versatilityExcavationsArchitectural engineeringLong span

Owner:SHANGHAI MECHANIZED CONSTR GRP +2

Anti-blocking device for muck slope drainage pipe and construction method

PendingCN109736292AGuaranteed anti-clogging effectAvoid crowdingExcavationsFiltration circuitsWater filterWater flow

The invention provides an anti-blocking device for a muck slope drainage pipe. The device comprises a drainage pipe and a water filter, a plurality of drainage holes are formed in the pipe wall of thedrainage pipe; a filter screen plate is arranged at one end of the water filter; a pipe cap sleeve is arranged at the other end of the water filter; the pipe cap sleeve is connected with a filter screen; a water inlet is formed in one end of the drainage pipe; the pipe cap sleeve is arranged at the water inlet in a sleeving manner; the water filter is accommodated in the drainage pipe; a reversefiltering layer is arranged in the water filter; the reverse filtering layer comprises a plurality of filtering layers, each filtering layer comprises particle contents and geotextile wrapping the particle contents, the particle sizes of the particle contents of the filtering layers are gradually increased in the water flow direction of the drainage pipe, and the hole diameters of the filtering net pieces are smaller than the particle sizes of the particle contents of the adjacent filtering layers. The invention has the beneficial effects that the pressure resistance of the water inlet end ofthe drainage pipe is improved, and the water inlet end of the drainage pipe is prevented from being extruded and damaged to cause drain pipe blockage.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

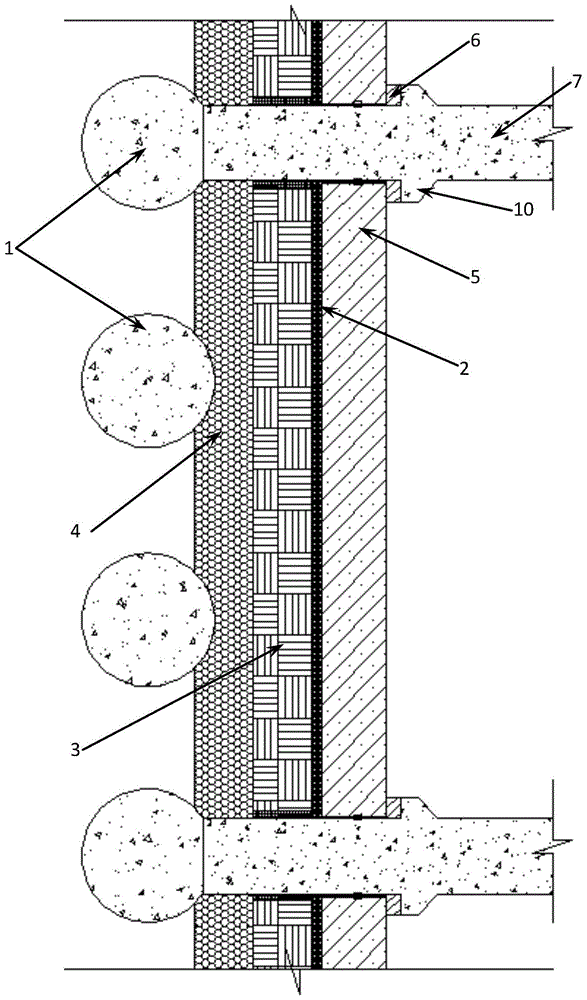

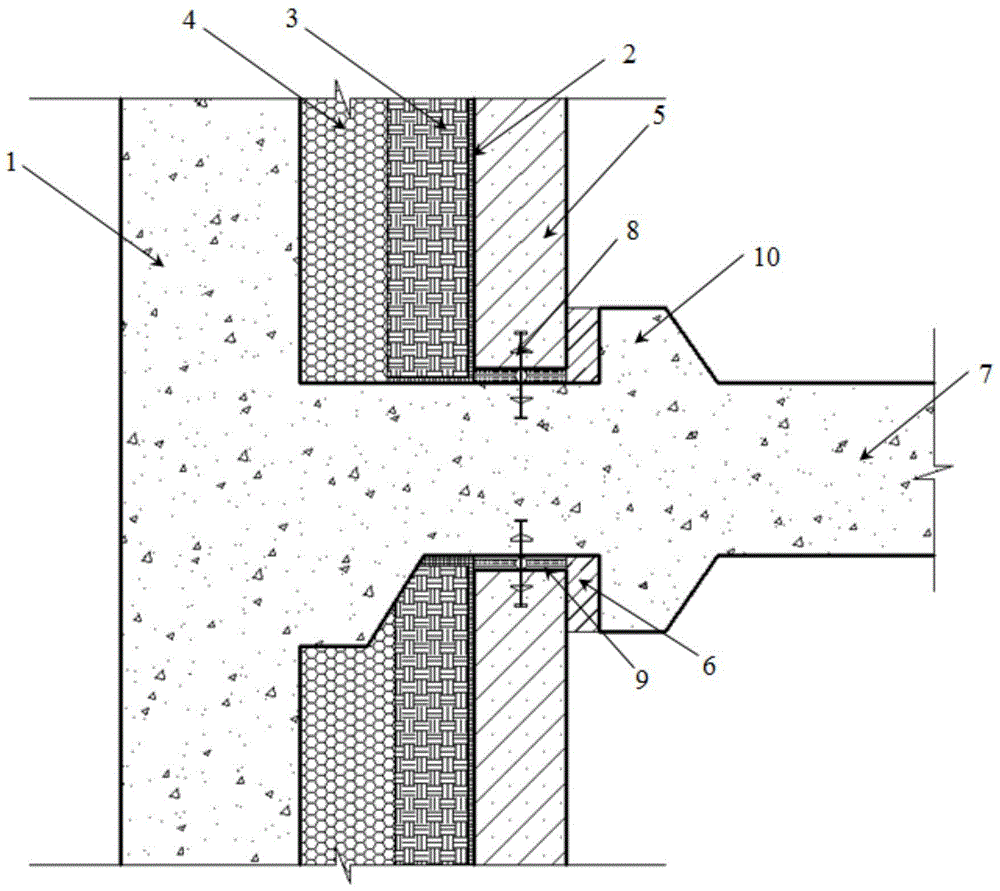

A connection structure and connection method between retaining piles and main beams of underground structures

ActiveCN104762991BReduce thicknessSave engineering materialsArtificial islandsExcavationsBasementPolystyrene

The invention discloses a connection structure and a connection method of a fender pile and a subsurface structure main body beam. The connection structure of the fender pile and the subsurface structure main body beam comprises a subsurface connection wall and the subsurface structure main body beam, wherein the subsurface structure main body beam passes through a basement exterior wall, and is connected with the fender pile, a circle of brackets is arranged on the subsurface structure main body beam, and the brackets are contacted with the basement exterior wall through a middle elastic sleeper block, and achieve a suppression function for offsetting of the basement exterior wall. The connection method of the fender pile and the subsurface structure main body beam includes: pasting a waterproof coiled material on the exterior of the basement exterior wall, and then laying polystyrene board protection materials, and finally compacting the basement exterior wall through backfill. By using the connection method of the fender pile and the subsurface structure main body beam, force and a bending moment on the subsurface structure main body beam directly act on the fender pile, and therefore the thickness of the basement exterior wall is reduced, and a subsurface structure is reasonably stressed and harmonically deformed.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Method for lowering spraying drip irrigation engineering cost

InactiveCN101796917AEasy to assemble and disassembleEasy to carryWatering devicesCultivating equipmentsAgricultural irrigationDrip irrigation

The invention relates to the field of agricultural irrigation, in particular to a method for lowering spraying drip irrigation engineering cost, which is concretely realized through the following three approaches of: 1. omitting a trunk pipe, wherein a system comprises a mobile water pump set, a water inlet plug and a water inlet pipe, a branch trunk pipe, a branch pipe or a capillary pipe, and a spray head or a dropping head, wherein the spray head or the dropping head is installed on the branch pipe or the capillary pipe, the branch pipe or the capillary pipe is connected with the branch trunk pipe, and the essential thereof is that water is taken by the mobile water pump set from a riverway or a slot, supplied for the water inlet plug and sequentially sent to the spray head or the dropping head through the water inlet pipe, the branch trunk pipe, the branch pipe or the capillary pipe to implement spraying drip irrigation so as to reduce the length of the trunk pipe and lower the engineering cost; 2. reducing the diameter of the trunk pipe, realizing through dividing a small rotational irrigation area, and qualitatively lowering the cost of a pipeline; and 3. accurately calculating the diameter of the pipeline, and quantitatively further lowering the construction cost of a pipeline system. The invention effectively lowers the spraying drip irrigation engineering cost, is easy to popularize and apply and supplies equipment for scientific irrigation, fertilization, temperature reduction and yellow sand flushing to modern agriculture.

Owner:奕永庆

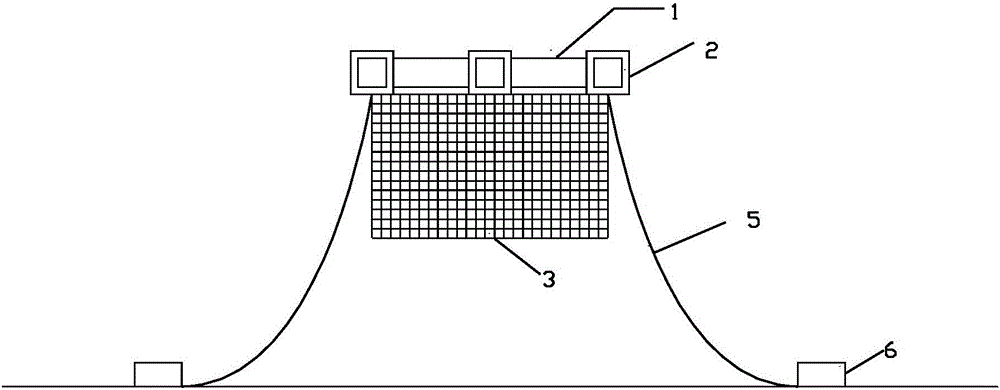

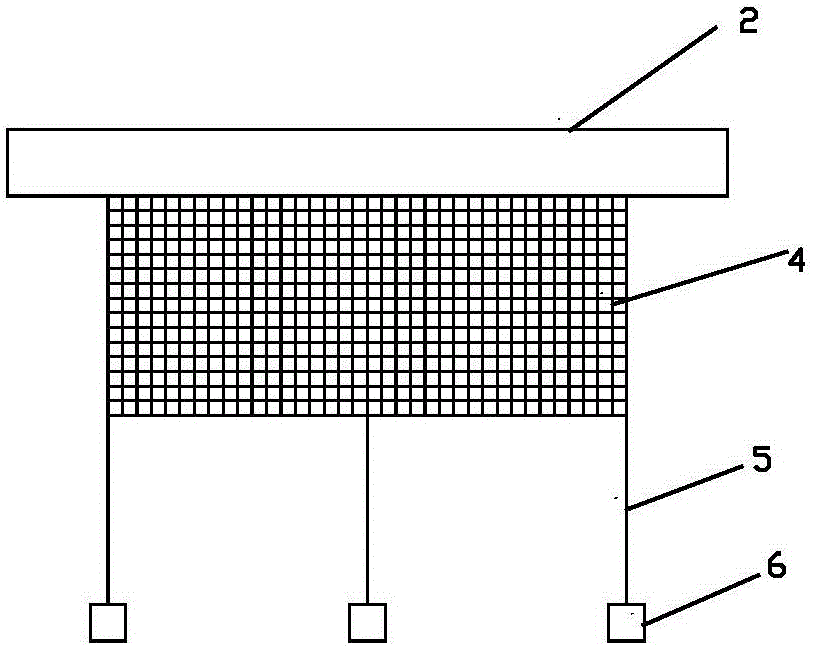

Case net type floating breakwater based on FRP material

The invention provides a case net type floating breakwater based on a FRP material. The case net type floating breakwater comprises a buoyant box, and grids, an anchor chain and an anchor which are connected below the buoyant box, wherein the buoyant box is formed by lengthwise rectangular concrete buoyant box beams and transverse rectangular concrete buoyant box beams; the lengthwise rectangular concrete buoyant box beams are prefabricated into a whole by adopting concrete; the transverse rectangular concrete buoyant box beams are distributed in a '#'-shaped beam structure; the FRP grids are arranged below both of the lengthwise rectangular concrete buoyant box beams and the transverse rectangular concrete buoyant box beams; and all the FRP grids are connected to form a grid net case structure. The case net type floating breakwater provided by the invention has the functions of reflecting, dissipating and breaking and suppressing wave, is applicable to offshore waters which are characterized in that the surrounding is open, wave action is small and wave directions are uncertain, can provide effective covering for occasions such as aquaculture, artificial bathing beach and marina, and has wide practical prospect.

Owner:HARBIN ENG UNIV

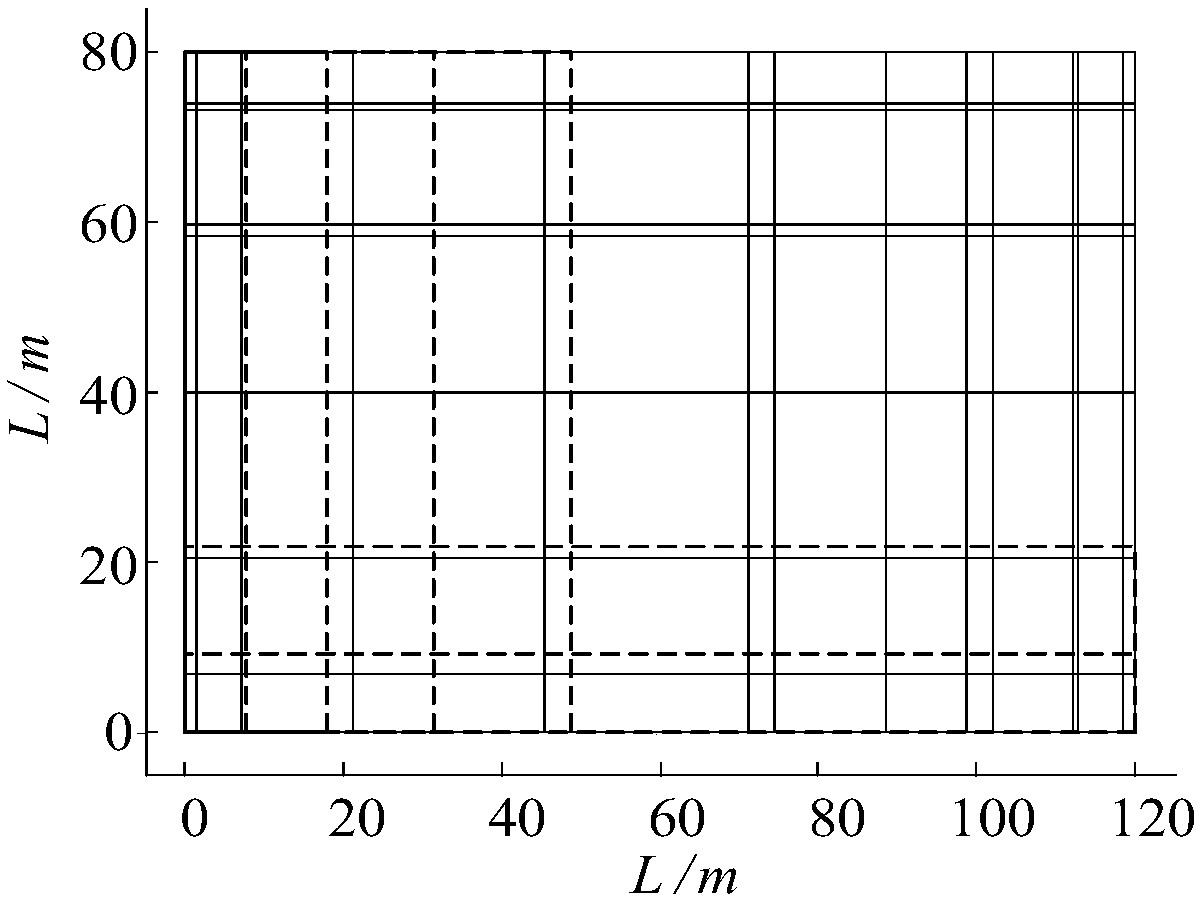

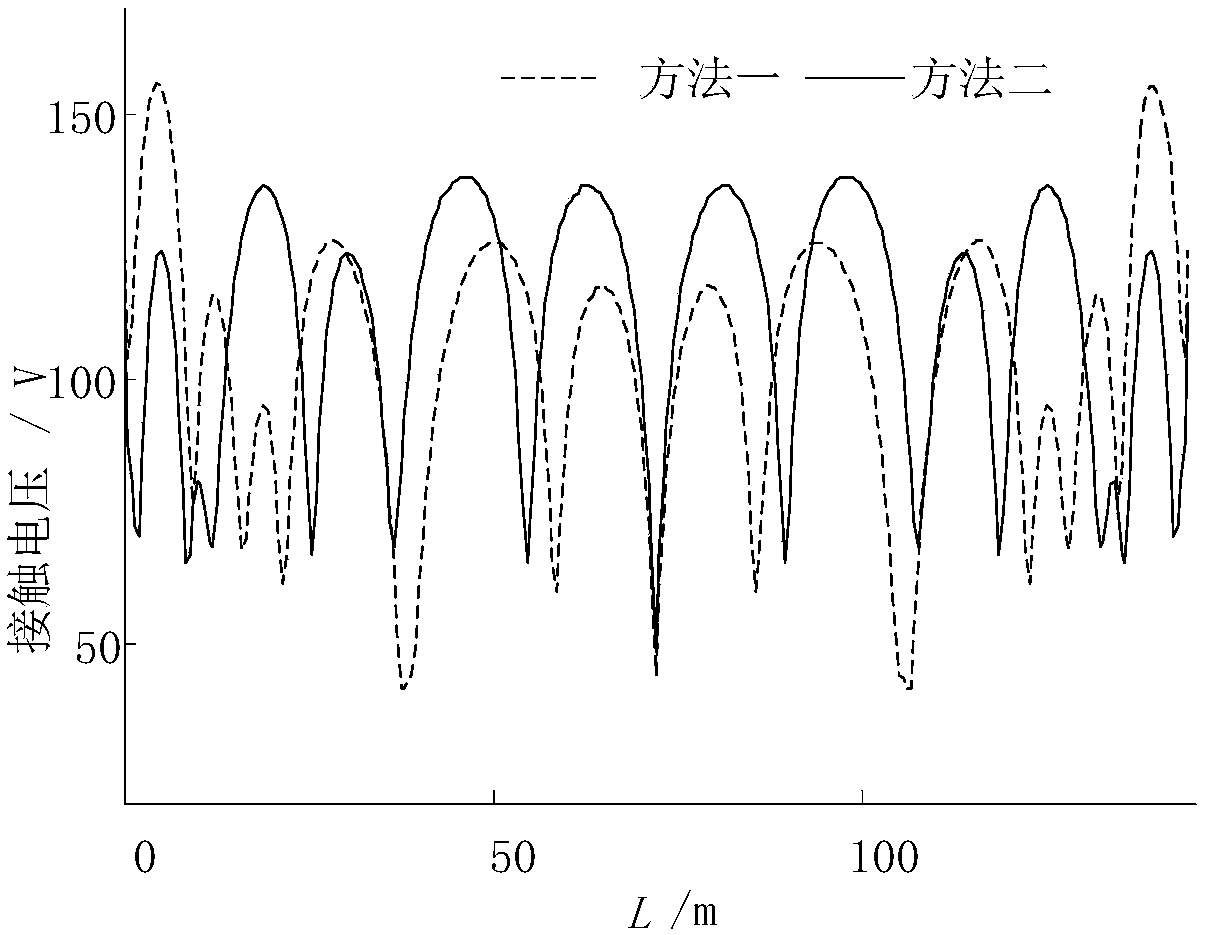

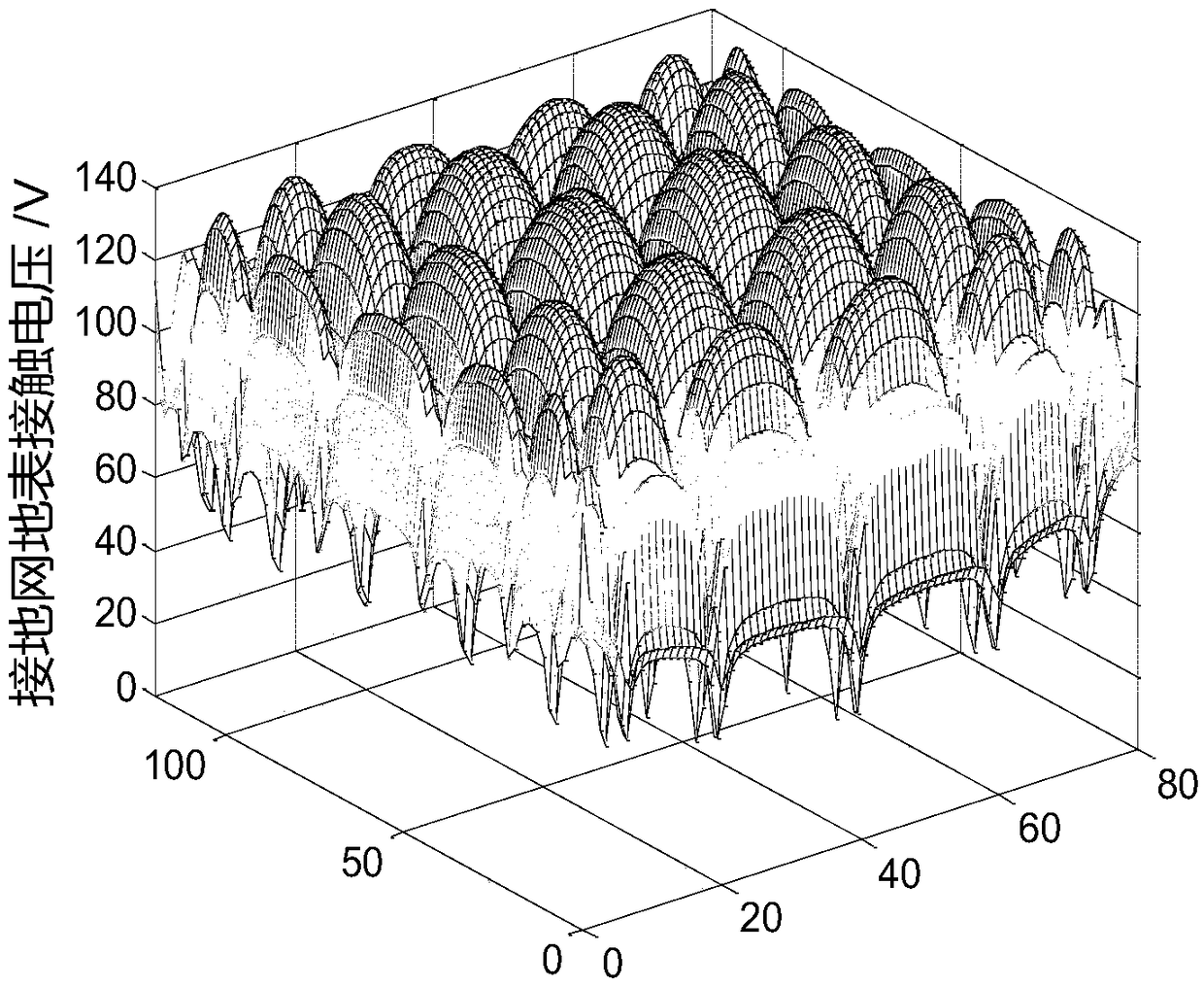

Optimized unequal-interval layout method for grounding network

InactiveCN108846226AIncrease profitSave engineering materialsGeometric CADLine/current collector detailsInterval methodAlgorithm

The invention discloses an optimized unequal-interval layout method for a grounding network. The optimized unequal-interval layout method for the grounding network comprises the steps of: (1), deducing a fitting function: modelling and moving a voltage-equalizing belt by using an optimized rectangular grounding network layout scheme, so that the position of an optimized voltage-equalizing belt isobtained, and obtaining an optimization function through function fitting; (2), analyzing influence of the optimization function on the optimization coefficient in the aspects of different soil reflection coefficients, the upper soil thickness and the area of the grounding network; and (3), applying the fitting function to optimization of the rectangular grounding network under non-uniform soil.

Owner:INST OF ECONOMIC & TECH STATE GRID HEBEI ELECTRIC POWER +1

Reserved electricity box hole mould and using method thereof

InactiveCN108756233AAvoid size differencesSave engineering materialsForms/shuttering/falseworksElectricityMagnet

The invention provides a reserved electricity box hole mould. The reserved electricity box hole mould comprises an upper plane frame, a lower plane frame and vertical frames. Pieces of connecting angle steel are arranged at the upper side edge and the lower side edge of each vertical frame, and rubber sandwich cushion blocks are arranged between the connecting angle steel and the plane frames; theconnecting angle steel is fixedly connected with the upper plane frame and the lower plane frame through bolts; and rubber plates covering the periphery of the outer surface of the frames are arranged on the outer side of the mould. A method for constructing a hole through the reserved electricity box hole mould comprises the steps that the mould assembled into a whole is placed at the designatedposition of a wall, the interior of the mould is connected with a steel platform through high-strength magnets, and pre-embedded line pipes are mounted; after the prefabricated wall reaches the mould-dismantling strength, fixing bolts are taken down; then, rubber sandwiches are dismantled, so that mould-dismantling gaps are formed in the upper sides and the lower sides of the vertical frames, andthe vertical frames are knocked lightly to fall off; the plane frames are dismantled in the direction of the line pipes; and finally, the peripheral rubber plates are removed. The mould is manufactured by combining steel members and rubber materials, the mould can be integrally dismantled after the wall is fixedly shaped, and the mould can be used repeatedly.

Owner:CHINA 22MCC GROUP CORP

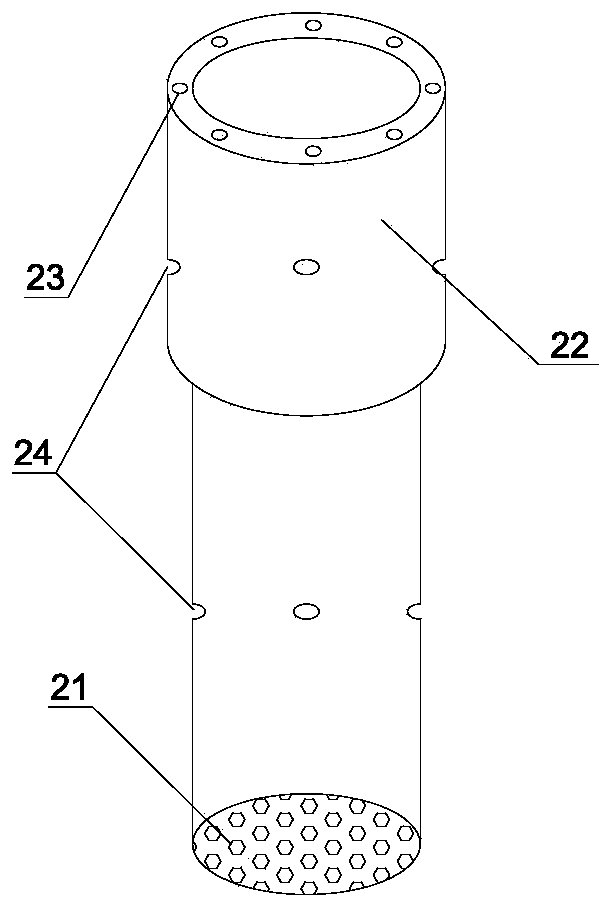

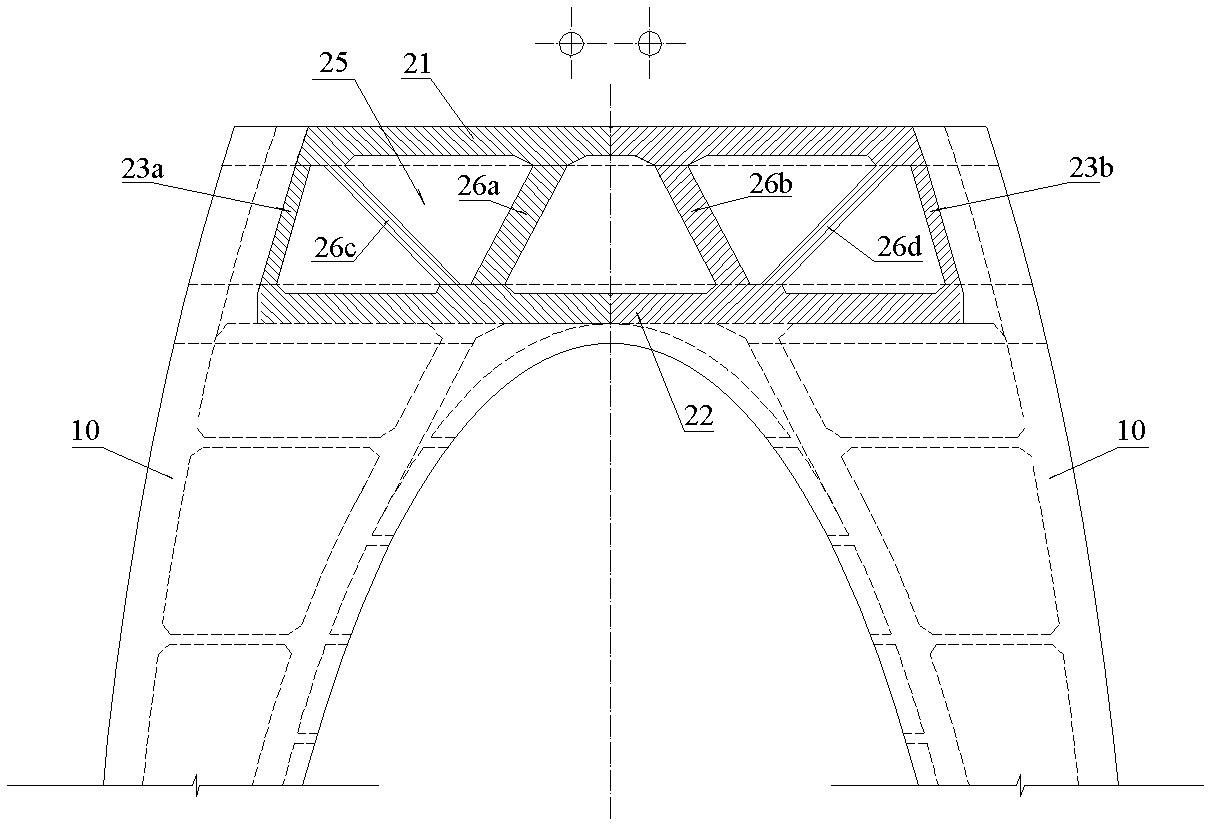

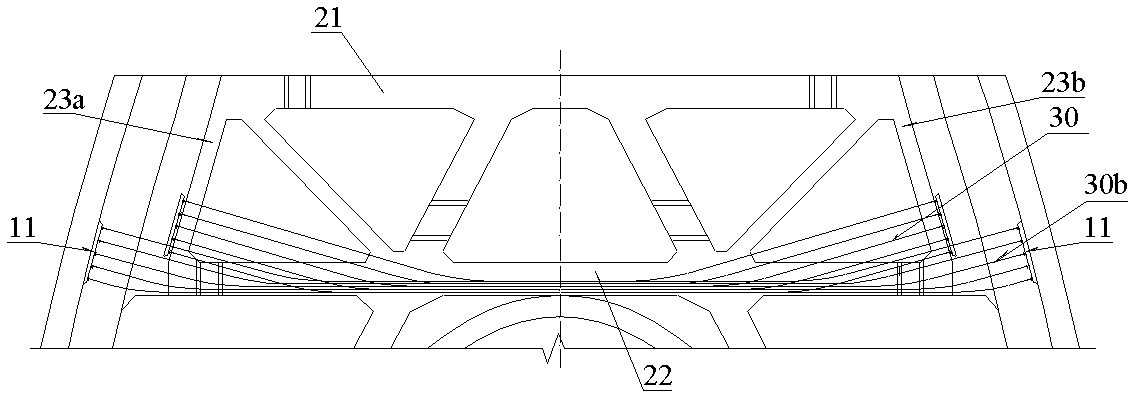

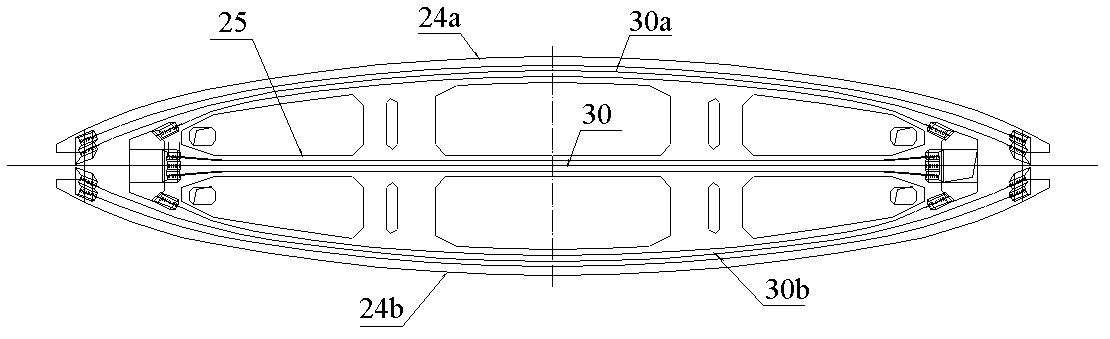

Concrete structure box, plate and joist combined beam

ActiveCN102409602BSolving the Scattered Delivery ProblemEnsure safetyBridge materialsInterior spacePre stress

A concrete structure box, plate and joist combined beam aims to transmit great concentration power and evenly disperse the concentration power onto a load-carrying member and meanwhile do not increase the construction cost excessively. The concrete structure box comprises a box-shaped cross beam fixedly connected to be a whole with a bearing body (10), and the box-shaped cross beam comprises a top plate (21), a bottom plate (22), two end diaphragm plates (23 a and 23 b), and two side webs (24a and 24 b). The concrete structure box, plate and joist combined beam is characterized in that a middle web (25) and inclined diaphragm plates in pair are arranged in the interior space of the box-shaped cross beam, the inclined diaphragm plates, a middle web (25), a top plate (21), and a bottom plate (22) form a truss frame, the middle web (25) is fixedly connected with the top plate (21), the bottom plate (22) and the two end diaphragm plates (23a and 23 b), and the inclined diaphragm plates are fixedly connected with the top plate (21), the bottom plate (22), the middle web (25) and the two side webs (24a and 24 b); and a pre-stress steel strand is configured in the bottom plate (22).

Owner:四川西南交大土木工程设计有限公司

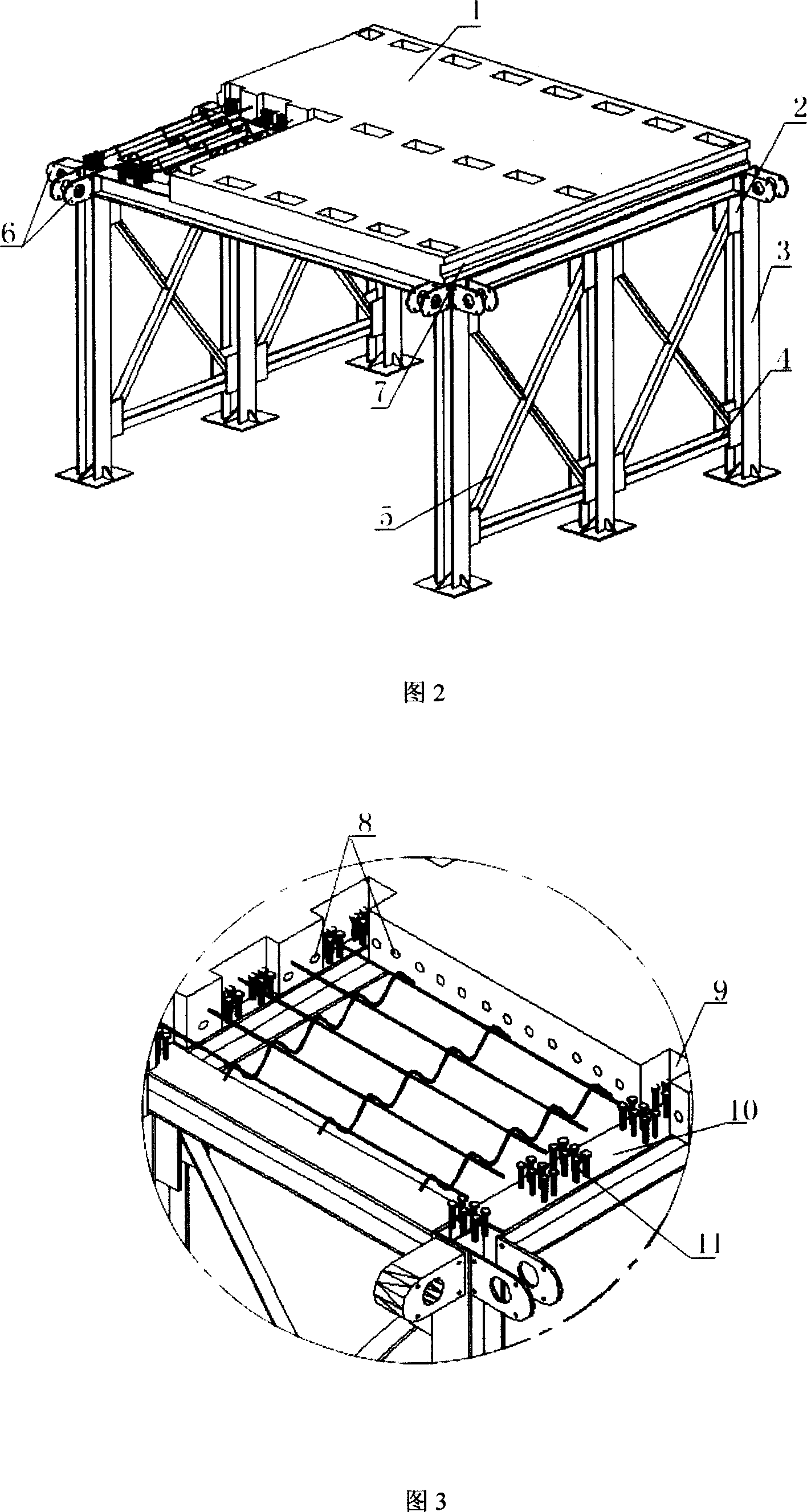

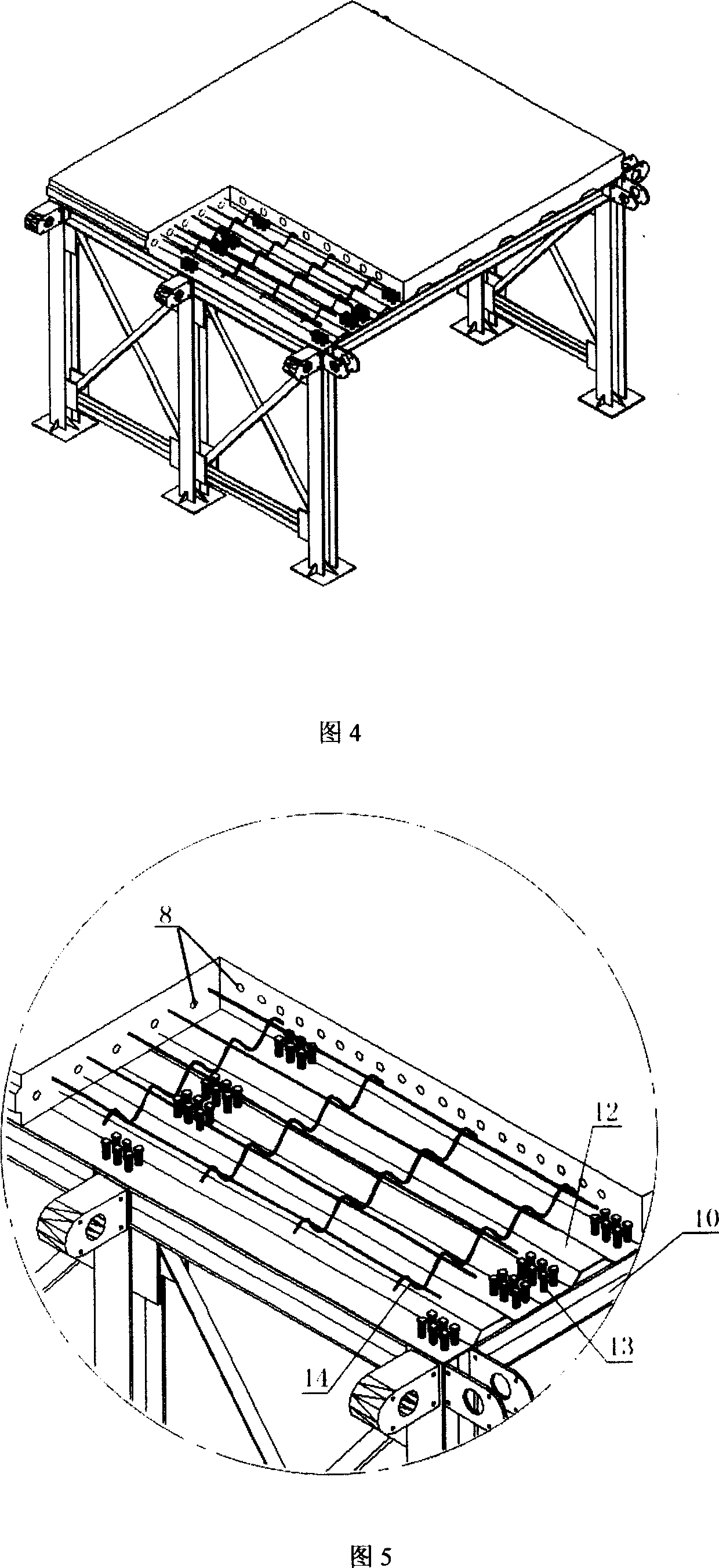

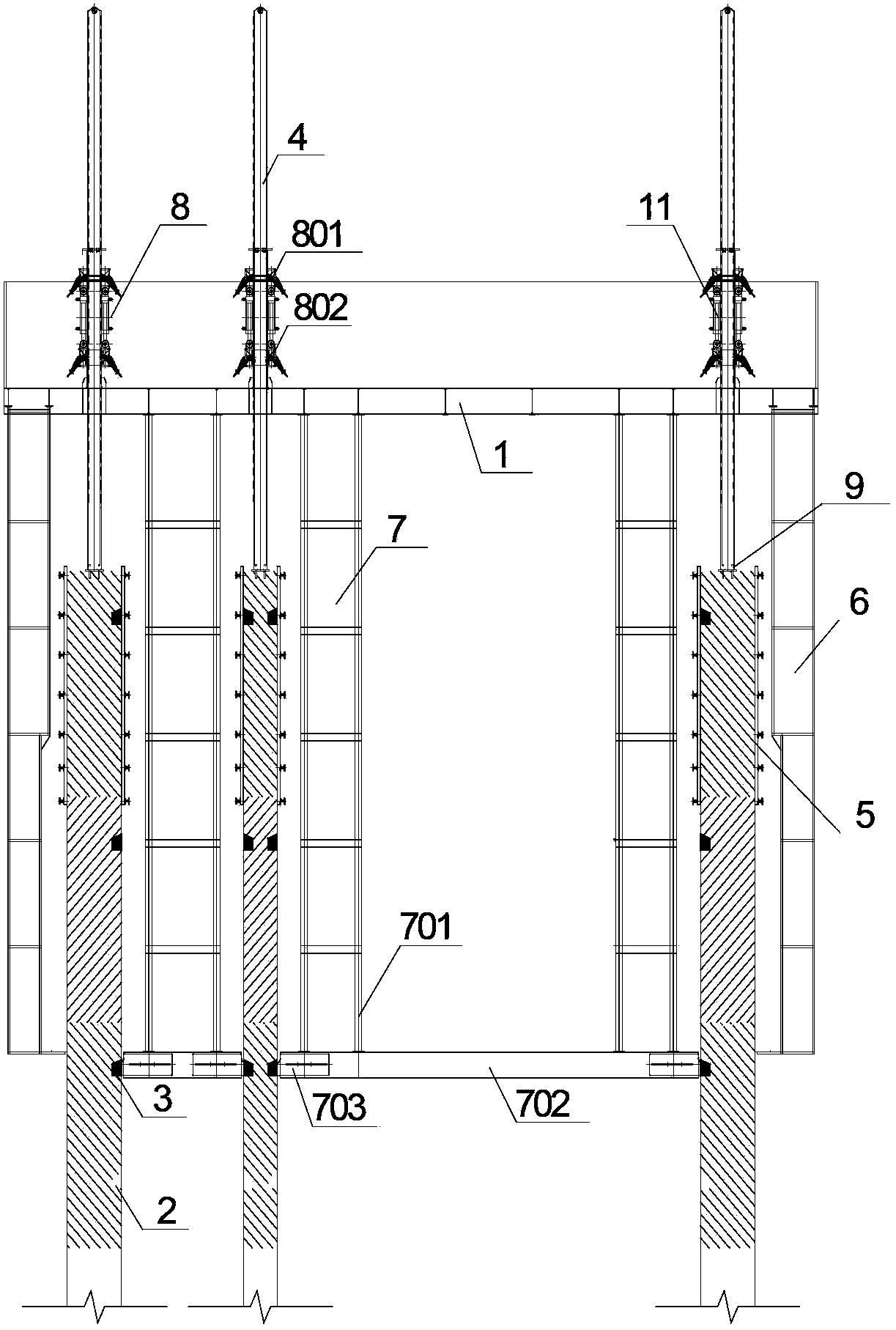

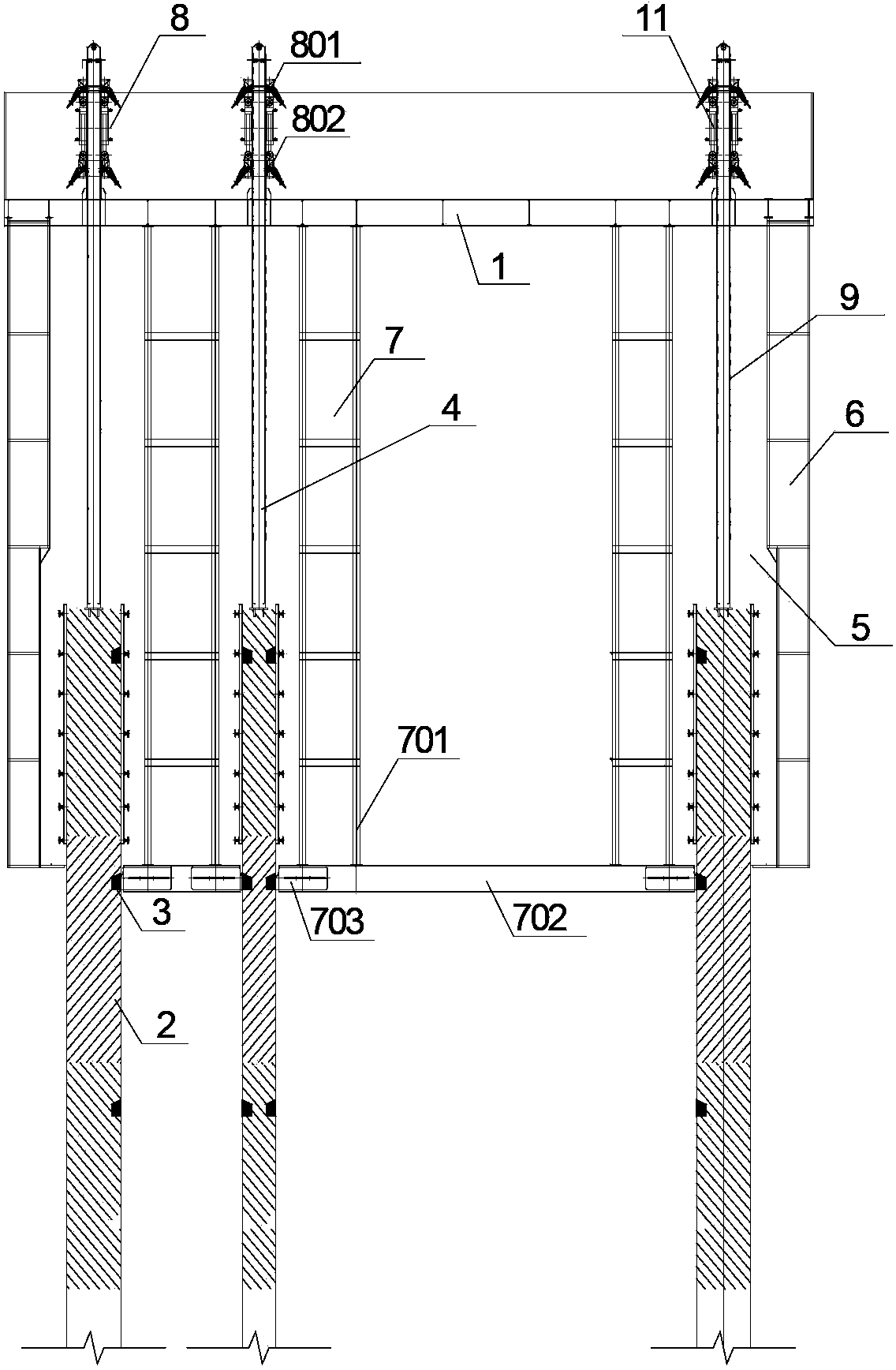

System for alternatively supporting whole lifting steel platform formwork by steel column casing rack and construction method

ActiveCN102677889BClimb achievedAchieve hydraulic climbForms/shuttering/falseworksBuilding material handlingSupporting systemArchitectural engineering

The invention discloses a system for alternatively supporting a whole lifting steel platform formwork by a steel column casing rack. The system comprises a steel platform, a template system, a scaffold system, a support system and a climbing system, wherein the support system comprises a casing rack support and a steel column support; the climbing system comprises climbing boosts and a hydraulic system; preformed core column holes are distributed on a core cylinder structure at intervals along the height direction; the casing rack support is fixedly arranged under the steel platform; the steel column support is fixed in the preformed core column holes under the construction state to serve as the support of a steel platform formwork under the construction state; under the climbing state, the steel column support is fixed to the upper end part of the concrete core cylinder structure and is used as the support of the steel platform formwork under the climbing state; and under the construction state, the steel column support is fixed to the steel platform by the climbing boosts. According to the system, the steel platform formwork system can greatly reduce the construction cost and save the engineering material by the whole hydraulic climbing supported by the tool type steel columns.

Owner:SHANGHAI CONSTRUCTION GROUP +1

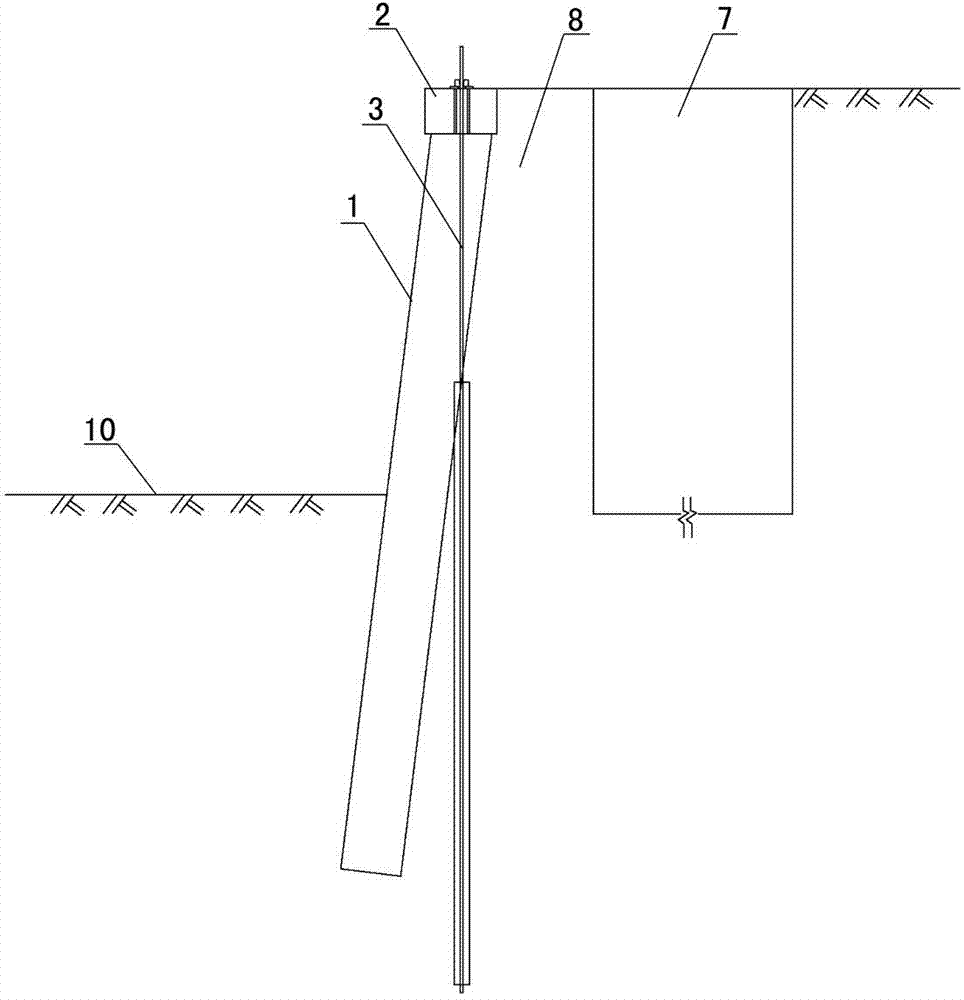

A flexible umbrella-shaped support bolt and its method for supporting soil slopes

ActiveCN104179178BIncrease anchoring forceConstruction quality is easy to ensureExcavationsBulkheads/pilesGeogridRock bolt

The invention relates to a flexible umbrella supporting anchor bolt and a method for supporting a soil slope thereby. An end ring and an end circular connector are fixedly disposed at one end of a round anchor bolt. A spring circular connector and a middle ring are fixedly disposed in the middle of the round anchor bolt. A lower circular connector adjacent to the right side of the middle ring movably sleeves the round anchor bolt. A drag umbrella surrounding the round anchor bolt comprises reacting plates evenly arranged, pull rods and compression springs. One end of a flexible pull rope is fixed to a round hole arranged in the other end of the round anchor bolt. More than one flexible umbrella supporting anchor bolt is connected with a soil high slope protective structure, composed of a geogrid mesh, a vegetation protective layer and a retaining wall, through the flexible pull ropes, and a whole for firmly and reliably anchoring and protecting the soil high slope is formed. The umbrella reacting plates are connected with the protective structural mesh through the flexible pull rope, anchoring force is greatly higher than that of a traditional anchor bolt, anchoring effect is more reliable, and engineering cost can be decreased by 50-60%.

Owner:NANCHANG INST OF TECH

Multi-sandwich building outer enclosure structure and manufacturing process thereof

PendingCN110792192ALight weightImprove bearing capacityWallsHeat proofingFoam concreteArchitectural engineering

The invention provides a multi-sandwich building outer enclosure structure. The multi-sandwich building outer enclosure structure comprises a fiber reinforced composite sandwich panel. Hanging nets are arranged on the two outer side faces of the fiber reinforced composite sandwich panel. An embedded part is arranged in the fiber reinforced composite sandwich panel. A fiber reinforced foam concreteprotection layer wraps the periphery of the fiber reinforced composite sandwich panel. The fiber reinforced composite sandwich panel is fixedly connected with the fiber reinforced foam concrete protection layer through connecting pieces. The connecting pieces penetrate the two outer side faces of the fiber reinforced composite sandwich panel and extends into the fiber reinforced foam concrete protection layer. The outer enclosure structure achieves the integration of structure stress, water proofing, airtightness, heat preservation, sound isolation, durability and the like and has the beneficial effects of light weight, high bearing capacity, good ductility and strong energy dissipation capability.

Owner:CHINA JINGYE ENG TECH CO LTD

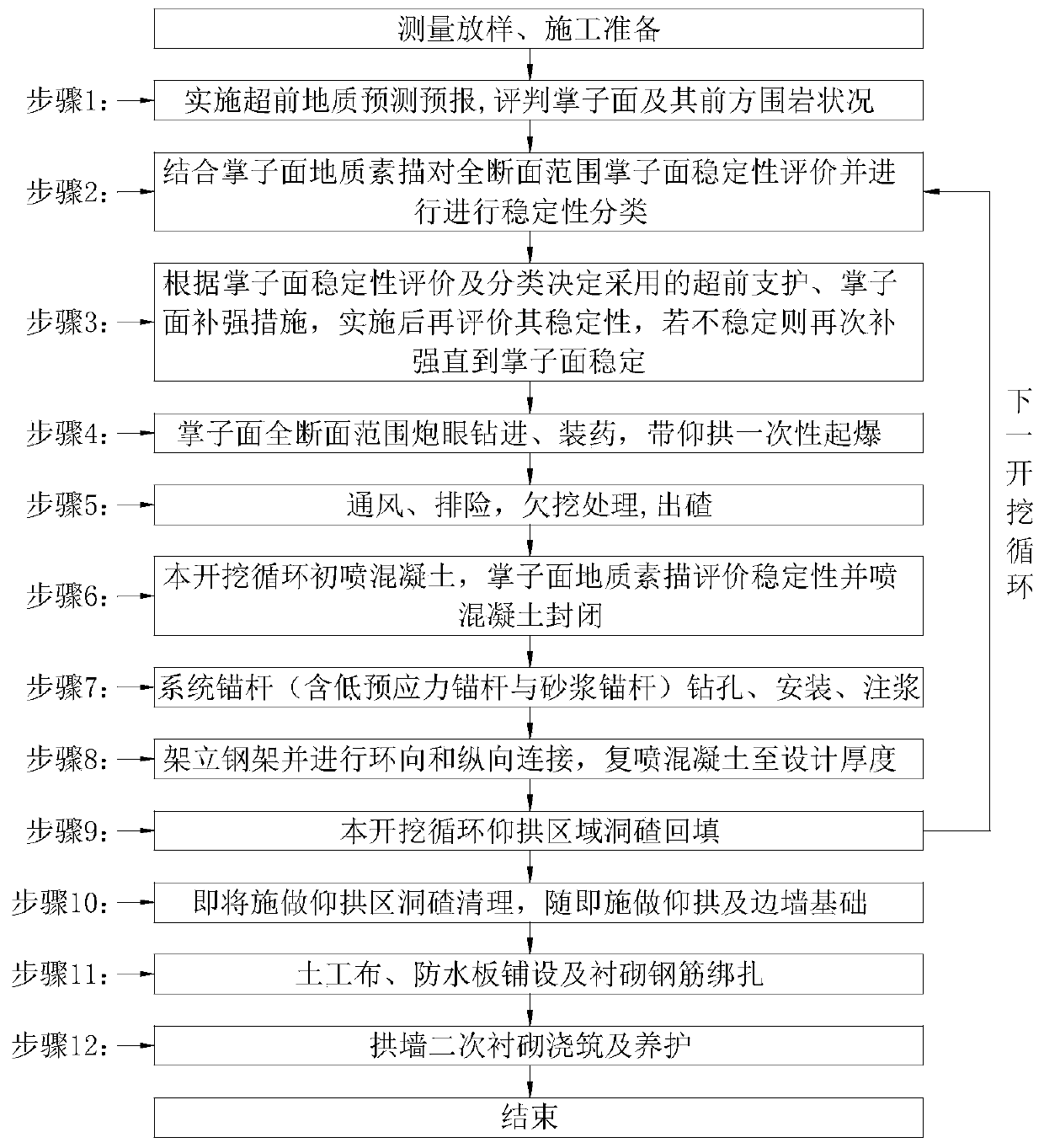

Full-circle excavation method suitable for ⅳ-Ⅴ grade surrounding rock of large-section tunnels

ActiveCN109209392BImprove securityReduce the number of disturbancesUnderground chambersBlastingDetonationRock cutting

The invention discloses a full-ring excavation method suitable for IV-V level of surrounding rocks of a large-section tunnel. Advanced geologic prediction is implemented, the tunnel face stability isevaluated and classified in the full section range; whether to implement advanced support and tunnel face reinforcement is decided, and corresponding concrete measures are taken till the tunnel face is stable; a drill jumbo drills blast holes and fill an explosive in the full section of the tunnel face, and detonation is carried out in one step; ventilation, danger removing, under-excavation handling and slag removing are carried out on the tunnel face; the tunnel face after cyclic excavation is sketched geologically, the stability of the tunnel face is determined, a wet spraying manipulator sprays an early high-strength concrete preliminarily, and the tunnel face is enclosed; a system anchor pole is constructed; an arc centering installation trolley erects a steel frame and implements annular and vertical connection, and concrete is sprayed again to reach a design thickness; an inverted arc area of a present excavation cycle is back filled with hole slag, and work of next cycle is carried out; a movable inverted arch trestle is used to pour the inverted arc and sidewall with basic concrete; earthwork cloths and waterproof boards are laid, and lining steel bars of an arch wall arelashed; and the lining of the arch wall is poured and maintained.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com