Concrete structure box, plate and joist combined beam

A technology for concrete structures and composite beams, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of uneconomical engineering, weak lateral torsional rigidity, and bulky appearance of beams, so as to improve the efficiency of cross-section use, durable and reliable appearance , The effect of saving engineering materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

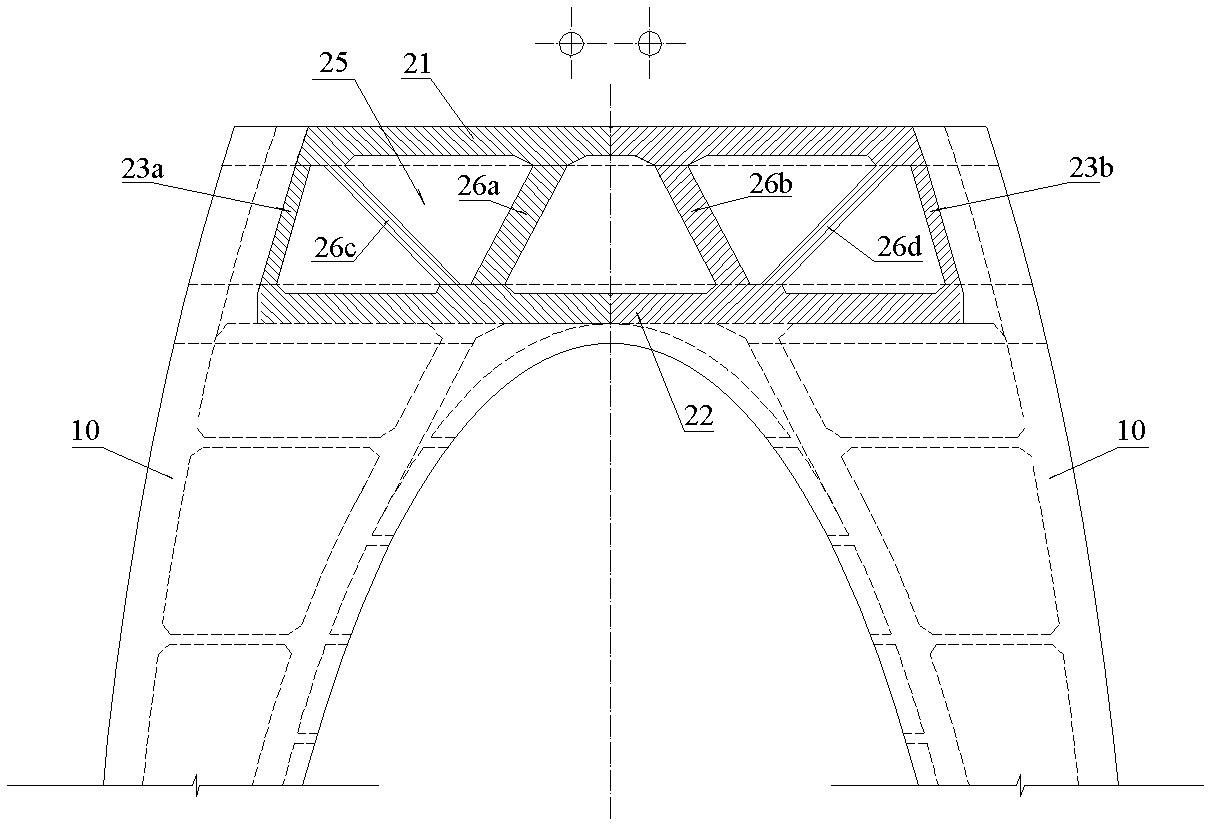

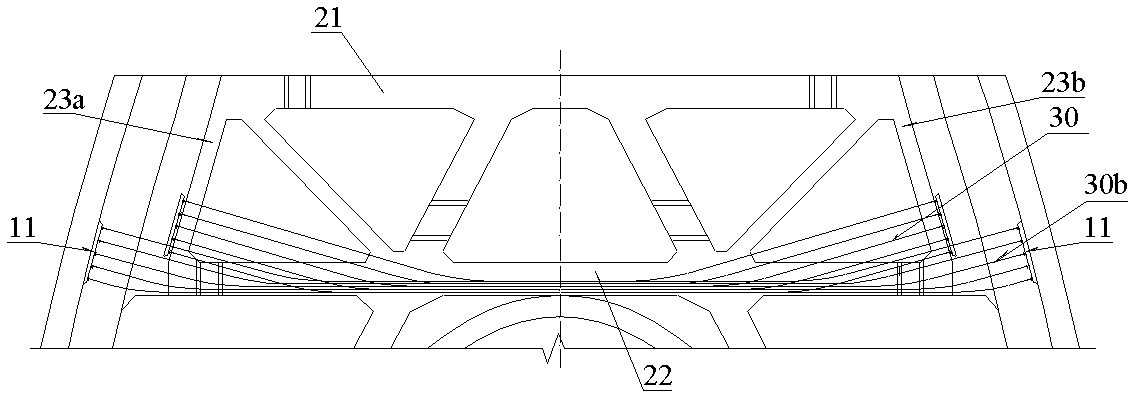

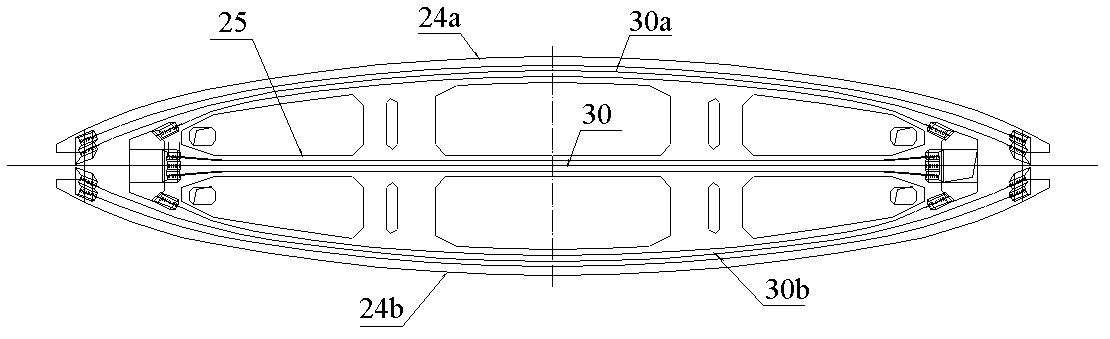

[0016] refer to figure 1 with image 3 , a concrete structure box slab truss composite beam, including a box-shaped beam integrated with the load-bearing body 10, the box-shaped beam includes a top plate 21, a bottom plate 22, two ends of the diaphragm 23a, 23b and two sides of the web 24a, 24b. The inner space of the box-shaped beam is provided with a middle web 25 and inclined transverse partitions arranged in pairs, and the inclined transverse diaphragm and the middle web 25, top plate 21, and bottom plate 22 form a truss, wherein the middle web 25 is connected with the top plate 21 and the bottom plate 22 It is consolidated with the transverse diaphragms 23a and 23b at both ends, and the inclined transverse diaphragm is consolidated with the top plate 21, the bottom plate 22, the middle web 25 and the webs 24a and 24b on both sides.

[0017] refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com