Combined type foundation pit supporting pile structure

A foundation pit support and combined technology, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as poor economic benefits and poor water-stopping effect, and achieve the effect of saving construction space, economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

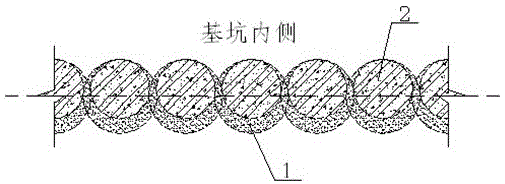

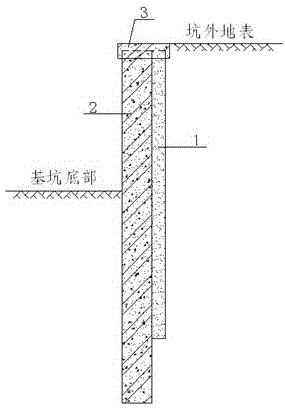

[0026] Embodiment 1: as figure 1 , 2 As shown in , 3, a combined foundation pit support pile structure is composed of a high-pressure jet grouting pile 1, a bored cast-in-situ pile 2 and a crown beam 3. The interlocking large-diameter high-pressure rotary grouting piles 1 are used as the water-proof curtain of the foundation pit, and the bored piles 2 are used as the foundation pit support and protection piles. After the quality of the pile 1 is basically stable, the construction of the bored pile 2 with a smaller diameter is carried out again at the same pile position, and the construction of the bored pile 2 is ensured on the premise that the occlusal part of the adjacent high-pressure jet grouting pile 1 is not occupied Next, inscribe the high-pressure jet grouting pile 1 on the side close to the foundation pit, and finally construct the crown beam 3 at the top of the pile, so as to jointly achieve the purpose of supporting the foundation pit and stopping water. High-pres...

Embodiment 2

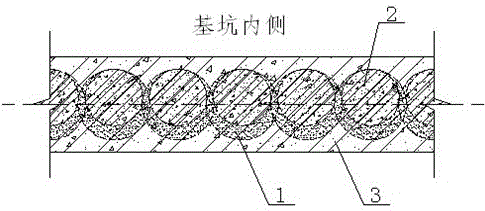

[0027] Embodiment 2: as figure 1 , 4 As shown in , 5, a combined foundation pit supporting pile structure is composed of high-pressure jet grouting pile 1, bored cast-in-place pile 2 and crown beam 3. The interlocking large-diameter high-pressure rotary grouting piles 1 are used as the water-proof curtain of the foundation pit, and the bored piles 2 are used as the foundation pit support and protection piles. After the quality of the pile 1 is basically stable, the construction of the bored pile 2 with a smaller diameter is carried out again at the same pile position, and the construction of the bored pile 2 is ensured on the premise that the occlusal part of the adjacent high-pressure jet grouting pile 1 is not occupied Next, inscribe the high-pressure jet grouting pile 1 on the side close to the foundation pit, and finally construct the crown beam 3 at the top of the pile, so as to jointly achieve the purpose of supporting the foundation pit and stopping water. The high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com