Deepwater Drilling Tube Support Device While Drilling and Design Method of Running Parameters

A support device and deep-water drilling technology, applied in drilling equipment, support devices, earthwork drilling and production, etc., can solve problems such as conduit inclination, mud line backing plate erosion, unfavorable cementing and drilling operations, etc., to reduce end resistance, The effect of improving bending moment resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated:

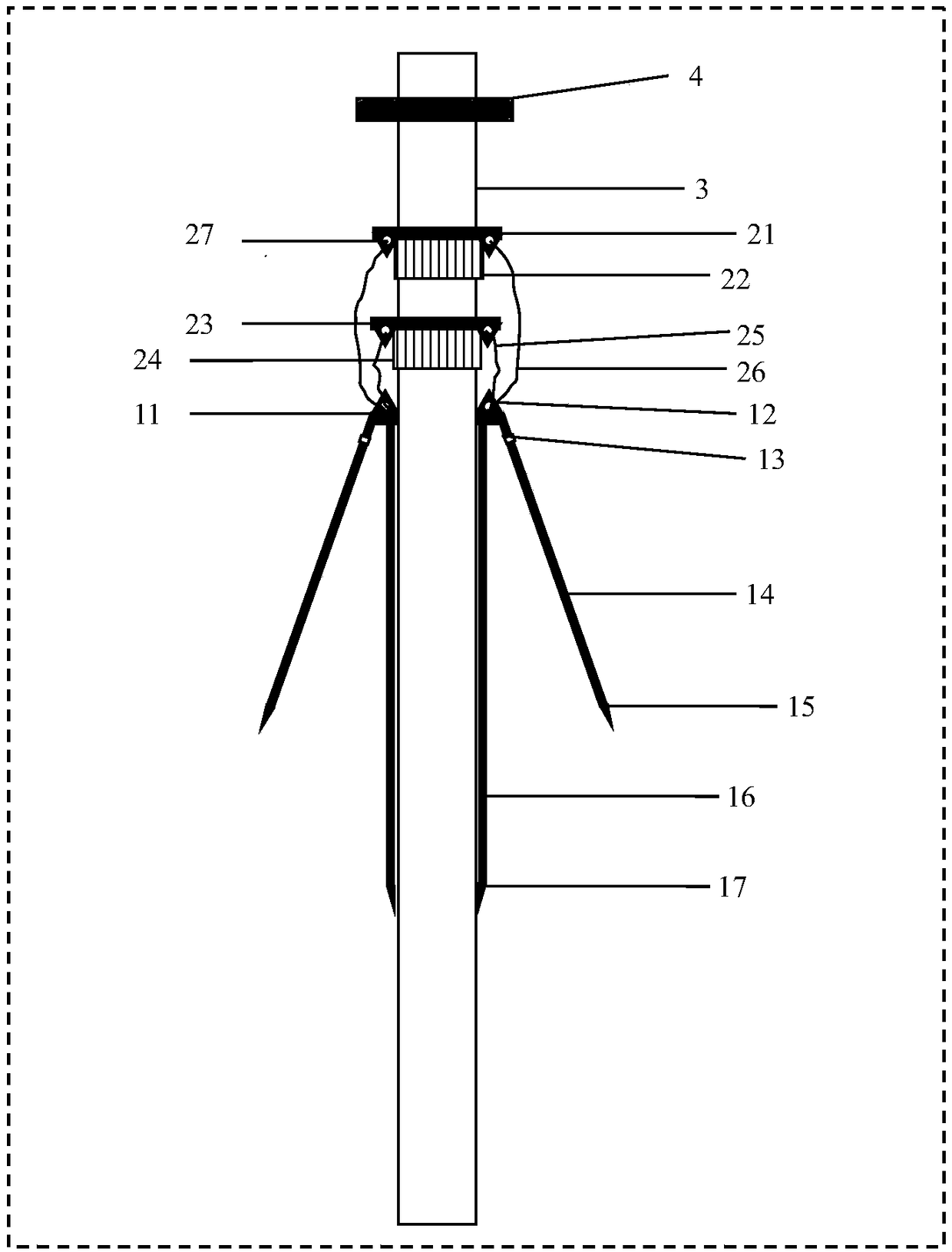

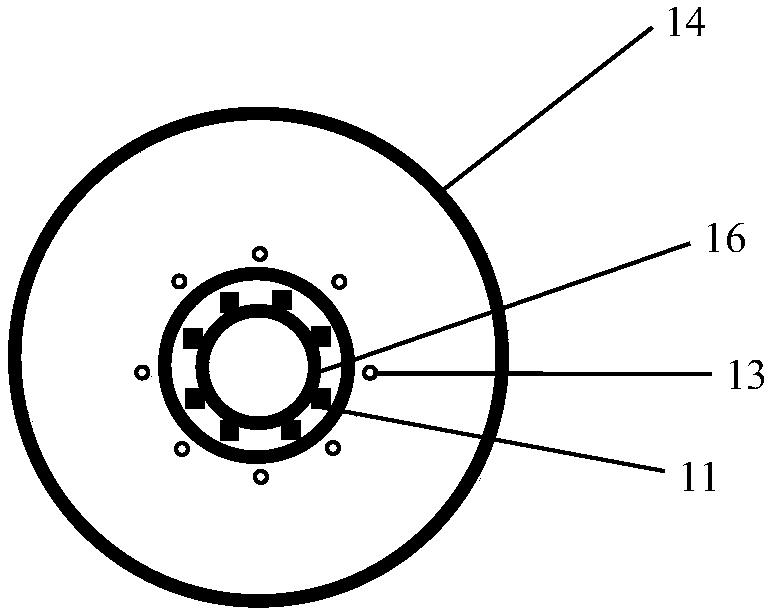

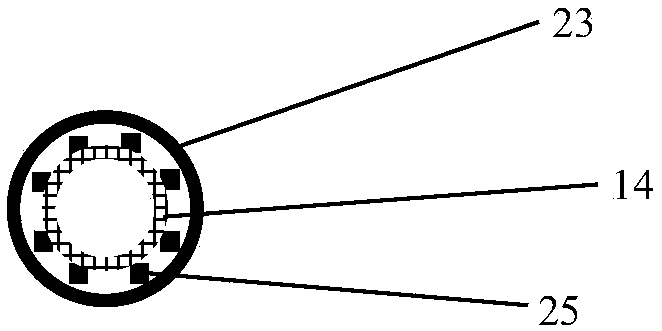

[0048] see figure 1 , figure 2 with image 3 , The deepwater drilling pipe support device while drilling includes a support assembly while drilling, a suspension assembly and a support plate 4 .

[0049] The support assembly while drilling is further divided into three parts, one part is the straight wall inner cylinder 16 in contact with the conduit, the other part is the inclined wall outer cylinder 14 with drainage holes 13 on the upper part, and the other part is the upper connection between the inner cylinder and the outer cylinder. top plate11. Most of the inner cylinder and the outer cylinder go deep into the soft soil below the seabed mud line to support the conduit and the weight attached to the conduit. The connecting top plate 11 is a thickened structure, one function is to connect the inner and outer cylinders, and the other function is to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com