Foundation pit supporting structure

A technology for supporting structures and foundation pits, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems that foundation pit support structures cannot be applied to large-span foundation pits, etc., to save engineering materials and time, improve stability, and be universal sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

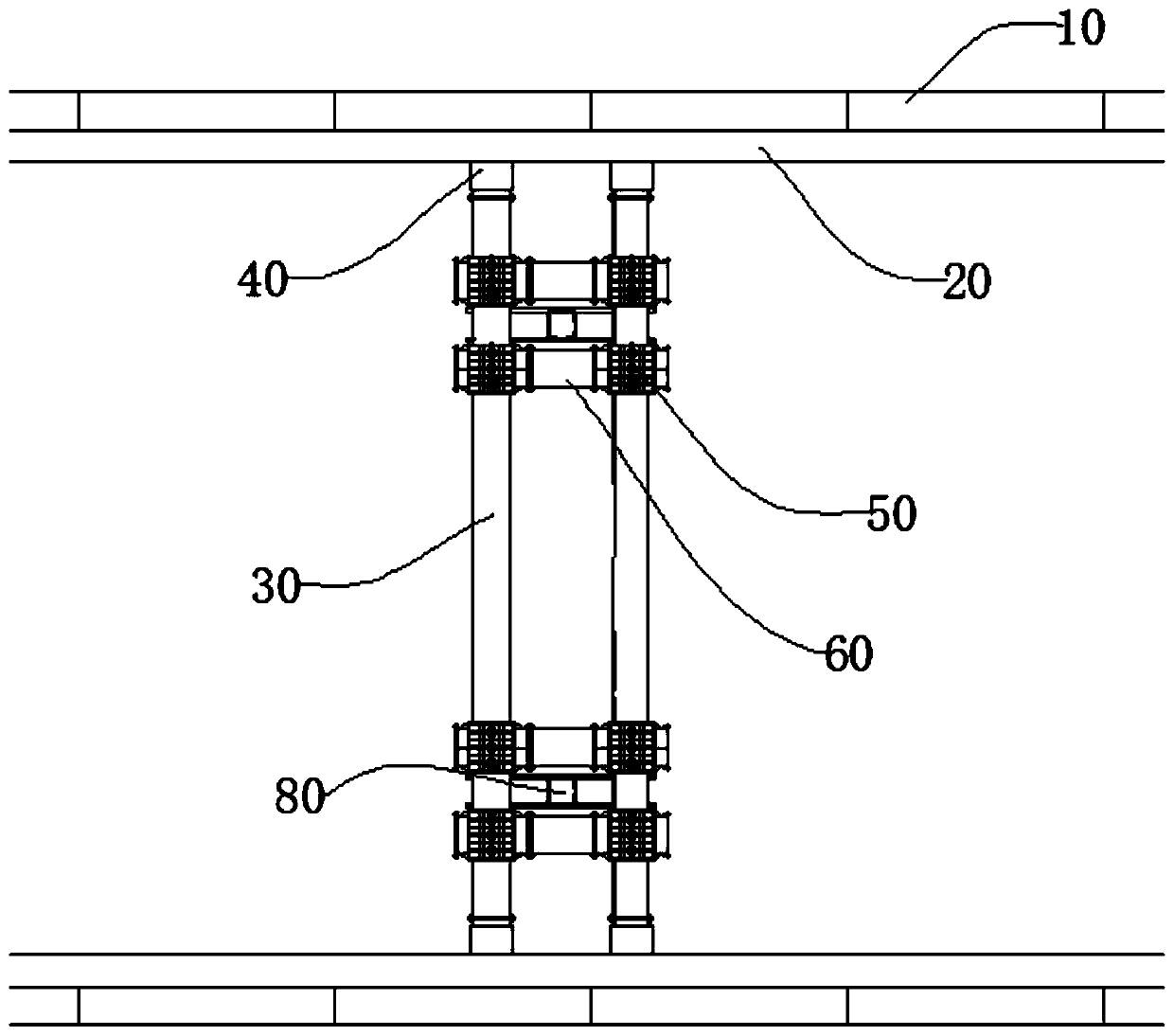

[0026] figure 1 For the schematic diagram of the foundation pit support structure provided by Embodiment 1 of the present invention, refer to figure 1 , The supporting structure of the foundation pit in this embodiment includes a steel purlin 20 , a supporting steel pipe 30 , an oil cylinder 40 , a movable cross 50 , a first connecting rod 60 and a bottom fixing member 80 . Two steel purlins 20 are respectively erected on two opposite side walls 10 of the foundation pit for fixing the side walls 10 of the foundation pit; one end of the oil cylinder 40 is fixed on the steel purlins 20, and the other end is fixed on the supporting steel pipe 30, A support steel pipe 30 and two oil cylinders 40 form a support group, the active cross 50 is set on the support steel pipe 30, and the first connecting steel pipe 60 is used to connect the two active cross 50 with flanges to realize the connection between the two support groups. Two bottom fixing parts 80 are fixed on the bottom of the...

Embodiment 2

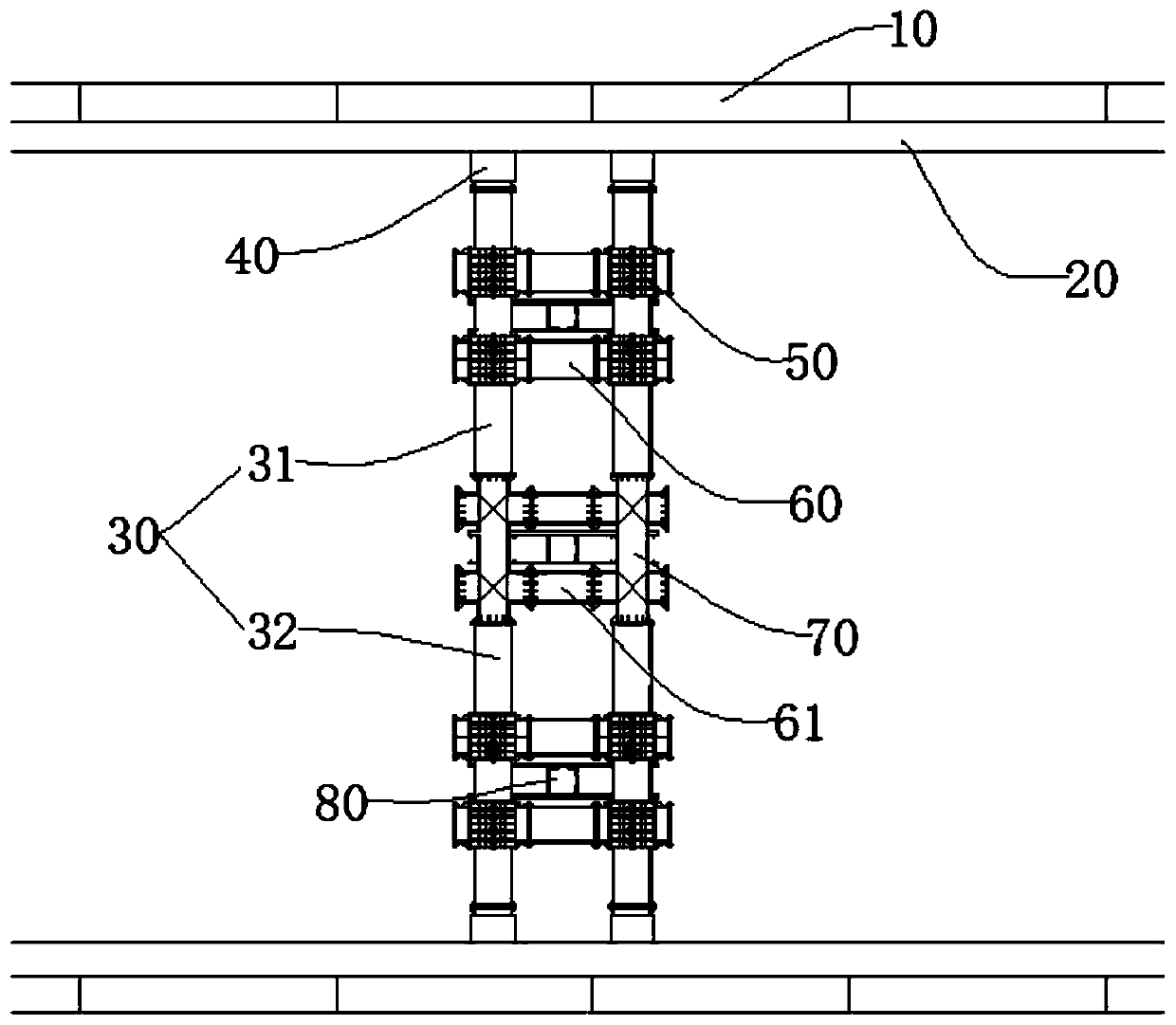

[0030] figure 2 For the schematic diagram of the foundation pit support structure provided by Embodiment 2 of the present invention, refer to figure 2 , the foundation pit supporting structure of the present embodiment comprises steel purlin 20, supporting steel pipe 30, oil cylinder 40, active four-way 50, first connecting rod 60, second connecting steel pipe 61, fixed six-way 70 and bottom fixing piece 80, supports The steel pipe 30 is divided into two sections, namely a first supporting steel pipe 31 and a second supporting steel pipe 32 . Two steel purlins 20 are respectively erected on two opposite side walls 10 of the foundation pit for fixing the side walls 10 of the foundation pit; one end of the oil cylinder 40 is fixed on the steel purlins 20, and the other end is fixed on the first supporting steel pipe 31 One end of the second supporting steel pipe 32, the other end of the first supporting steel pipe 31 and the other end of the second supporting steel pipe 32 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com