System for alternatively supporting whole lifting steel platform formwork by steel column casing rack and construction method

An overall climbing and steel platform technology, applied in the direction of building structure support, building structure support, formwork/formwork/working frame, etc., can solve the problems of large steel column support consumption, high construction cost, and unfavorable material saving, etc., to achieve The effect of saving engineering materials and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

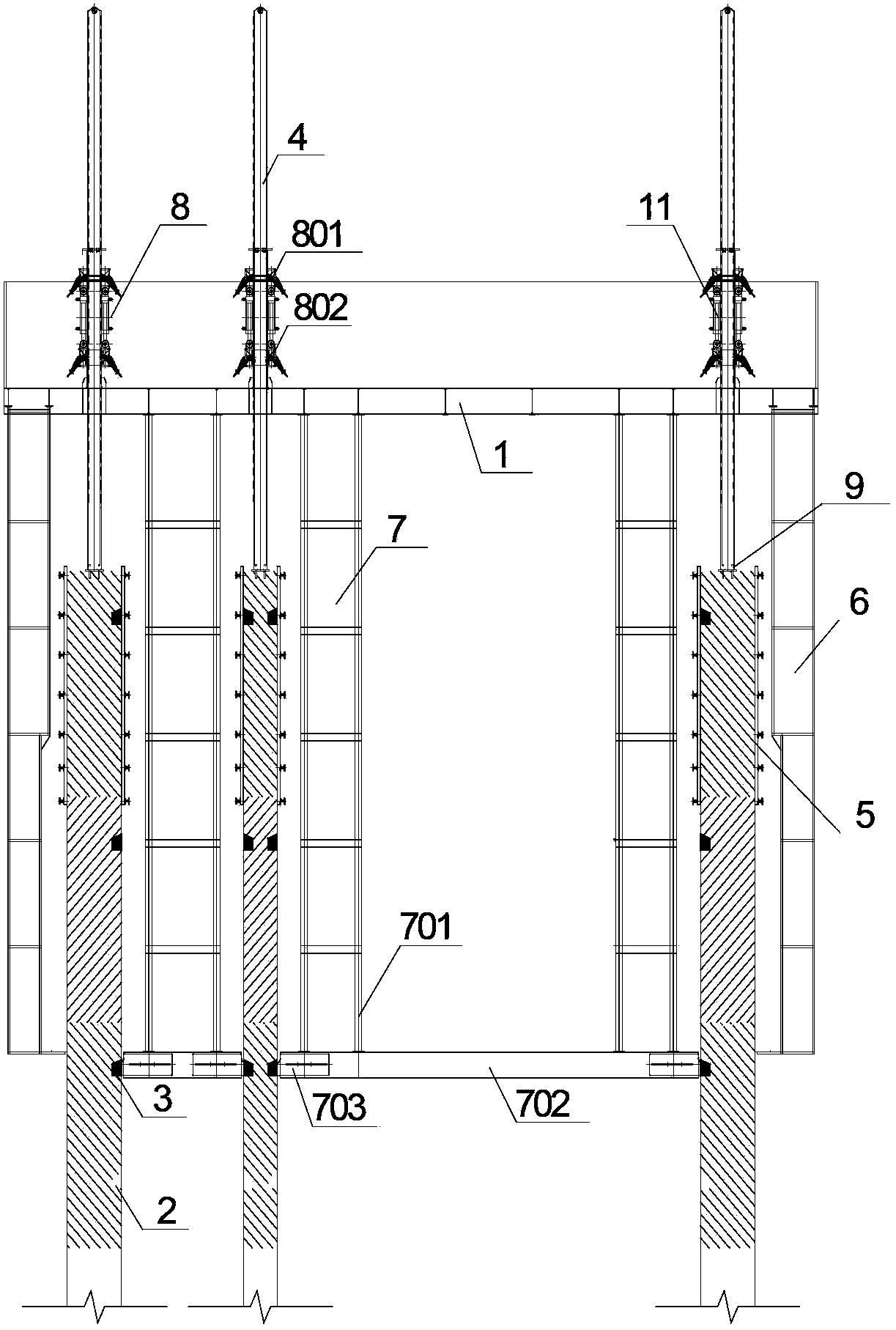

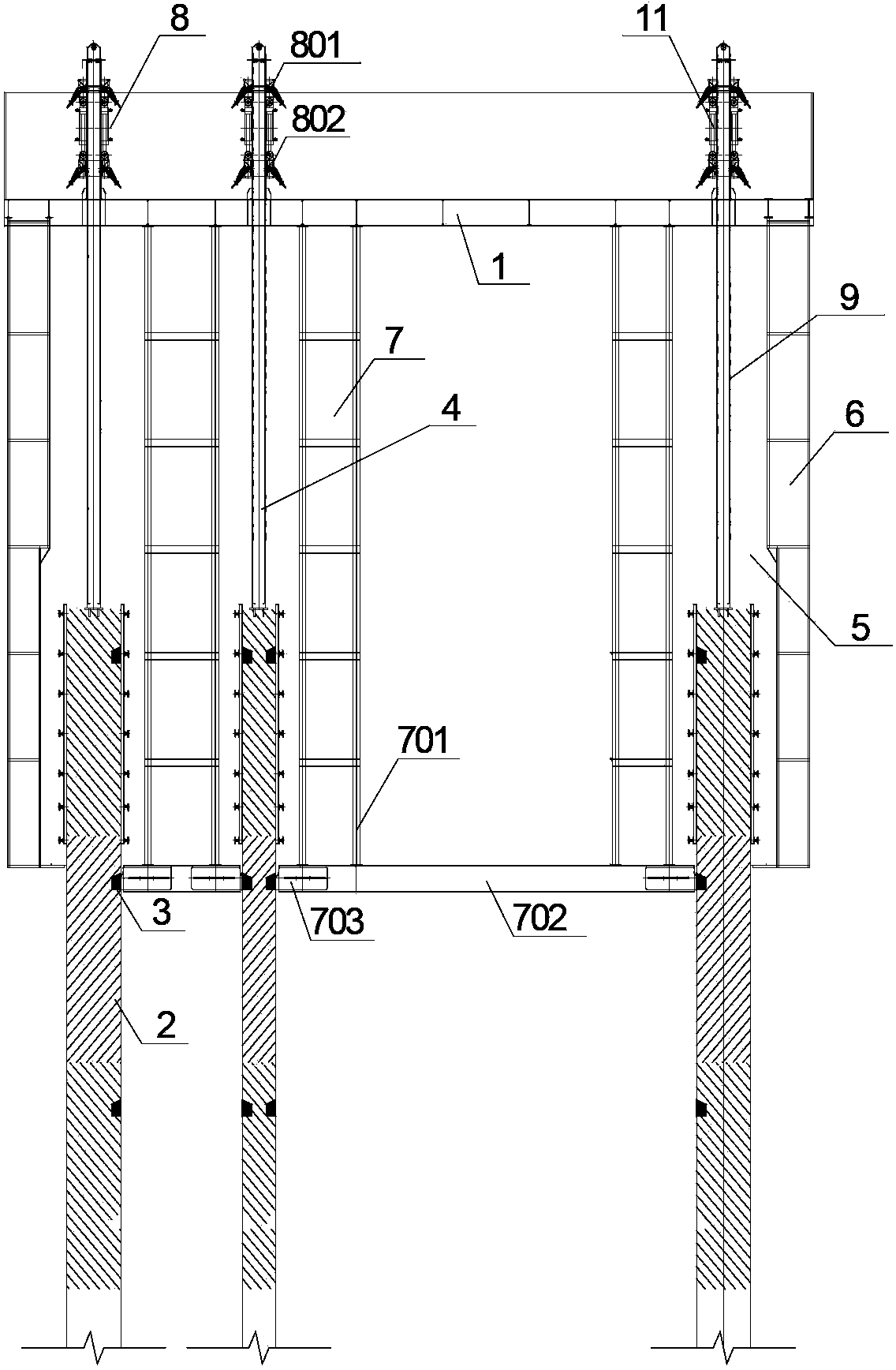

[0032] Specific embodiments, such as a super high-rise building with a height of 319m, a core tube area of 322m2 in the shape of a square, and a standard storey height of 4.5m. If the traditional steel column-supported steel platform formwork system is used, 15 steel columns with a length of 300m are required to be supported, and these steel columns must be buried in the concrete structure, which cannot be recycled, and the construction cost is relatively high.

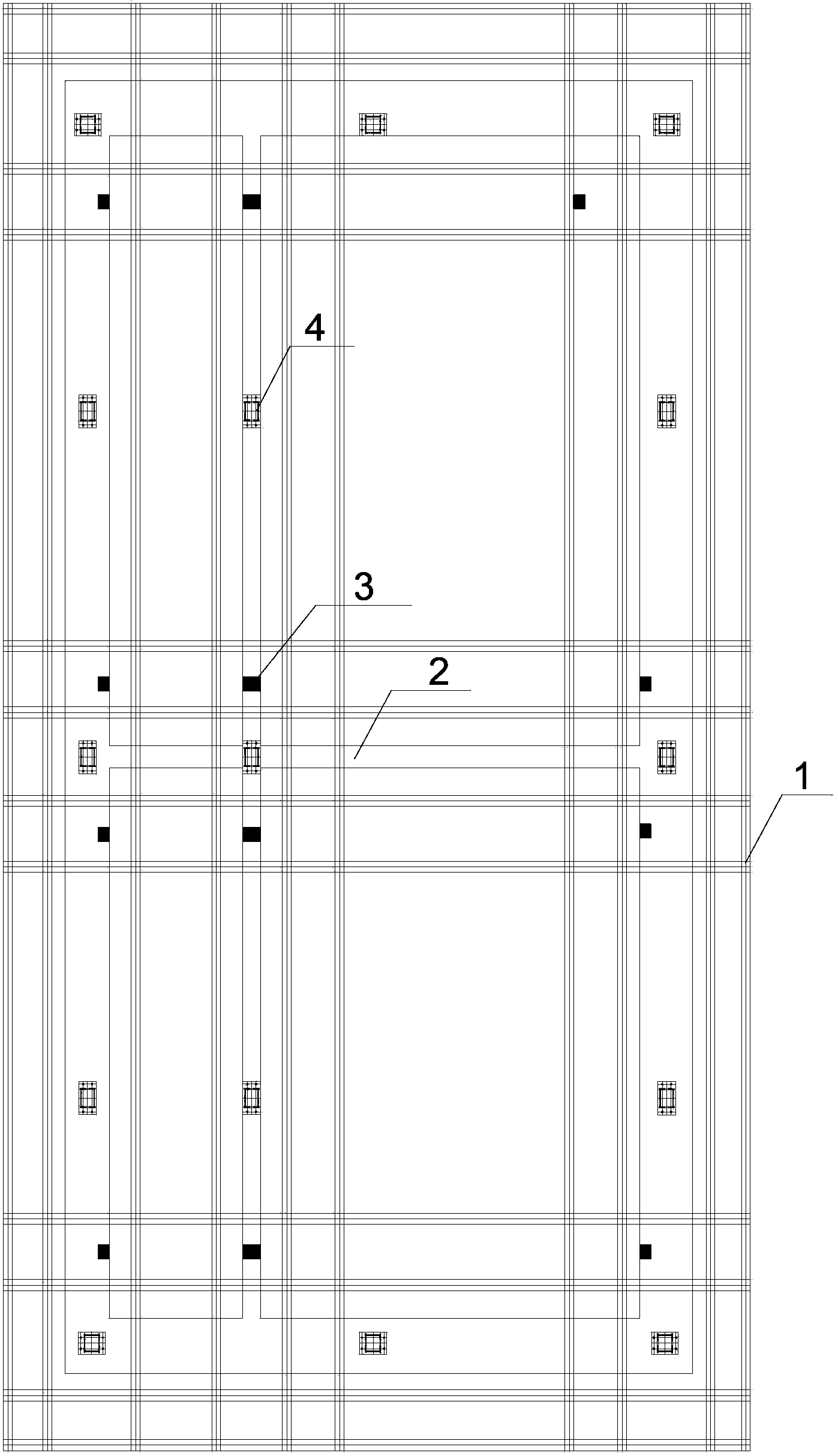

[0033] In order to save construction costs, the steel column frame of the present invention is used to alternately support the overall climbing steel platform formwork system for construction, such as Figure 1~6 As shown, the steel column frame of the present invention alternately supports the overall climbing steel platform formwork system, which includes a steel platform 1, a for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com