Multi-sandwich building outer enclosure structure and manufacturing process thereof

A technology of enclosure structure and manufacturing process, applied in building structures, building components, buildings, etc., can solve the problems of cumbersome construction process and low level of integration, and achieve the effect of simplifying construction procedures, saving engineering materials, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

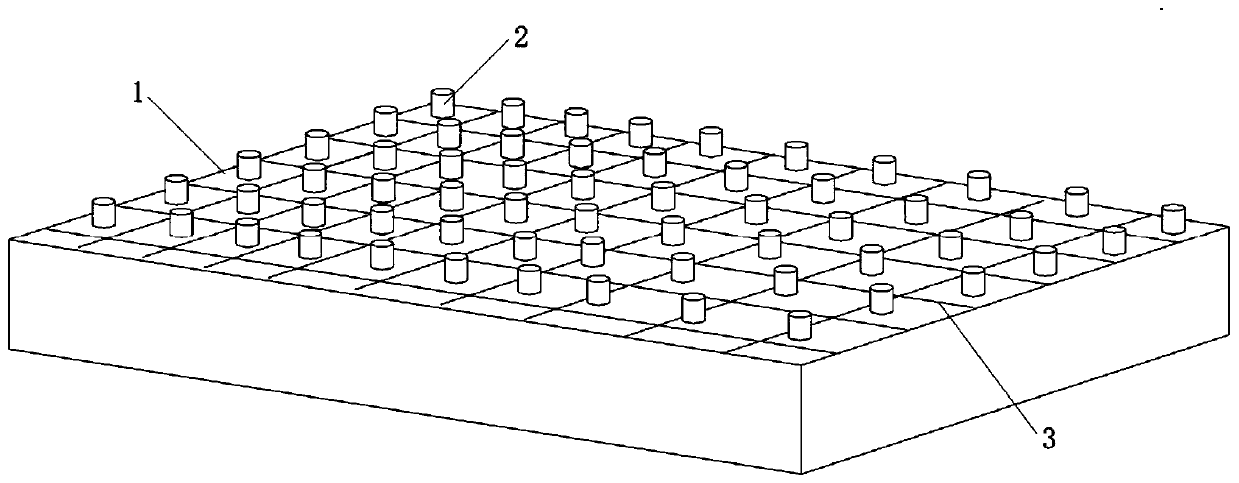

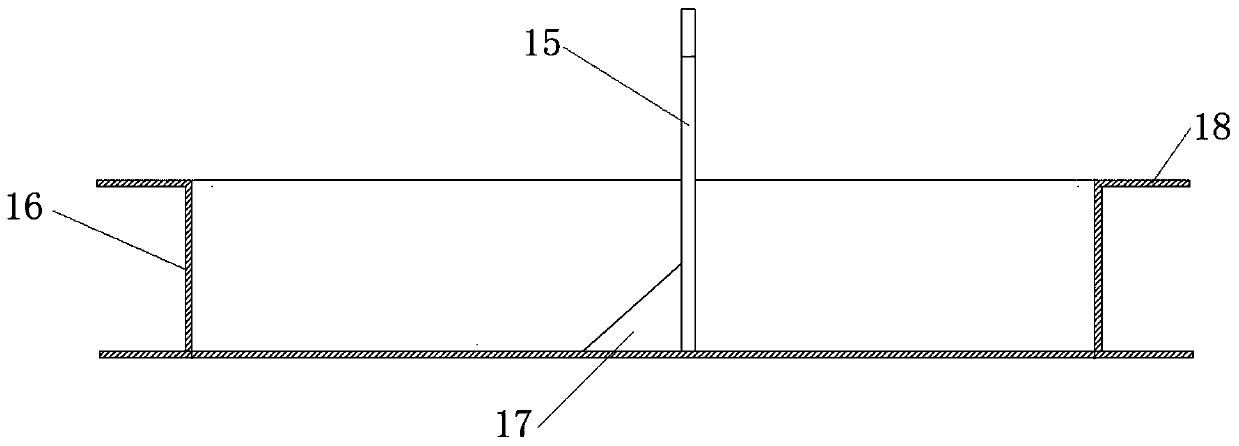

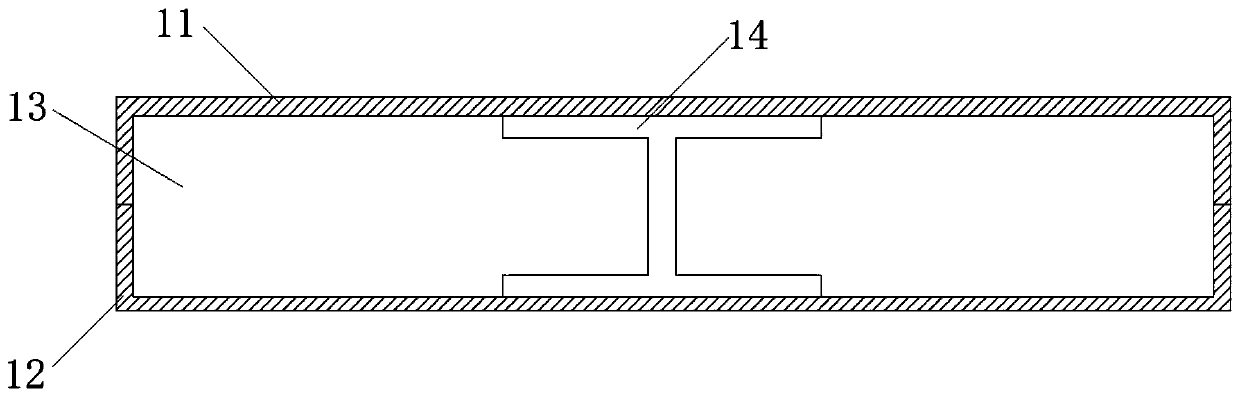

[0030] This embodiment provides a kind of multiple sandwich building outer envelope structure, such as figure 1 As shown, the building envelope structure includes a fiber reinforced composite sandwich panel 1, hanging nets 3 are arranged on the two outer surfaces of the fiber reinforced composite sandwich panel 1, and the fiber reinforced composite material The interior of the sandwich panel 1 is provided with embedded parts, such as figure 2As shown, in this embodiment, the embedded part includes an enclosure surrounded by side plates 16, a backing plate is provided at one end opening of the enclosure, and an installation key 15 is arranged in the enclosure, and the installation key 15 Fixedly installed on the backing plate and extending out of the encirclement, when the embedded part is placed in the fiber-reinforced composite sandwich panel, the installation key 15 is set through the fiber layer above it at the same time . The enclosure is filled with dense material, and...

Embodiment 2

[0040] This embodiment provides a kind of multiple sandwich building outer covering structure, such as figure 1 As shown, the building envelope structure includes a fiber reinforced composite sandwich panel 1, hanging nets 3 are arranged on the two outer surfaces of the fiber reinforced composite sandwich panel 1, and the fiber reinforced composite material The interior of the sandwich panel 1 is provided with embedded parts, such as figure 2 As shown, in this embodiment, the embedded part includes an enclosure surrounded by side plates 16, a backing plate is provided at one end opening of the enclosure, and an installation key 15 is arranged in the enclosure, and the installation key 15 Fixedly installed on the backing plate and extending out of the enclosure, the enclosure is filled with dense material, the dense material is a fiber-reinforced resin-based composite material, in this embodiment, between the installation key 15 and the enclosure A triangular support plate 17...

Embodiment 3

[0049] This embodiment provides a kind of multiple sandwich building outer covering structure, such as figure 1 As shown, the building envelope structure includes a fiber reinforced composite sandwich panel 1, hanging nets 3 are arranged on the two outer surfaces of the fiber reinforced composite sandwich panel 1, and the fiber reinforced composite material The interior of the sandwich panel 1 is provided with embedded parts, such as figure 2 As shown, in this embodiment, the embedded part includes an enclosure surrounded by side plates 16, a backing plate is provided at one end opening of the enclosure, and an installation key 15 is arranged in the enclosure, and the installation key 15 Fixedly installed on the backing plate and extending out of the enclosure, the enclosure is filled with dense material, the dense material is a fiber-reinforced resin-based composite material, in this embodiment, between the installation key 15 and the enclosure A triangular support plate 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com