A connection structure and connection method between retaining piles and main beams of underground structures

An underground structure and connection structure technology, applied in the field of connection between enclosure piles and the main beam of the structure, can solve the problems that the advantages are not exerted, the bending moment of the main structure cannot be borne, and the contribution of the rigidity of the enclosure piles is not large, etc. Anti-buoyancy and shock resistance, reduced thickness, and the effect of saving engineering materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

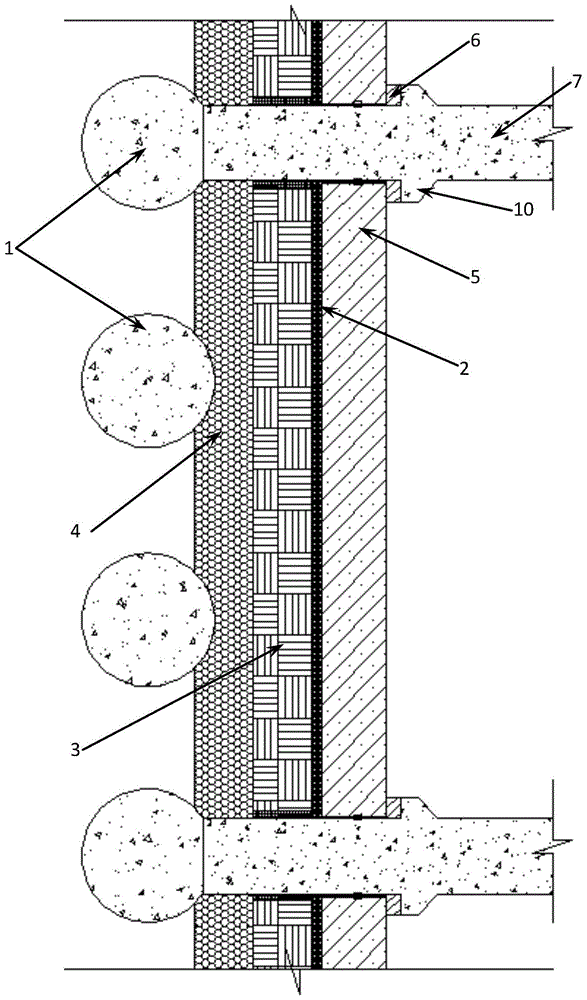

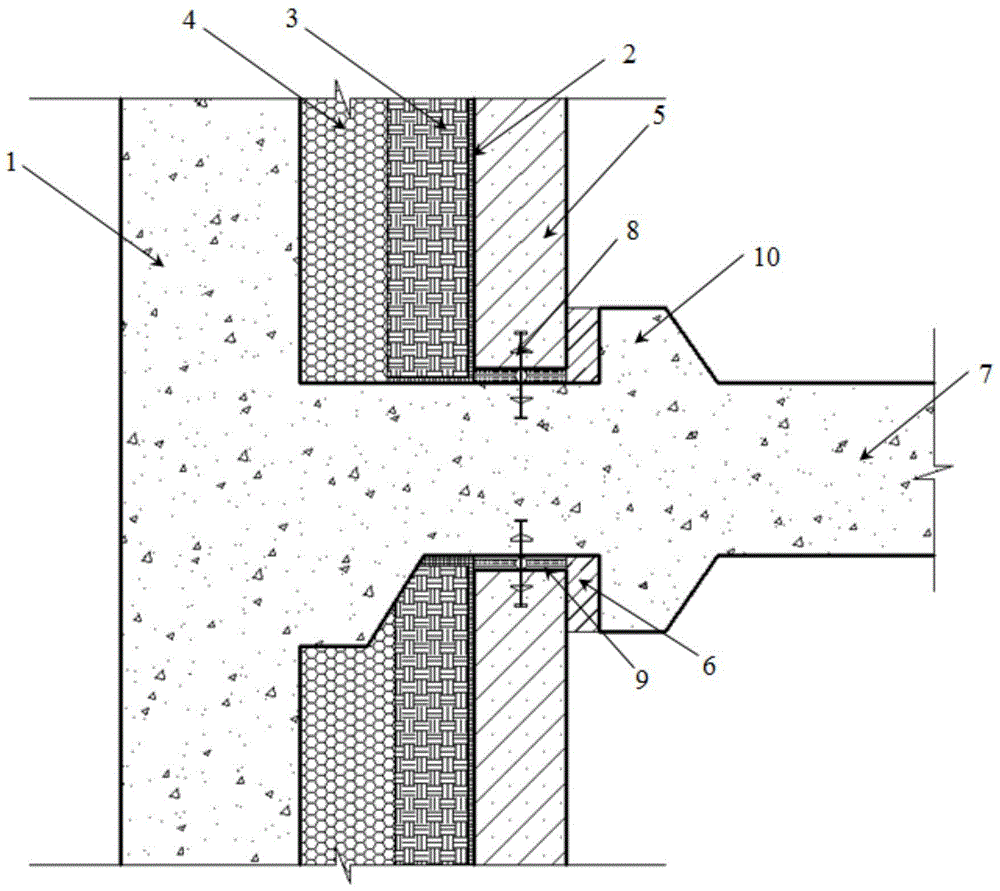

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

[0031] Such as figure 1 , 2 Shown, a kind of connection structure of enclosure pile and underground structure main beam, comprises enclosure pile 1 and underground structure main beam 7, and described underground structure main beam passes basement exterior wall 5 and is connected on the enclosure pile, in There is a circle of corbels 10 on the main beam, waterproof roll material 2 is laid on the outer side of the basement outer wall, and polystyrene board protective material 3 is laid on the outer side of the waterproof layer, and then the gap between the outer basement outer wall and the retaining pile is closed. Backfill densely. Adopting this structure can make the rigid connection between the retaining pile and the beam of the main structure, bear the load and bending moment of the main structure, and make the stress of the underground structure more reasonable.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com