Through hole type microcellular foam aluminum sheet with 0.07 to 0.3mm aperture and preparation method

A technology of microcellular foam and aluminum plate, applied in the field of materials, can solve the problems of particle bonding, agglomeration, inability to produce, etc., and achieve the effect of high yield, improved strength and saving engineering materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

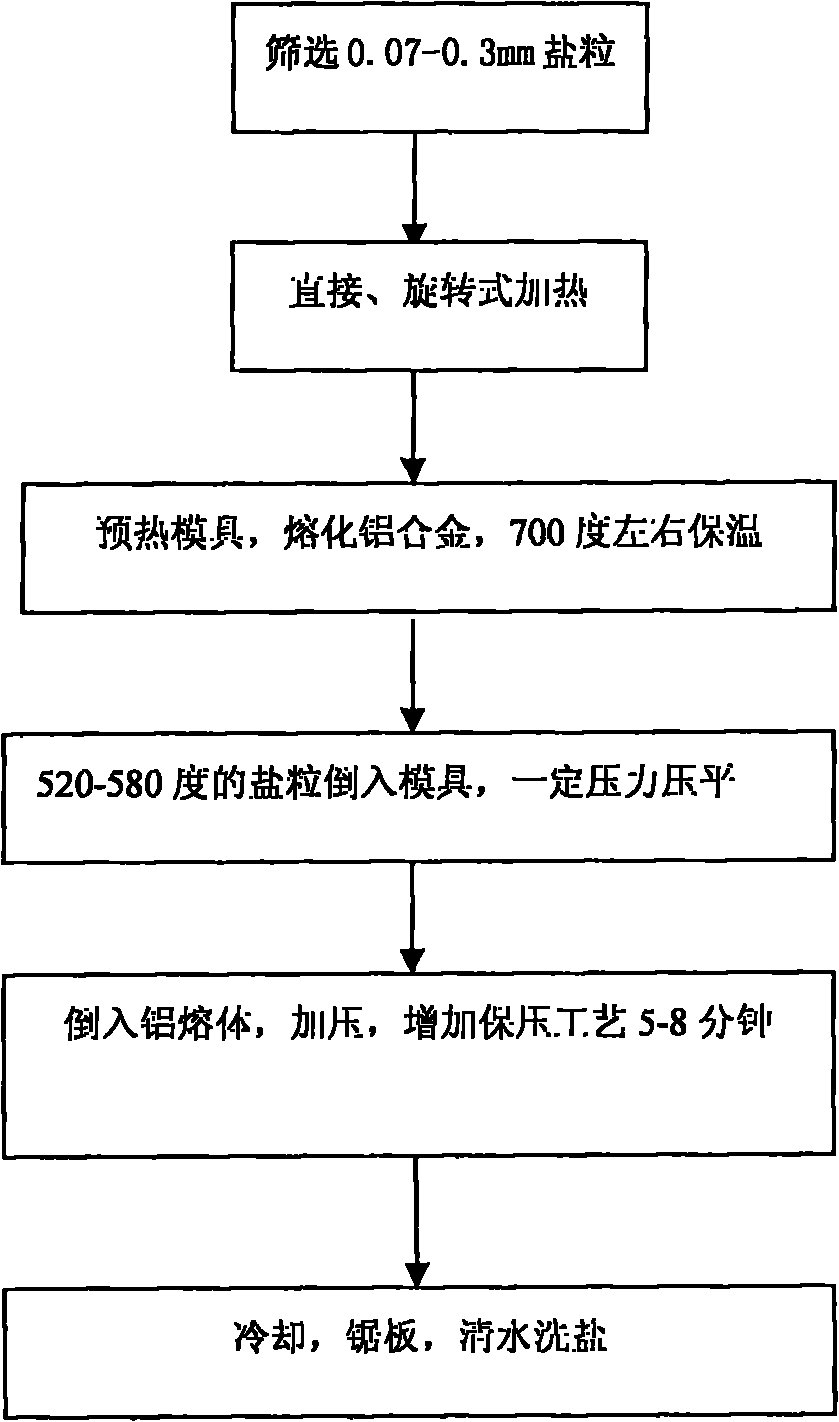

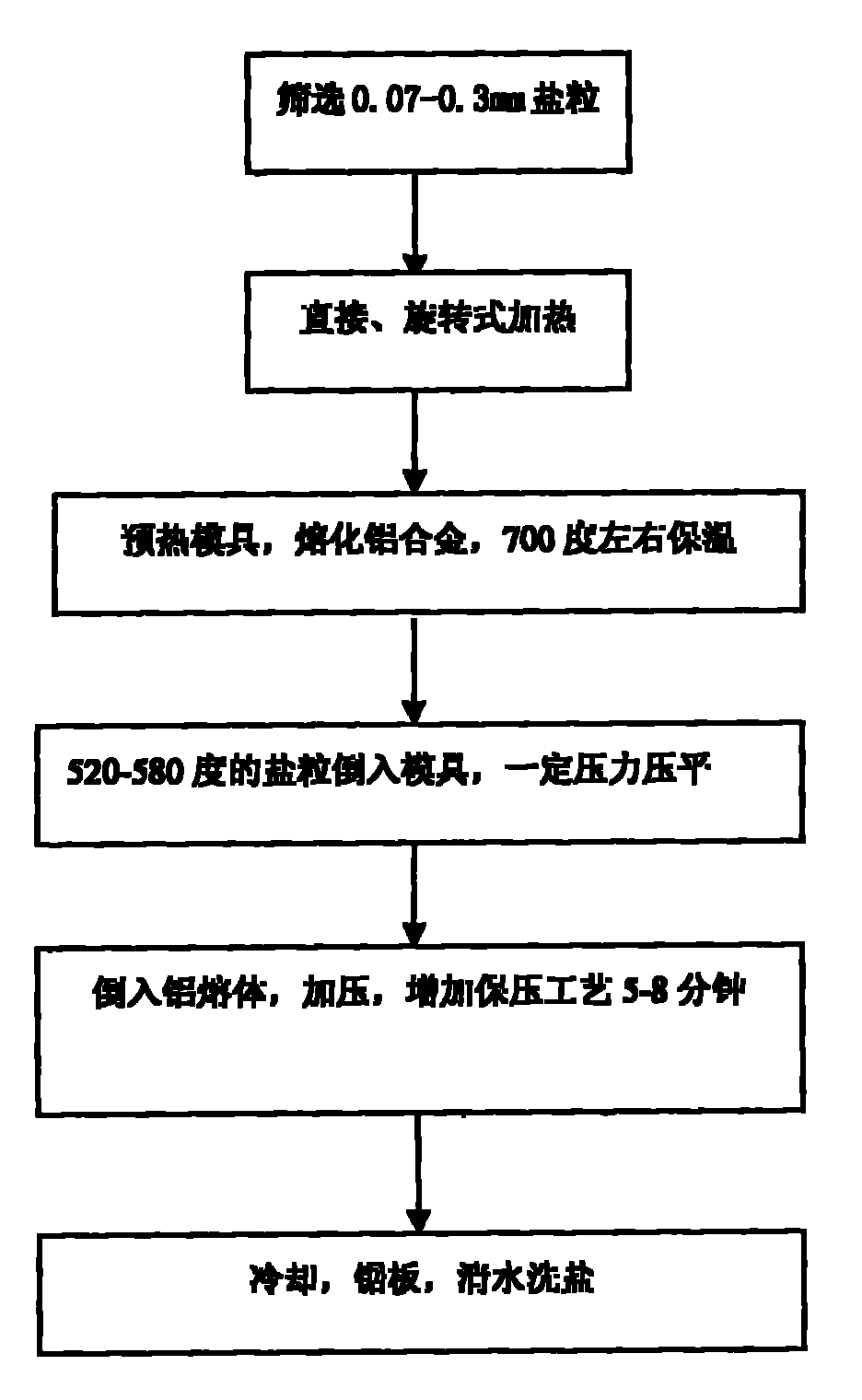

[0016] The concrete implementation of preparation method of the present invention is described below in conjunction with accompanying drawing:

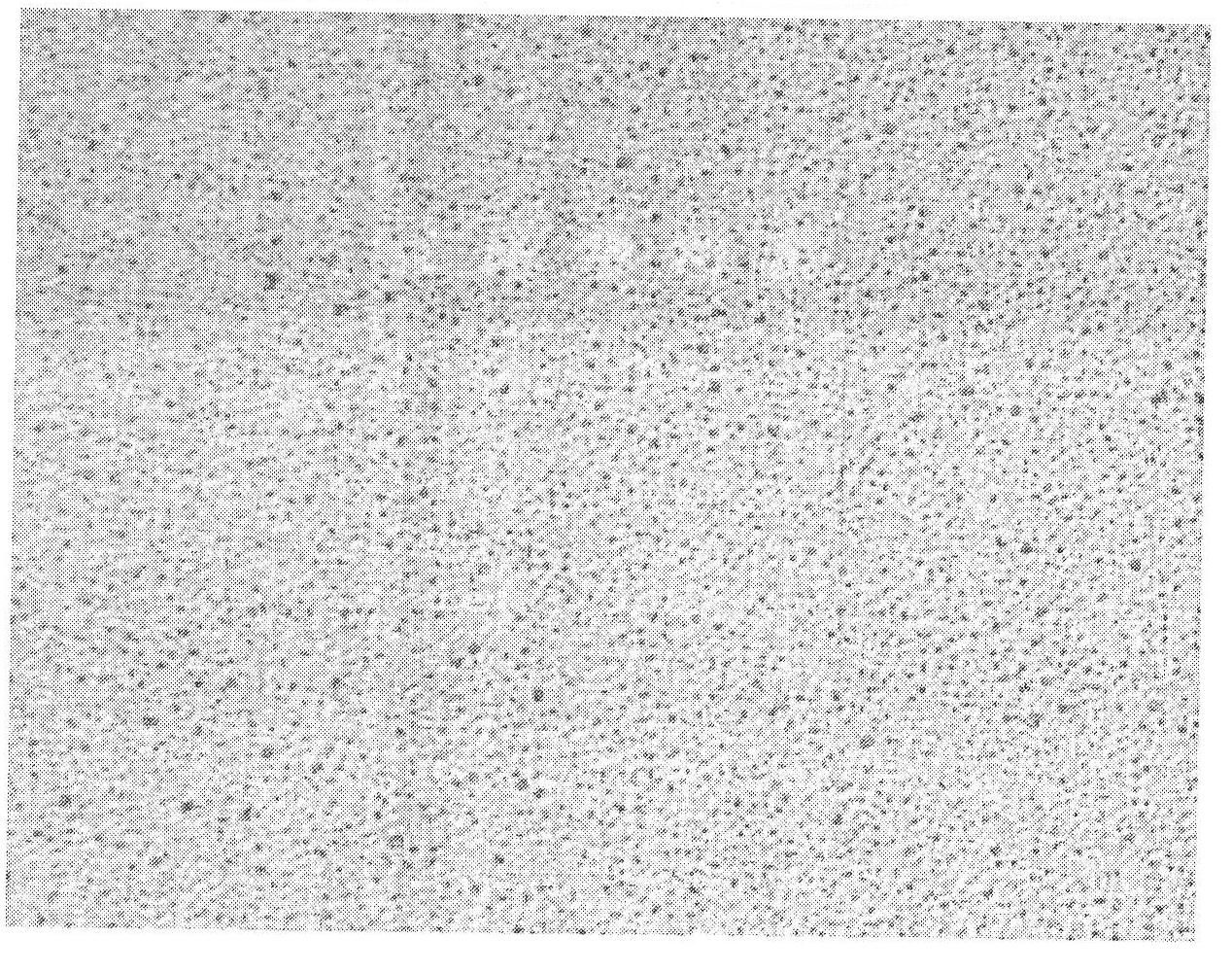

[0017] 1: Screen the salt grains with the required pore size (diameter 0.07-0.3 mm), such as figure 1 first step;

[0018] 2: Direct heating, using a rotary heating device, rotating while heating, and stirring with a stirrer at the same time, so that the salt particles are in full contact with the hot air, exchanging heat, so that the salt particles do not stick or agglomerate, and the temperature of the salt is heated to 520- between 580 degrees, such as figure 1 second step;

[0019] 3: At the same time, preheat the mold above 200 degrees. Heat aluminum alloy (various aluminum alloys) to over 700 degrees to keep warm, such as figure 1 third step;

[0020] 4: Pour a certain amount of salt particles that have reached the temperature into the mold quickly, and press the initial pressure at about 10KG / square centimeter to flatten; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com