Patents

Literature

174results about How to "Won't burst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-fingerprint TPU protective film for 3D curved screen and preparation method of anti-fingerprint TPU protective film

PendingCN111484810AGood optical performanceImprove smoothnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterColloidal silica

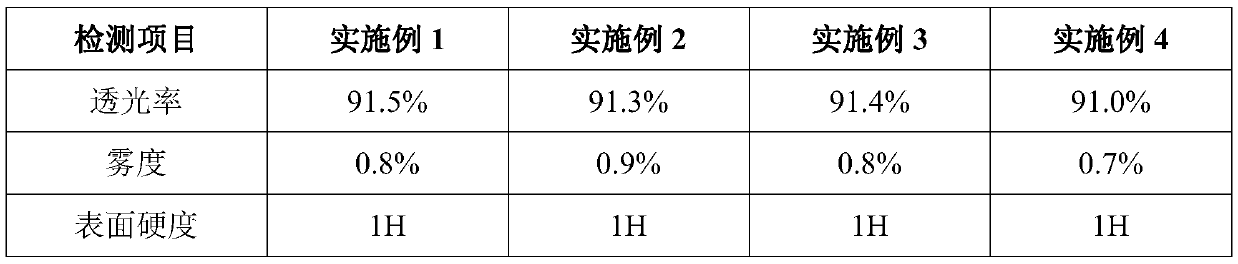

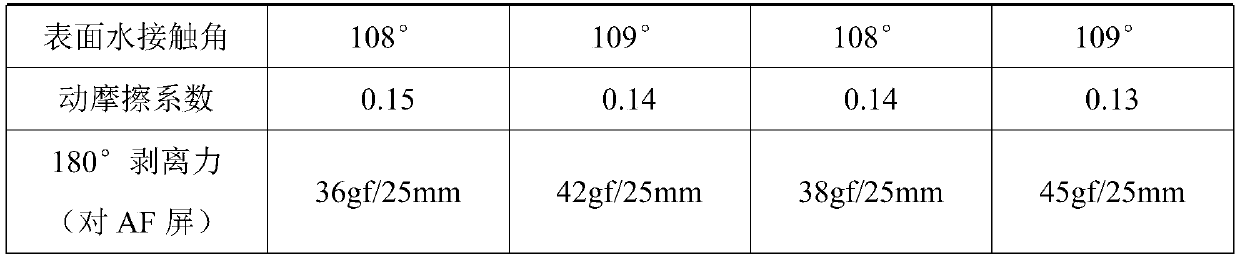

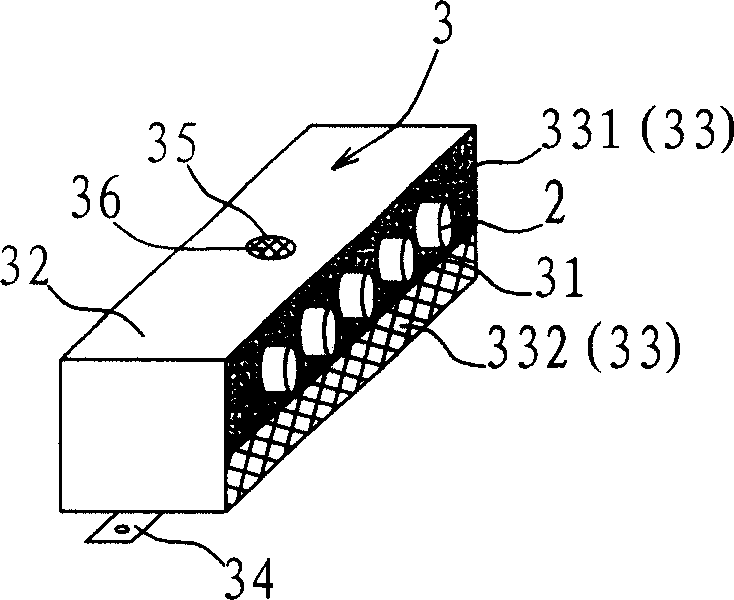

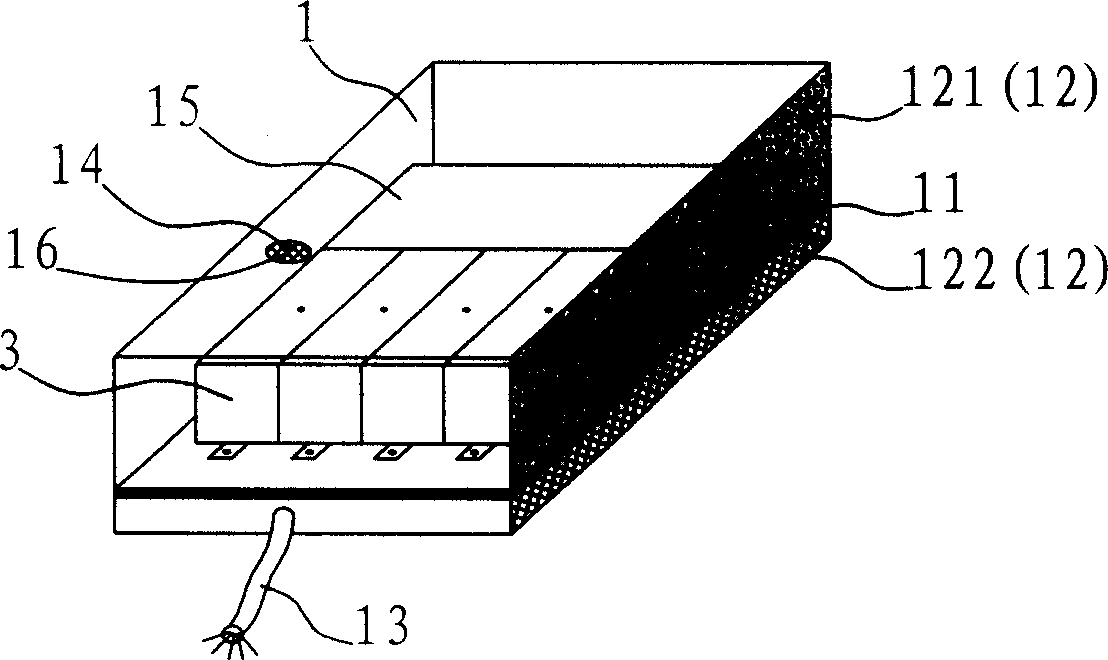

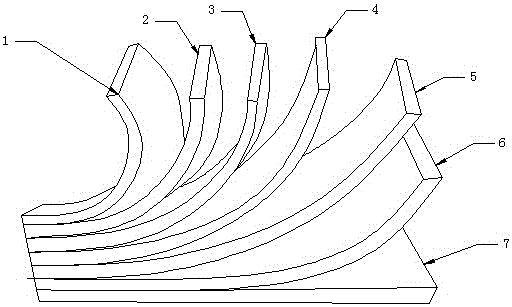

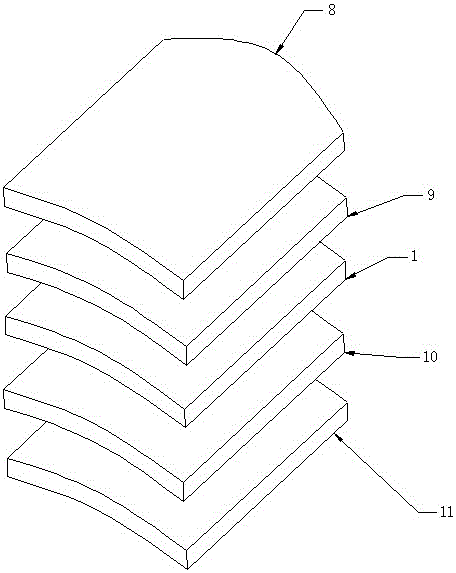

The invention discloses an anti-fingerprint TPU protective film for a 3D curved screen. The protective film comprises a low-viscosity protective film, an anti-fingerprint UV hardening coating, an optical hard TPU resin film layer, an optical-grade high-viscosity silica gel pressure-sensitive adhesive layer and a fluorine element release film which are attached from top to bottom; the anti-fingerprint UV hardening coating is formed by coating an anti-fingerprint UV hardening coating; the optical hard TPU resin film layer is formed by coating optical hard TPU glue, the optical-grade high-viscosity silica gel pressure-sensitive adhesive layer is formed by coating an optical-grade high-viscosity silica gel pressure-sensitive adhesive; the anti-fingerprint UV hardening coating is prepared fromthe following components: UV prepolymer resin, an acrylate reactive diluent, a photoinitiator, a slipping aid and a first solvent, the optical-grade hard TPU glue is formed by polymerizing polyisocyanate, polyester polyol and a chain extender in a second solvent under the action of a first catalyst; the optical-grade high-viscosity silica gel pressure-sensitive adhesive is composed of silica gel resin, a cross-linking agent, an anchoring agent and a second catalyst. The anti-fingerprint TPU protective film for a 3D curved screen has the properties of fingerprint resistance, scratch resistance,difficulty in bursting and good fitting property of the curved screen.

Owner:GUANGDONG BANGGU FILM COATING INNOVATION ACAD CO LTD

Toughened and reinforced ABS material and preparation thereof

The invention discloses a toughened and reinforced ABS material and a method for preparing the same. The toughened and reinforced ABS material is prepared by the following compositions by weight percentage: 55 to 75 percent of acrylonitrile-butadiene-styrene copolymers, 5 to 15 percent of toughening agent, 10 to 30 percent of reinforcing agent, 3.0 to 7.0 percent of compatilizer, 0.3 to 0.5 percent of coupling agent, 0.1 to 1.0 percent of antioxidant and 0.3 to 0.7 percent of glass-fiber exposure resistant agent. The method effectively improves the impact strength and the toughness of a whole system through addition of the toughening agent into an ABS and GF system. During the process of fusing and extruding the toughened and reinforced ABS, the toughening agent is uniformly distributed in ABS resins; when the material or a molded piece is impacted, the toughening agent which is uniformly dispersed in the ABS resins can effectively absorb the impact energy in time so as to improve the toughness of the reinforced ABS and make the molded piece achieve the effect that the molded piece can not be cracked when a self-tapping screw is tightened.

Owner:SHENZHEN KEJU NEW MATERIAL

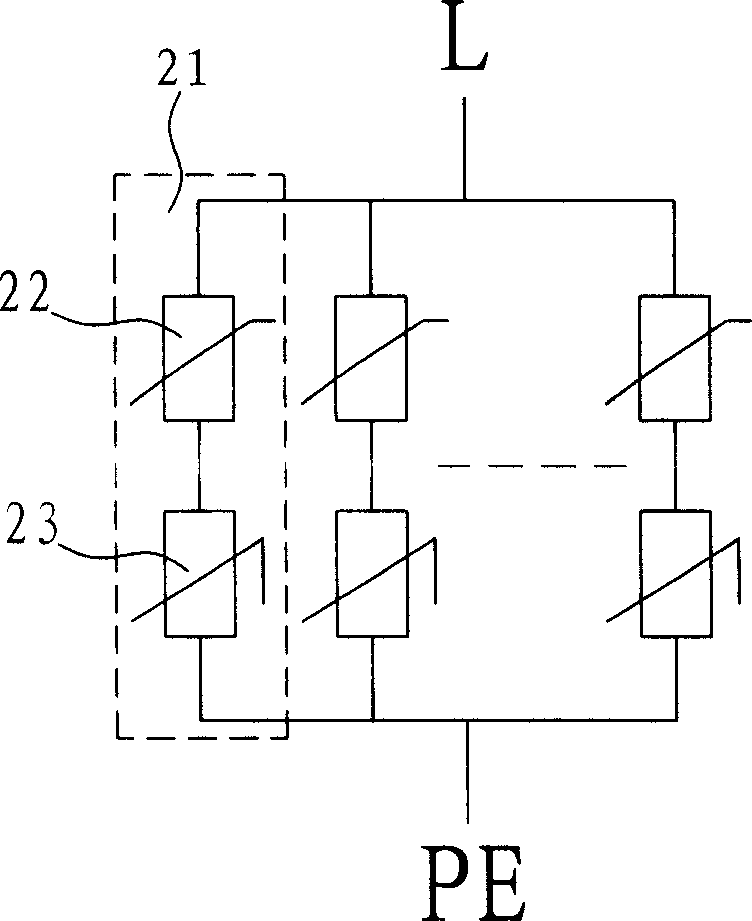

Anti-explosion power source surge protector

ActiveCN1684331AKnow the damage statusTimely replacementEmergency protective arrangements for limiting excess voltage/currentSurge protectorLightning

An explosion-proof power supply surge protector includes a shell and a protection circuit mounted on a circuit board in box filed with high insulation fire-retartant packaged fillers, a connector is set on the box to form a protection circuit module, multiple protection circuit modules are mounted on a circuit board in the shell to be filled with high insulation fire-retartant package filler again and lead out wires connected with the connector on the module are set outside of the shell. The protector will not burst when meeting lightning by twice package, which can be used in the inflammable and explosive environment or humid fields.

Owner:四川中光信息防护工程有限责任公司

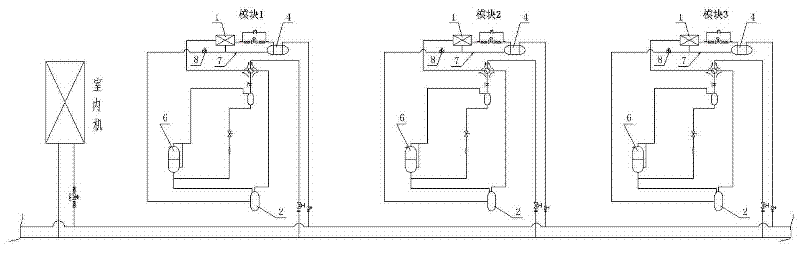

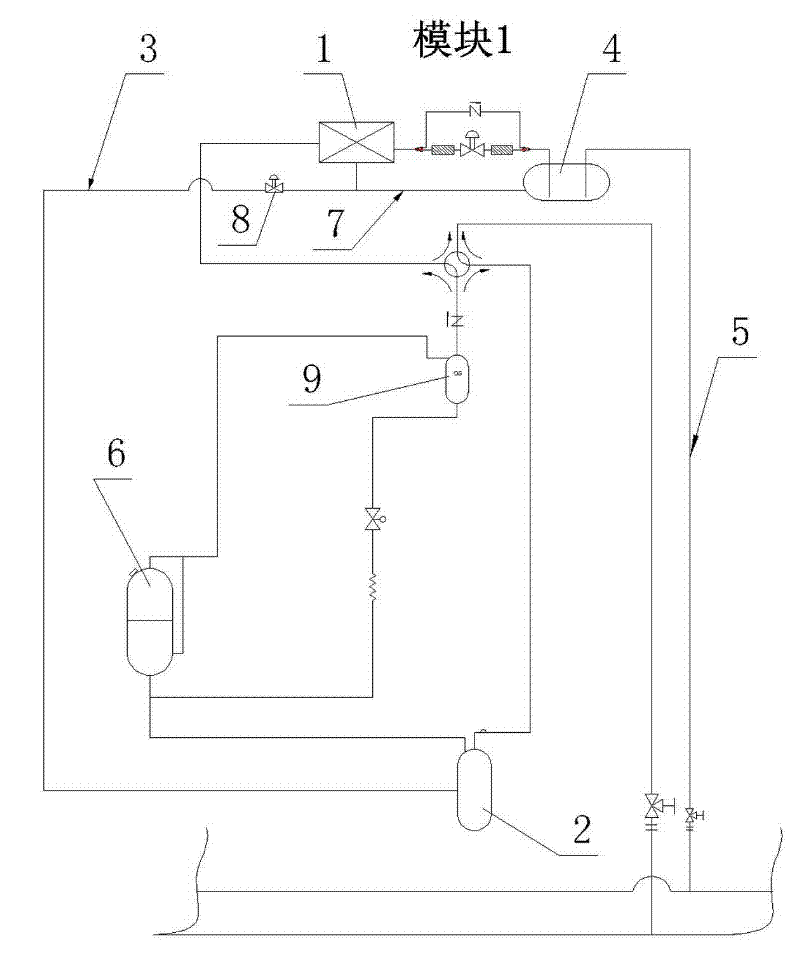

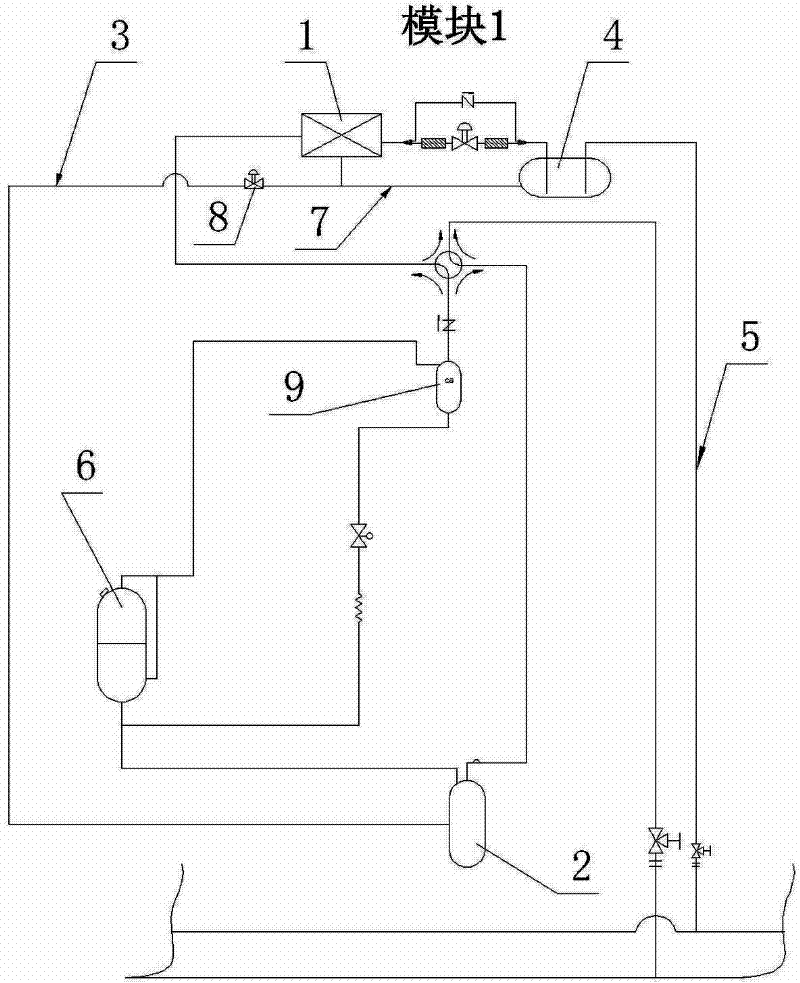

Explosion-proof control method of multi-connected air conditioning unit at runtime

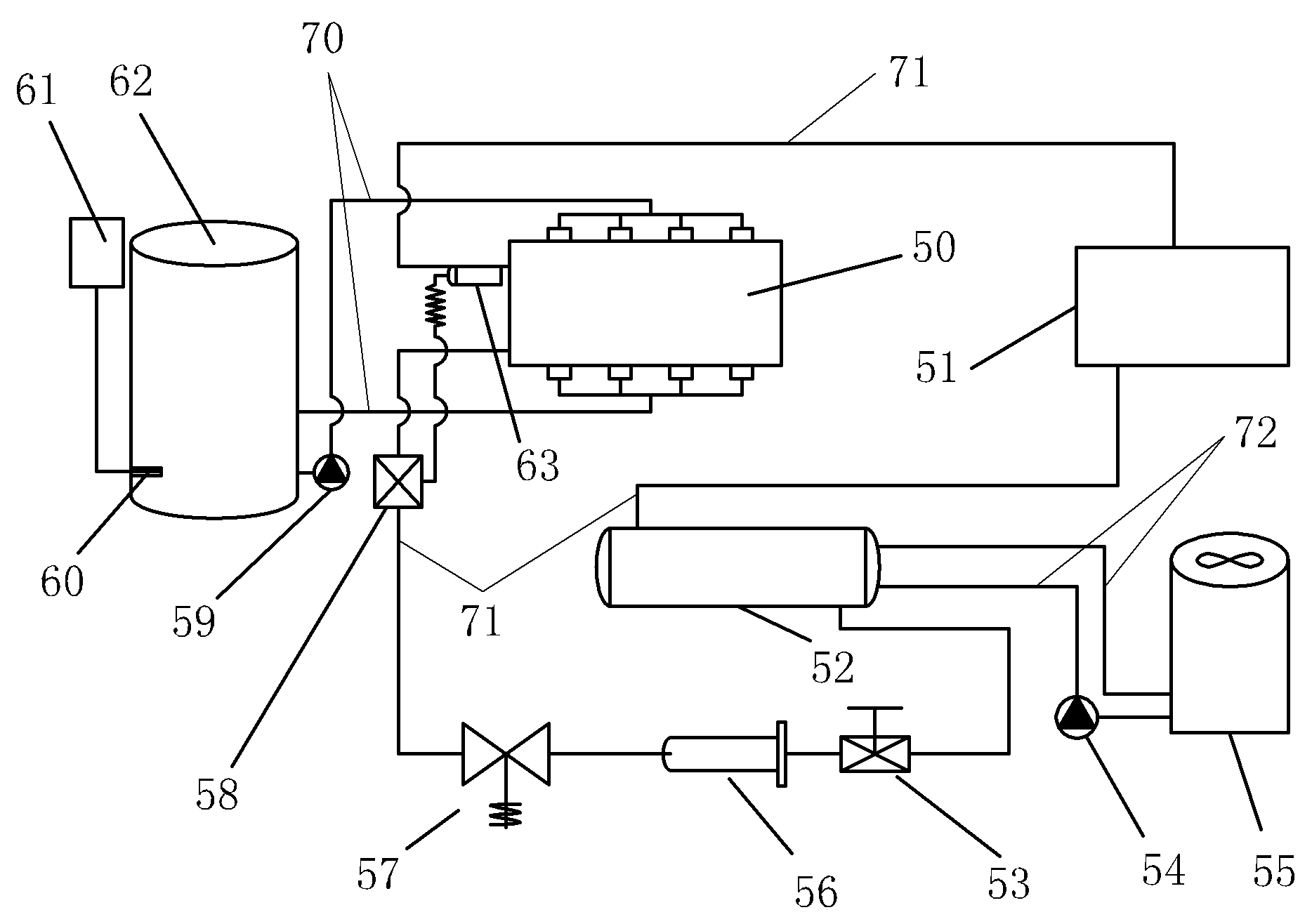

ActiveCN102353116APrevent leakageReduce air pressureSpace heating and ventilation safety systemsLighting and heating apparatusVapor–liquid separatorComputer module

The invention discloses an explosion-proof control method of a multi-connected air conditioning unit at runtime. The method comprises the following steps: a, when the unit is turned off, additionally arranging a first air pressure balance tube (3) with a mechanical high-pressure switch valve (8) between an outdoor heat exchanger (1) and a gas-liquid separator (2) of each outdoor unit module, and arranging a high-pressure switch at the outlet end of an oil separator (9); b, running the unit; c, stopping the whole unit by virtue of a master controller of an air conditioner when the pressure value P0 of the outlet end of the oil separator (9) of the outdoor unit module is greater than or equal to a warning value Pb; d, opening the mechanical high-pressure switch valve (8) of the outdoor unitmodule when the pressure value Pt of the outdoor heat exchanger (1) of the outdoor unit module is greater than or equal to a zero bound pressure value Pa. The control method can be used for avoiding the coil burst of the outdoor heat exchanger.

Owner:NINGBO AUX ELECTRIC

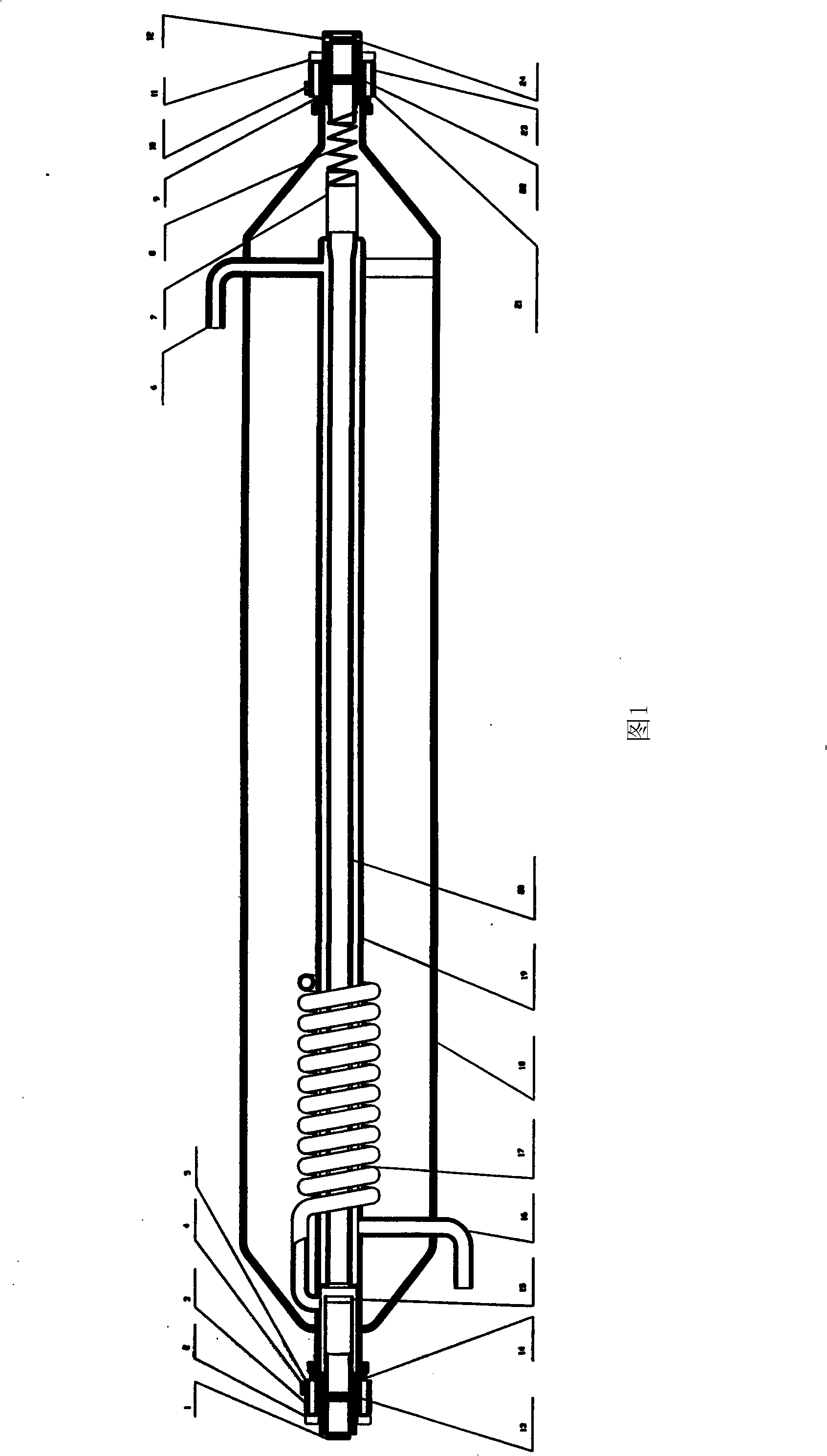

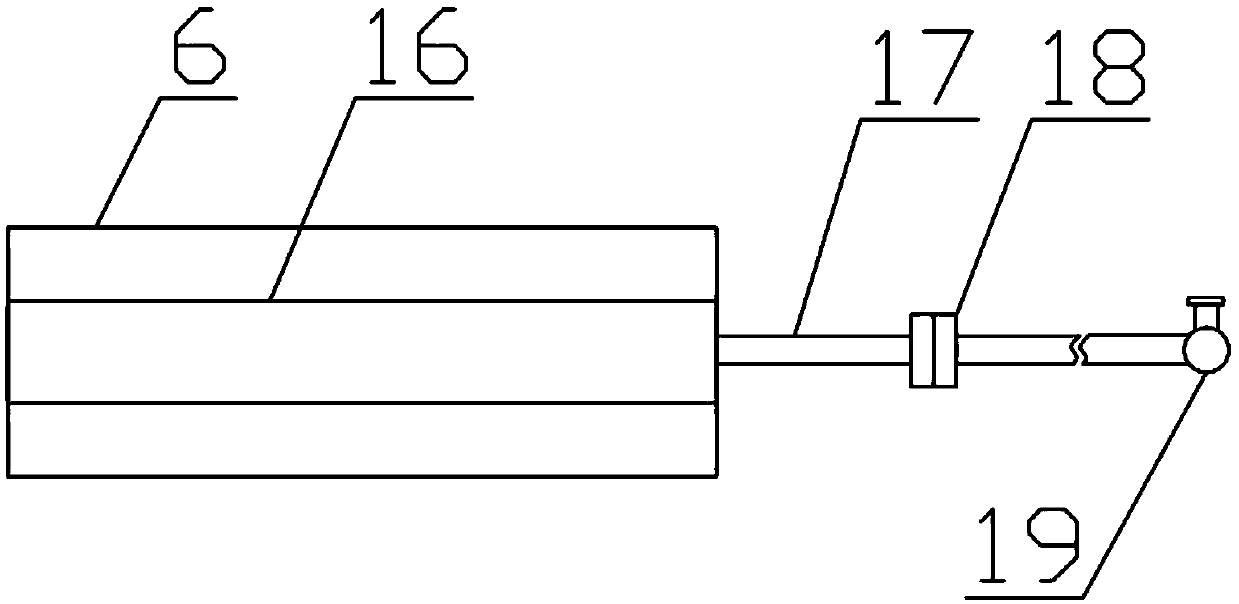

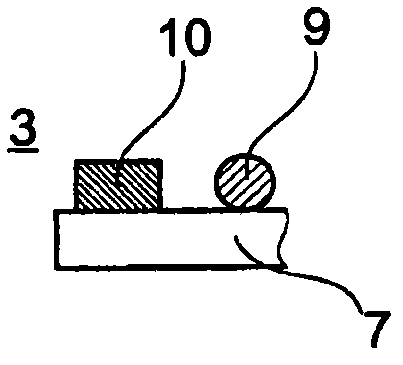

A CO2 laser with new structure

ActiveCN101262112AIncrease output powerHigh beam qualityGas laser constructional detailsOptoelectronicsLaser cutting

The invention relates to a carbon dioxide laser with new structure. Sealing and connecting metal structures at two sides can adjust the angle of a lens (1) and a lens (12); the major structure of the laser pipe shaft comprises a glass material discharge tube (20), a jacket pipe (19), an air-storing pipe (18), an air-returning pipe (17), a water inlet (16) and a water outlet (6); a resonant cavityis composed of a total reflective mirror (1) and an output mirror (23); an angle adjusting system for the total reflective mirror comprises a fixed flange (5), an adjustable flange (3), a soft metal gasket (13) and an adjusting screw (2); the metal structure of the angle adjusting system is sealed and connected with the glass structure of the laser pipe shaft by spacer flange chips (14)(9); a high pressure protective sleeve (24) plays a role in protecting the laser metal structure part with a high pressure; an output mirror protective sleeve (23) plays a role in protecting the output mirror (12) and releasing heat. The carbon dioxide laser is mainly applicable to the laser cutting and the carving machine tool with medium and small power and material processing.

Owner:ZHEJIANG RECI LASER TECH CO LTD

Deoxidant body

The present invention relates to one kind of deoxidant body. The deoxidant body includes a casing with opening, an opening plug and stuffing inside the casing. The casing consists of mixed conductor of stable zirconia mixture 80-85 wt% and high temperature resisting metal 15-20 wt%, the said stable zirconia mixture consists of zirconia 92-98 wt% and magnesia and / or yttrium oxide 2-8 wt%; and the high temperature resisting metal is metal Mo or metal Ni. The casing of the deoxidant body has concurrent oxygen ion conduction and electronic conduction of the mixed conductor as well as excellent thermal vibration resisting performance without burst during deoxidation and pollution.

Owner:BAOSHAN IRON & STEEL CO LTD

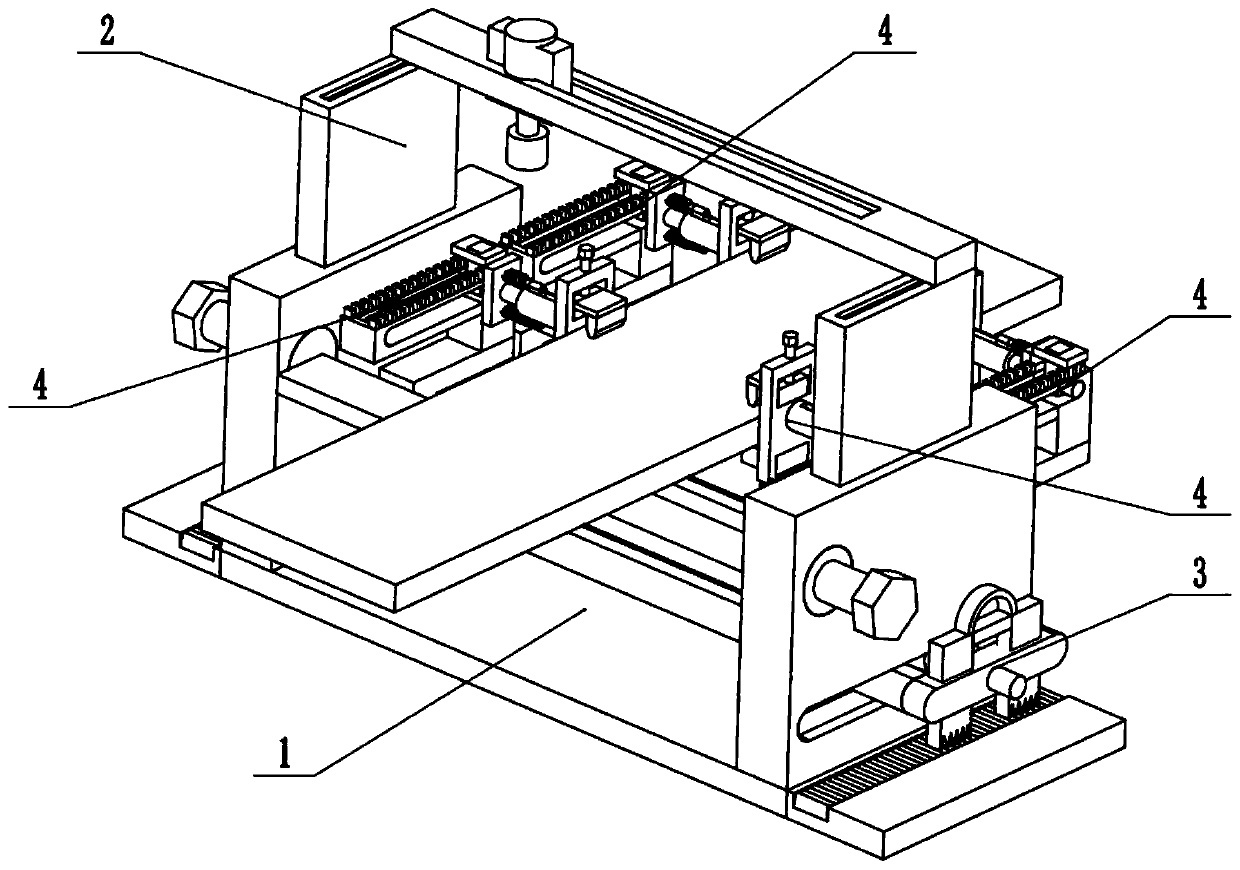

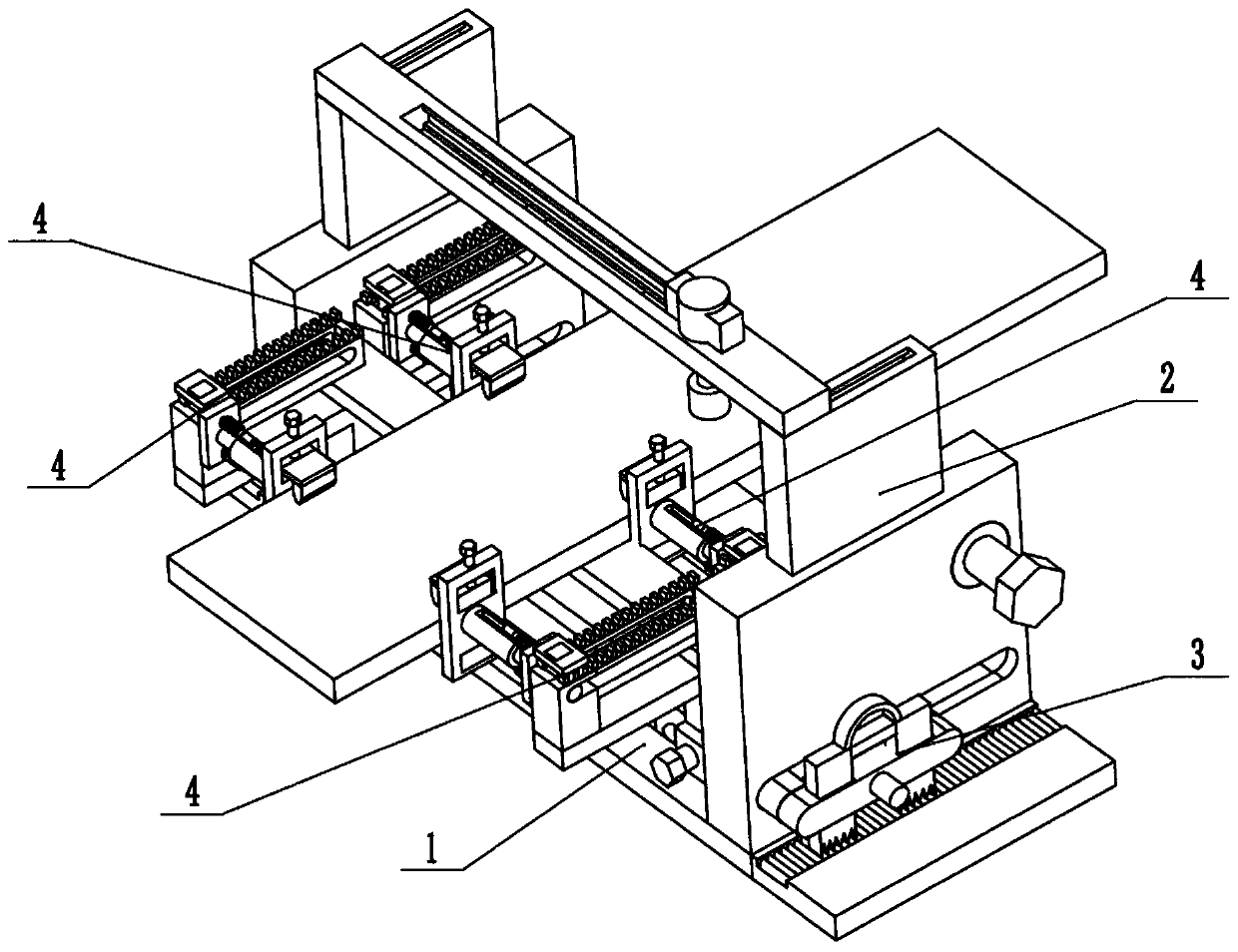

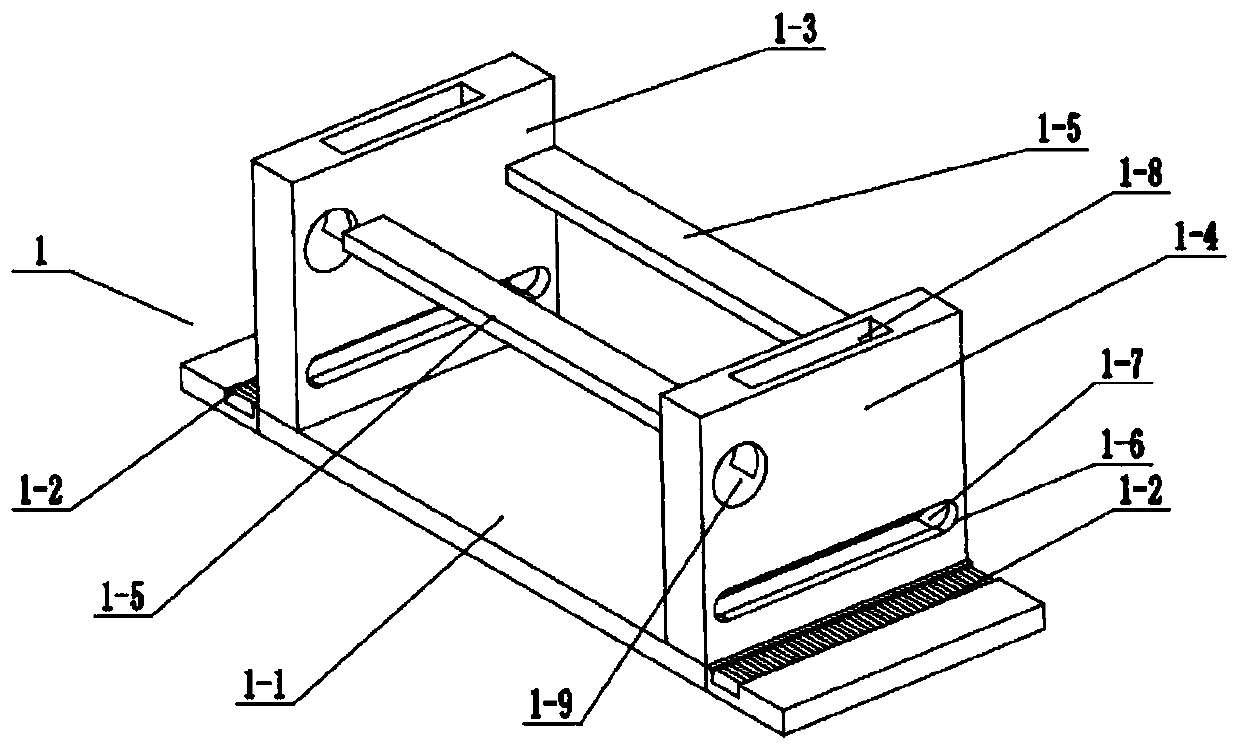

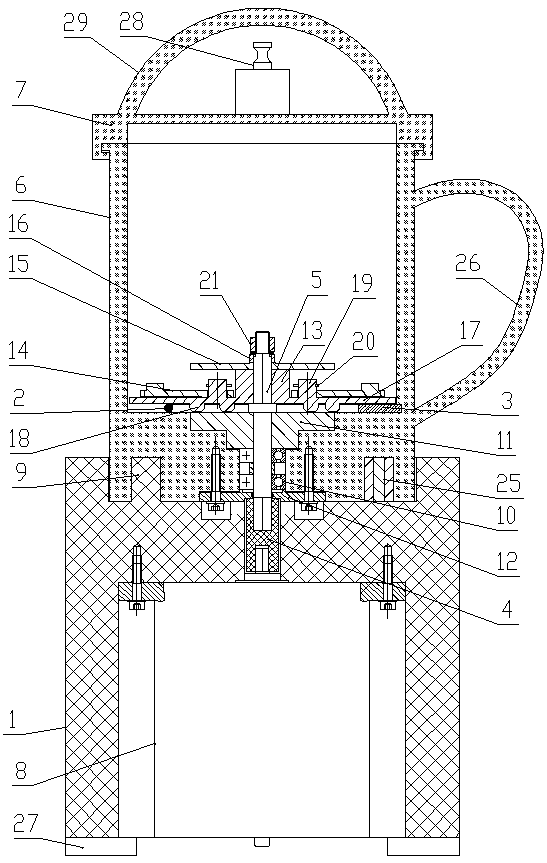

Building board processing device

ActiveCN110666895AWon't burstAvoid damageProfiling/shaping machinesWood mortising machinesPunchingArchitectural engineering

The invention relates to the field of building processing, in particular to a building board processing device. The building board processing device comprises a base fixing device, a punching depth adjuster, a position moving base and four multi-style clamping devices; the punching depth adjuster is in sliding connection in the base fixing device; the position moving base is in sliding connectionin the base fixing device; the lower end of the position moving base is engaged with the base fixing device; and the four multi-style clamping devices are all in sliding connection on the position moving base. The building board processing device has the beneficial effects that a thin wood board integrated with decoration can be clamped and machined, rectangular or circular holes required temporarily are machined in the middle of the wood board, and then the wood board is prevented from being cracked in the machining process, and unnecessary loss is avoided; and meanwhile, wood boards with different sizes and shapes can be clamped and matched through adjustment, so that the situation of damage caused by uneven stress is avoided.

Owner:合肥森岑汽车用品有限公司

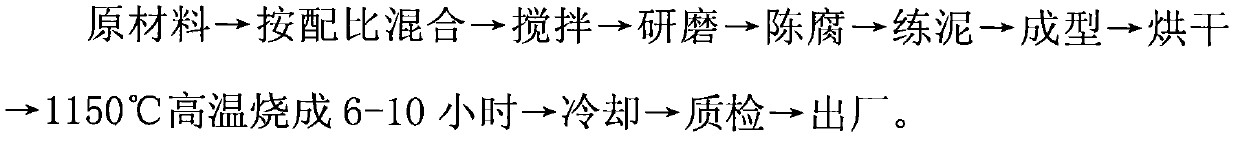

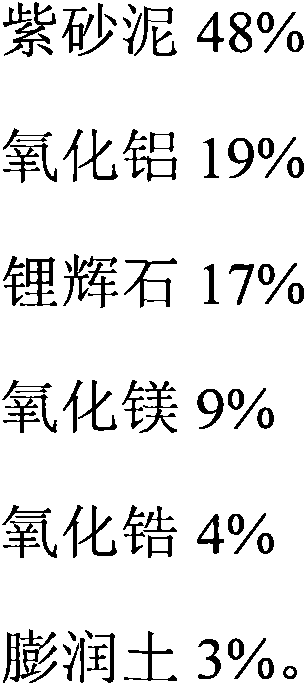

Anti-burst purple-sand ceramic utensil

The invention relates to an anti-burst purple-sand ceramic utensil. According to the anti-burst purple-sand ceramic utensil provided by the invention, the shortcomings that the traditional purple-sand ceramics are poor in sudden change performance, are not resistant to high temperature and easily burst and blast are overcome; and under the condition that the anti-burst purple-sand ceramic utensil is heated by a gas stove for daily use and is subjected to dry burning, when cold water is added suddenly, the anti-burst purple-sand ceramic utensil does not burst, does not blast and is good in sudden change performance, and the original characteristics of purple sand, such as trace element and mineral substance release, are not changed. The anti-burst purple-sand ceramic utensil consists of the following ingredients in percentage by weight: 48% of purple sand clay, 19% of alumina, 17% of spodumene, 9% of magnesia, 4% of zirconia and 3% of bentonite, and is widely applied to the production of purple-sand ceramic pots, tableware and tea sets.

Owner:陈建华

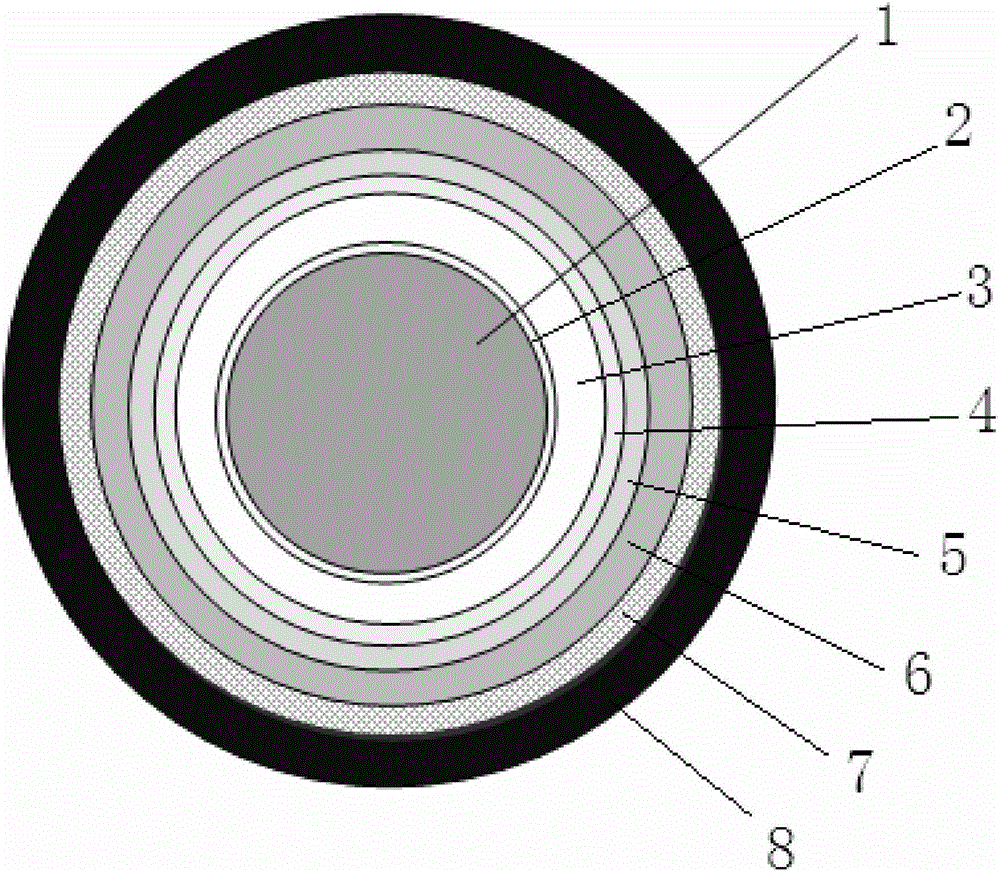

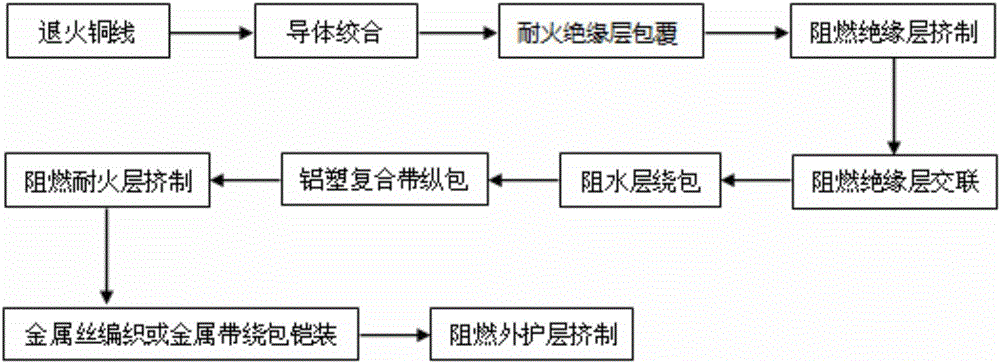

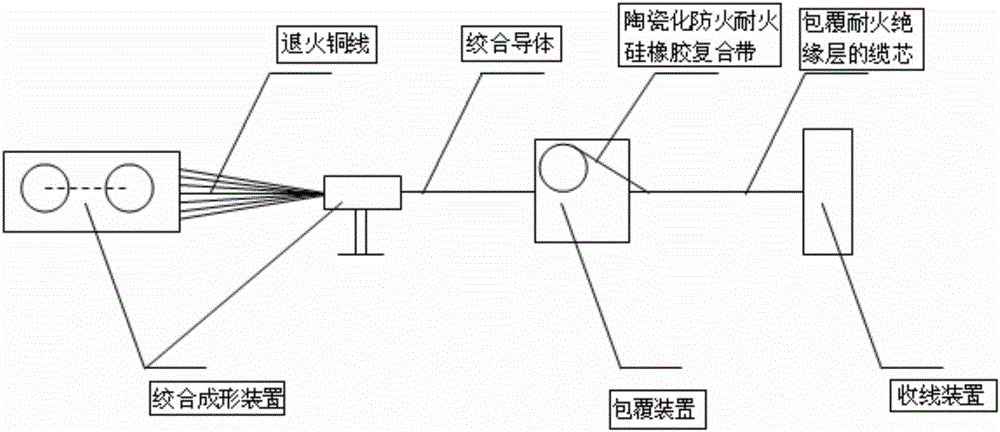

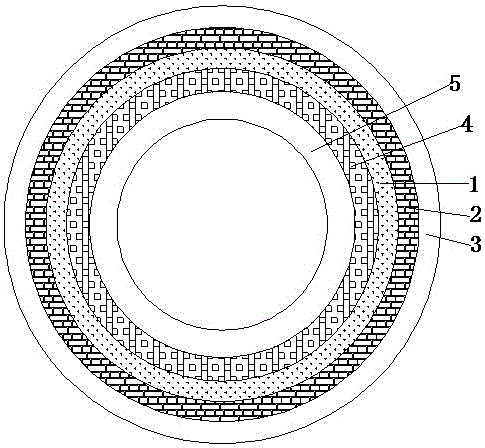

Flame-retardant and fire-resistant direct current power cable applied to rail transit and production system and method

ActiveCN106448796ASimple processingIncrease productivityNon-insulated conductorsClimate change adaptationBlocking layerSmoke

The invention discloses a flame-retardant and fire-resistant direct current power cable applied to rail transit and a production system and method. The cable comprises a stranded conductor, a fire-resistant insulation layer, a flame-retardant insulation layer, a water-blocking layer, a flame-retardant and fire-resistant waterproof isolation layer, an armor layer and a flame-retardant outer protective layer. The flame-retardant and fire-resistant waterproof isolation layer comprises an inner longitudinal package aluminum-plastic composite belt, and an outer flame-retardant and fire-resistant polyolefin cover. The longitudinal package aluminum-plastic composite belt and the flame-retardant and fire-resistant polyolefin cover are spliced and combined into a composite integral structure. The stranded conductor is formed by stranding annealed copper wires into a regular stranded conductor or soft conductor of 50mm<2> to 400mm<2>. The fire-resistant insulation layer is formed by wrapping double-layer ceramic fireproof and fire-resistant silicone rubber composite tapes on a wrapping device in an overlapped manner. An ultraviolet light irradiation crosslinking halogen-free low smoke flame-retardant polyolefin insulation material is extruded on an insulation extrusion crosslinking production device to form a coating structure. The cable provided by the invention has the advantages of high flame-retardant and fire-resistant ability, good insulation performance, great fire resistance and high cable production efficiency.

Owner:JINAN RUITONG RAILWAY ELECTRIC SERVICE

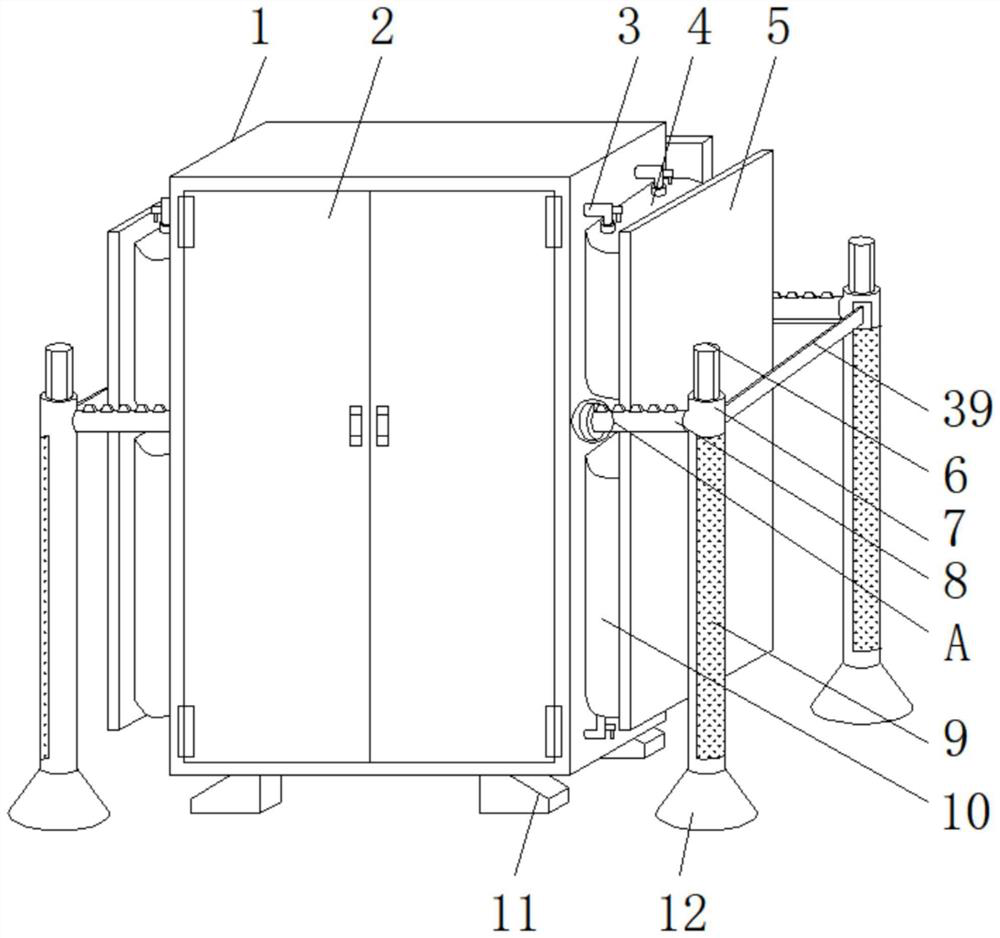

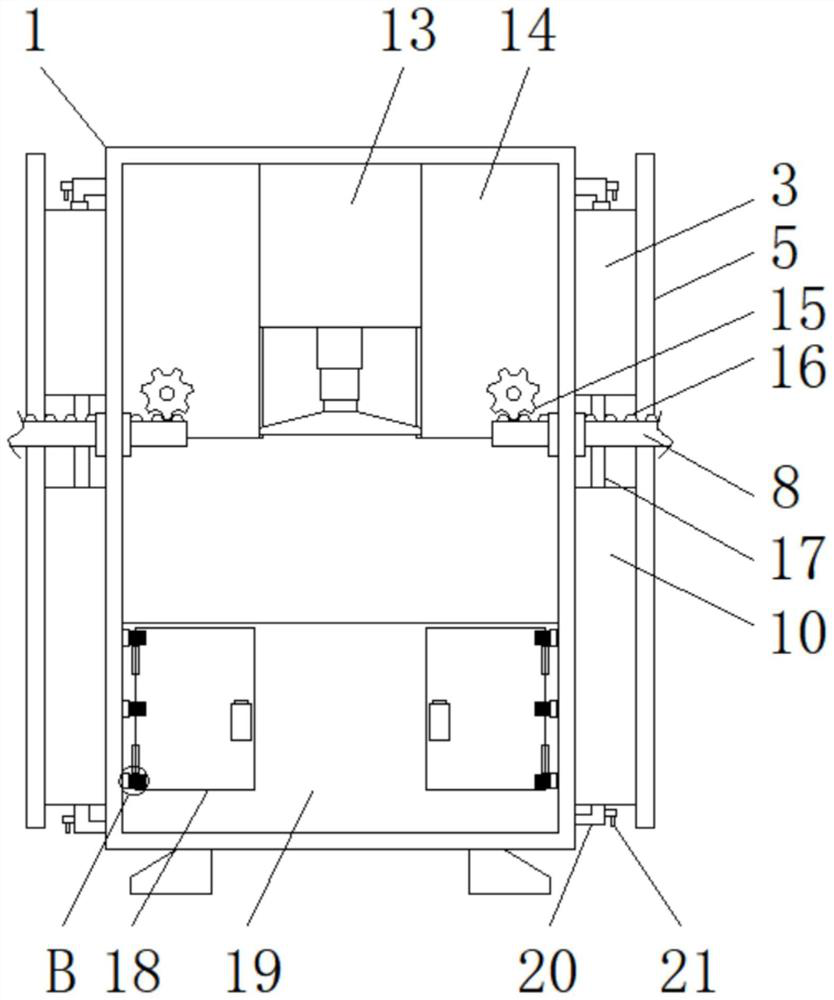

Electrical automation equipment maintenance protection device

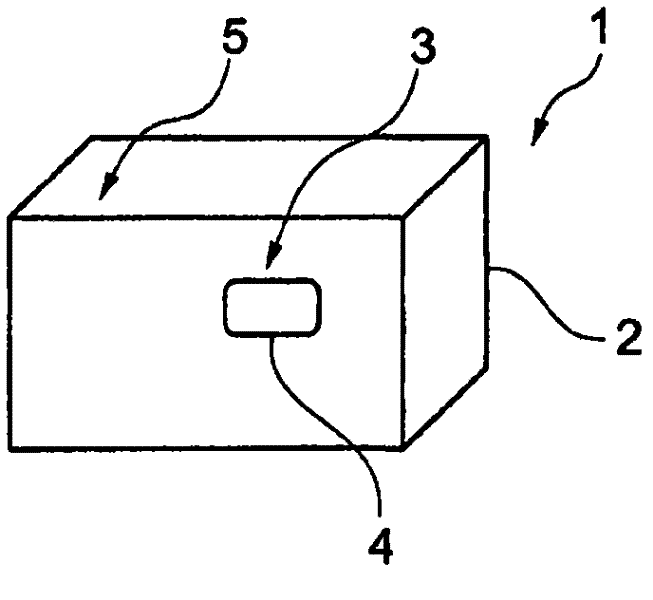

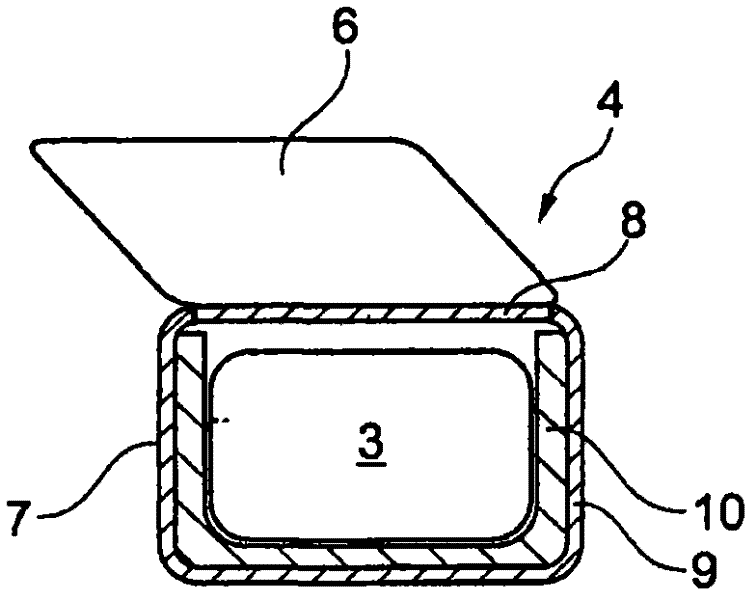

InactiveCN111712090AWon't burstEfficient reuseFencingCasings/cabinets/drawers detailsElectric machineryAir pump

The invention discloses an electrical automation equipment maintenance protection device, and belongs to the field of electrical equipment maintenance devices. The electrical automation equipment maintenance protection device comprises a machine shell, a first protection air bag, a protection outer plate and a second protection air bag, wherein a first installation inner shell and a second installation inner shell are fixedly installed on the inner wall of the top face of the machine shell, an electric air pump and a driving motor are fixedly installed in the second installation inner shell, and an inflation pipe is fixedly installed at the output end of the electric air pump. According to the invention, the protection outer plate with the protection air bag is arranged outside, and compared with a traditional spring buffer structure, the air bag has an effective expansion space and cannot occur explosion, so that the protection effect of the device is improved; and one end of the airbag is connected with the deflation pipe, when the device is not used, air in the air bag can be directly released through the deflation pipe, and dust blowing and heat dissipation treatment can be conducted on maintained electrical equipment through the air, so that the air in the air bag is effectively recycled, structures such as a fan and the like do not need to be used, and energy is saved.

Owner:马鞍山威莎自动化设备科技有限公司

Ocean light purse seiner

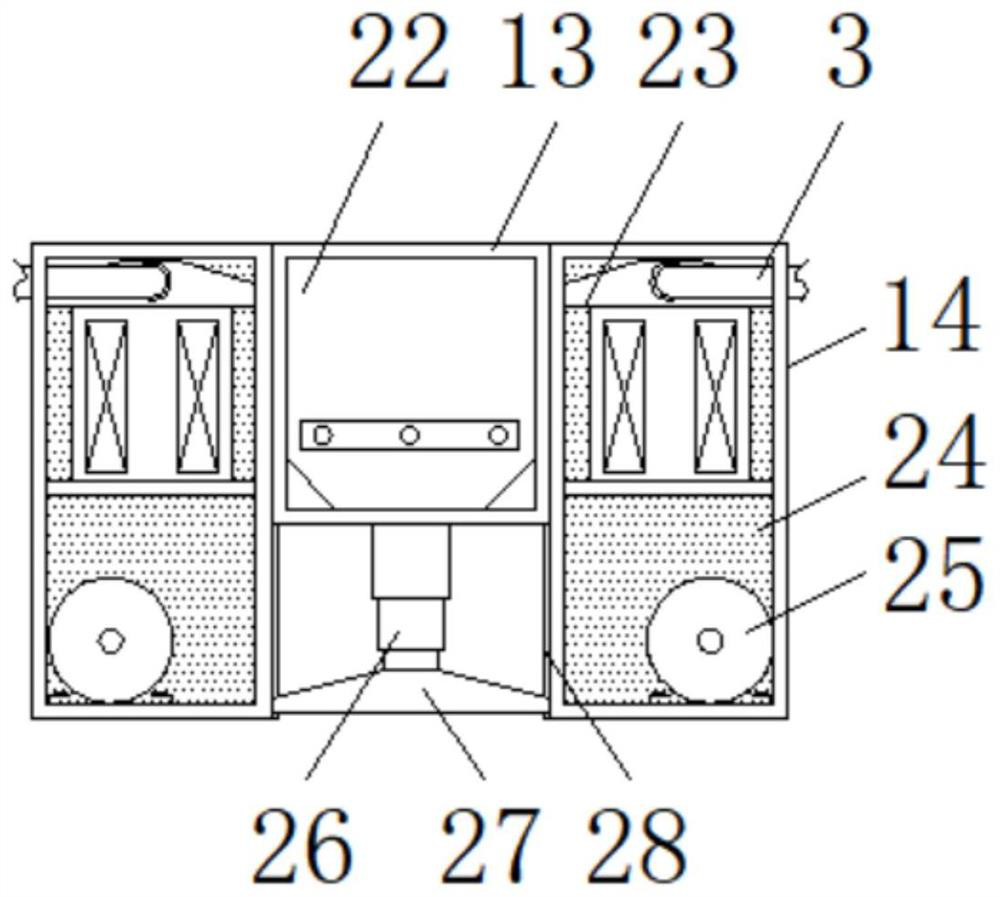

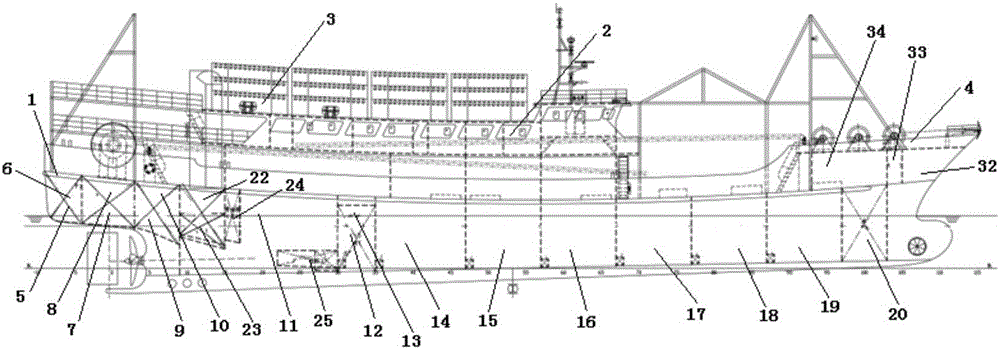

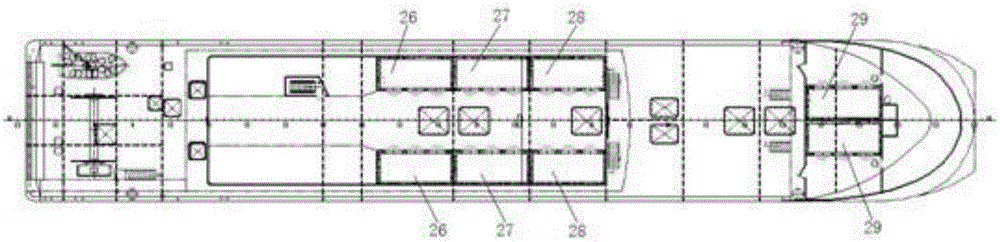

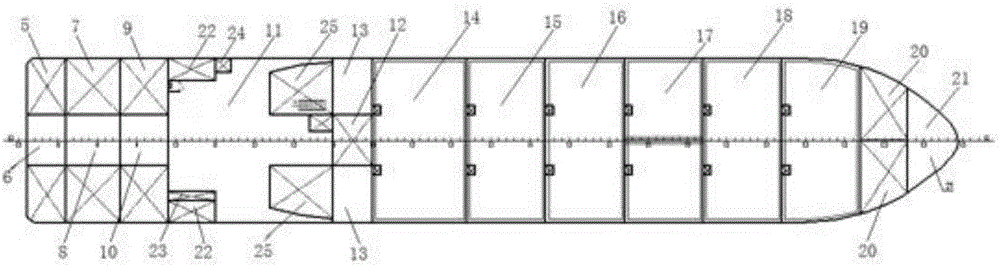

ActiveCN106184637AEasy to shapeIncrease speedAuxillariesNavigational aid arrangementsWater desalinationPropeller

The invention provides an ocean light purse seiner. The ocean light purse seiner comprises a seiner body, a main engine, a fixed pitch propeller, outfitting equipment, fuel oil equipment, fire fighting equipment, life equipment, ventilation equipment, exhaust equipment, fire extinguishing equipment, pollution prevention equipment, lifting equipment, deck machinery equipment, navigation equipment, life-saving equipment, signal equipment, a power system, power distribution equipment and electrical equipment, wherein the outfitting equipment, the fuel oil equipment, the fire fighting equipment, the life equipment, the ventilation equipment, the exhaust equipment, the fire extinguishing equipment, the pollution prevention equipment, the lifting equipment, the deck machinery equipment, the navigation equipment, the life-saving equipment, the signal equipment, the power system and the power distribution equipment are all arranged on the seiner body. The ocean light purse seiner provided by the invention has a good ship type and high endurance, and is provided with a sea water desalination device, and thus the fresh water carrying quantity can be reduced, and the long-distance navigation endurance exceeds thirty days.

Owner:福建西华科技有限公司

Ice crystal evaporator and ice crystal water cooling device producing from same

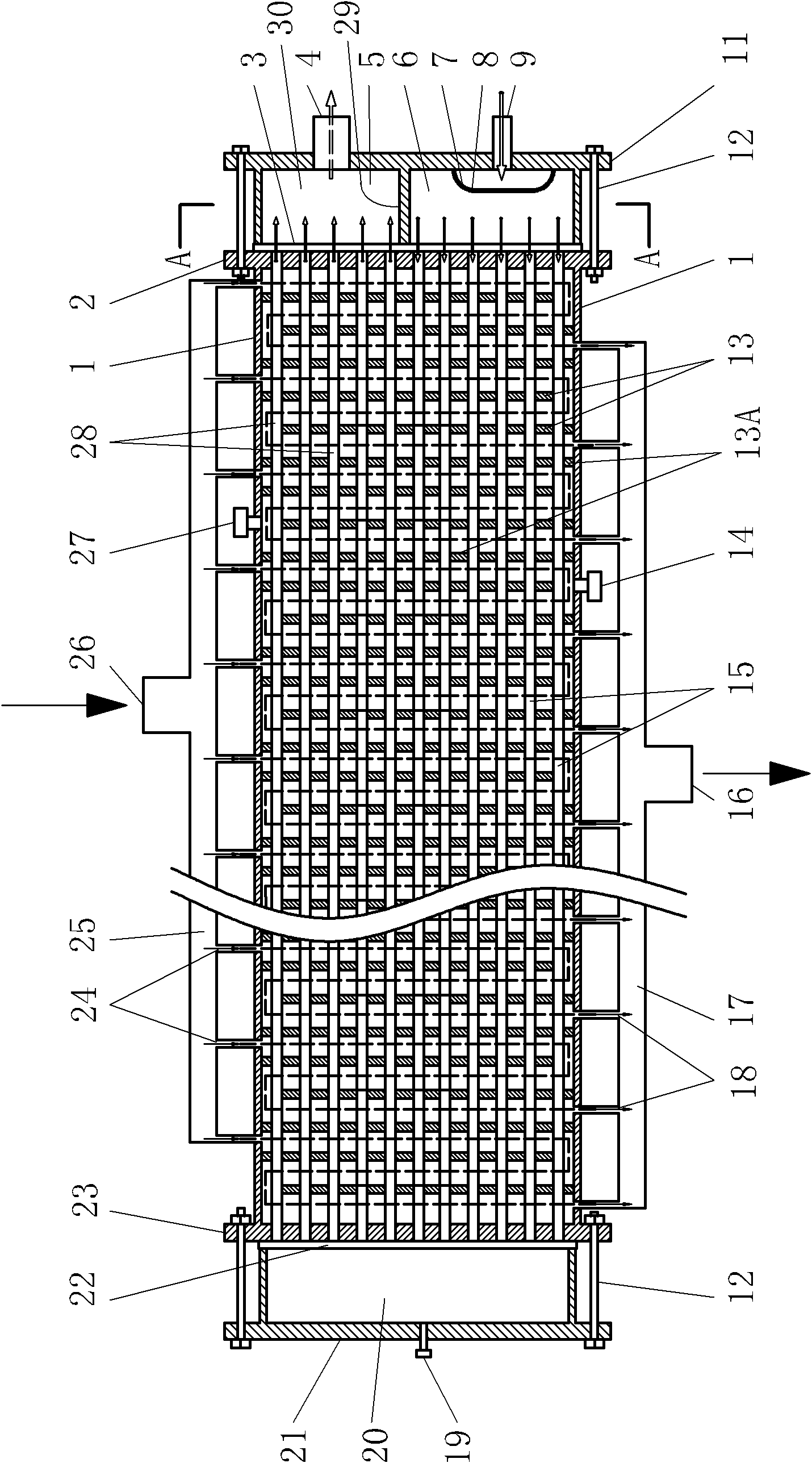

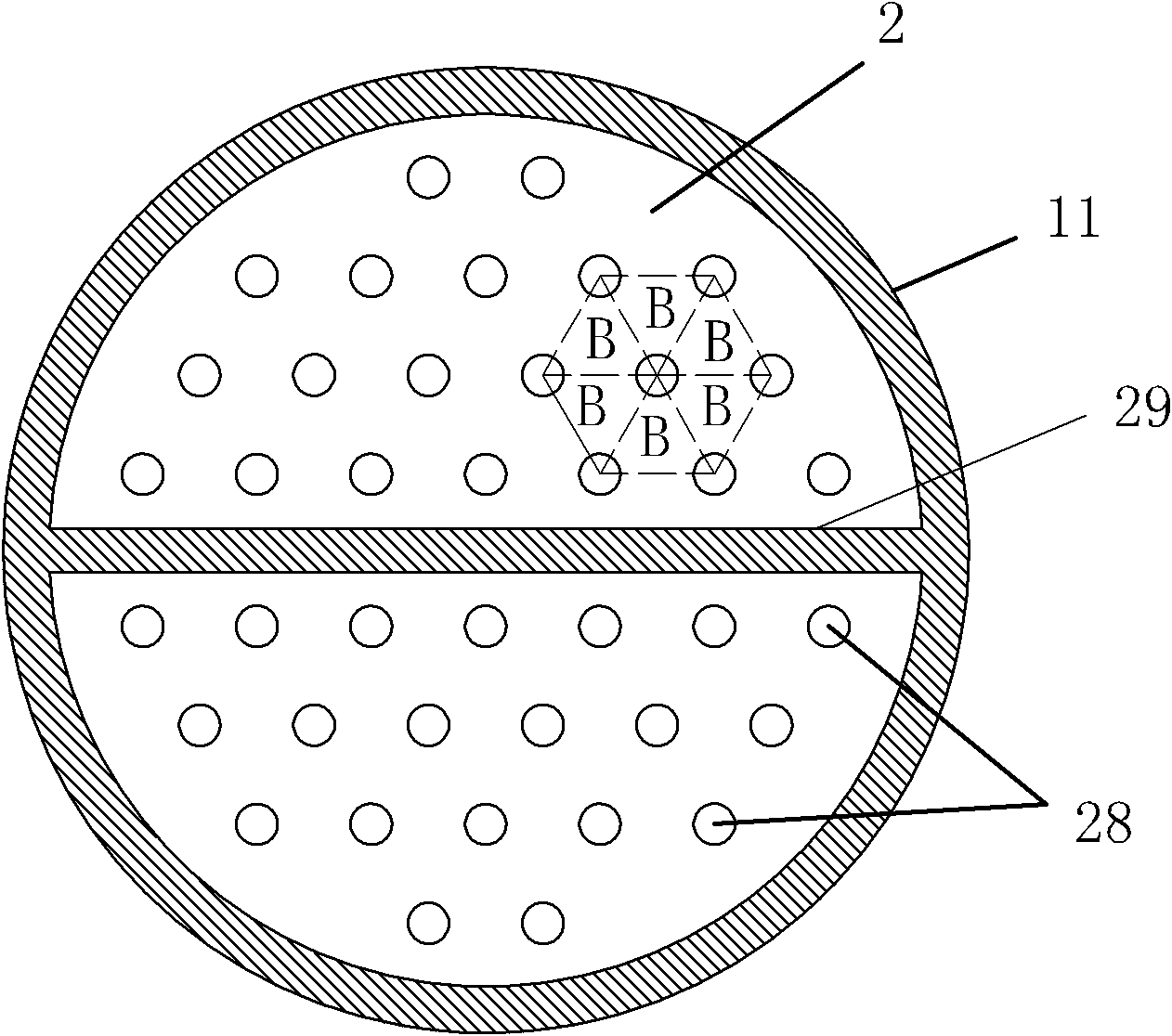

ActiveCN102095290AWon't burstShort flow timeIce productionEvaporators/condensersCooling temperatureEvaporator

The invention relates to an ice crystal evaporator and an ice crystal water cooling device producing from the same, belonging to the technical field of refrigeration. The ice crystal evaporator is characterized in that a liquid inlet channel is formed by an evaporator tube, a liquid inlet and a liquid outlet in a tubular casing; and the outer channel of the evaporator tube of the tubular casing is divided into more than one S-shaped channel forming a water return channel through a water inlet of a water divider and a water outlet of a water collector. The ice crystal water cooling device is characterized in that the return air inlet of the ice crystal evaporator is communicated with a compressor, a condenser, a liquid feeding valve, a dry filter, a liquid feeding electromagnetic valve anda thermostatic expansion valve in sequence, and then is communicated with the liquid inlet of the ice crystal evaporator; a cooling water inlet / outlet of the condenser is connected with a cooling tower in series; and a water inlet / outlet of the ice crystal evaporator is communicated with a water circulating pump and an ice crystal energy storage tank in series. The invention has the advantages ofhigh cooling efficiency, no icing and low cooling temperature and is suitable for production of energy storage central air-conditioning, marine fishing, seafood processing, fruit, vegetable or meat processing, and the like; the cooled medium is municipal water.

Owner:蒋军闽

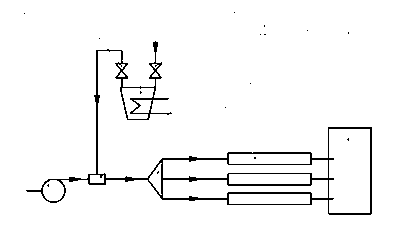

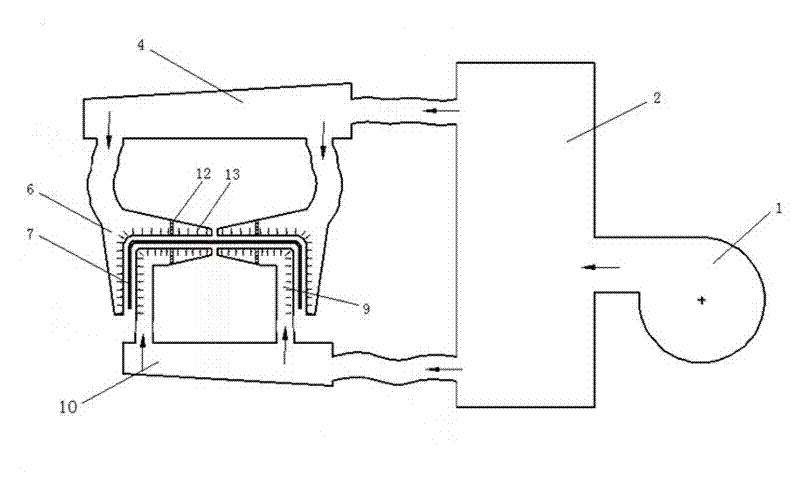

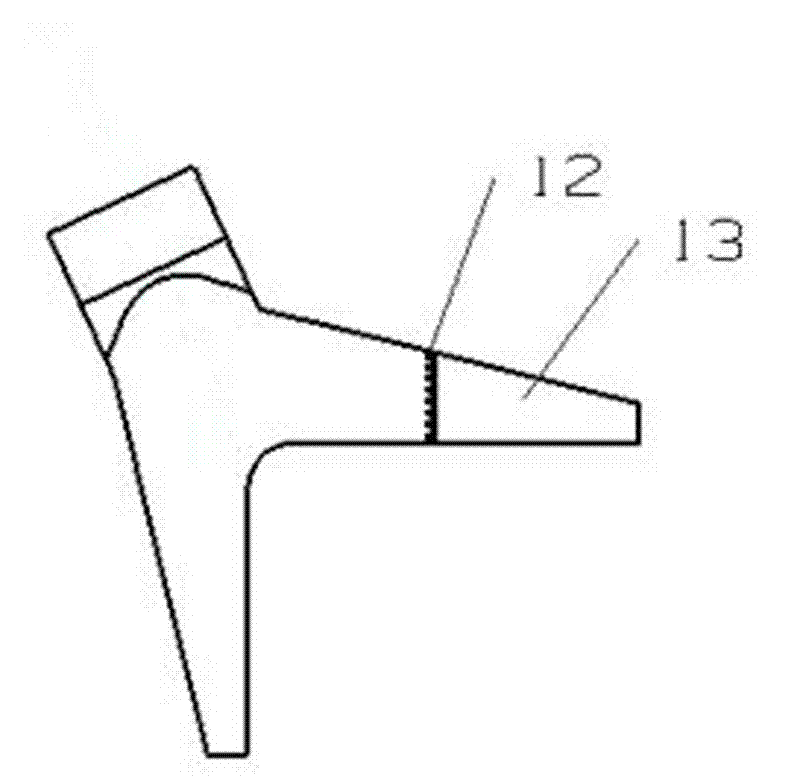

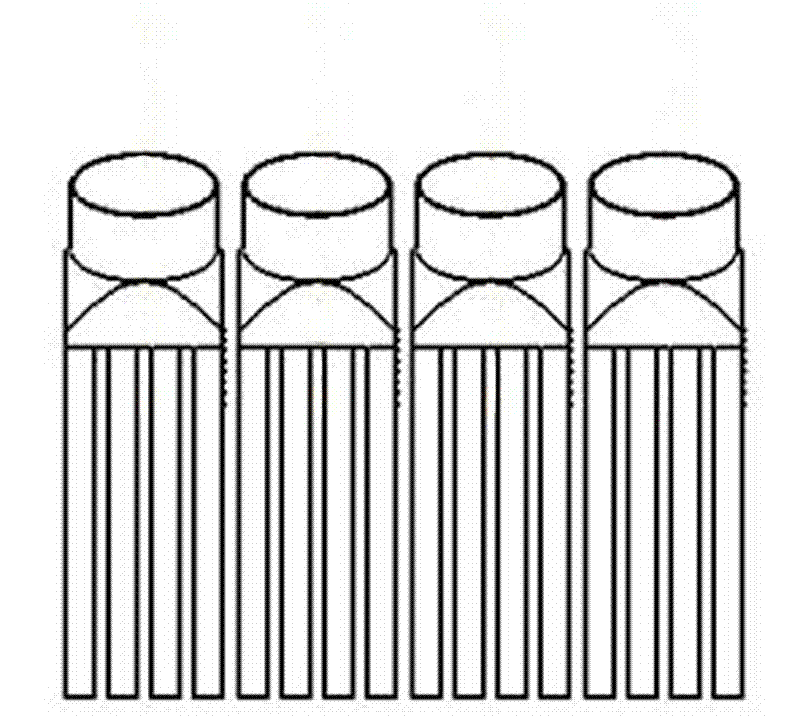

Dry method selective non-catalytic reduction method and device

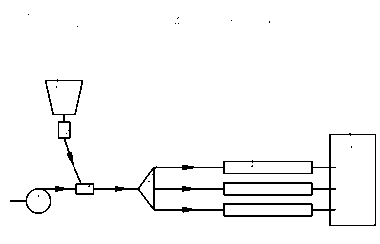

ActiveCN103007722AThe process is simple and reliableLow running costDispersed particle separationDistributorHeat consumption

The invention relates to a dry method selective non-catalytic reduction method and device, which belongs to the field of flue gas denitration. The method comprises the steps: smashing urea particles into urea powder or heating the urea particles to urea gas or heating and liquefyingthe urea particles to urea melt; or heating and gasifying liquid ammonia to ammonia; using urea powder, urea melt, urea gas or ammonia as a reducer, using air, flue gas or steam as a conveying medium, spraying the reducer to high temperature flue gas, and removing oxynitride in the flue gas. The denitration device of the method comprises a bunker, a feeder, an air source, a mixer, a distributor and a spray gun. The bunker is connected with the feed inlet of the mixer, the air source outlet is connected with an air inlet of the mixer, the feed outlet of the mixer is connected with the inlet of the distributor, and the outlet of the distributor is connected with the inlet of the spray gun. The invention is characterized in that the process is simple and reliable, and the operating cost is low; and the three deficiencies of large heat consumption, corrosion of water cooling wall and high fly ash content caused by gasifying aqueous solution by the wet method are overcome.

Owner:徐州燃烧控制研究院有限公司

Method for producing frosted glass

InactiveCN101618648AReduce cleaning processReduce cleaning costsPattern printingSurface treatment compositionsChemistryAqueous sodium hydroxide

The invention relates to a method for producing frosted glass, which comprises the following steps: firstly, selecting original white glass sheets, jointing the two sheets, and sealing four edges by tapes; putting the glass into a weak acid pool for soaking for 2 minutes; conveying the glass into a corrosion pool for frosting; clearing the frosting liquid after the glass is frosted, and drying the glass; removing the sealing tapes at the four edges of the glass; then, adopting a silk screen to print the preliminarily designed glass pattern on one surface, air-drying the glass for 2 hours, andthen, conveying the glass into a dryer for drying; pasting a protective film on the glass surface which is not printed with the pattern; scrubbing the surface which is printed with the glass pattern with weak acid liquid; soaking the glass into the corrosion liquid for 80-120 minutes; putting the glass into a sodium hydroxide solution for cleaning; and then, conveying the glass into a cleaning and drying machine for cleaning and drying to obtain a finished product. The patterned glass which is produced by the method of the invention has uniform and fine etched depth, strong aesthetic feeling of the pattern, better quality, simple processing method and environment protection, and can greatly reduce the production cost in the production process.

Owner:杜广武

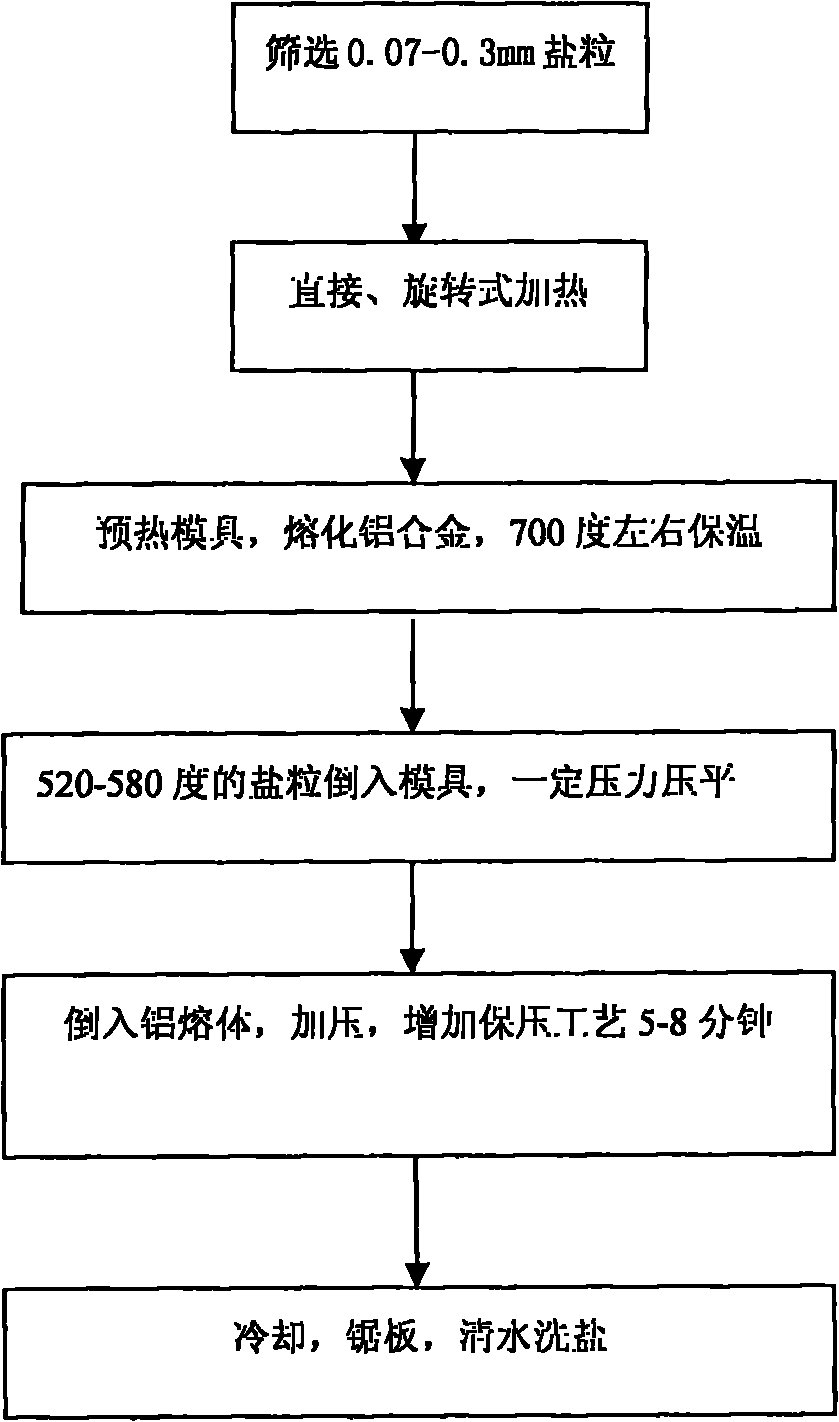

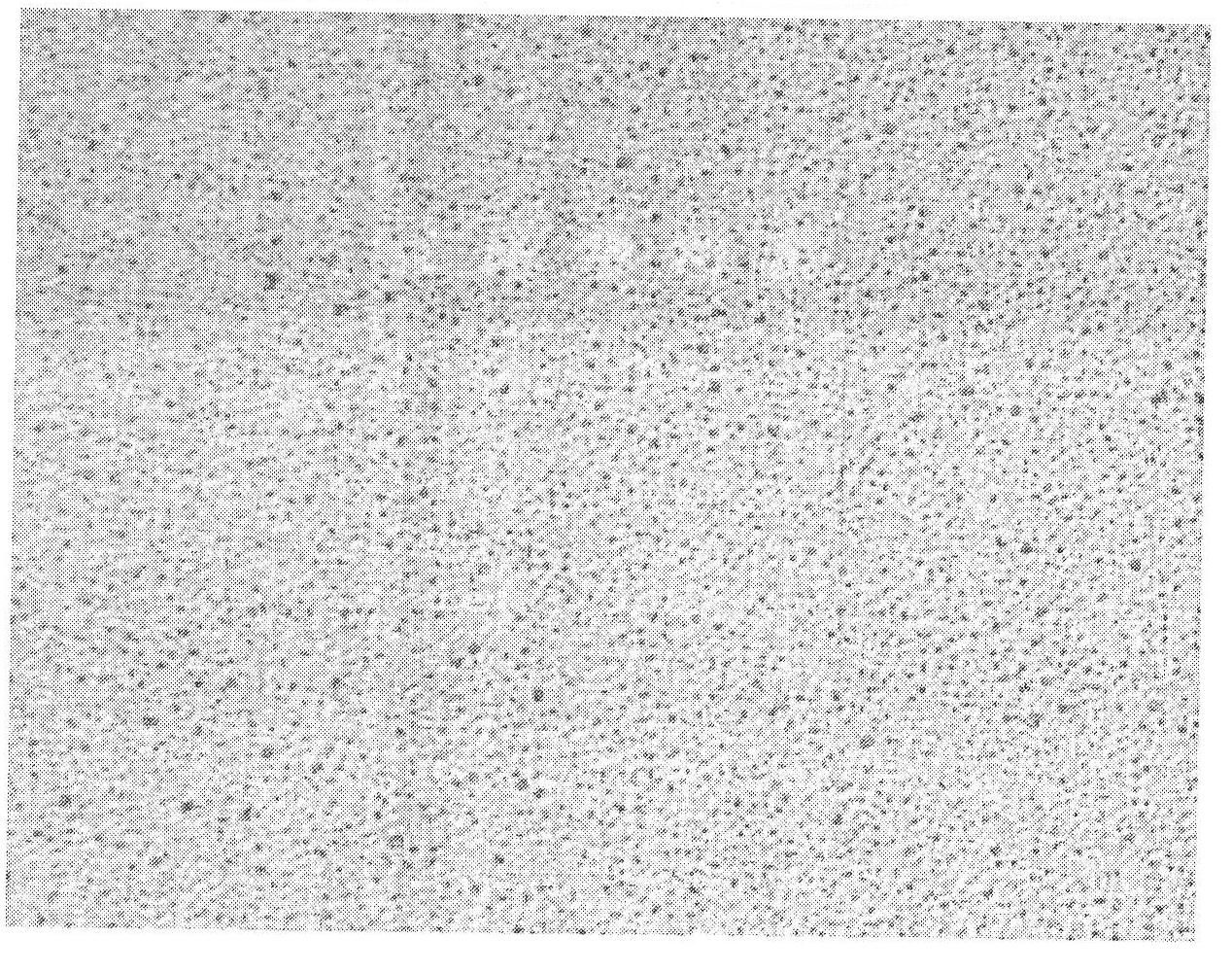

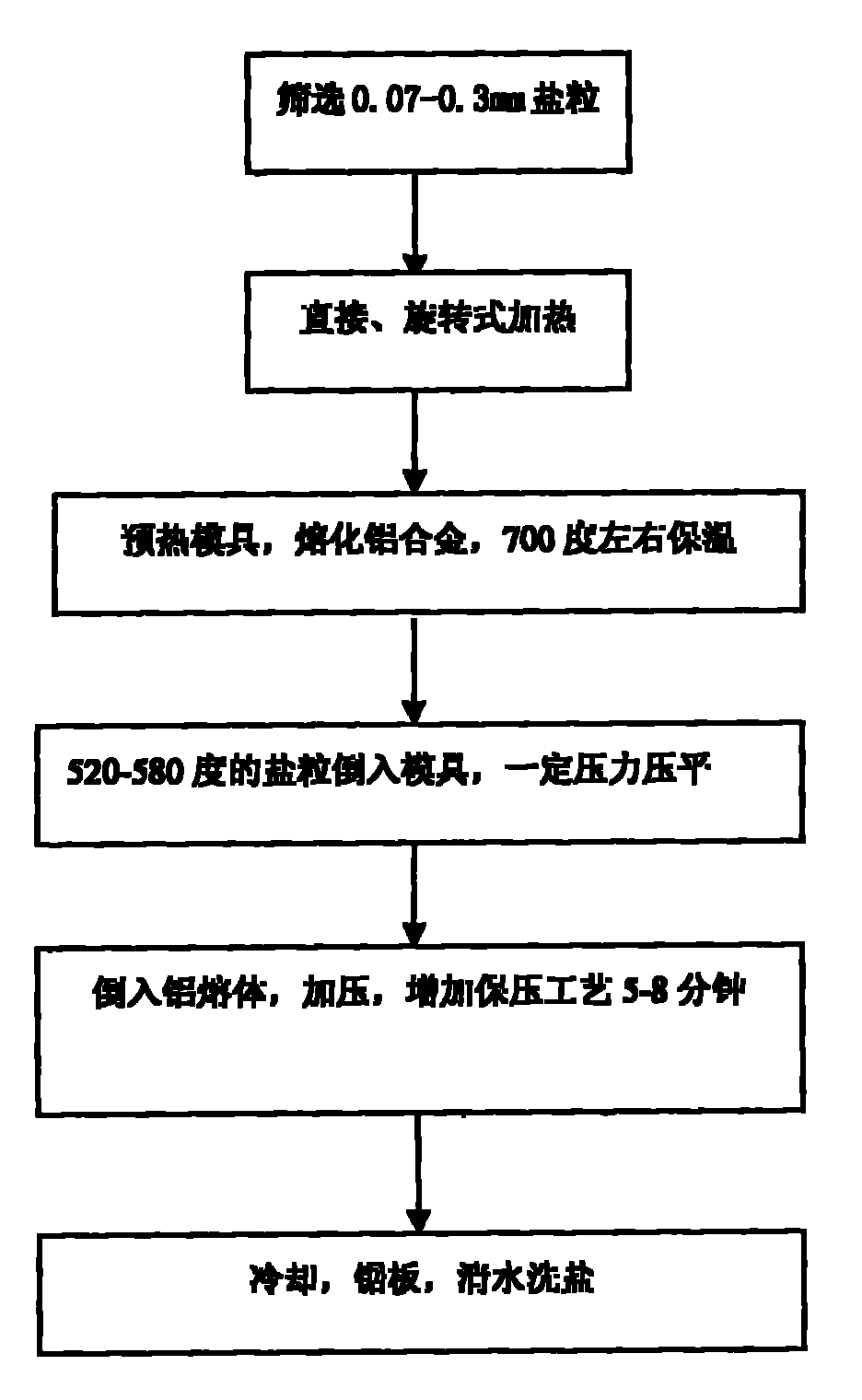

Through hole type microcellular foam aluminum sheet with 0.07 to 0.3mm aperture and preparation method

The invention discloses a through hole type microcellular foam aluminum sheet and a preparation method. The microcellular foam aluminum sheet has an aperture of 0.07 to 0.3mm, a void ratio of 45 to 70 percent, a thickness of more than 2mm and a volume weight of 0.8 to 1.5g / cm<3>. The preparation method thereof mainly comprises the following steps of: filtering salt particles, heating, melting aluminium alloy, pouring the salt particles into a mould and pressing initially, pouring into aluminum melt and pressing, cooling, rinsing salt by clean water and the like and finally obtaining the foam aluminum sheet. The invention is mainly characterized in that: in the heating processing, directly heating is adopted without preheating, a revolving heater is adopted to heat while revolving, a mixer is used for mixing and making the salt particles fully contact hot air. The invention has the technical advantages: the foam aluminum sheet having an aperture of 0.07 to 0.3mm has excellent sound absorption performance and greatly improved intensity. In the invention, revolving heating is adopted, so bonding and agglomeration of salt particles with a diameter of 0.07 to 0.7mm when the salt particle is heated to 520 to 580 DEG C are avoided and seepage is completed.

Owner:朱旭

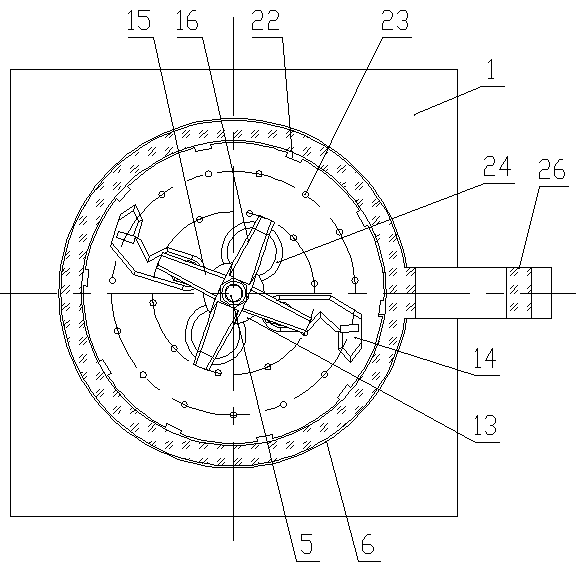

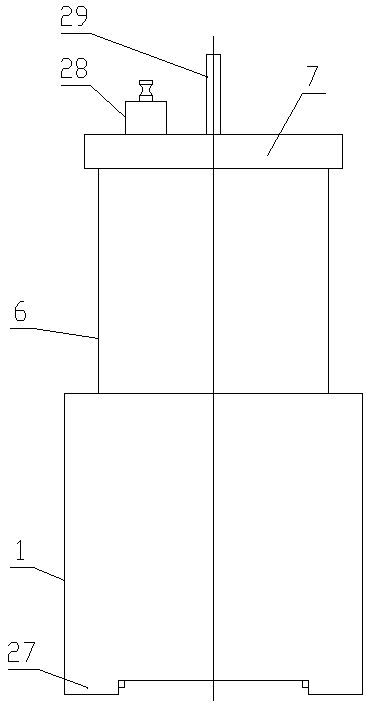

Four-level food grinding smashing high speed blender

The invention discloses a four-level food grinding smashing high speed blender. The blender comprises a base, an electric heater, a dry burning resistance electrode, a temperature sensor, a rotary shaft, a cup body, a cup cover, a motor and a four-level grinding smashing assembly, and the bottom of the cup body is arranged on the base; an up-down through ladder hole is formed in the center which is located at a placing groove and is of the base, a main shaft is in transmission connection with the lower end of the rotary shaft through a coupler, the ladder hole extends upward and is located atthe upper portion of the ladder hole, the rotary shaft is rotatably connected with the inner wall of the ladder hole through a bearing assembly, a sealing disc sleeves the rotary shaft and is arrangedon the upper portion of the ladder hole, and an end cover used for limiting the axial position of the bearing assembly is arranged at the bottom of the ladder hole; the electric heater, the dry burning resistance electrode and the temperature sensor are all arranged at the bottom of the cup body, and the four-level grinding smashing assembly is fixedly arranged on the upper end portion of the rotary shaft. The four-level food grinding smashing high speed blender has the advantages that the blender is reasonable in design and compact in structure, the grinding and smashing effect is good through four-level high speed rotating cutters, better damping effect is achieved, the stability is strong, and the noise is low.

Owner:刘建秀

Composite slag remover for casting

The invention discloses a slag remover, in particular relates to a composite slag remover for casting, and belongs to the technical field of metal processing slag removing. The composite slag remover is composed of 75-95 wt% of pearlite fine powder with particle size <0.3mm, 0.2-10wt% of active SiO2, 0.1-5wt% of active Al2O3 and 2-15 wt% of water glass and prepared through even mixing, drying, curing, breaking and screening. The composite slag remover can meet different production requirements from small packets to large packets and from iron casting to steel casting. The produced slag remover is light, quiet on metal liquid, high in melt viscosity after melting, and favorable for slag accretion and slag removing.

Owner:LINYING YUZHONG FERROALLOYS

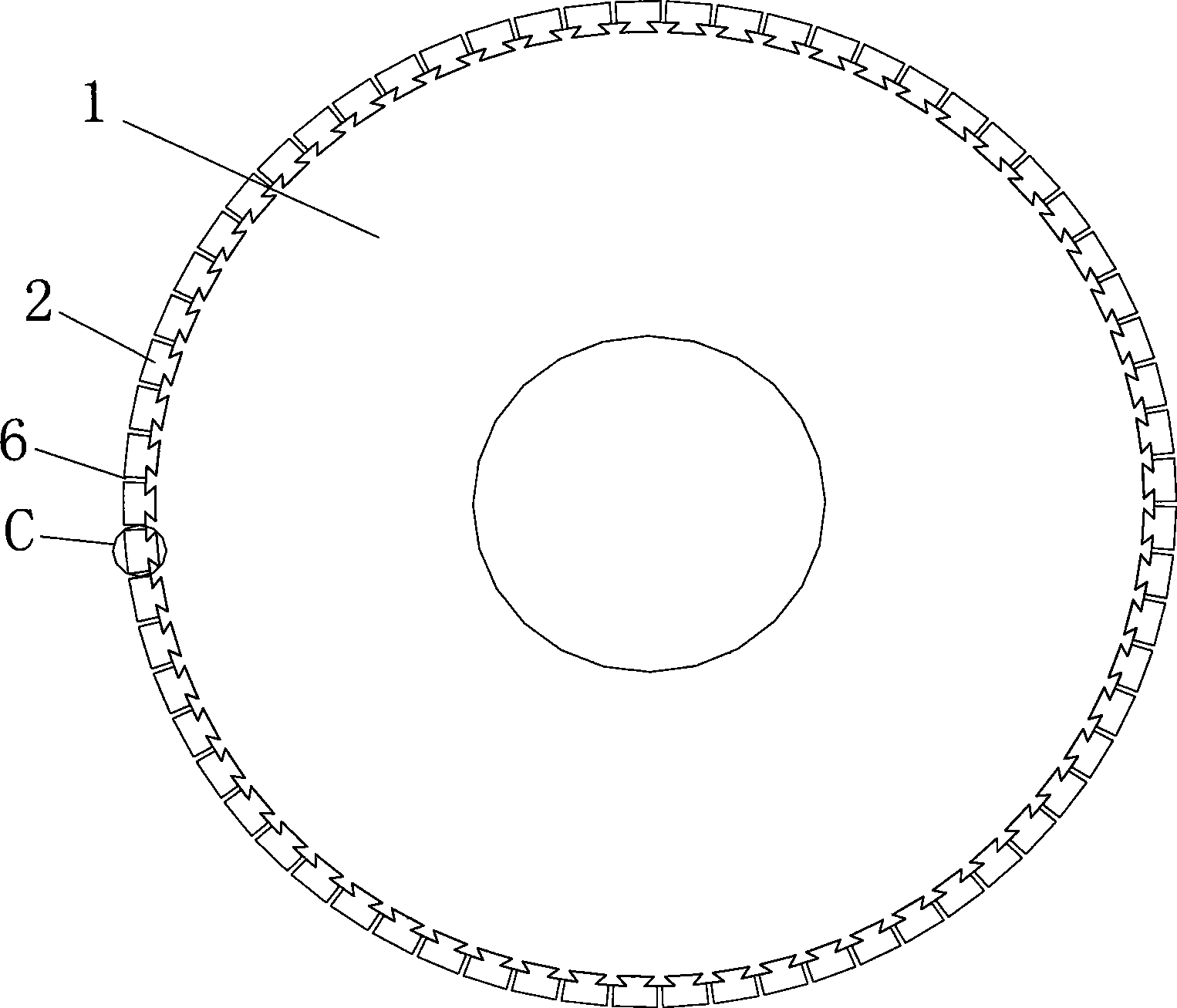

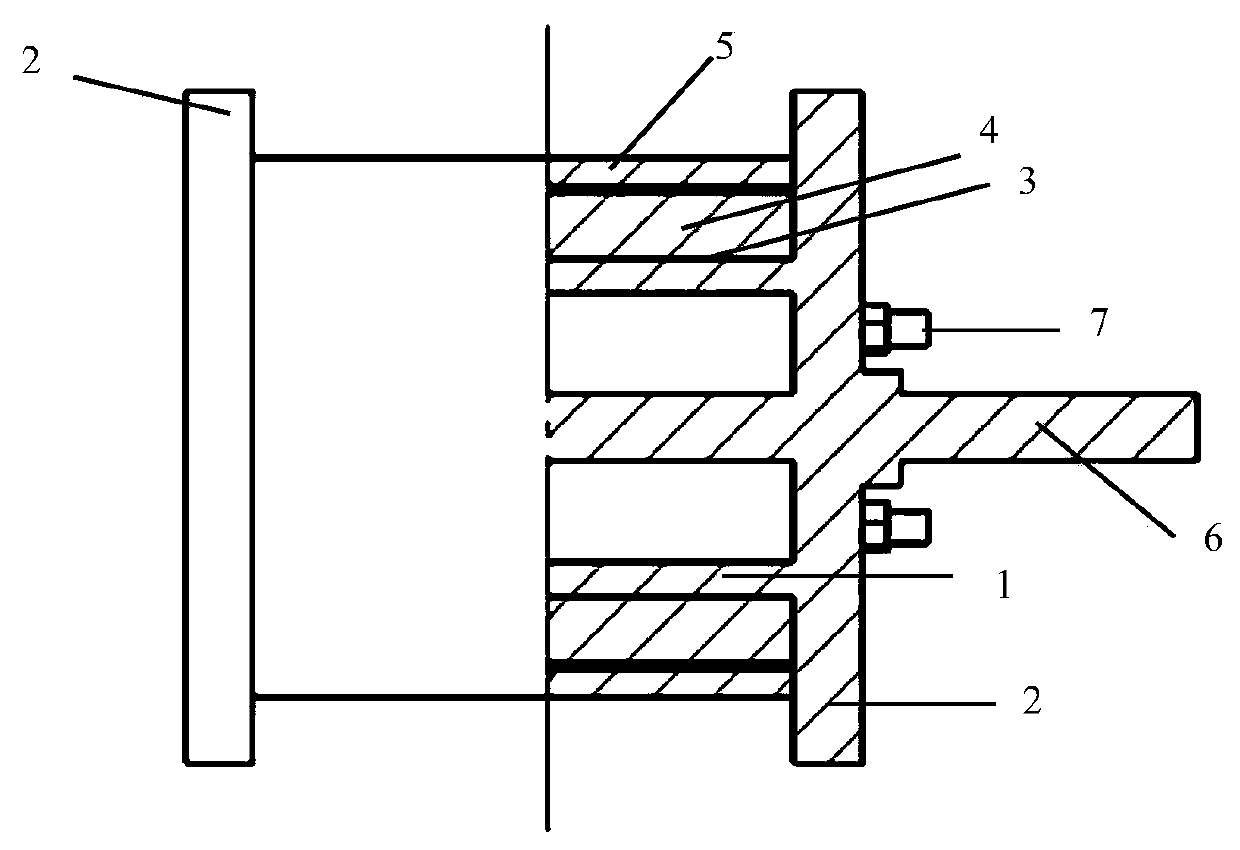

Grinding wheel structure and manufacturing method

InactiveCN103707205AExtended service lifeHigh line speedBonded abrasive wheelsEngineeringGrinding process

The invention relates to a grinding wheel structure and a manufacturing method, and belongs to the technical field of grinding tools. The grinding wheel structure comprises a base and split type grinding blocks, dovetail grooves are formed in the base, a dovetail protrusion corresponding to the corresponding dovetail groove is arranged on the bottom of each grinding block, and the grinding blocks are fixed on the base through the matching of the dovetail protrusions and the dovetail grooves. Compared with the prior art, the split type structure is adopted by the grinding blocks, the notches of the dovetail grooves in the base are small in outside and big in inside, the grinding blocks are not fixed only through thermosetting resin, the grinding blocks can also be clamped through the shapes of the dovetail grooves, the grinding blocks can be fixed more firmly and prevented from falling off the base in a grinding process, the qualified rate is high, clearances are reserved between the grinding blocks and serve as interval grooves for draining water, lowering temperature and removing chips, and the service life is long. The split type grinding blocks are small in size, the manufacturing process is easier to control, the qualified rate is high, and the production cost is low.

Owner:GUIZHOU JINTE GRINDING TECH DEV

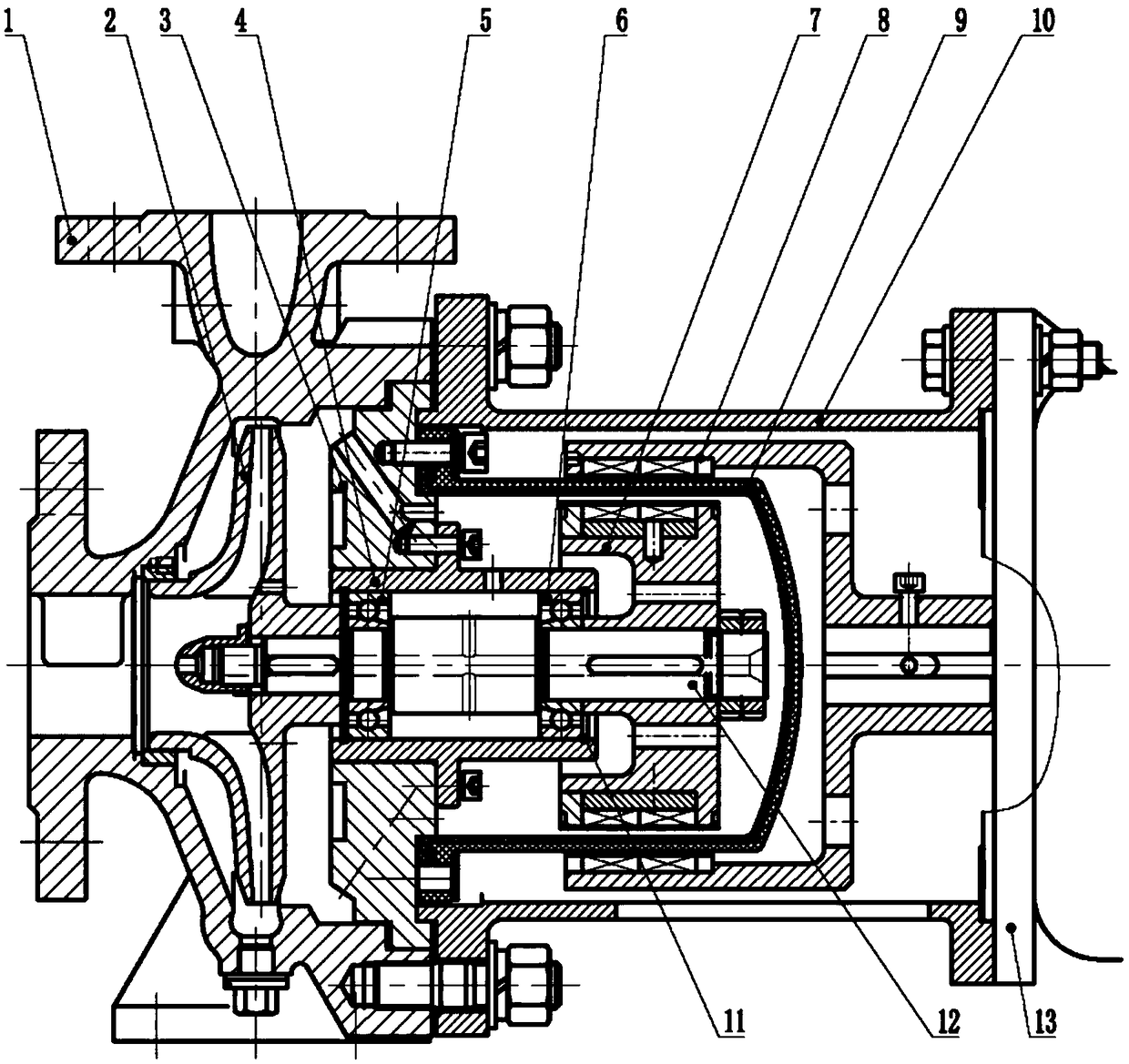

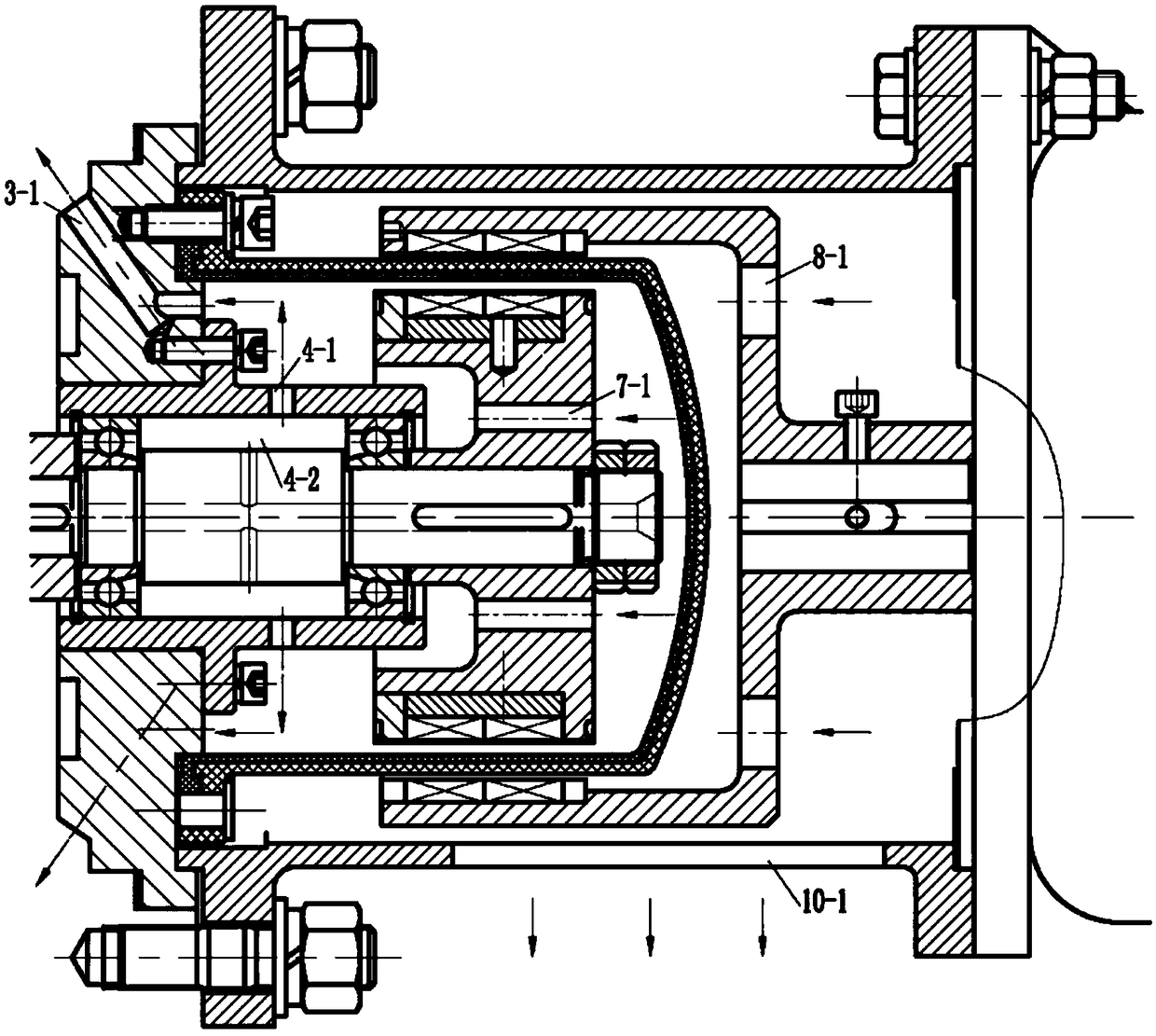

Stainless steel dry-resistant running magnetic pump

PendingCN109236674ABreaking through the restricted area of "no empty load"Breaking through the restricted zone of no-loadPump componentsDynamo-electric gearsImpellerBall bearing

The invention discloses a stainless steel dry-resistant running magnetic pump, comprising a pump body, an impeller, a pump cover, a bearing seat, a coupling frame, a pump shaft, a spacer sleeve, an outer magnetic rotor, an inner magnetic rotor, a motor, a first ceramic bearing, and a second ceramic bearing, and a circlip for a hole. The bearing seat is installed between a pump shaft and the spacersleeve, and the first ceramic bearing and the second ceramic bearing capable of withstanding high temperature and low temperature are respectively disposed on both ends of the bearing seat. Both bearings are zirconia ceramic ball bearings, and an annular heat-dissipating inner cavity is formed between the two bearings. A double-layer isolating sleeve made of a non-metallic engineering material isarranged between the inner magnetic rotor and the outer magnetic rotor, so that eddy current heat generated when magnetic field lines are cut is zero. The large-opening type coupling frame is provided with the outer magnetic rotor and the inner magnetic rotor, the pump cover and a plurality of venting holes on the bearing seat, and forms a unique cooling ventilating and cooling system. The dry-resistant running magnetic pump realizes no temperature rise of the pump during dry running, and breaks through a forbidden zone that a traditional magnetic pump is strictly prohibited from being idling.

Owner:浙江腾宇泵阀设备有限公司 +1

High-temperature glass cup welding process

ActiveCN103936268AQuality improvementNice appearanceGlass reforming apparatusThermal insulationEngineering

The invention discloses a high-temperature glass cup welding process, which is implemented through the following steps of 1) according to the requirements on the size and shape of a prepared glass cup, selecting an appropriate high-temperature glass tube, and cutting the high-temperature glass tube to be taken as a cup body; 2) according to the requirements on the size and shape of the cup body, preparing a cup bottom having an appropriate size and matched with the cup body; 3) carrying out die molding on the cup bottom, and then putting the obtained product into a thermal insulation box to carry out heat preservation for 20-26 hours at a temperature of 35-45 DEG C; 4) slowly heating the cup bottom subjected to heat preservation to 280-320 DEG C, and meanwhile, slowly heating the cup body to 280-320 DEG C, so that the cup body and the cup bottom are the same in temperature; 5) welding the cup body and the cup bottom by coal gas and oxygen, wherein the welding temperature is controlled at 580-620 DEG C; 6) after welding for forming is completed, carrying out annealing treatment on the glass cup, when the temperature is reduced to 35-45 DEG C, carrying out heat preservation for 12-24 hours, and then cooling the glass cup; 7) slowly heating the glass cup subjected to cooling from 0 DEG C to 600 DEG C, and then carrying out annealing treatment on the glass cup; 8) carrying out polishing treatment on the glass cup subjected to stain removal; and 9) after polishing is completed, sealing the glass cup, so that a single-layer glass cup can be prepared, or adding a linear to prepare a double-layer glass cup.

Owner:HEBEI ML GLASSWARE CO LTD

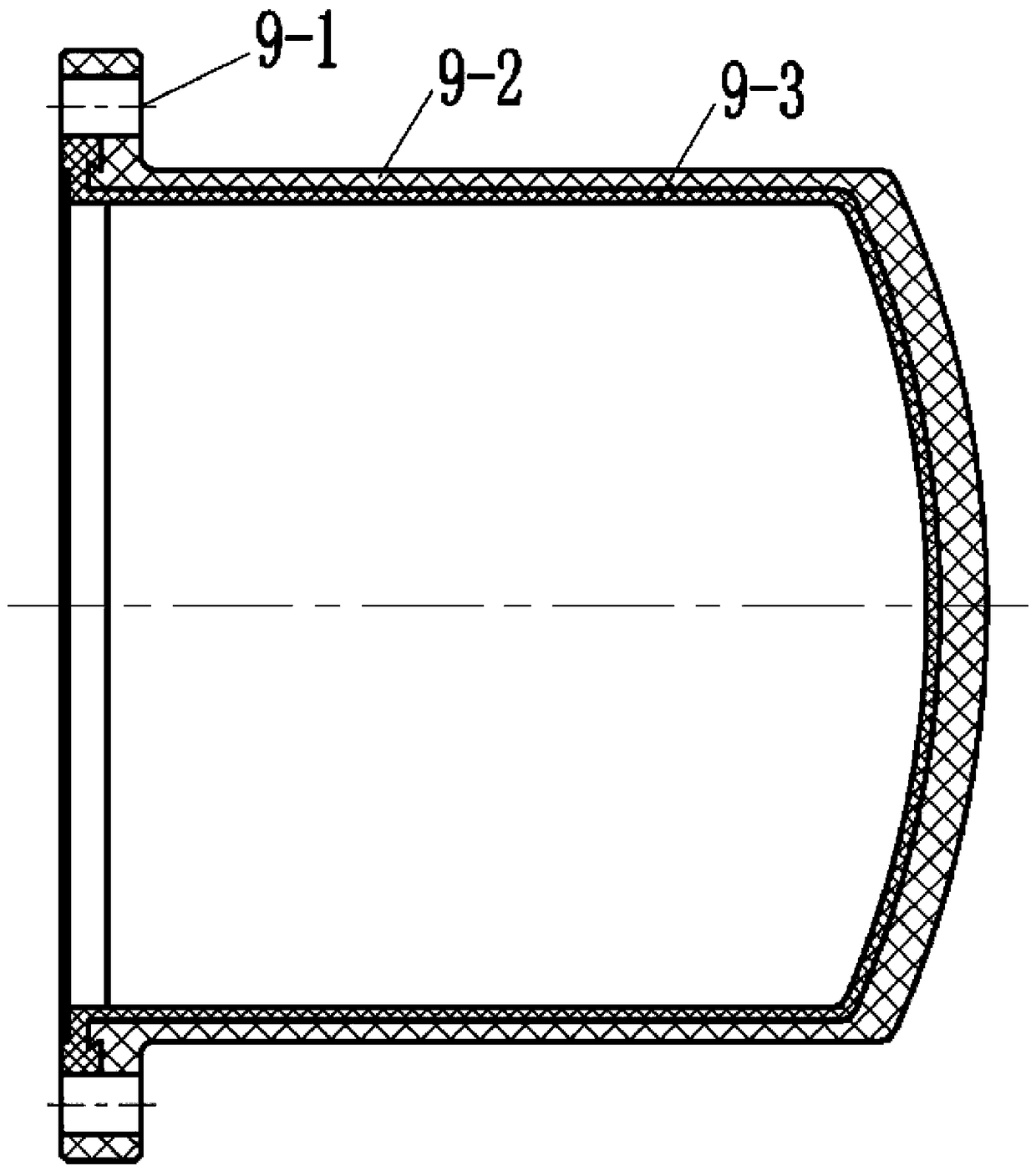

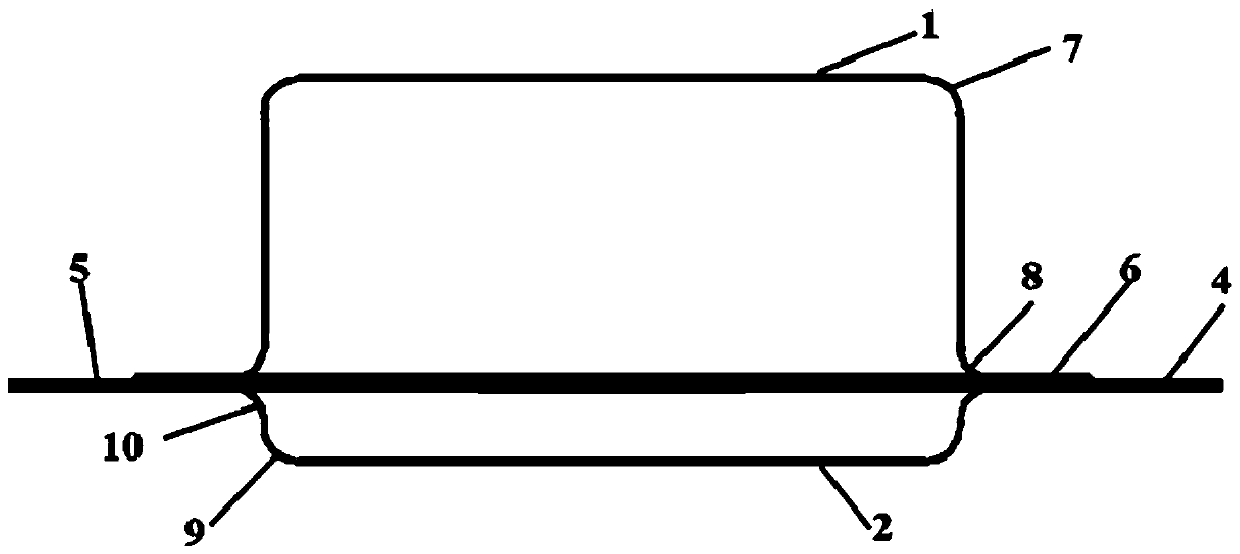

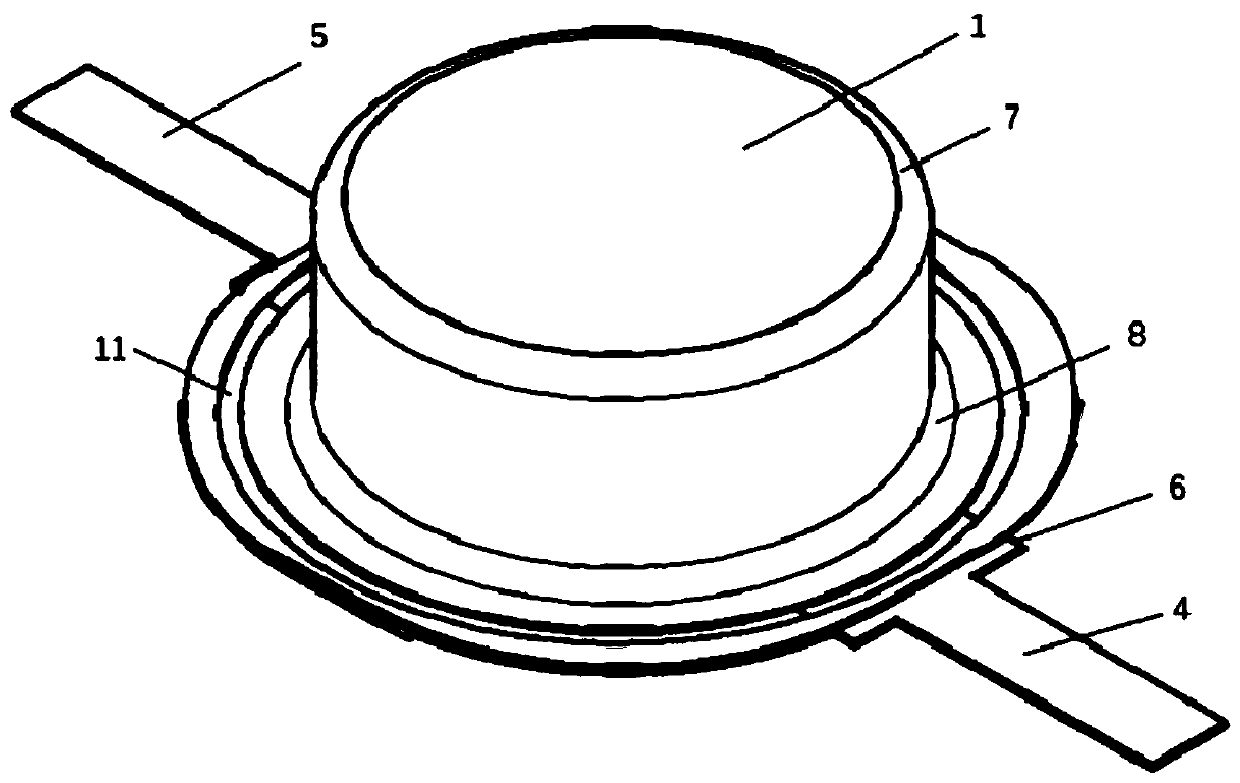

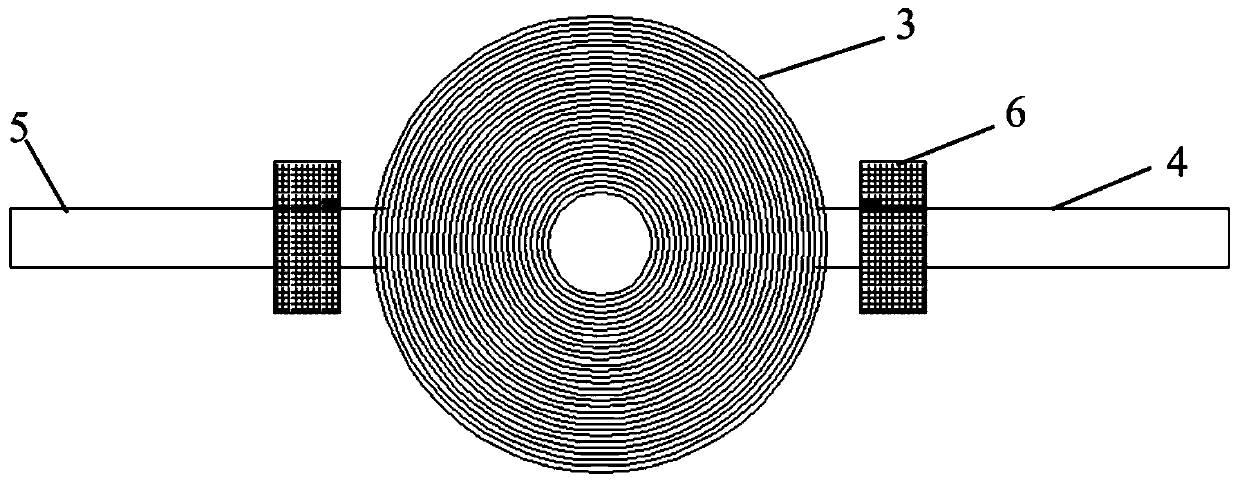

Micro-buckle battery and preparation method thereof

PendingCN110739487AIncrease volumetric energy densityIncrease energy densityFinal product manufactureSecondary cellsStructural engineeringMechanical engineering

The invention relates to a micro-buckle battery. The micro-button battery comprises a soft coating shell and a battery core which is arranged in the soft coating shell and has a winding structure, wherein the soft coating shell is divided into an upper shell and a lower shell which are provided with pits, arc-shaped outer chamfers are formed between side walls of the pits and top layers of the pits in the upper shell and the lower shell, and inner chamfers are formed on edges of openings of the pits on the upper shell and the lower shell. The micro-button battery is advantaged in that a specially designed punch forming die is adopted for the soft coating film, lead angles (outer chamfer and inner chamfer) of the formed soft coating film are optimized and calculated, so a problem of liquidleakage or damage of the battery caused by tensile cracking of the battery in the forming or using process can be effectively solved; the battery core with a winding type structure is adopted, the soft coating shell is arranged to be of a pit structure, so the effective space in the battery shell can be fully utilized, the volume energy density of the battery is improved, and the energy density ofthe battery is further improved due to the design of the light-weight soft coating shell.

Owner:东莞维科电池有限公司

Method for repairing slope vegetation

The invention relates to a dome repairing method that drills some deep holes on the dome by jack hammer or drilling machine, adds mixture vegetation in it and plants climbing plant on it, and uses the haulm of the plants to cover the dome. The method has little engineering work load, and the nutritive layer is not easy to be swept away, and it could also fix the dome.

Owner:CHINA THREE GORGES UNIV +2

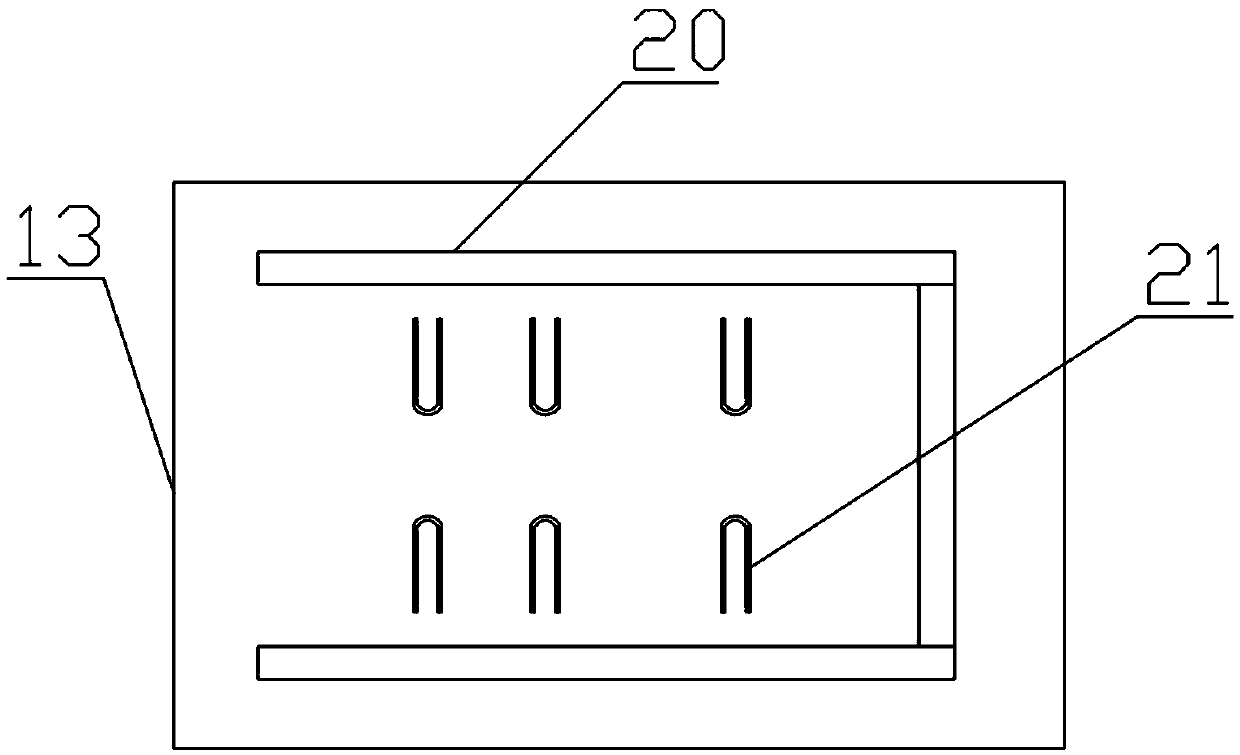

Bending glass tempering and blast cooling device and cooling method thereof

The invention discloses a bending glass tempering and blast cooling device and a cooling method thereof. The cooling device consists of a blast blower, an air power buffering chamber, an upper air chamber, a lower air chamber, an upper air outlet grid, a lower air outlet grid and a connecting pipeline. The upper air chamber and the lower air chamber are respectively provided with a plurality of air distributing channel outlets; the air chambers are manufactured to have inclined rectangular pyramid structures according to the air power distribution principle, so that each air distribution channel outlet has uniform air quantity and air pressure, and connected with one air outlet grid; and the air outlet grid consists of an interface and a plurality of rectangular-pyramid-shaped air grid sheets formed according to the air power distribution principle, a plurality of small air outlets are arranged on one surface of the air grid sheet, corresponding to glass to be cooled, air from the blast blower enters the air power buffering chamber for buffering, then enters the air chambers and is uniformly distributed to all the air grids by the air chambers and then uniformly distributed to all the air grid sheets, and air blown from the small air outlets has uniform air quantity and air pressure, thereby realizing the uniform cooling on the whole piece of glass, and manufacturing excellent bending and tempering glass products.

Owner:陈永乐

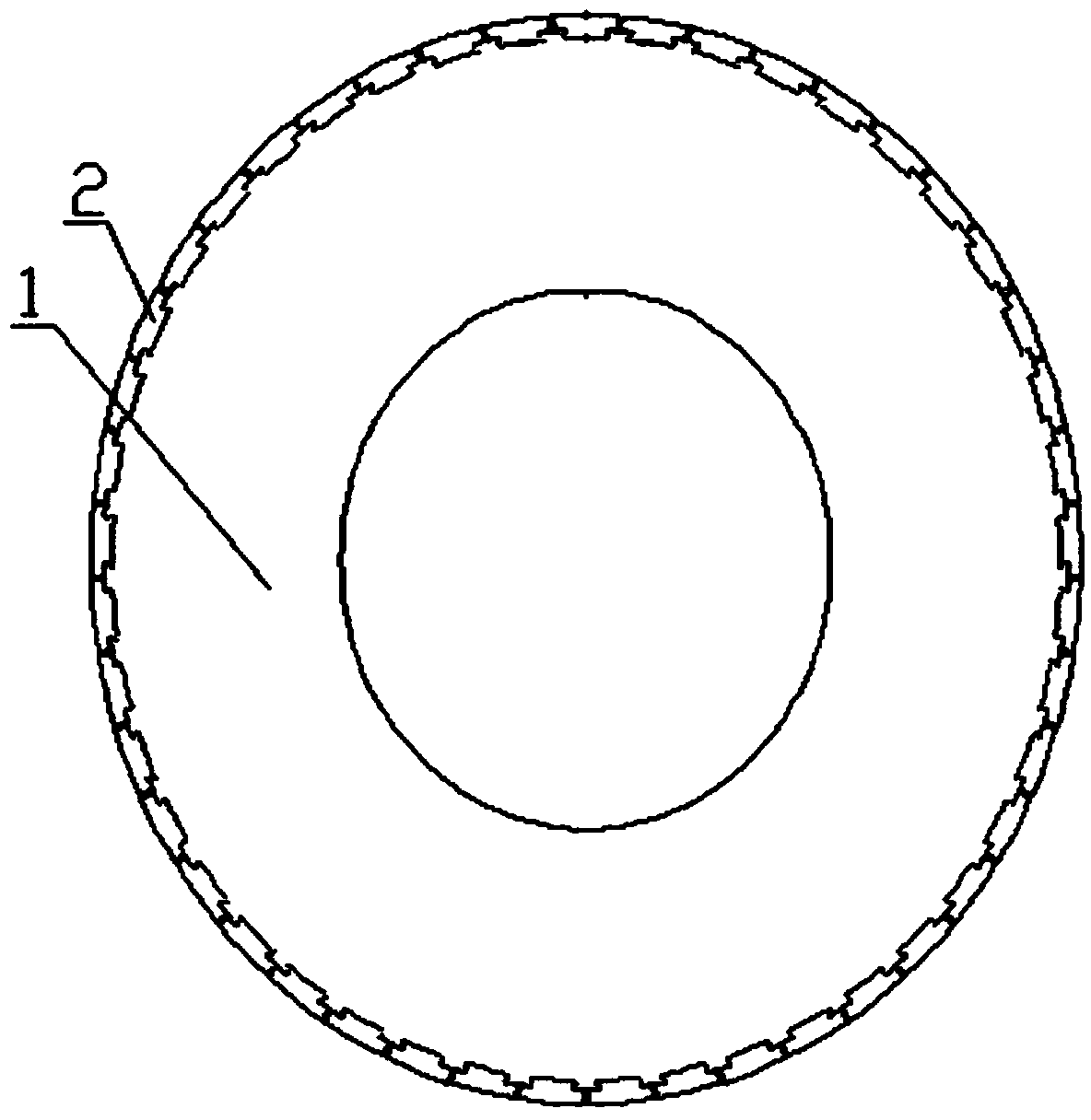

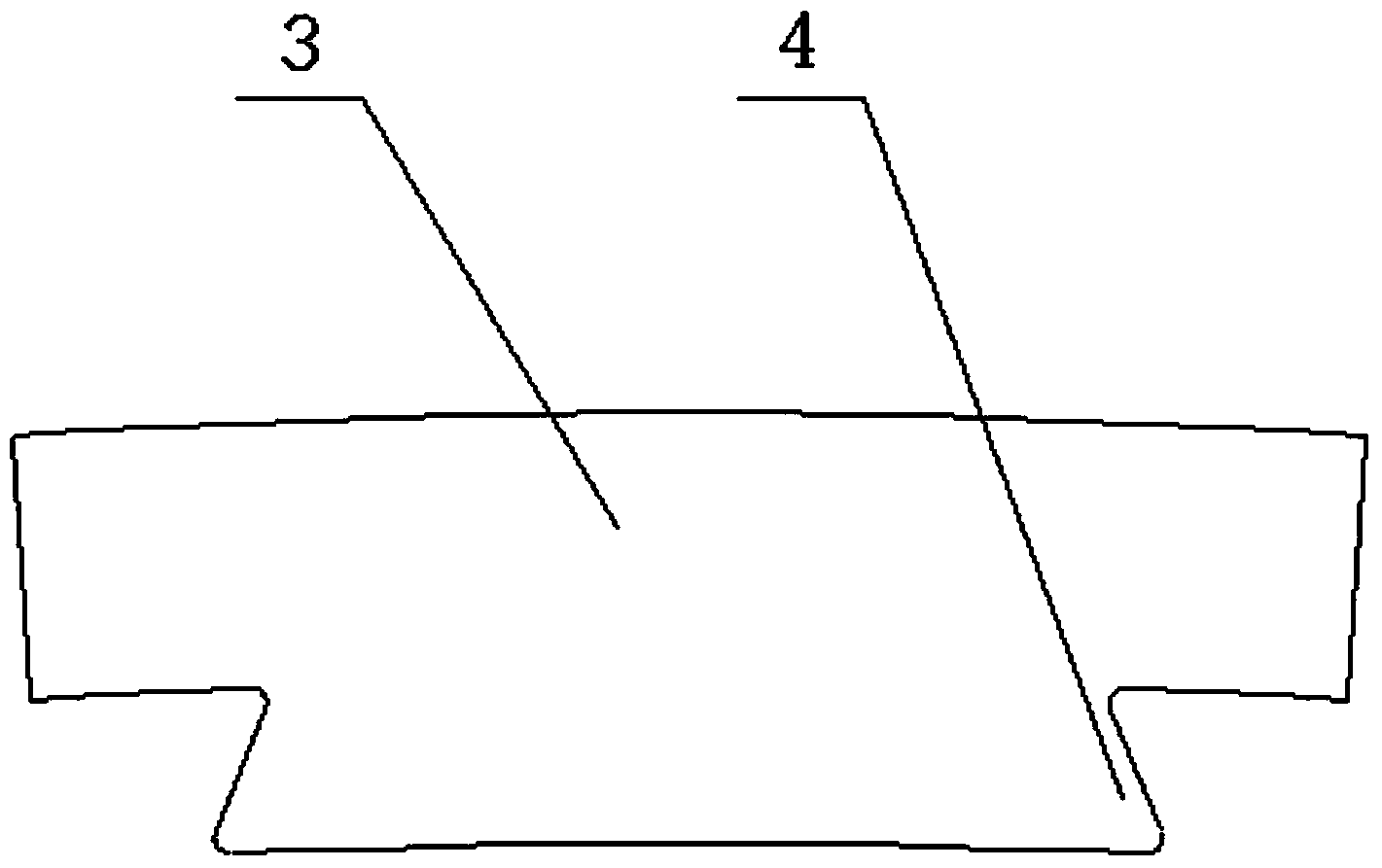

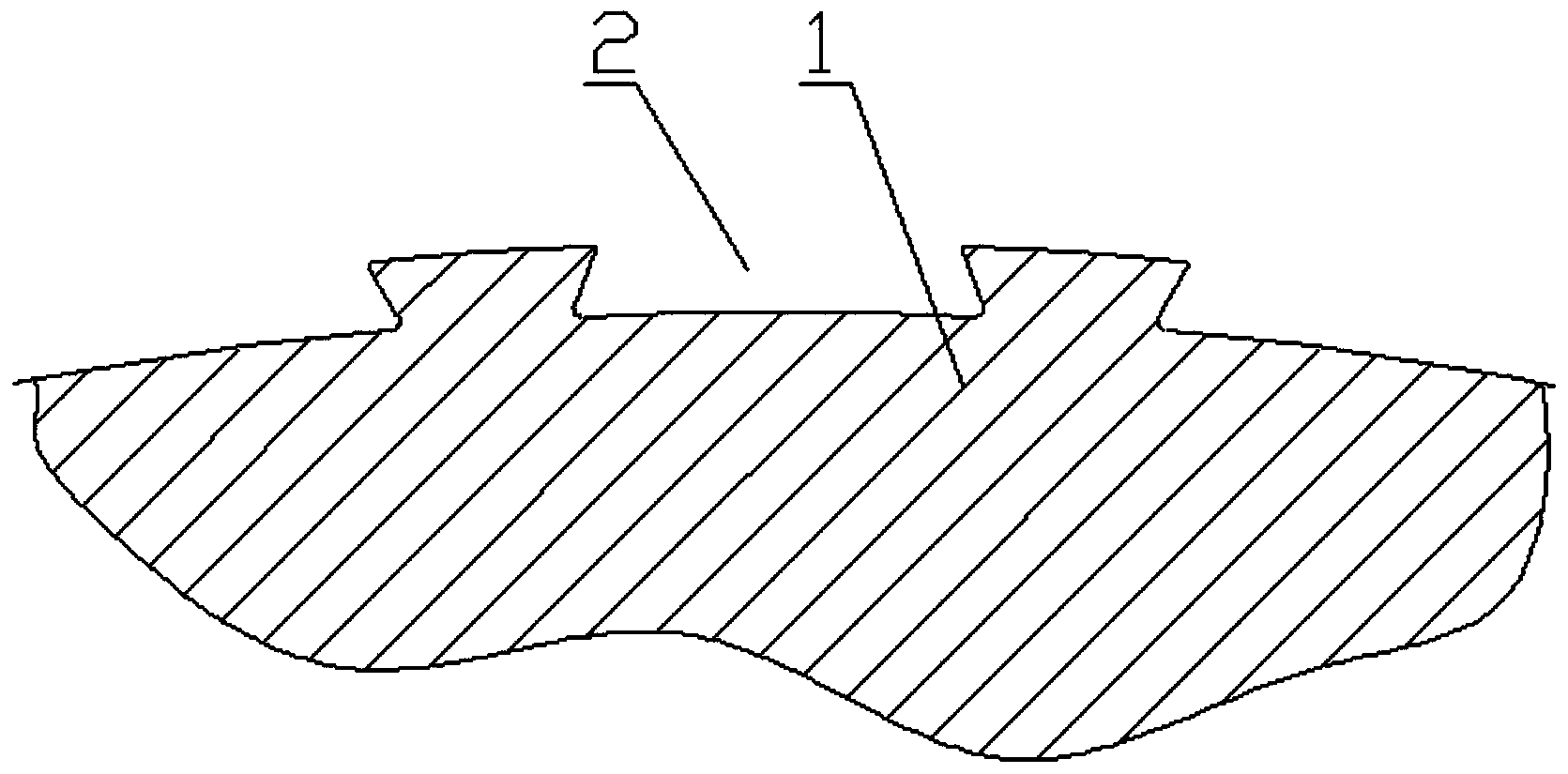

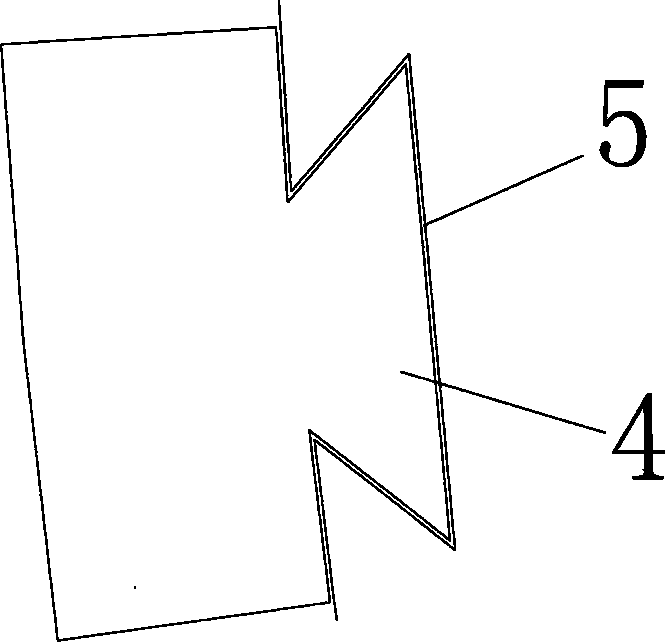

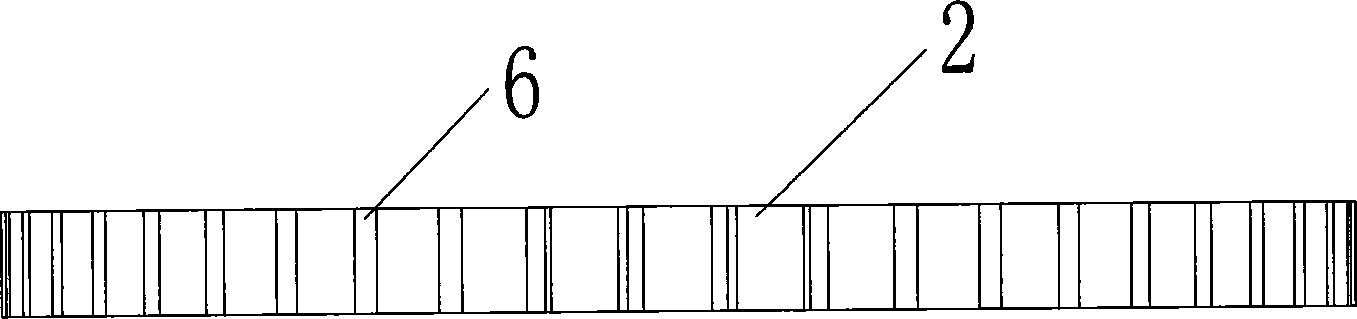

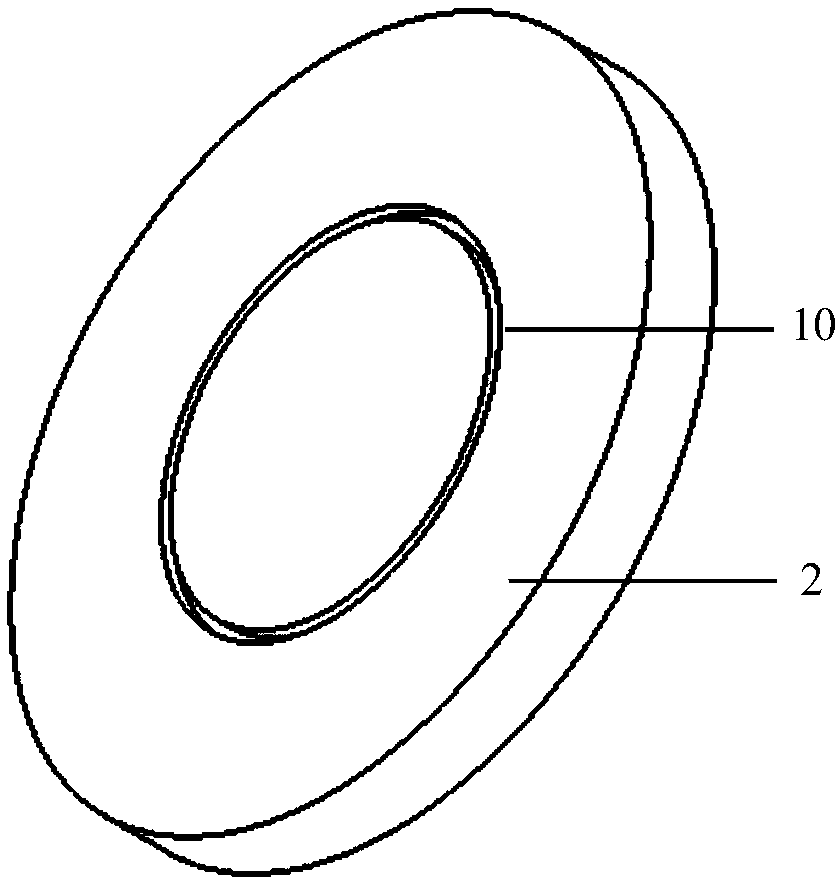

Grinding wheel with split dovetail groove structure

The invention discloses a grinding wheel with a split dovetail groove structure. The grinding wheel comprises an annular metal base body (1) and a grinding wheel grinding layer fixed on the peripheral surface of the metal base body (1), wherein the grinding wheel grinding layer is formed by combining a plurality of grinding wheel grinding blocks (2); dovetail grooves (3) are formed in the peripheral surface of the metal base body (1); a dovetail bugle (4) is arranged at the bottom of each grinding wheel grinding block (2); the dovetail bugles (4) of the grinding wheel grinding blocks (2) are embedded into the dovetail grooves (3) of the metal base body (1); the grinding wheel grinding blocks (2) are fixed to the metal base body (1); gaps (5) are formed in the embedded parts of the dovetail bugles (4) and the dovetail grooves (3). According to the grinding wheel, the split dovetail groove structure is adopted, so that materials are saved and the use cost is reduced; the grinding wheel has the characteristics that the production investment is small, the cost is low, the manufacturing process is easy to control, the scrap rate is low and the safety is good.

Owner:贵州荣清工具有限公司

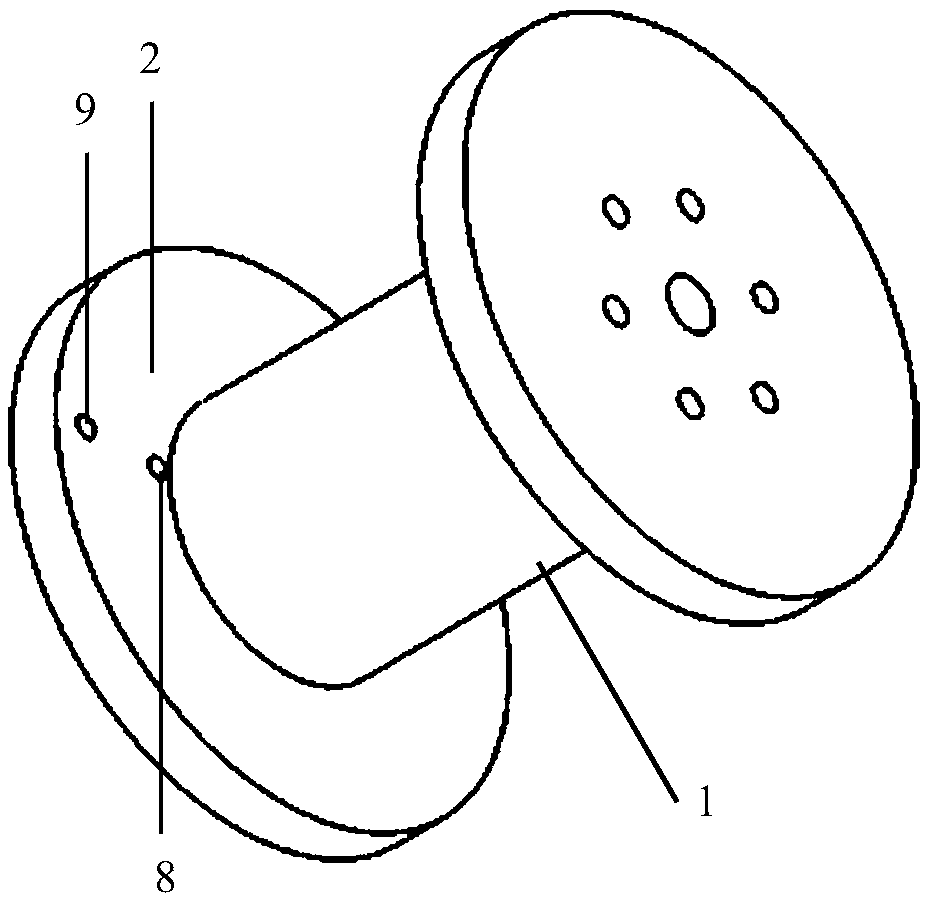

Manufacturing method for skeleton-free niobium-tri-tin superconducting coil

ActiveCN109545539AGood thermal stabilitySmall expansion coefficientCoils manufactureVacuum pressureNiobium

A manufacturing method for a skeleton-free niobium-tri-tin superconducting coil is disclosed. According to the method, a cylindrical quartz tube (1) and two end plate flanges (2) are assembled by nutfixation to be a skeleton for wrapping wires; a quartz skeleton is mounted on a winding machine to wind a niobium-tri-tin wire superconducting wire; when the wire is changed between layers, a layer ofglass wool cloth is laid on the surface of the upper layer of the niobium-tri-tin wire superconducting wire; after winding of a niobium-tri-tin superconducting coil (4) is completed, a wire is discharged at a wire outlet hole (9) of an end plate; the glass wool cloth is wrapped around the outermost layer of the niobium-tri-tin superconducting coil (4) in a half-lapping manner; then a binding layer (5) is wound around the outermost side; after the winding of the binding layer (5) is completed, the niobium-tri-tin superconducting coil equipped with tooling is placed in a vacuum heat treatment furnace for performing vacuum heat treatment and vacuum pressure impregnation, and finally an epoxy resin curing process is performed; and after the curing, the quartz tube (1) is removed to obtain theniobium-tri-tin superconducting coil (4) containing no skeleton.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Production process of 300sec viscosity nitrocotton

The invention discloses a production process of 300sec viscosity nitrocotton. The process comprises the steps of: first, refined cotton heating: in certain environment, heating refined cotton for a certain period of time; second, refined cotton nitrification: using certain acid to conduct nitrification for certain period of time; third, nitrocotton acid removal: removing acid from the nitrified refined cotton by specific instrument; fourth, nitrocotton boiling washing: subjecting the acid removed nitrocotton to boiling washing through a specific solution; and fifth, nitrocotton dehydration: dehydrating the boiling washed nitrocotton and preliminarily controlling the water content of the nitrocotton. The method provided by the invention can obviously improve the stability, avoids the problem of unstable performance of 2000300sec viscosity nitrocotton, can endure a short period of time of local high temperature, avoids the acid liquid boiling phenomenon caused by local high temperature, and avoids the release of nitrogen dioxide, cannot cause bursting of a nitrocotton holding container, eliminates unnecessary risks, and avoids waste and loss.

Owner:NANTONG TAILIDA CHEM

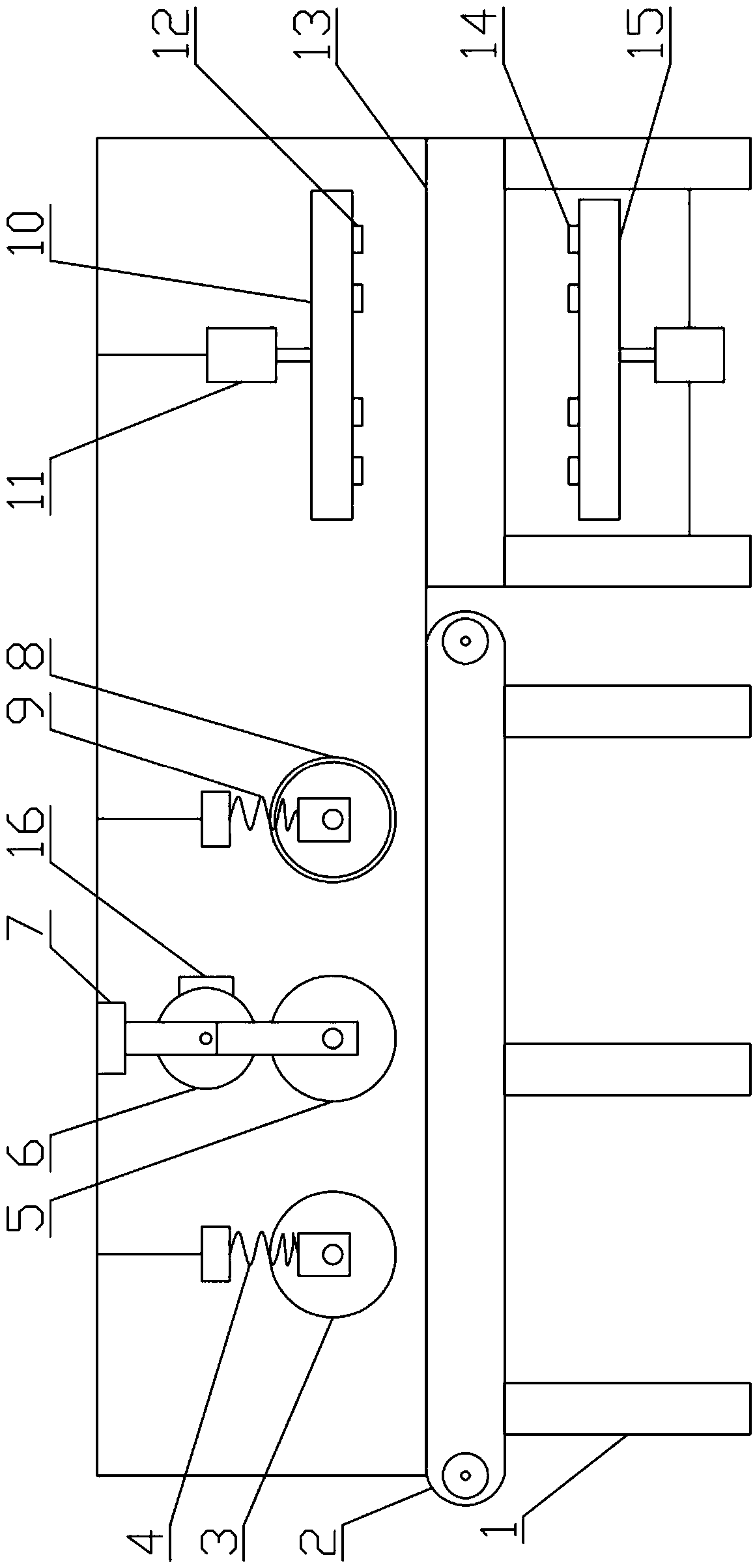

Carton grooving device with carton bursting prevention function and grooving method

A carton grooving device with a carton bursting prevention function comprises a machine frame. A conveying belt which is used for conveying carton boards is arranged on the machine frame. A humidifying mechanism which is used for humidifying the carton boards is arranged above the conveying belt. A grooving mechanism which is used for grooving the carton boards is arranged at the tail end of the conveying belt. The humidifying mechanism comprises a humidifying wheel and a water feeding wheel. The humidifying wheel is installed above the conveying belt, and the water feeding wheel is installedover the humidifying wheel. A water feeding sponge strip is installed on the water feeding wheel. The distance between the humidifying wheel and the conveying belt is smaller than or equal to the thickness of each carton board, and the distance between the water feeding wheel and the humidifying wheel is smaller than the thickness of the water feeding sponge strip. The carton grooving device withthe carton bursting prevention function is reasonable in design and convenient to use. The carton boards are humidified and then grooved, the phenomenon that when the carton boards are grooved, the carton boards burst is effectively avoided, and therefore the reject ratio of cartons is greatly reduced, and normal production of the cartons is guaranteed.

Owner:连云港市振扬纸品有限公司

UV hardening decorative film capable of being processed and formed deeply and preparation method of UV hardening decorative film

InactiveCN106046405AHigh surface hardnessWon't burstPolyurea/polyurethane coatingsHardnessMaterials processing

The invention discloses a UV hardening decorative film capable of being processed and formed deeply and a preparation method of the UV hardening decorative film. A UV coating in the UV hardening decorative film consists of acrylic polyurethane, hydroxyl-containing resin and a photoinitiator. The UV coating can be used in the industries of printing products, aluminum material processing, transfer printing films and the like. The UV hardening decorative film is high in hardness and high in scratching resistance, has excellent mechanical property and chemical resistance, and can be processed and formed deeply, and a UV coated layer cannot be exploded. Hardening can be implemented without spraying equipment, production is flexible and convenient, a production process is environmentally friendly, and integral pollution emission can be reduced.

Owner:李炳恩

Magnetically sealing valve device for a battery casing

InactiveCN102468462AGuaranteed closureReduce magnetic forceOperating means/releasing devices for valvesCell component detailsFuel cellsMagnetic valve

A valve apparatus (4) is provided for a housing (2) of an electrochemical current source (1). Furthermore, the magnetic valve apparatus (4) is provided for, among other things, battery housings, fuel cell housings as well as chemical or biological reactors. As a result of using a magnetic valve apparatus (4) as an excess pressure valve, the housing (2) can be designed to operate safely even after years of use, and in addition, the valve apparatus (4) can automatically change back into the closed position after an opening and a pressure degradation and can thus build up again a protection against the penetration of fluids into the inner space (5) of the housing without external action.

Owner:CARL FREUDENBERG KG

Steel pipe for water delivery pipeline

InactiveCN105937666AWon't burstWaterproofThermal insulationCorrosion preventionSteel tubeWater delivery

The invention discloses a steel pipe for water delivery pipeline. The steel pipe comprises a steel pipe body, an anti-scaling coating, an antibacterial coating, a first temperature sudden drop protective layer and a second temperature sudden drop protective layer, wherein the outer surface of the steel pipe body is sequentially provided with the anti-scaling coating and the antibacterial coating from inside to outside; and the inner surface of the steel pipe body is sequentially provided with the first temperature sudden drop protective layer and the second temperature sudden drop protective layer from outside to inside. In such a way, the steel pipe has anti-scaling and antibacterial functions, and steel pipe explosion caused by outside temperature shock cannot happen.

Owner:无锡必胜必精密钢管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com