Ice crystal evaporator and ice crystal water cooling device producing from same

An evaporator and water cooling technology, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of difficult wide application, high manufacturing cost, low energy efficiency, etc., and achieve high refrigeration efficiency and long flow time Short, high energy efficiency ratio effect

Active Publication Date: 2011-06-15

蒋军闽

View PDF7 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are three sources of this water: one is directly obtained by dissolving ice; the second is to use a salt water tank device of tens of tons, and water tanks ranging from tens of tons are placed in the tank at the same time. The antifreeze performance of salt water, through a refrigeration cycle system, the temperature of the salt water is reduced to about -20 degrees, and then the temperature in the water tank is reduced to about zero degrees through the heat exchange between the salt water and the water tank. This device is currently widely used in the seafood quick-freezing industry or large-scale lettuce In the manufacturing market, this method has made great progress compared to the method of directly using ice to melt, but the energy efficiency of heat exchange is still not high, the volume of the device is large, and the manufacturing cost is high, so it is difficult to be widely used; the third is The national standard evaporator is used for refrigeration, and its general structure is shown in Figure 5: it includes a shell 90, and one end of the shell 90 is provided with a refrigerant medium liquid inlet chamber and a refrigerant medium return air chamber separated by a partition, and the other end of the shell 90 is set There is a cooling medium return cavity, and uniformly distributed cooling copper tubes 94 are arranged in the housing 90 between the liquid inlet cavity, the air outlet cavity and the return cavity, and the cavity between the inner wall of the housing 90 and the cooling copper tube 94 is perpendicular to The axis of the cooling copper pipe 94 is provided with several partitions 93, and a flow opening 97 is provided at different angles outside each partition 93, so that the flow direction of the cooled medium is from the shell wall at the right end of the cooling copper pipe 94. After the water inlet 91 on the top enters, it passes through the flow opening 97 on each partition 93 in turn, and then flows out from the water outlet 92 on the shell wall at the left end of the cooling copper tube 94, and the cooling medium flows from the liquid inlet 95 in turn. Through the liquid inlet chamber, copper pipe 94, return chamber, copper pipe 94, and air outlet chamber, the gas is drawn out from the air return port 96. The disadvantages are: the one is that the cooling medium (water) flows from one end of the cooling copper pipe to the other. During the flow at one end, due to the low temperature of the cooling medium and the slow flow rate of the cooled medium when passing through, it is easy to cause the cooled medium to freeze and block the passage of the cooled medium, resulting in the failure of the evaporator due to the inability to cool within a certain period of time. If the work fails, if you want to eliminate the fault, you must stop the machine for deicing and then start it for use. In severe cases, it will cause the bursting of the evaporator shell and the internal cooling copper pipe, which will affect the need for refrigeration at that time and increase the purchase cost of the equipment; the second is Refrigeration units equipped with this evaporator have the same failure and inconvenience due to failure of the evaporator

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

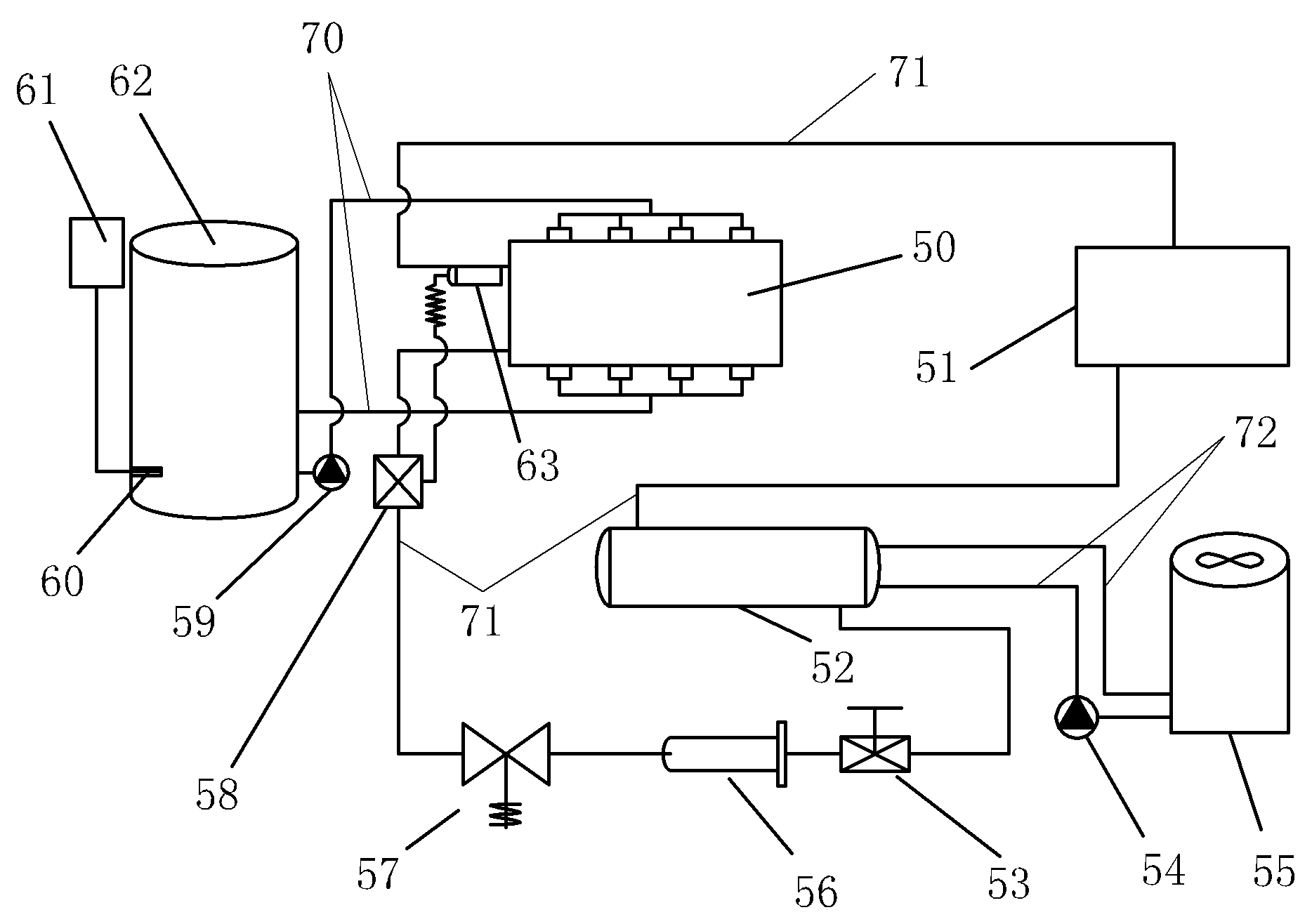

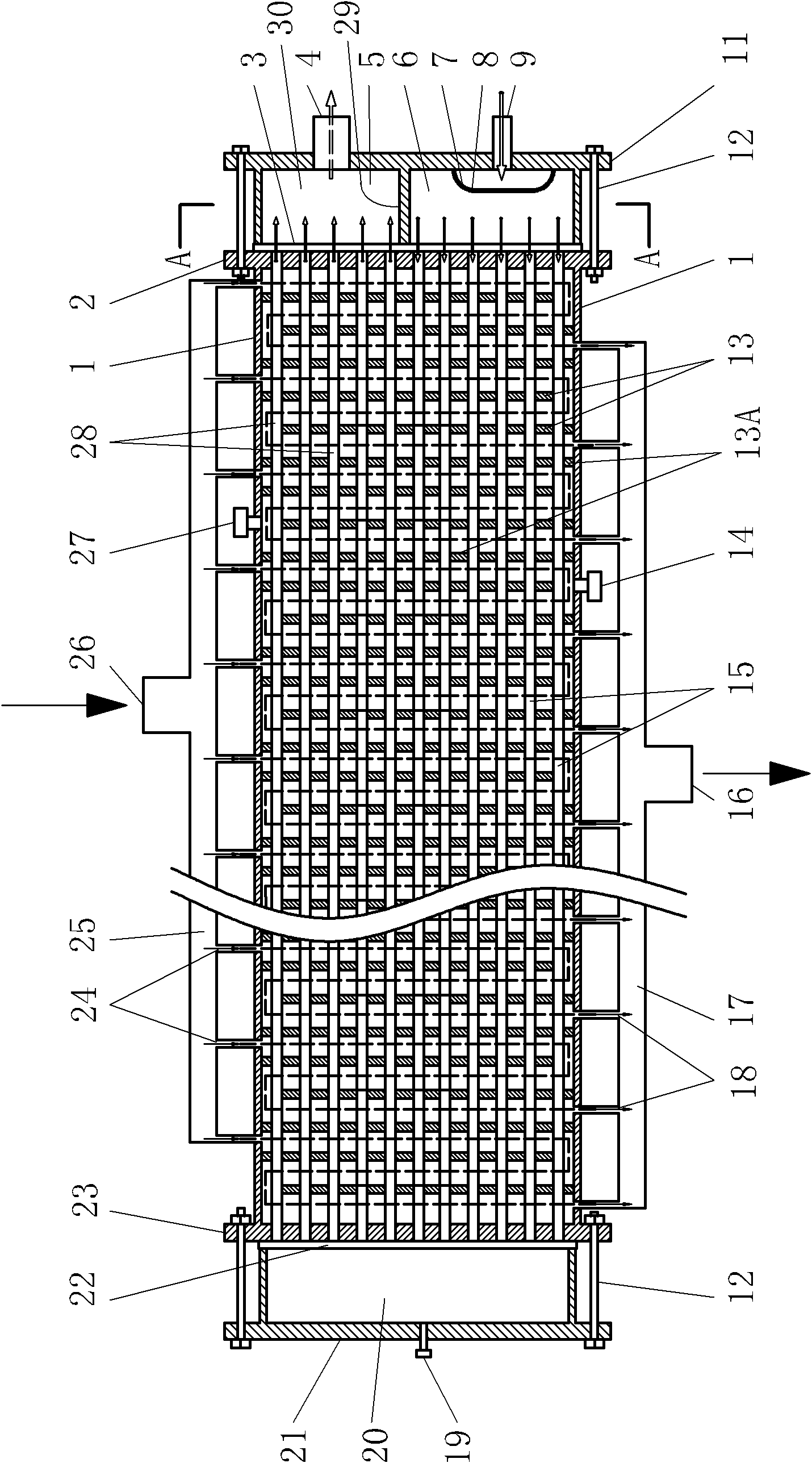

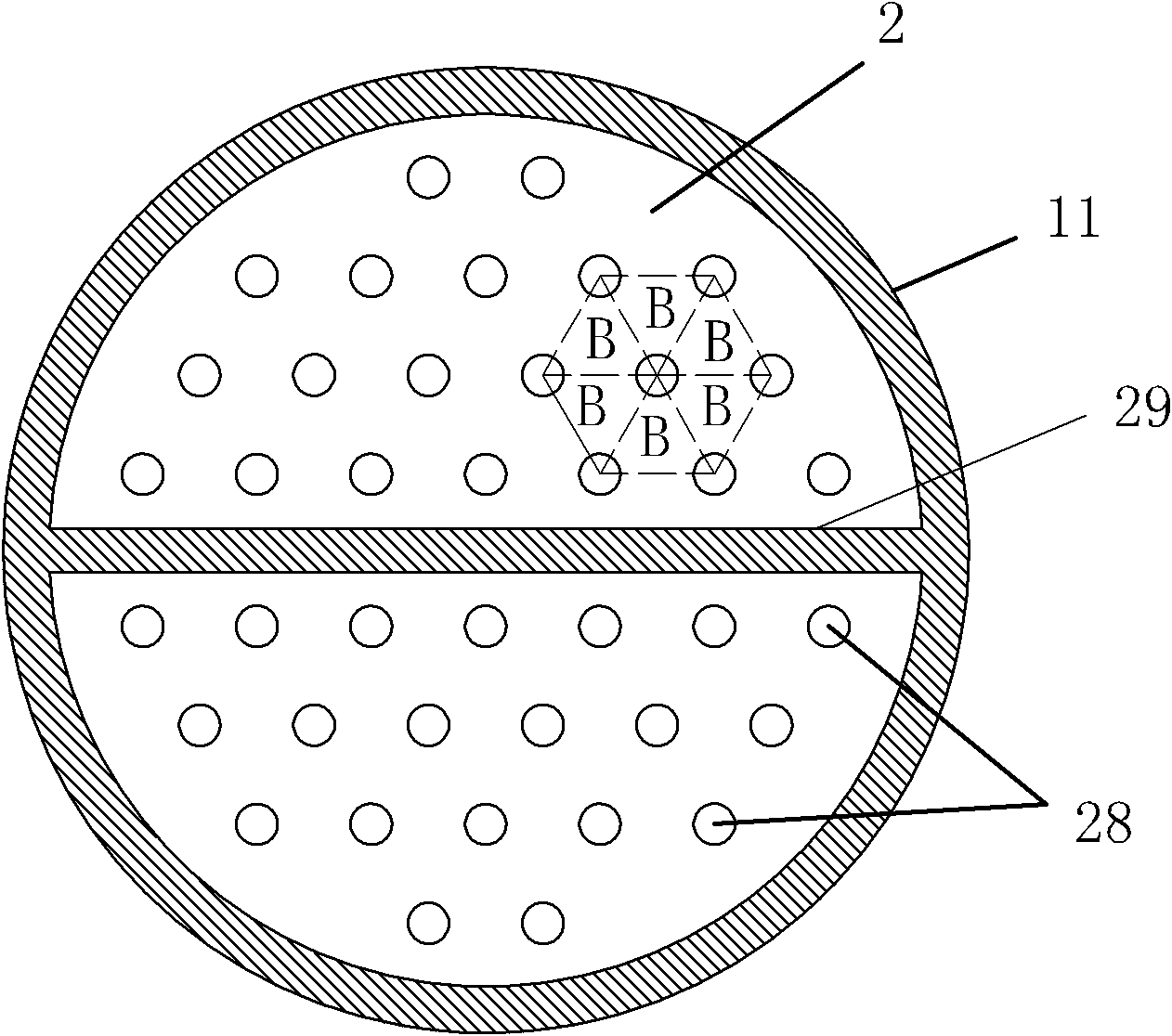

The invention relates to an ice crystal evaporator and an ice crystal water cooling device producing from the same, belonging to the technical field of refrigeration. The ice crystal evaporator is characterized in that a liquid inlet channel is formed by an evaporator tube, a liquid inlet and a liquid outlet in a tubular casing; and the outer channel of the evaporator tube of the tubular casing is divided into more than one S-shaped channel forming a water return channel through a water inlet of a water divider and a water outlet of a water collector. The ice crystal water cooling device is characterized in that the return air inlet of the ice crystal evaporator is communicated with a compressor, a condenser, a liquid feeding valve, a dry filter, a liquid feeding electromagnetic valve anda thermostatic expansion valve in sequence, and then is communicated with the liquid inlet of the ice crystal evaporator; a cooling water inlet / outlet of the condenser is connected with a cooling tower in series; and a water inlet / outlet of the ice crystal evaporator is communicated with a water circulating pump and an ice crystal energy storage tank in series. The invention has the advantages ofhigh cooling efficiency, no icing and low cooling temperature and is suitable for production of energy storage central air-conditioning, marine fishing, seafood processing, fruit, vegetable or meat processing, and the like; the cooled medium is municipal water.

Description

Ice crystal evaporator and ice crystal water refrigeration device made of it technical field The invention belongs to the technical field of refrigeration, in particular to an ice crystal evaporator and an ice crystal water refrigeration device made of the ice crystal evaporator. Background technique At present, a kind of quick-freezing fresh-keeping treatment method is used many times in the ocean fishing chilling process, seafood processing, vegetables and fruits or frozen meat food processing technology. This process is to soak the product to be processed in water, and then put it in Quick-freezing is performed in an ultra-low temperature environment, so that an ice layer is formed on the surface of the product to achieve the purpose of freshness preservation. In consideration of efficiency, the water used for soaking is zero-degree or below-zero water. There are three sources of this water: one is directly obtained by dissolving ice; the second is to use a salt water t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F25B39/02F25C1/00

Inventor 洪志文

Owner 蒋军闽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com