Building board processing device

A processing device and technology for building boards, applied in wood processing equipment, manufacturing tools, forming/shaping machines, etc., can solve problems such as cracking of wood boards, failure to clamp and match wood boards, etc., and achieve the effect of avoiding uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

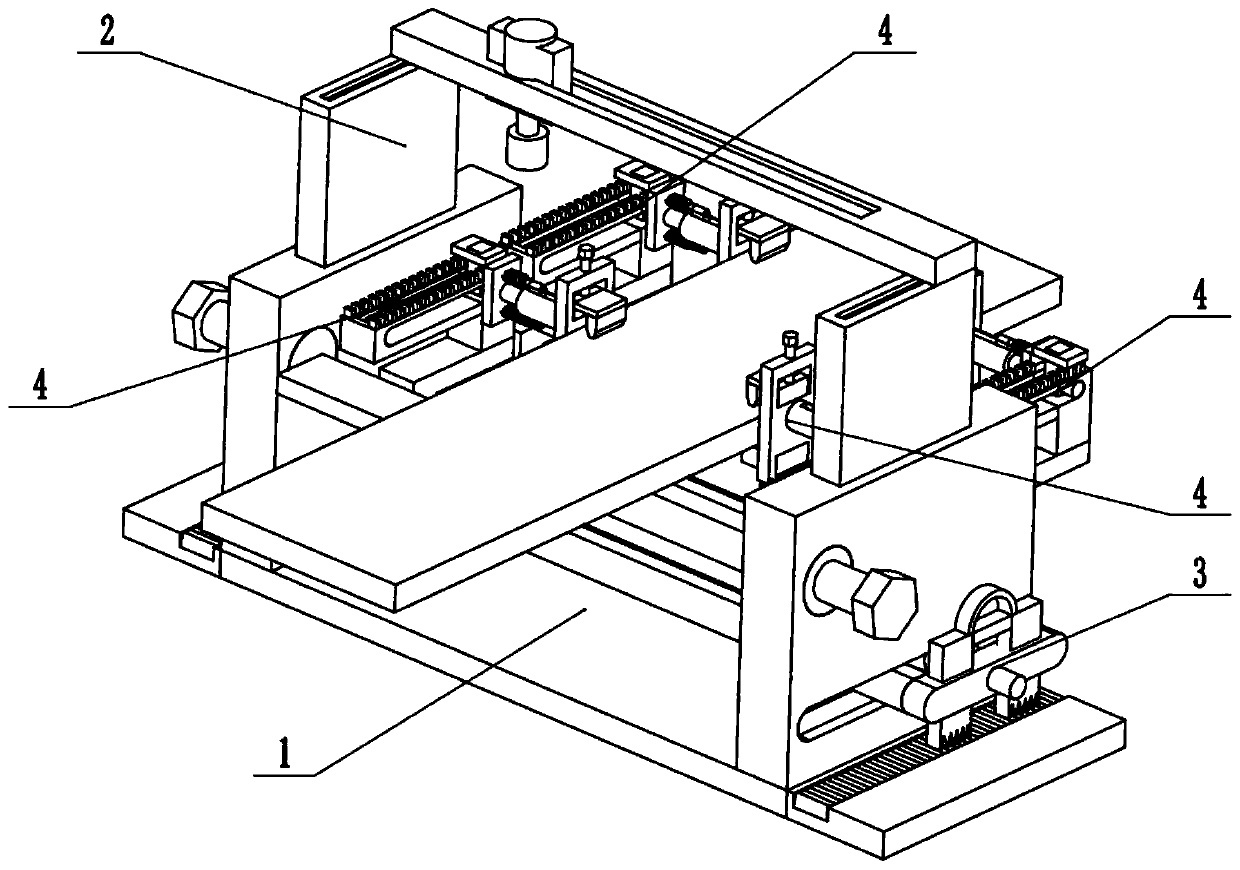

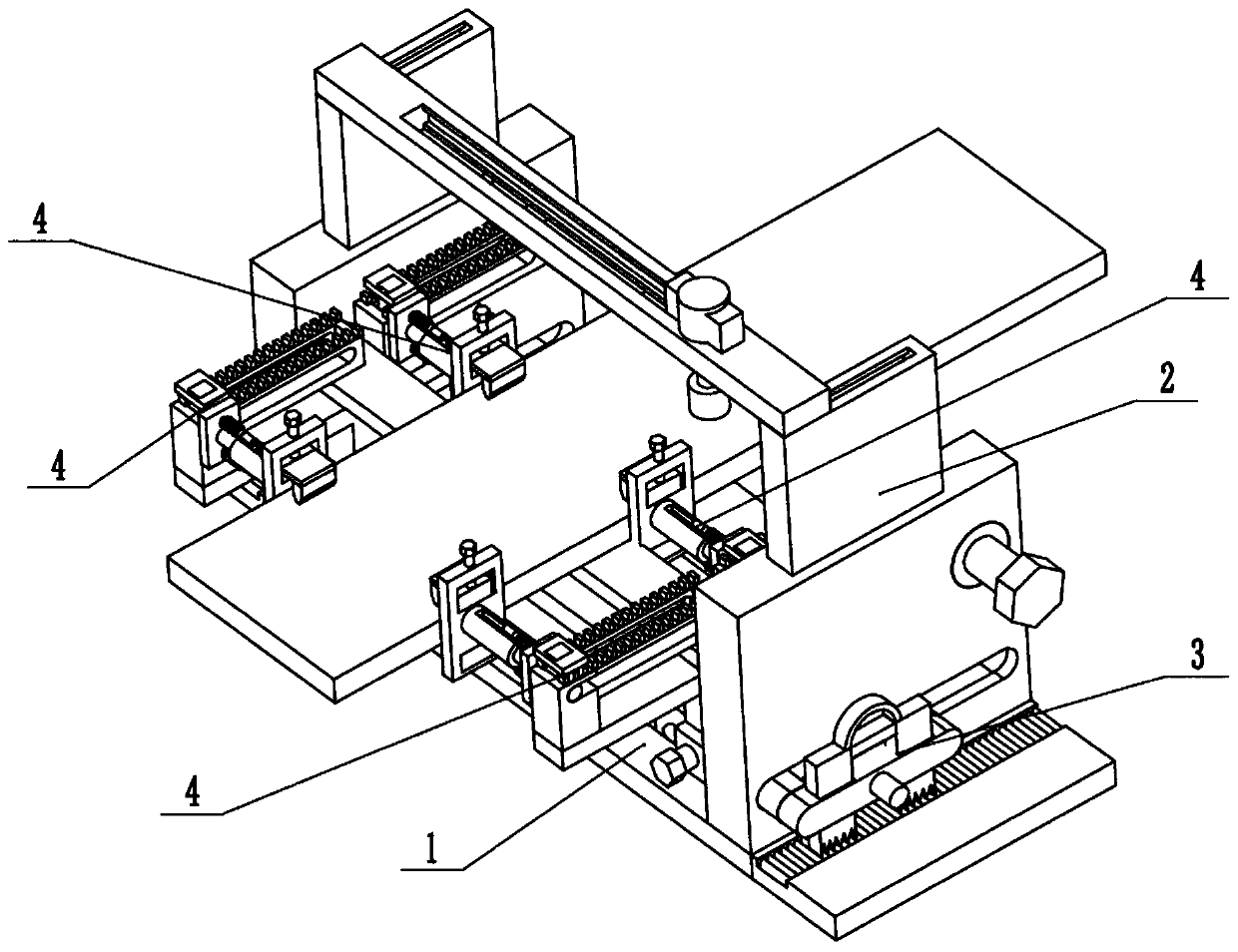

[0029] Such as Figure 1 to Figure 10 As shown, a building board processing device includes a base fixing device 1, a drilling depth regulator 2, a position moving base 3 and four multi-style clamping devices 4, and the drilling depth regulator 2 is slidably connected to the base In the fixing device 1, the position moving base 3 is slidably connected in the base fixing device 1, the lower end of the position moving base 3 is engaged with the base fixing device 1, and the four multi-style clamping devices 4 are all slidably connected on the position moving base 3. During the home decoration process, if it is necessary to temporarily punch holes or cut off a part of the integrated gusset plate according to the actual situation, in order to avoid the wooden board from bursting during processing, place the wooden board on the base fixing device 1, and according to the punching The position and the shape of the board are adjusted through four multi-style clamping devices 4, and the ...

specific Embodiment approach 2

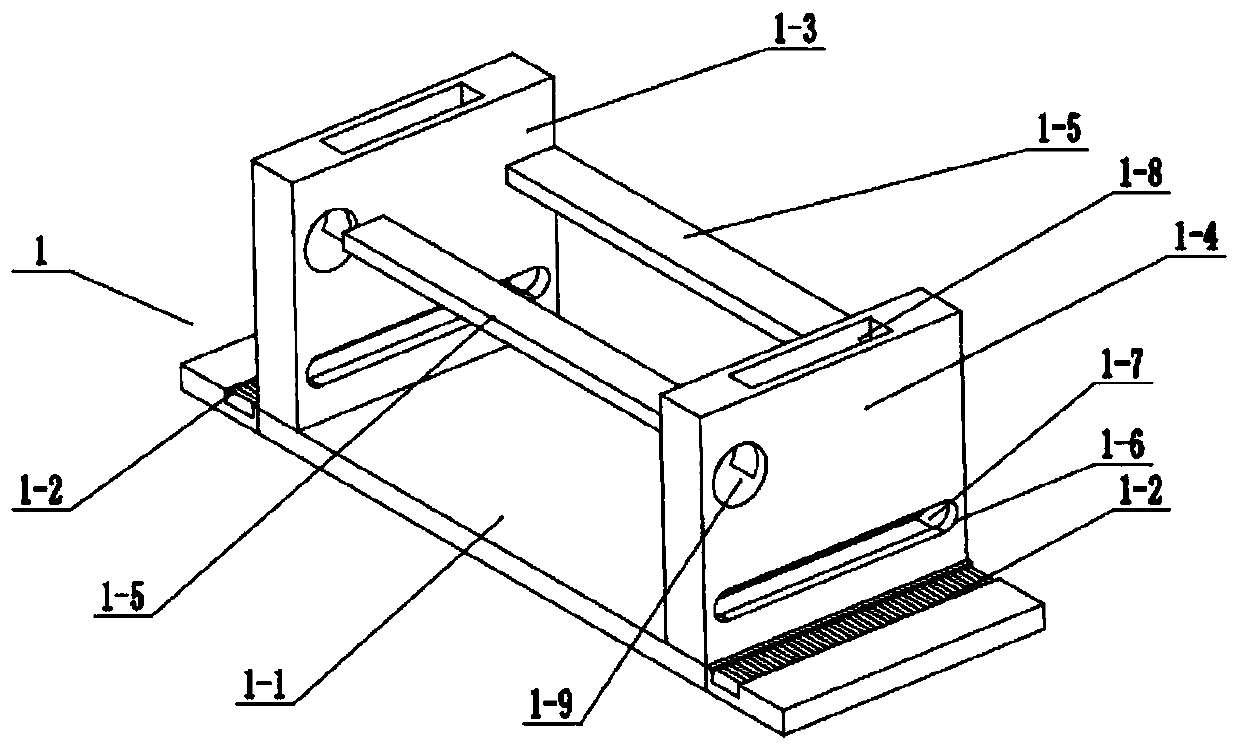

[0031] Such as Figure 1 to Figure 10 As shown, this embodiment will further explain Embodiment 1. The base fixing device 1 includes a bottom plate 1-1, two fixing racks 1-2, a front fixing seat 1-3, a rear fixing seat 1-4, two A placement plate 1-5, two chute 1-6 through front and back, two slide rails 1-7, two rectangular chute 1-8 and two connected rotating round holes 1-9, the bottom plate 1 The front and rear sides of the -1 upper end are respectively fixedly connected with two fixed racks 1-2, the front fixed seat 1-3 and the rear fixed seat 1-4 are all fixedly connected on the bottom plate 1-1, and the two placement plates 1-5 are all fixedly connected to each other. Fixedly connected between the front fixed seat 1-3 and the rear fixed seat 1-4, the lower side of the front fixed seat 1-3 and the rear fixed seat 1-4 are all provided with the chute 1-6 that runs through front and back, two slides The inner wall of the slot 1-6 is provided with a slide rail 1-7, the upper...

specific Embodiment approach 3

[0033] Such as Figure 1 to Figure 10 As shown, this embodiment will further illustrate the second embodiment. The perforating depth regulator 2 includes two tooth slide frames 2-1, two upper T-shaped slide grooves 2-2, and an adjustment slide bar 2-3. , adjusting slide rail 2-4, adjusting sliding seat 2-5, milling motor 2-6, milling cutter 2-7, two adjusting drive gears 2-8, two manual rotary rods 2-9, two front covers 2-10 and two rear end covers 2-11, the two tooth sliding frames 2-1 are respectively slidably connected in the two rectangular chute 1-8, and the upper ends of the two tooth sliding frames 2-1 are set There is a horizontal upper T-shaped chute 2-2, and the two ends of the adjustment slide bar 2-3 are slidably connected in the two upper T-shaped chute 2-2 through a T-shaped slider, and the adjustment slide bar 2-3 is set There are adjustment slide rails 2-4, the adjustment slide seat 2-5 is slidably connected in the adjustment slide rail 2-4, the milling motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com