Bending glass tempering and blast cooling device and cooling method thereof

A blast cooling and glass tempering technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as affecting tempering quality, failing to achieve cooling speed, affecting the appearance and use of glass, and achieving uniform blasting The effect of the cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

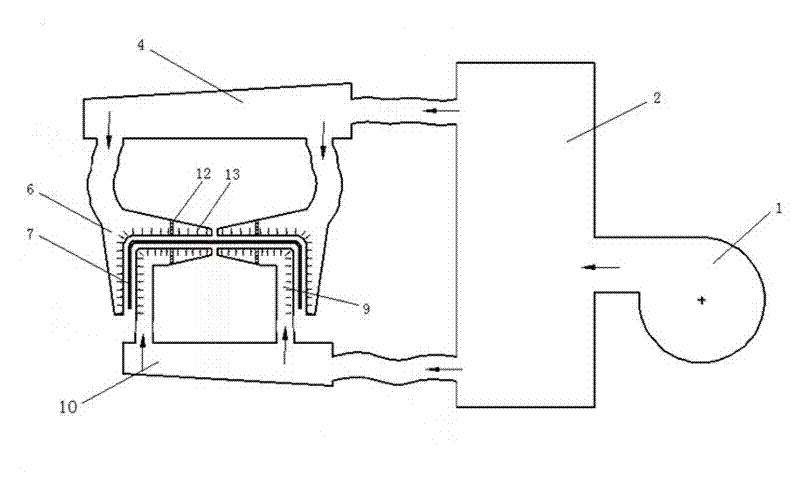

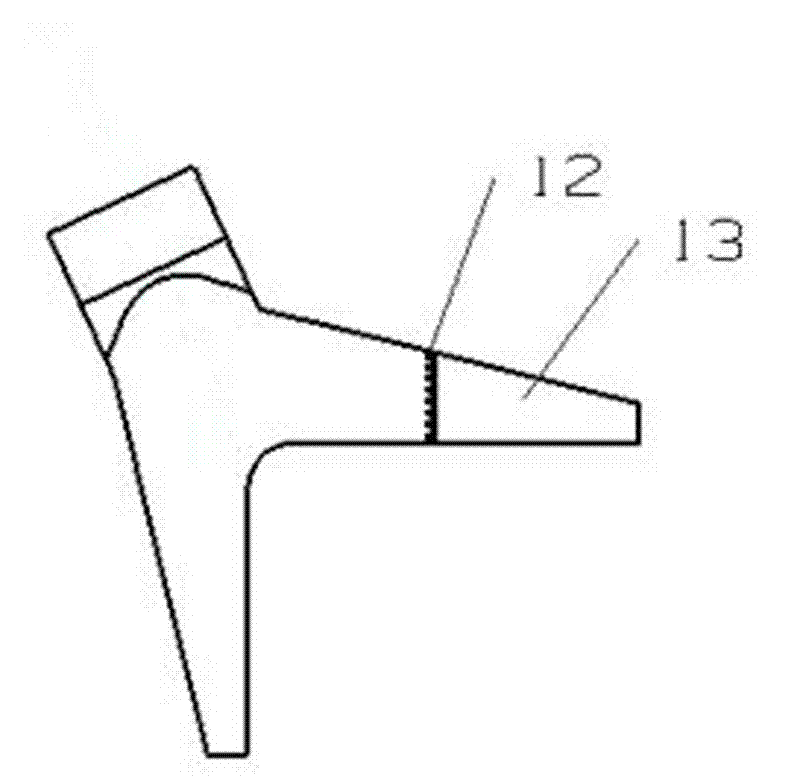

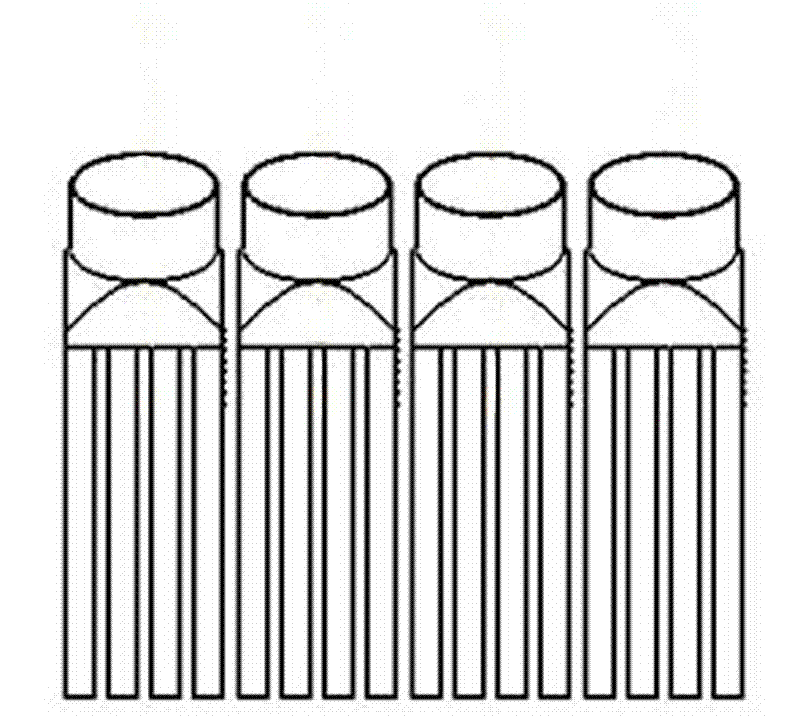

[0027] exist figure 1 In the shown embodiment, a blower cooling device for curved tempered glass mainly consists of a blower 1, a wind buffer chamber 2, an upper wind chamber 4, a lower wind chamber 10, an upper air outlet grid 6, a lower air outlet grid 9 and connecting pipes, etc. Partial composition. The upper, lower, left, and right distances corresponding to the upper air outlet grille and the lower outlet air grille can be adjusted. The blower is connected to the wind buffer chamber with the first connecting pipe, the wind buffer chamber is provided with upper and lower air outlets, the upper air outlet is connected with the upper air chamber with the second connecting pipe, and the upper air chamber is provided with several upper air passage outlets 14 , each outlet of the upper air duct is connected to an upper air outlet grid, and the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com