Grinding wheel structure and manufacturing method

A manufacturing method and grinding wheel technology, which are applied in the direction of bonding grinding wheels, manufacturing tools, abrasives, etc., can solve the problems of uneven quality of grinding wheels, difficult sintering control, and large production investment, and achieve flexible arrangement of grinding blocks, long service life, and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description:

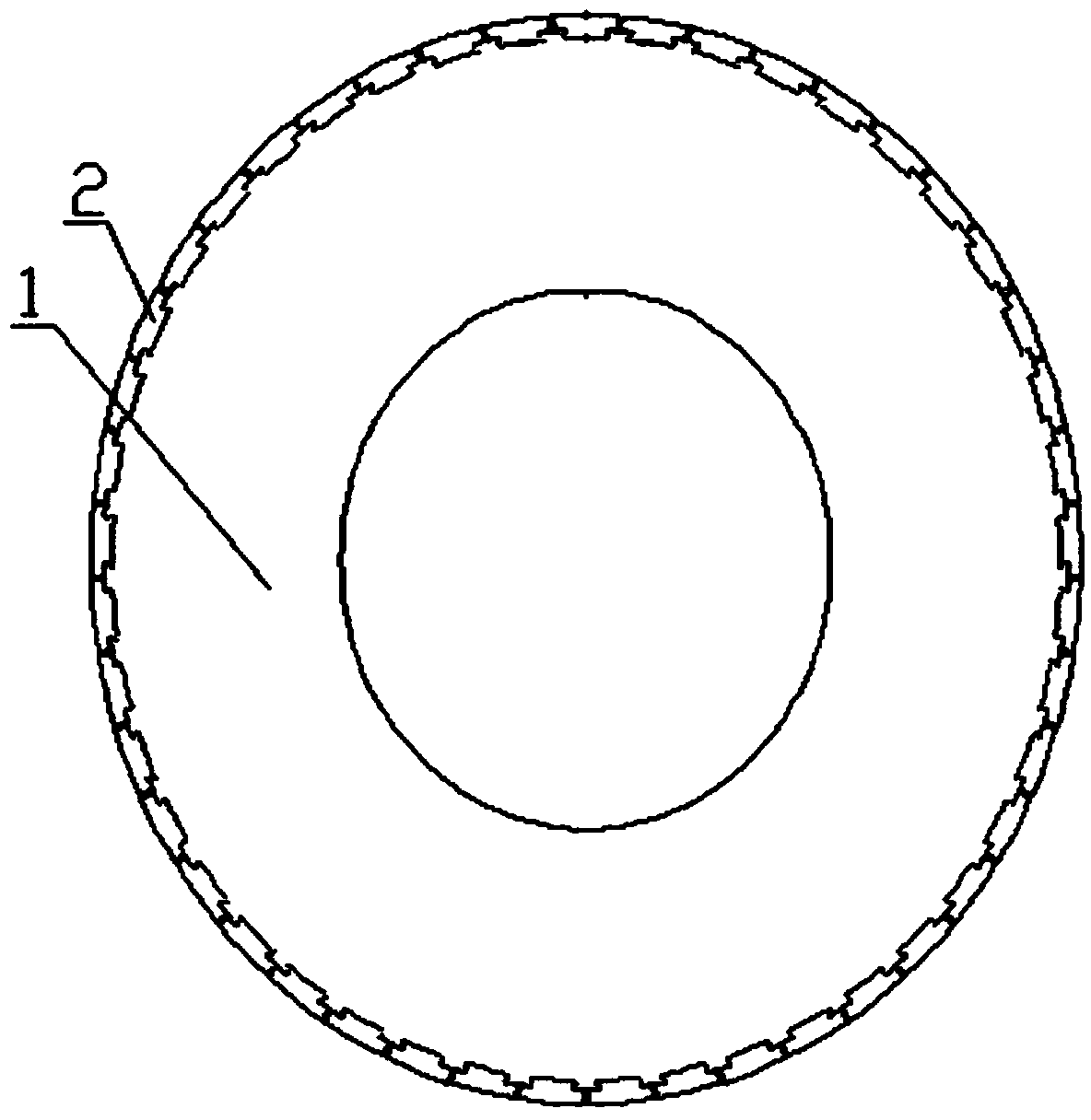

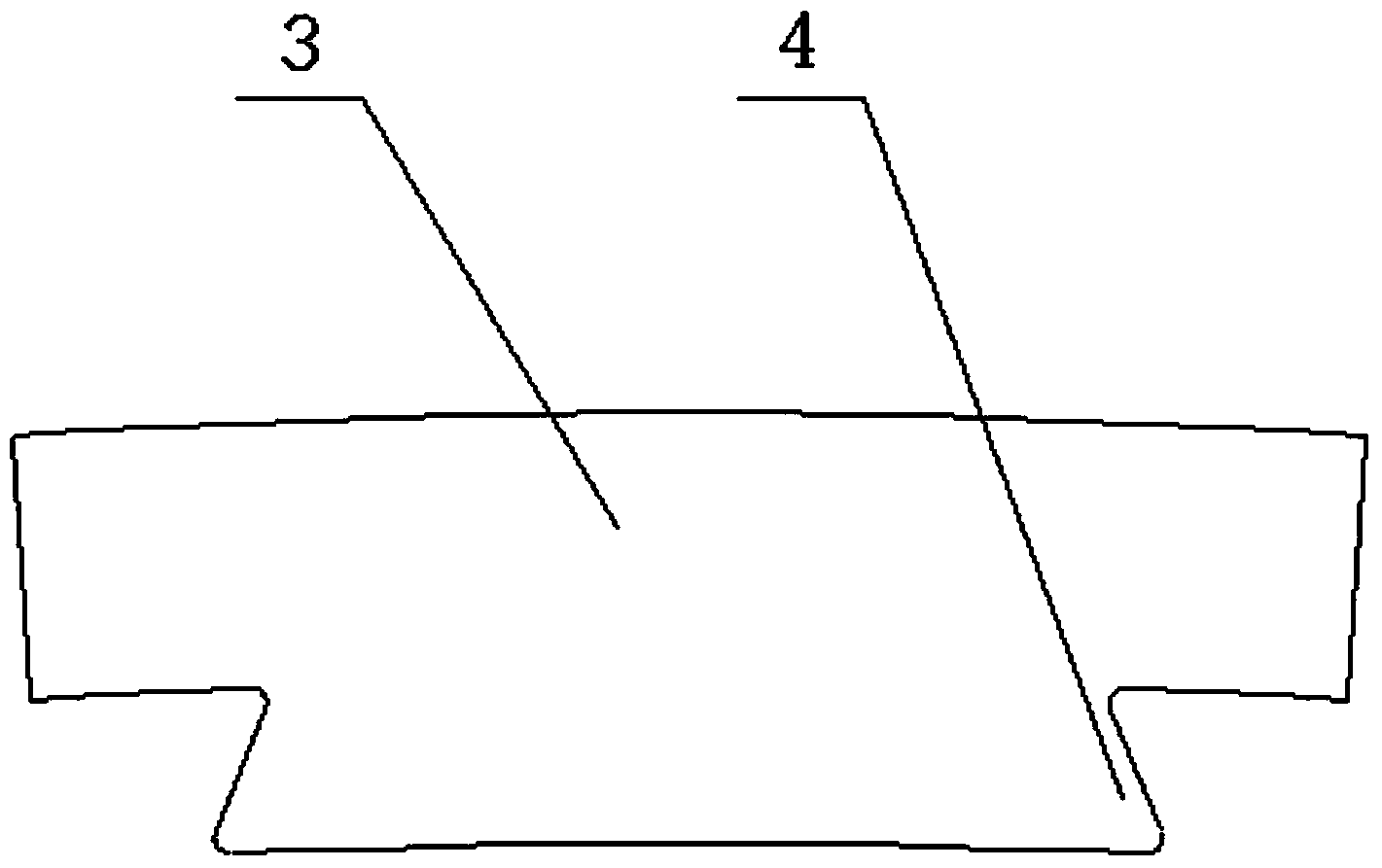

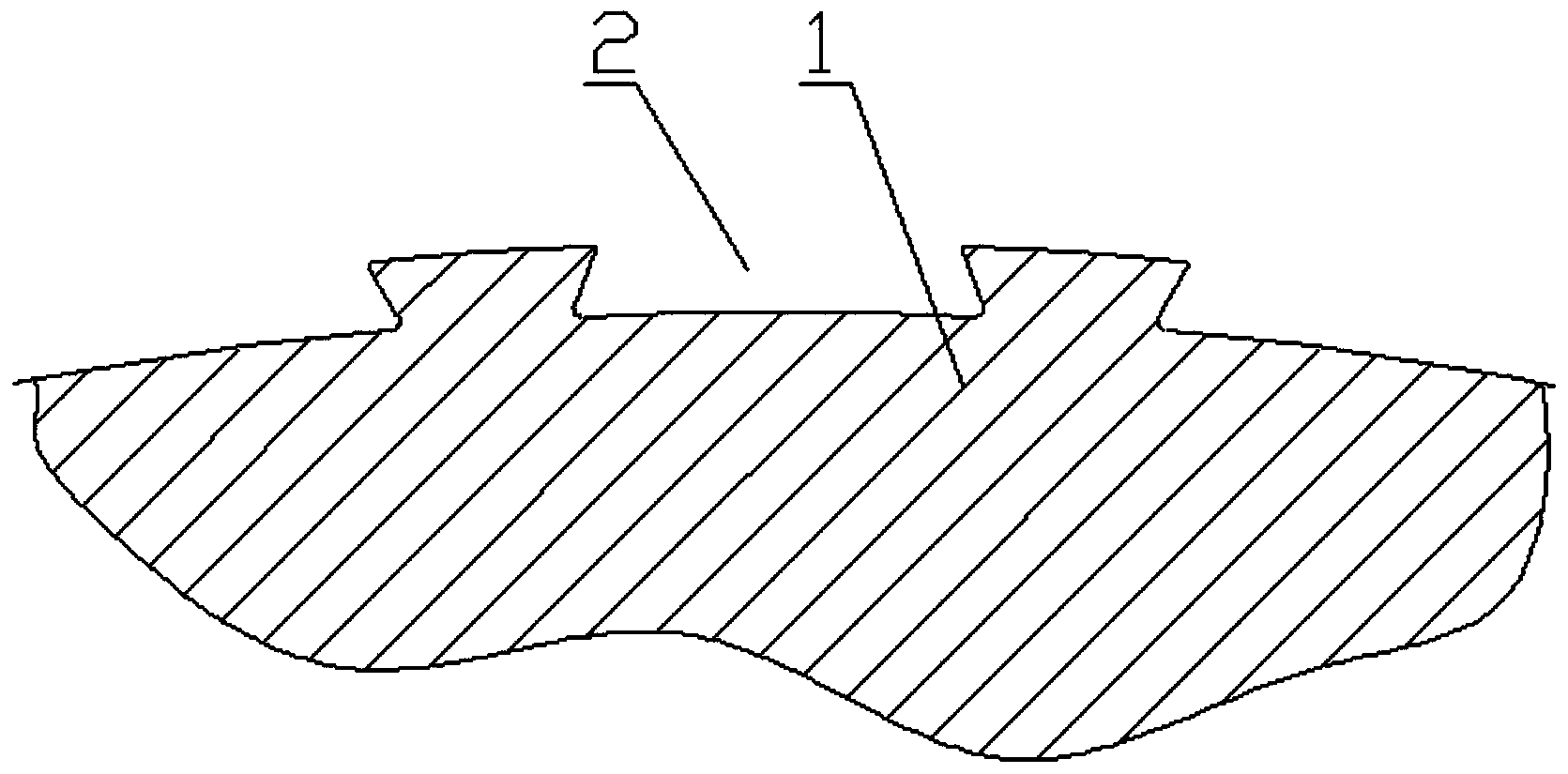

[0019] Such as Figure 1-3 As mentioned above, the present invention is a grinding wheel structure, including a base body 1 and a split grinding block 3, the base body 1 is provided with a dovetail groove 2, and the bottom of the grinding block 3 is provided with a dovetail protrusion 4 corresponding to the dovetail groove , The grinding block 3 is fixed on the base 1 through the cooperation of the dovetail protrusion and the dovetail groove.

[0020] The dovetail groove 2 on the base body 1 is connected with at least one side wall of the base body 1, and the dovetail protrusion 4 of the grinding block 3 is inserted into the dovetail groove 2 from the side wall of the base body 1, and is bonded and fixed by a resin layer.

[0021] The dovetail grooves 2 on the base body 1 are in one or t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com