Micro-buckle battery and preparation method thereof

A button battery and cell technology, applied in the field of micro button battery and its preparation, can solve problems such as damage, easy stretching and cracking, battery leakage, etc., and achieve the effects of improving energy density, uniform stretching, and optimizing chamfering angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

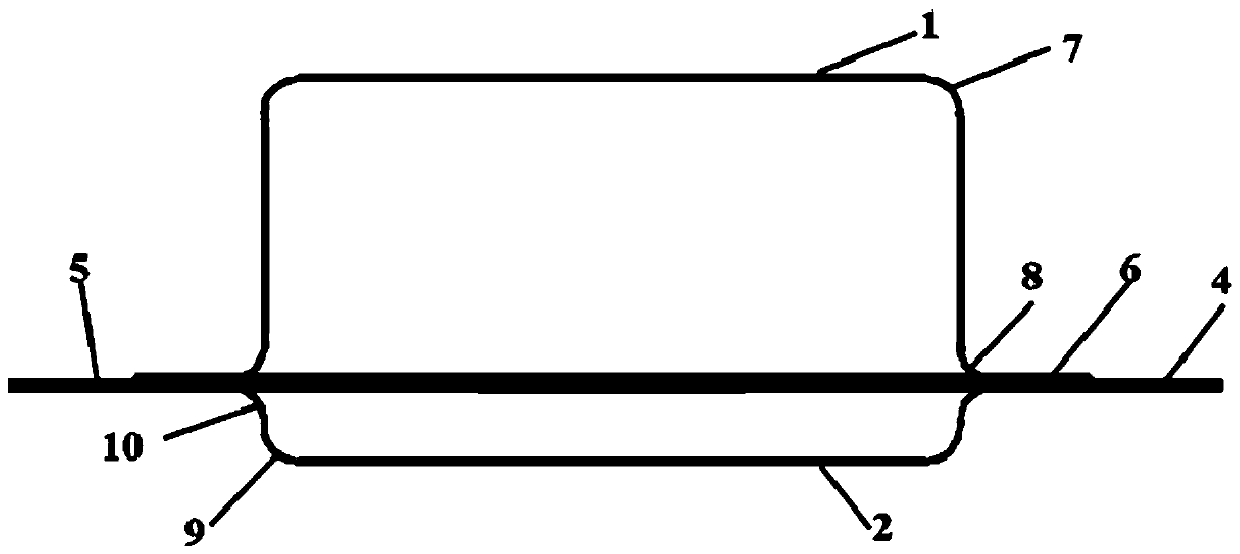

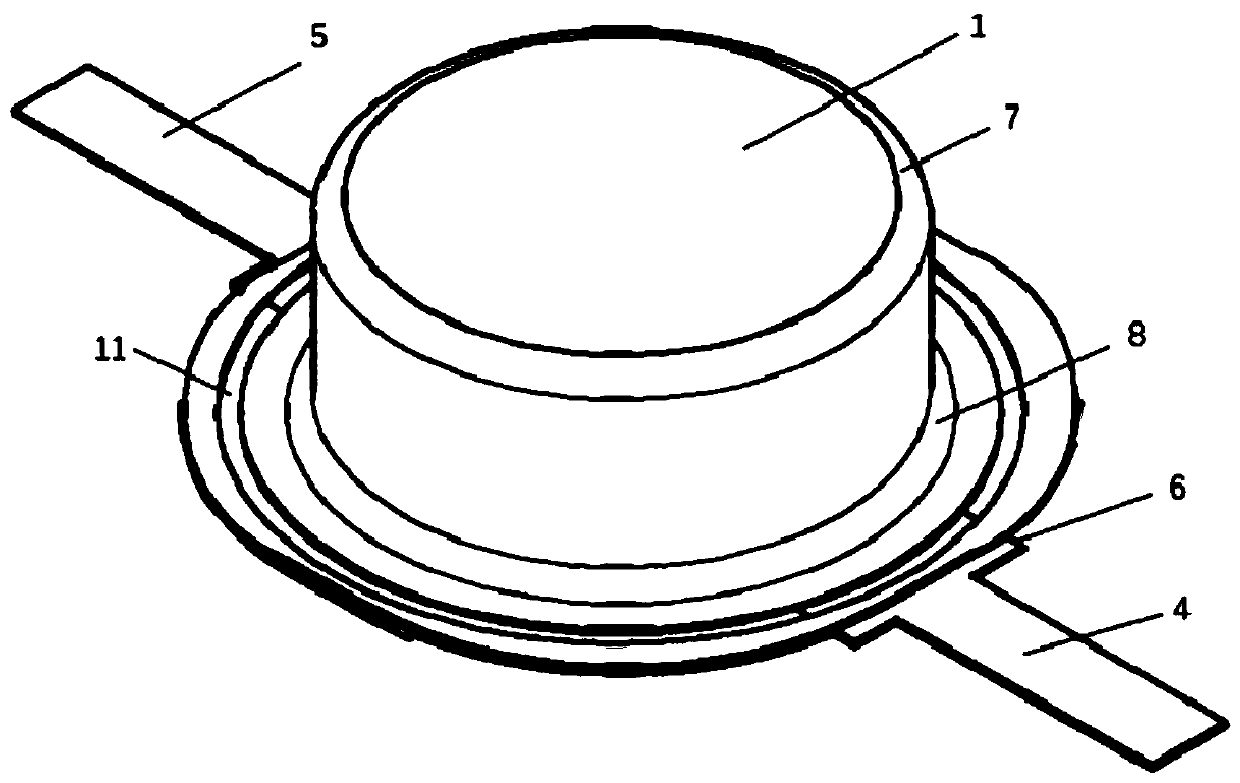

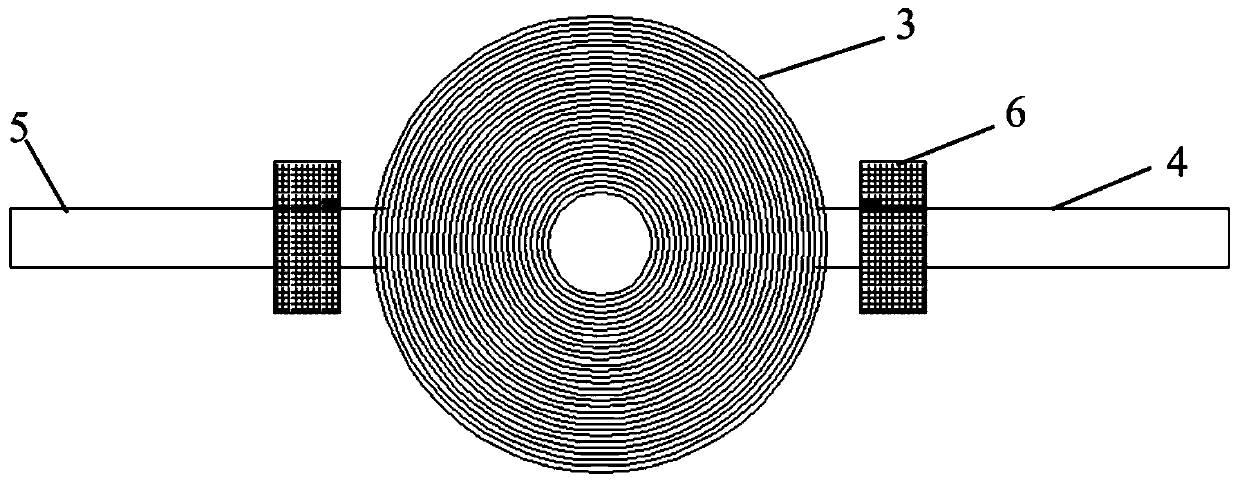

[0062] This embodiment provides a kind of micro-button battery, and its structural diagram is shown in Figure 1-Figure 4 , the micro-button battery includes a soft-coated casing and an electric core 3 of a winding structure placed in the soft-coated casing, and the soft-coated casing is divided into an upper casing 1 and a lower casing 2 with pits , the upper shell 1 and the lower shell 2 are combined to form a hollow cavity, and the battery core 3 is placed in the cavity; a pit with a radius of R1 is formed between the side wall of the pit in the upper shell 1 and the top layer of the pit. The first outer chamfer 7; the edge of the mouth of the pit in the upper shell 1 forms a first inner chamfer 8 with a radius of R2; the pit side wall and the top layer in the lower shell 2 form a radius of R3 The second outer chamfer 9; the edge of the mouth of the pit in the lower shell 2 forms a second inner chamfer 10 with a radius of R4; A circle of encapsulation area 11 of the core; ...

Embodiment 2

[0072] The difference from Example 1 is that the punched pit depth (pit depth) of the upper shell 1 is 4.4 mm, the gap size of the concave and convex dies is 0.25 mm, the maximum diameter of the pit is 12 mm, and the first outer chamfer is 7 mm. The radius R1 of the first chamfer 8 is 1.95mm, and the radius R2 of the first inner chamfer 8 is 0.6mm;

[0073] The depth of the punched pit of the lower shell 2 is 1.0mm, the gap size of the concave and convex die is 0.25mm, the maximum diameter of the pit is 12mm, the radius R3 of the second outer chamfer 9 is 0.25mm, and the radius of the second inner chamfer 10 R4 is 0.6mm.

Embodiment 3

[0075] The difference from Example 1 is that the depth of the punched pit (pit depth) of the upper shell 1 is 6mm, the gap size of the concave and convex dies is 0.30mm, the maximum diameter of the pit is 12mm, and the first outer chamfer 7 The radius R1 is 2.75mm, and the radius R2 of the first inner chamfer 8 is 0.8mm;

[0076] The depth of the punched pit of the lower shell 2 is 4mm, the gap size of the concave and convex die is 0.25mm, the maximum diameter of the pit is 12mm, the radius R3 of the second outer chamfer 9 is 1.75mm, and the radius R4 of the second inner chamfer 10 is 0.8mm, and the obtained battery model is 1210.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pit depth | aaaaa | aaaaa |

| Pit depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com