Patents

Literature

106results about How to "Guaranteed electrochemical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

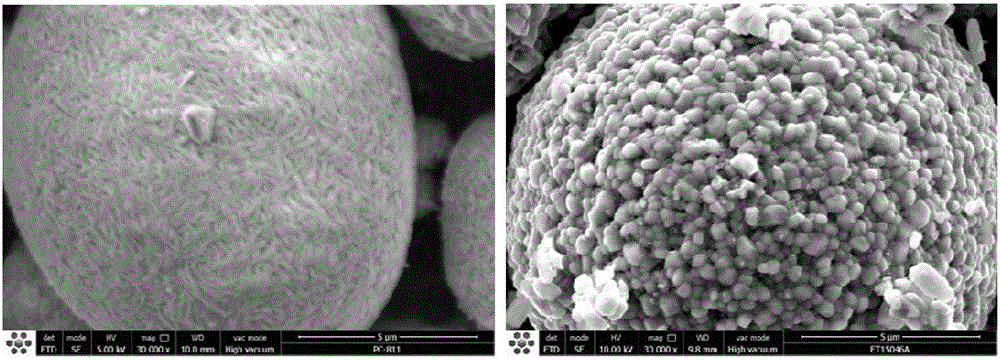

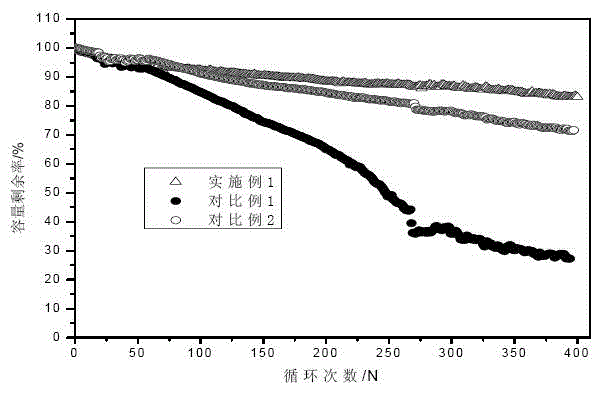

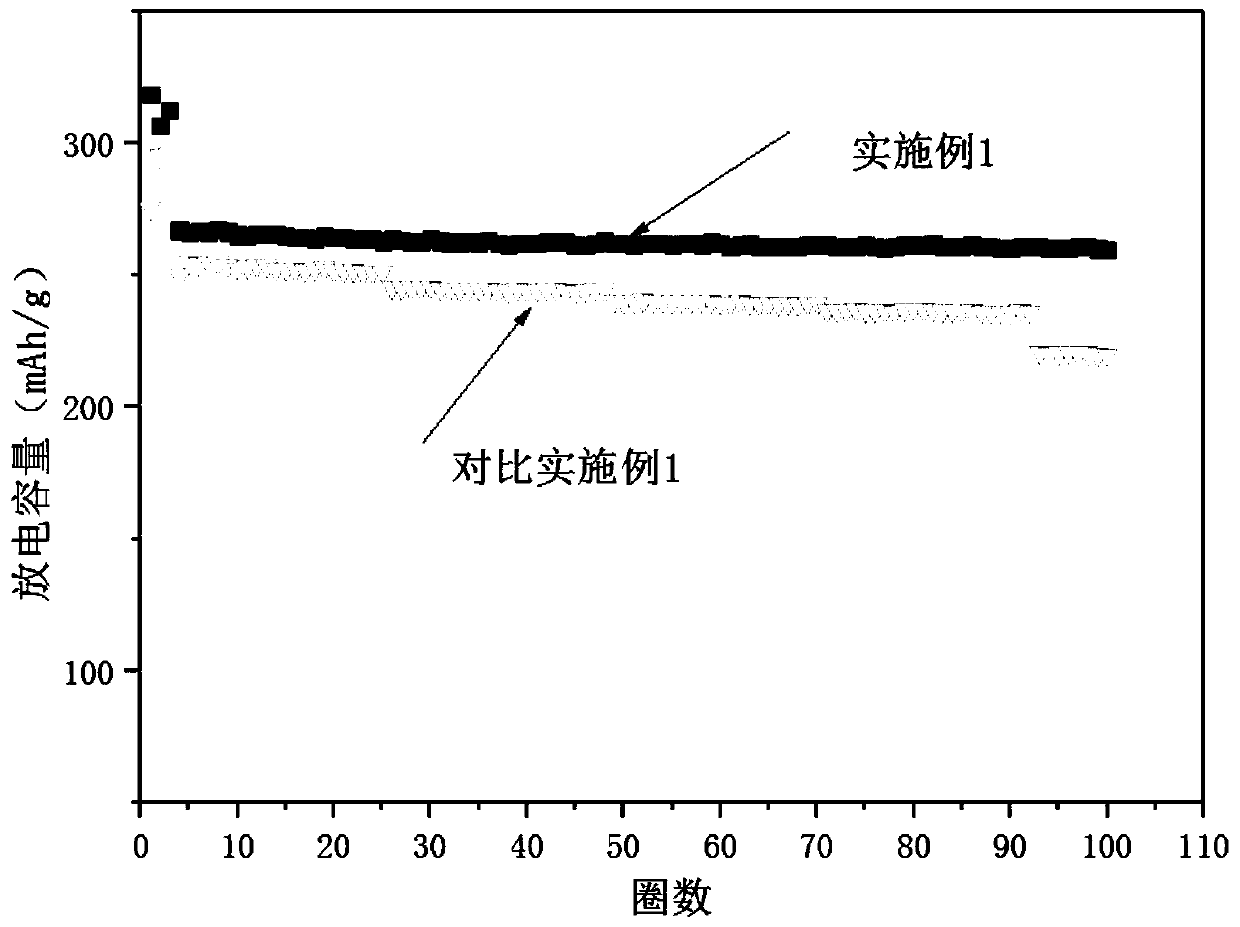

Polycrystal high-nickel positive electrode material used for lithium ion battery and preparation method for polycrystal high-nickel positive electrode material

InactiveCN105958062AExtended storage timeReduce lithiumCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

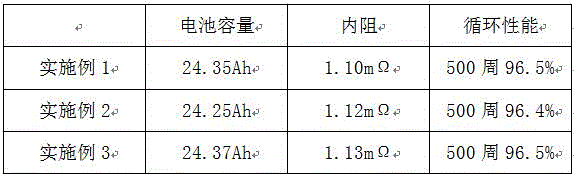

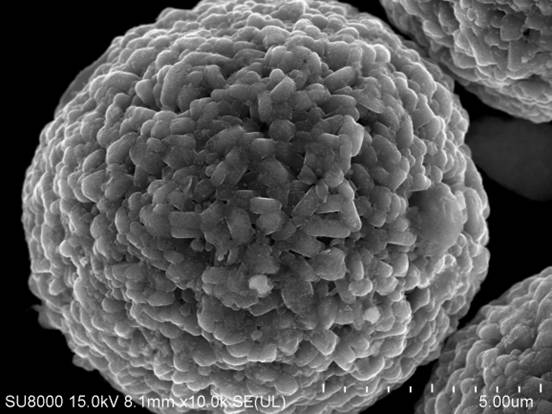

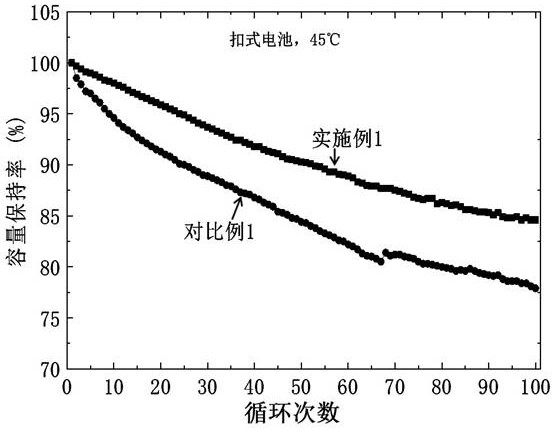

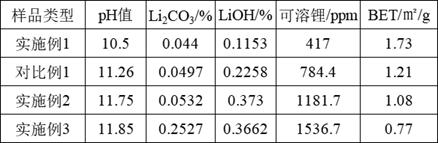

Disclosed is a polycrystal high-nickel positive electrode material used for a lithium ion battery. The polycrystal high-nickel positive electrode material comprises a base material with a layered structure and a coating layer which is arranged outside the base material and has a spinel structure; the general formula of the base material is LiNi<1-x-y>Co<x>M<y>O<2>, wherein M is at least one kind of Mn and Al; the coating layer is lithium manganese oxide; the mass percentage of the total impurity lithium on the surface of the base material is less than 0.085% based on the total mass percentage of the base material; the preparation method for the positive electrode material comprises the following steps of weighing Ni<1-x-y>Co<x>M<y>(OH)<2>, and mixing with a lithium source, then carrying out thermal treatment, cooling, crushing and sieving to obtain the base material; measuring the content of the residual impurity Li<2>CO<3> and LiOH on the surface of the base material, adding into the metal Mn compound according to the measurement result, and carrying out low-temperature thermal treatment in an oxygen atmosphere to obtain the polycrystal high-nickel positive electrode material used for the lithium ion battery. The polycrystal high-nickel positive electrode material provided by the invention has the advantages of low material alkalinity, low inflatable degree, excellent processing property and cycling performance, and the like.

Owner:HUNAN SHANSHAN NEW ENERGY CO LTD

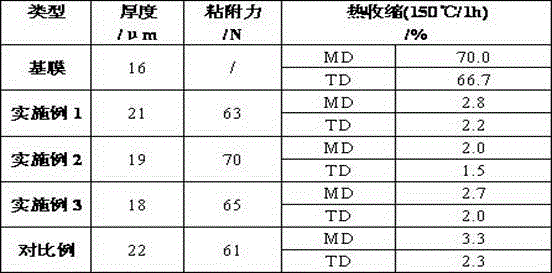

Lithium ion battery ceramic diaphragm paste

InactiveCN105489819ALow costAdjustable viscosityCell seperators/membranes/diaphragms/spacersInorganic particleShrinkage rate

The invention discloses paste for a lithium ion battery ceramic diaphragm. The lithium ion battery ceramic diaphragm comprises a basic membrane and a coating coated on a single side or double sides of the basic membrane. Paste adopted for the coating is paste which is formed in the mode that inorganic nanoparticles and whiskers are composited with a basic material and water. The inorganic nanoparticles are prepared from one of alumina, boehmite, silicon dioxide and barium sulfate, the whiskers are prepared from one of alumina and boehmite, and the basic material is prepared from a thickening agent, a dispersing agent and an adhering agent. The paste can continuously form a uniform inorganic nanometer and whisker coating on PE / PP in a roller painting mode, and the composite diaphragm with the ultra-thin coating and high adhesive force is obtained through drying. The composite diaphragm can effectively reduce the heat-shrinkage rate of the lithium ion battery ceramic diaphragm, and compared with a traditional composite diaphragm prepared from single inorganic particle paste, the ultrathin coating is favorable for increase of air permeability and ionic conductivity, and space in a battery and paste cost are saved.

Owner:EAST CHINA UNIV OF SCI & TECH

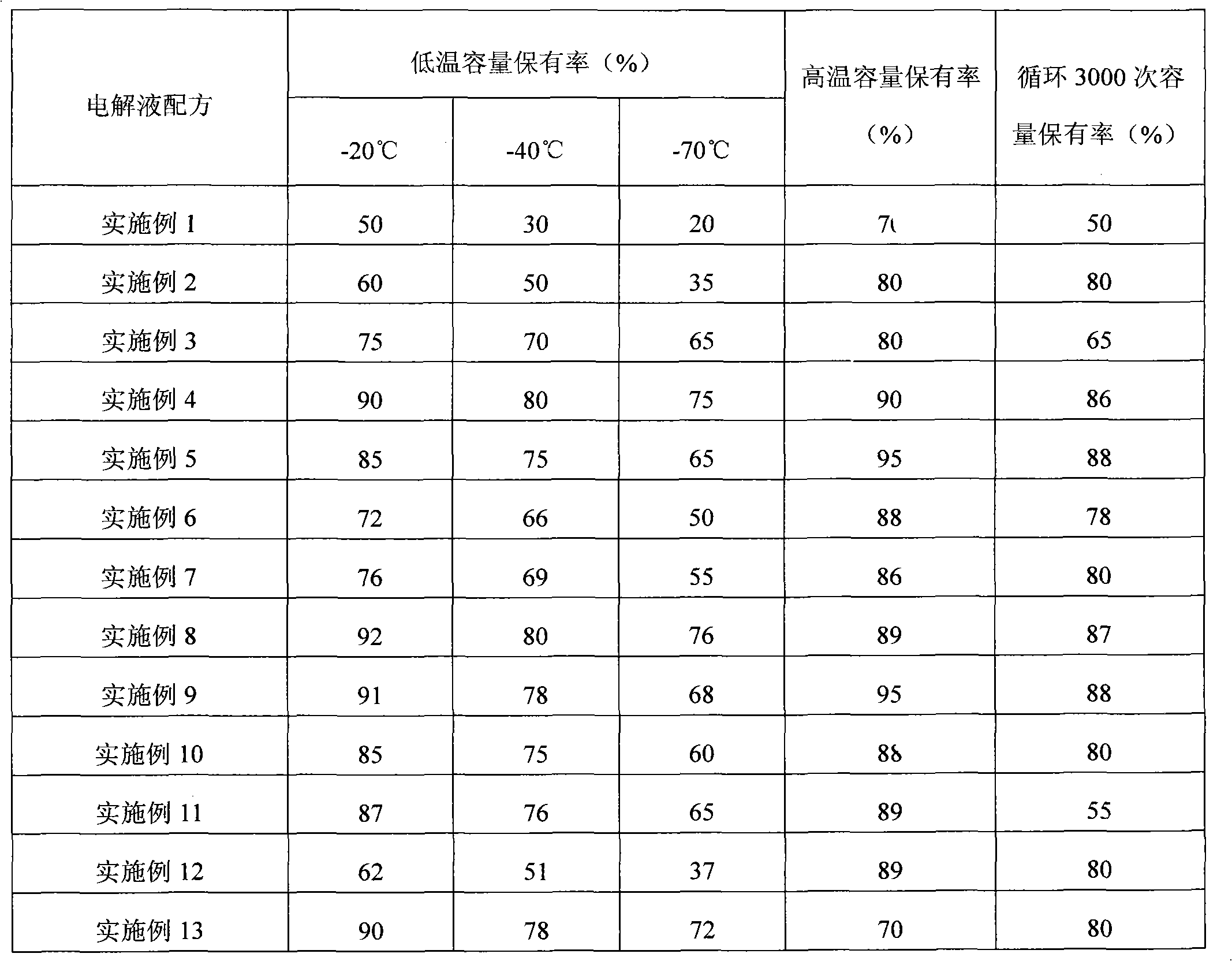

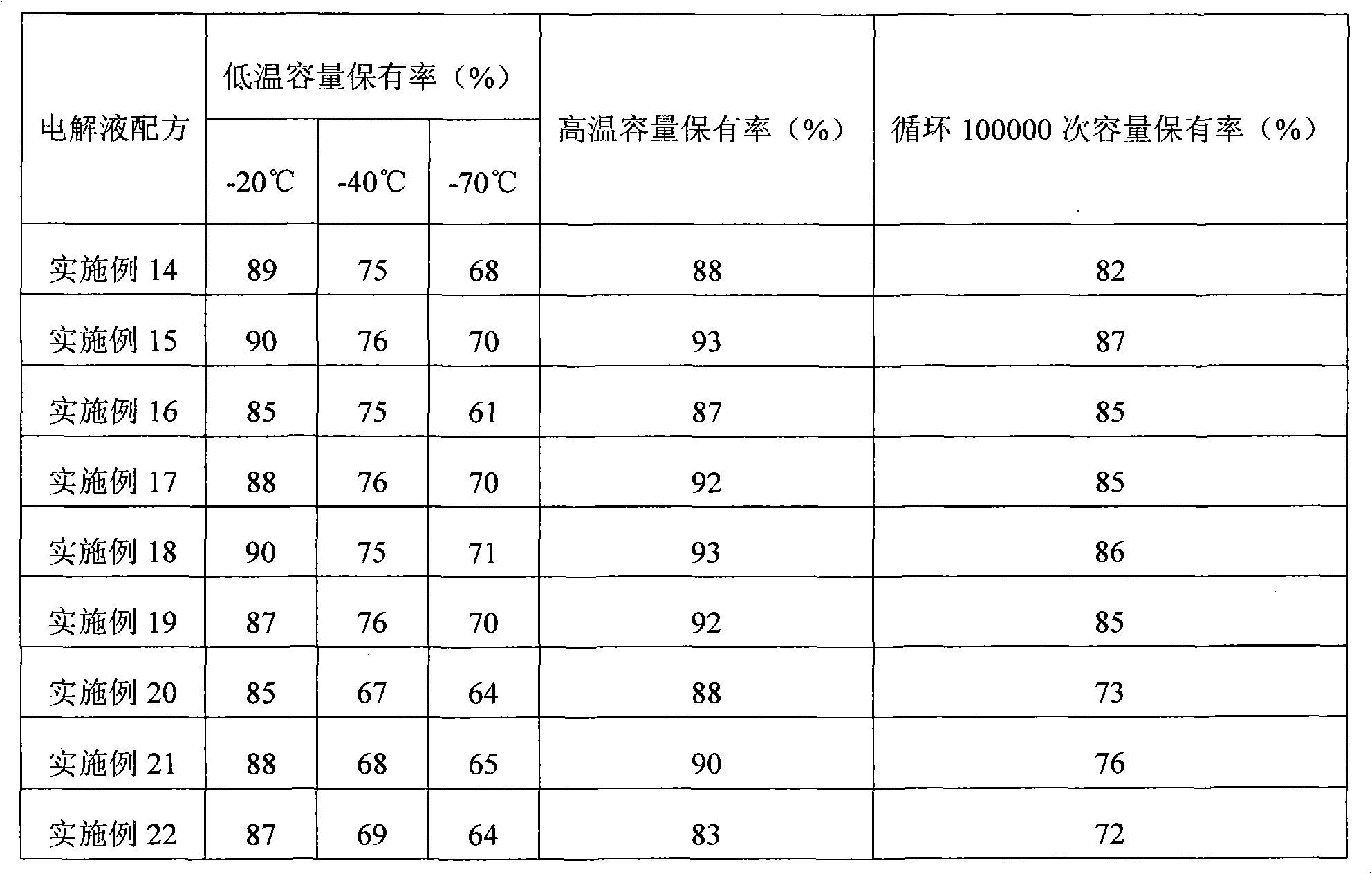

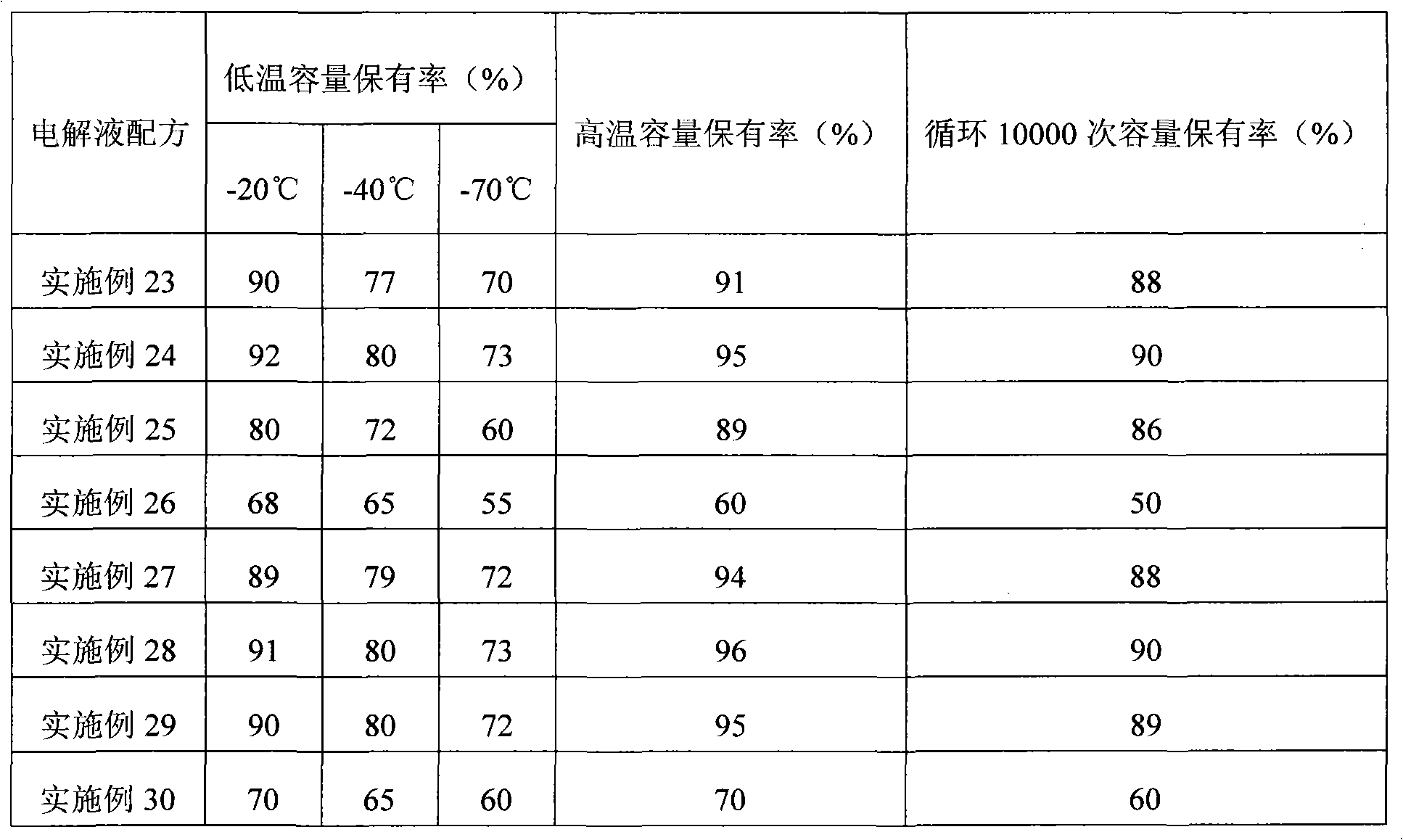

Low-temperature organic electrolyte taking gamma-butyrolactone as base solvent and application thereof

ActiveCN101916878AImprove low temperature performanceImprove cycle lifeHybrid capacitor electrolytesElectrolytic capacitorsCapacitanceGraphite

The invention discloses low-temperature organic electrolyte taking gamma-butyrolactone as a base solvent and a preparation method thereof. The organic electrolyte comprises a solvent and lithium tetrafluoroborate (LiBF4), wherein the solvent is a mixture of cyclic gamma-butyrolactone, chain carbonic ester and chain carboxylic ester. The organic electrolyte is suitable to be used by a non-graphite-based cathode lithium ion capacitor, a non-graphite-based cathode lithium ion battery and a non-graphite-based cathode lithium ion system. Compared with the formula of the traditional electrolyte, the organic electrolyte greatly improves the low-temperature performance of an electrochemical device and prolongs the cyclic service life of the electrochemical device on the basis of ensuring the electrochemical performance, and meanwhile is favorable for the safety of the electrochemical device; and the formula of the electrolyte is suitable for the non-graphite-based cathode lithium ion capacitor, the non-graphite-based cathode lithium ion battery and the non-graphite-based cathode lithium ion capacitance battery.

Owner:SHANGHAI AOWEI TECH DEV

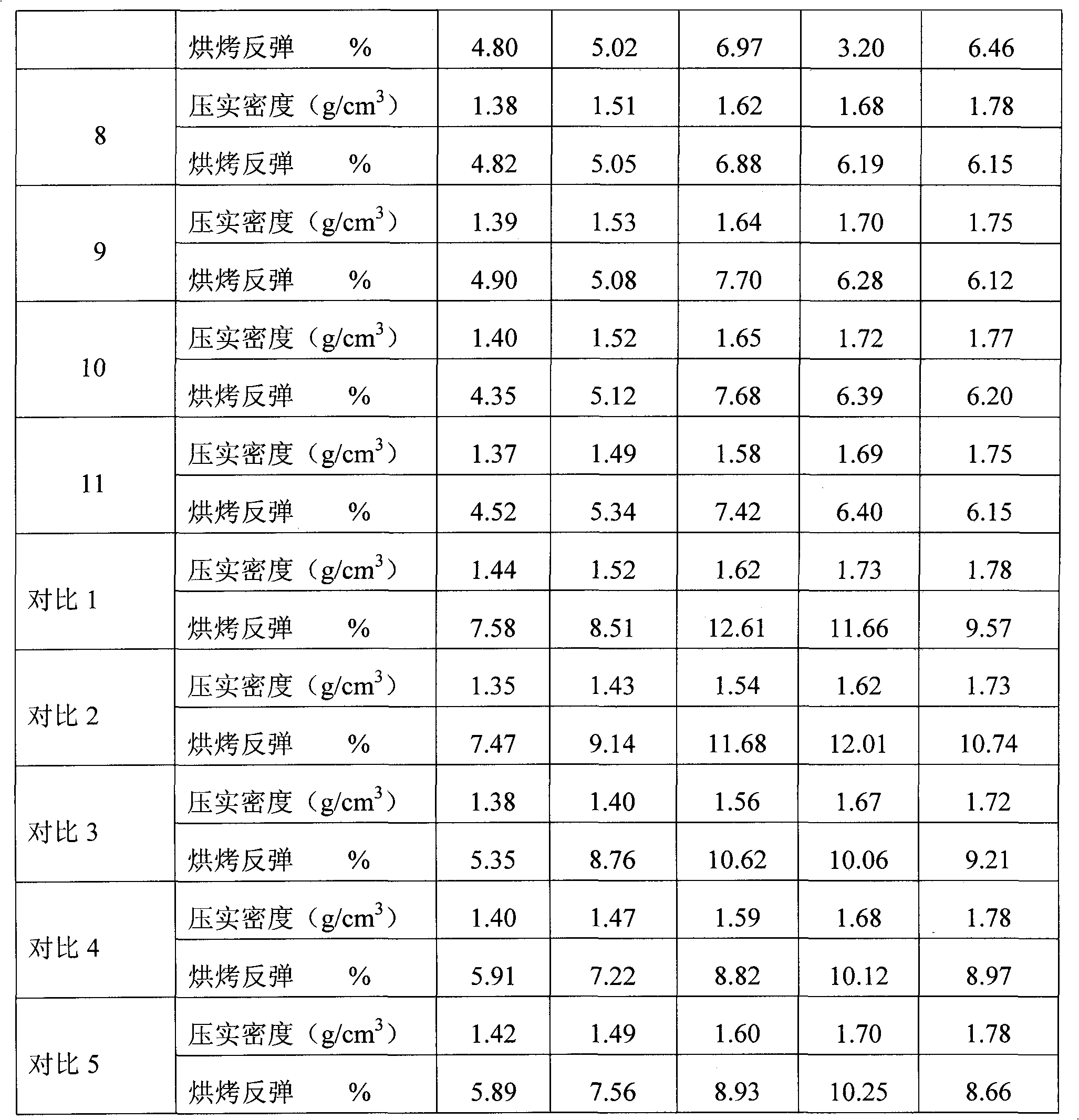

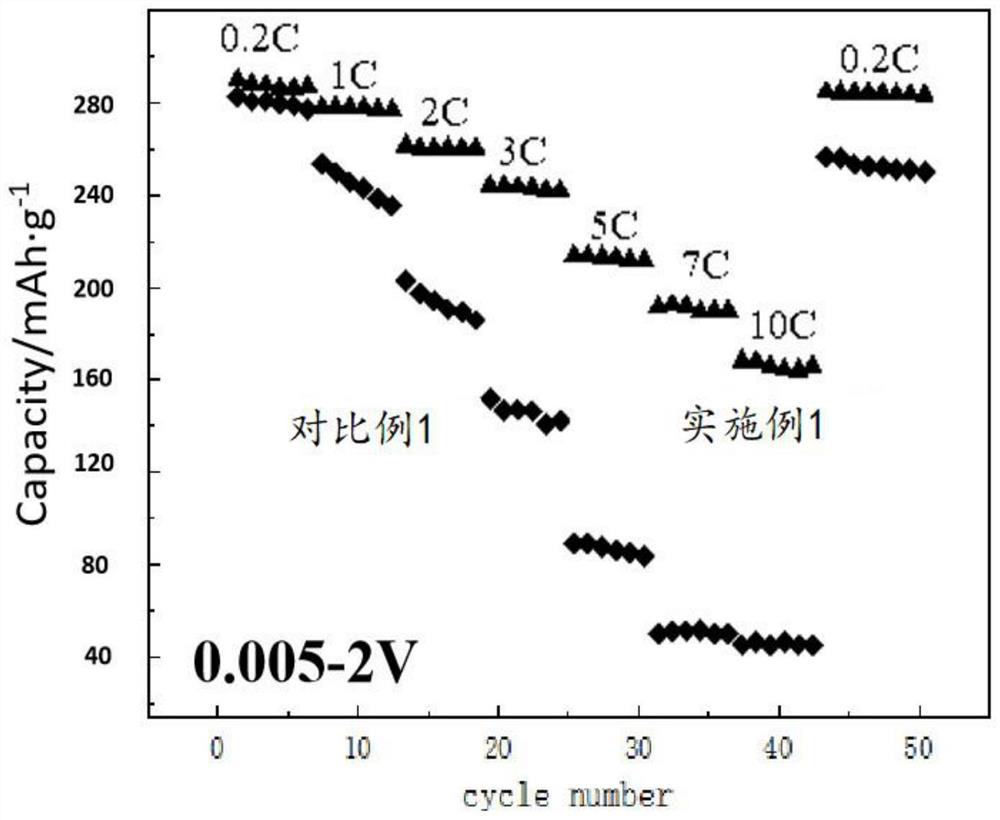

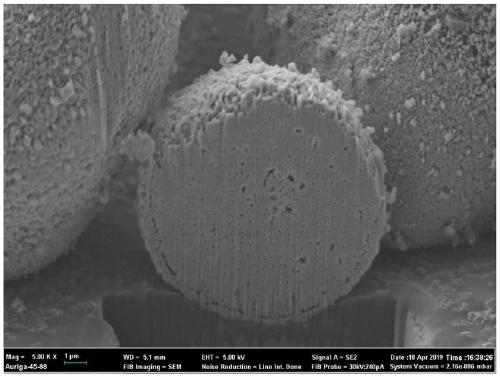

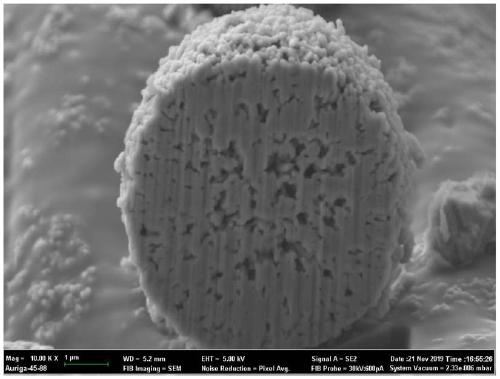

Isotropous graphite secondary particle, and preparation method and use thereof

ActiveCN102931381AImprove fast charge and discharge capabilityReduce entryCell electrodesPowder mixtureElectrical battery

The invention relates to a preparation method of an isotropous graphite secondary particle. The preparation method comprises the following steps: 1, mixing initial carbon material particles with modified asphalt particles to obtain a powder mixture with the initial carbon material particles as a continuous phase and the modified asphalt particles as a dispersion phase; 2, carrying out hot isothermal pressing treatment of the powder mixture, and removing the initial carbon material particles unbonded by the modified asphalt to obtain an isotropous graphite secondary particle precursor; and 3, sequentially carrying out heat treatments comprising non-melting treatment, charring treatment and graphitization treatment of the isotropous graphite secondary particle precursor. The isotropous graphite secondary particle macroscopically has the isotropy, can maintain the specific mass capacity of a cathode material, and simultaneously solves problems comprising low compacted density of a graphite cathode material piece and large baking expansion rate after the compacting of the piece, so the specific volume capacity of a lithium ion battery is improved.

Owner:内蒙古杉杉科技有限公司

Organogel polymer electrolytic solution, preparation method, application, sodium-based dual-ion battery and preparation method thereof

ActiveCN109638344AGuaranteed electrochemical performanceImprove securityFinal product manufactureSecondary cellsElectrochemistrySodium salt

The invention belongs to the technical field of energy storage devices and relates to an organogel polymer electrolytic solution, a preparation method, application, a sodium-based dual-ion battery anda preparation method thereof. The organogel polymer electrolytic solution of the present invention comprises a solid polymer substrate and an organic electrolytic solution; wherein the solid polymersubstrate comprises an organic polymer and an inorganic additive; and the organic electrolytic solution comprises sodium salt and an organic solvent. The liquid electrolytic solution and the diaphragmin a traditional battery are replaced by the rigid-flexible organogel polymer electrolytic solution where the organic and inorganic materials coexist, thereby improving the safety of the battery under the premise of ensuring the electrochemical performance of the battery, broadening the application field of dual-ion batteries, bringing new design opportunities for energy storage devices in the field of wearable electronic devices in the future, achieving low-cost batteries without using the diaphragm and a protection circuit.

Owner:SHENZHEN INST OF ADVANCED TECH

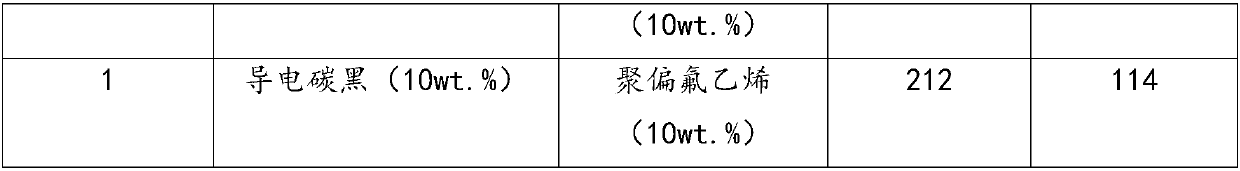

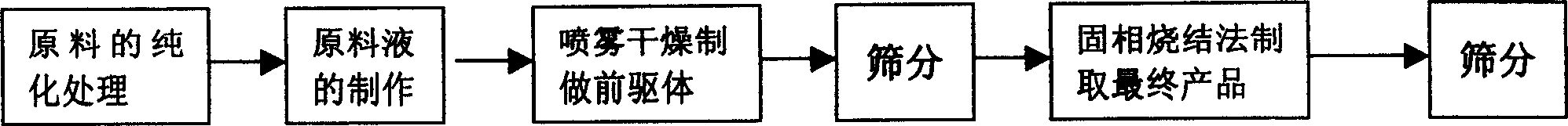

Method for preparing cathode material of lithium iron phosphate lithium-ion battery

ActiveCN101764218AGuaranteed electrochemical performanceWell mixedCell electrodesPhosphorus compoundsSucroseLithium hydroxide

The invention provides a method for preparing a cathode material of a lithium iron phosphate lithium-ion battery, and relates to a method for preparing the cathode material of a lithium-ion battery. The invention solves the problems of low specific capacity, poor loop stability and high cost in the preparation of the cathode material of the lithium iron phosphate lithium-ion battery by the prior solid phase method t. The method comprises the following steps: firstly rolling lithium hydroxide, ferrous oxalate, ammonium dihydrogen phosphate, conductive agents and dispersants by a double-roll blender mill, crushing, sintering, rolling after adding pitch, crushing and resintering; or firstly extruding the lithium hydroxide, the ferrous oxalate, the ammonium dihydrogen phosphate, the conductive agents and the dispersants by a double-screw extruder, crushing, sintering, rolling after adding pitch, crushing and resintering. Compared with the materials using sucrose as the carbon source, the cost of the cathode material of the lithium iron phosphate lithium-ion battery is reduced by 40-55%, the specific capacity is 100mA.h / g-120mA.h / g, the cyclical stability is good, so the prepared cathode material can be applied to the batteries used by mobile telephones, notebook computers and electrocars.

Owner:哈尔滨昆宇新能源有限公司

Anode material--lithium nickelate cobalt for lithium ion battery and preparation method thereof

InactiveCN1567620AReduce dosageReduce consumptionElectrode manufacturing processesLithium compoundsLithium chlorideNickel salt

The invention is a method of preparing lithium ion cell anode material-nickel cobalt acid lithium, and its characteristic: in the proportion of its formula, A-group matters: water-soluble lithium salt which is one of the lithium chloride, lithium sulphate, lithium nitrate and lithium acetate, water cobalt salt which is one of the cobalt chloride, cobalt sulphate, cobalt nitrate and cobalt acetate, and water nickel salt which is one of the nickel chloride, nickel sulphate, nickel nitrate and nickel acetate, the molar ratio of the three matters is 1.00-1.1 : 0.2-0.3 : 0.8-0.7; B-group matters: complexant is one of the oxalic acid, tartaric acid, citric acid, succinic acid, malonic acid, and maleic acid; the molar ratio of A to B is 1.0 : 0.6 -0.8; C-group polymers: gelatin, modified starch and polyvinyl alcohol. The beneficial effects: it can effectively reduce cost and the made LiNi1-yCoyO2 has the advantages of both LiCoO2 and LiNiO2, i.e. easy to synthesize, stable-property, high-specific capacity (higher than that of LiCoO2 by above 20%), etc. Additionally, because the use of Co is reduced, thus it reduces the environmental pollution. Therefore, LiNi1-yCoyO2 has a great hope of becoming the preferred substitute for LiCoO2, and its market demand is quite considerable.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD

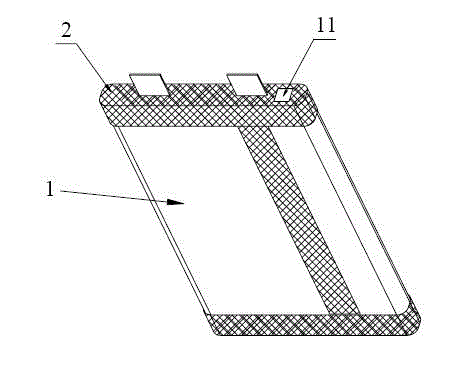

Non-metal case lithium ion battery

InactiveCN101494277AEnsure safetyGuaranteed electrochemical performanceSecondary cellsCell component detailsOperabilityEngineering

The invention relates to the technique field of battery, in particular to a nonmetallic shell lithium ion battery which comprises a battery cell and a nonmetallic shell. The nonmetallic shell ensures the safety performance and electrochemical property of the lithium ion battery effectively; in addition, the nonmetallic shell lithium ion battery has the advantages of low manufacturing cost, convenient recycling, little energy consumption, various apparent colors which can be adjusted according to actual needs, strong operability, good repeatability and products with stable quality and good performance.

Owner:桐乡市众胜能源科技有限公司

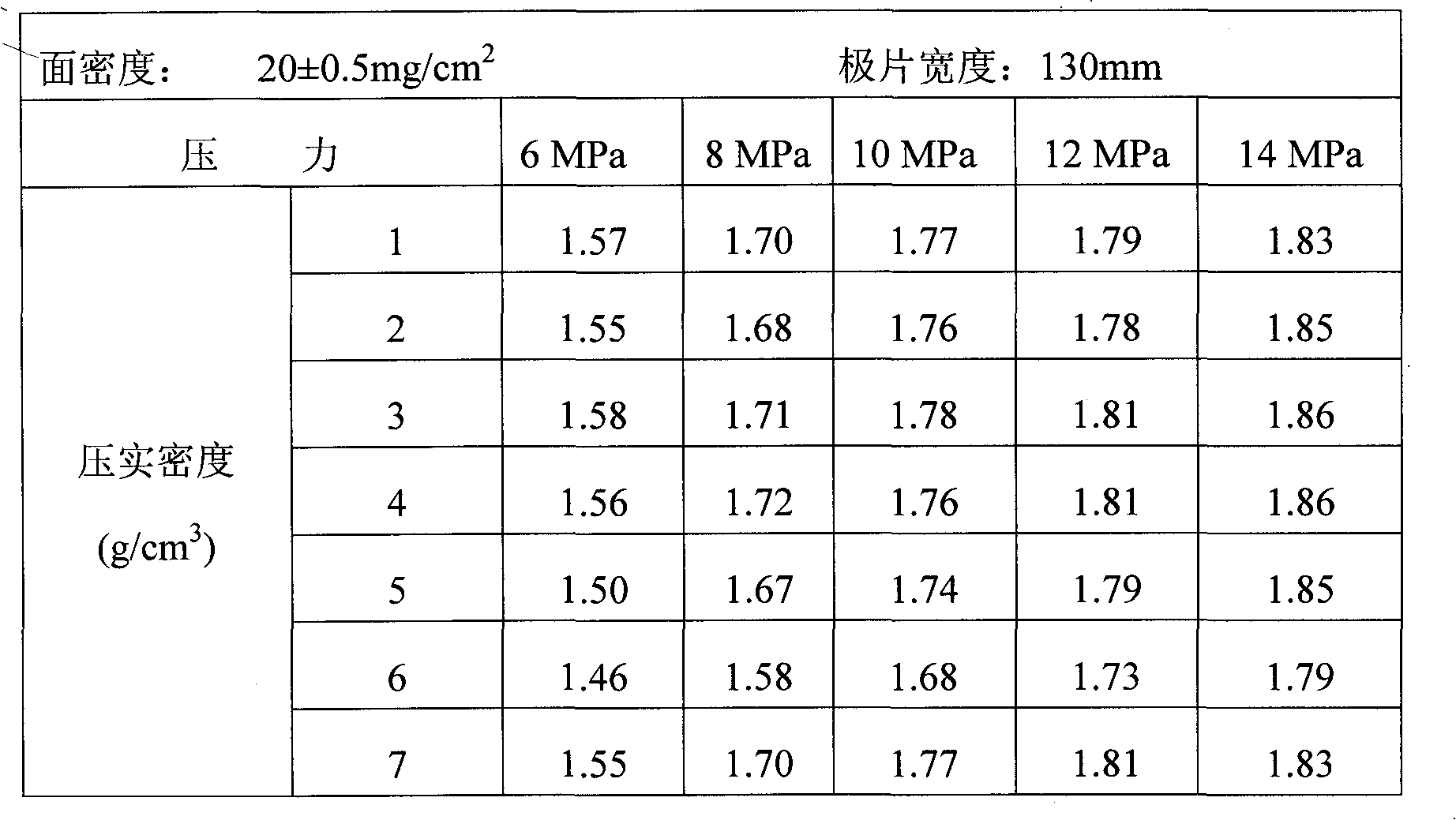

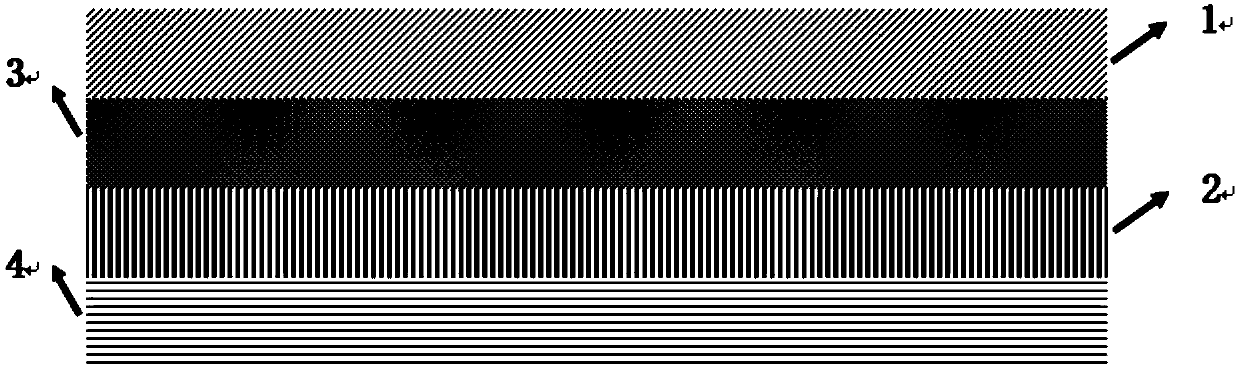

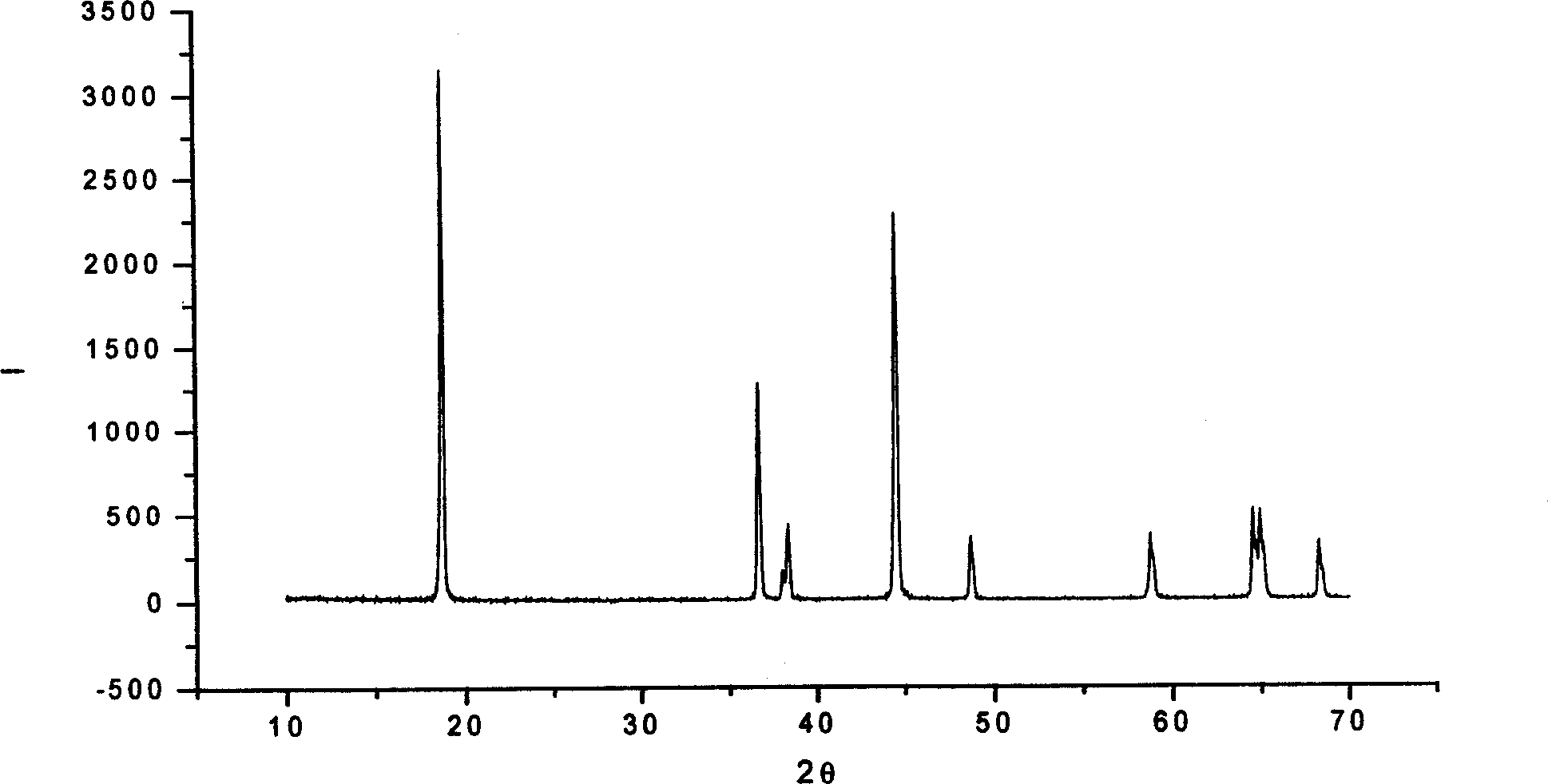

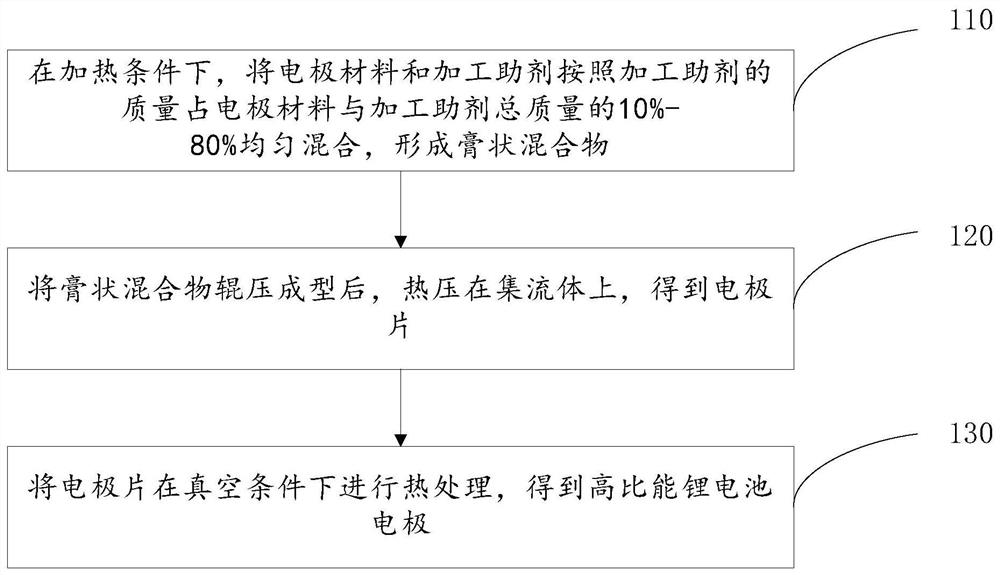

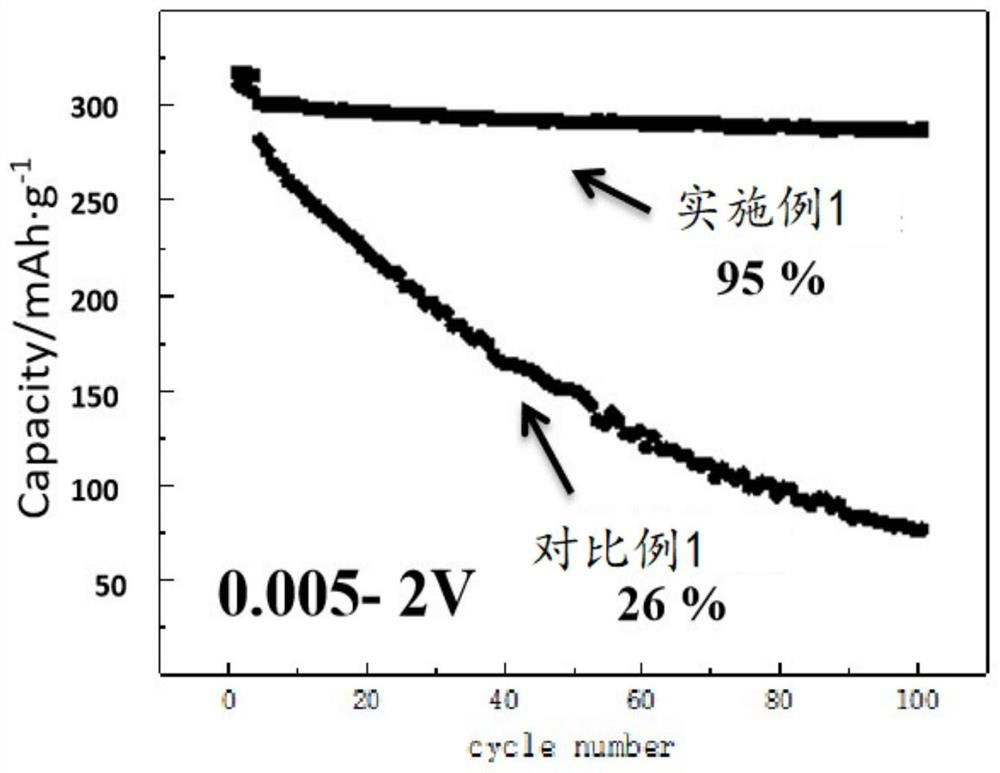

High-specific-energy lithium battery electrode, dry preparation method thereof and lithium battery

ActiveCN111916678AGuaranteed electrochemical performanceImprove cycle stabilityElectrode rolling/calenderingElectrode thermal treatmentCyclohexeneBattery electrode

The invention relates to a high-specific-energy lithium battery electrode, a dry preparation method thereof and a lithium battery. The method comprises the following steps: under a heating condition,uniformly mixing an electrode material and a processing aid according to the mass of the processing aid accounting for 10%-80% of the total mass of the electrode material and the processing aid to form a paste mixture, wherein the electrode material comprises an electrode active substance, a conductive agent and an adhesive, the processing aid comprises one or a combination of more than one of Poly(ethylene carbonate) (PEC), Poly(propylene carbonate)(PPC), Poly(butylene carbonate)(PBC), Poly(cyclohexene carbonate) (PPC) and Poly(trimethylene carbonate) (PTMC); carrying out roll forming on thepaste mixture, and then carrying out hot pressing on a current collector to obtain an electrode plate; and carrying out heat treatment on the electrode plate under a vacuum condition to obtain the high-specific-energy lithium battery electrode.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD +1

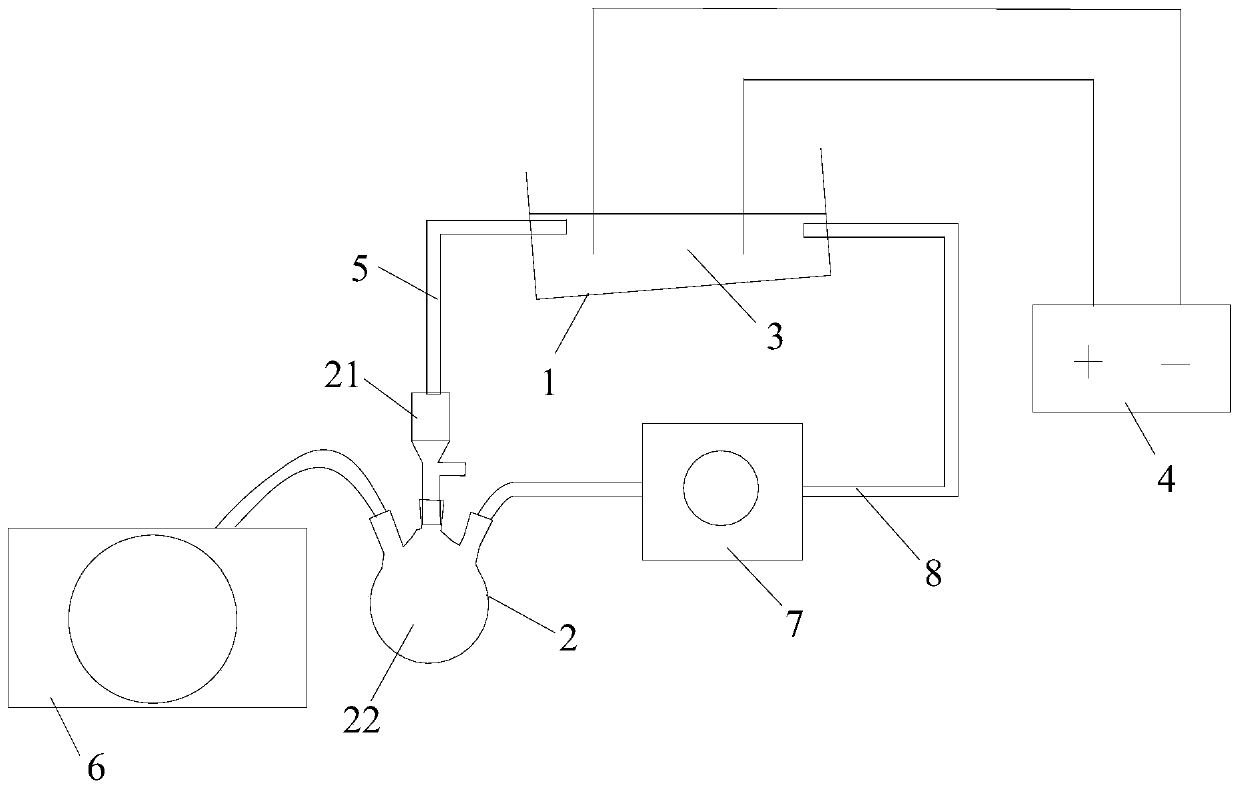

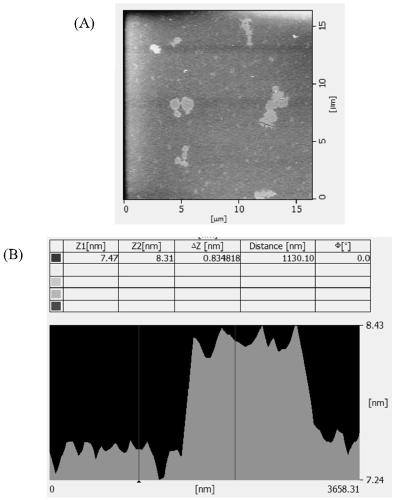

Method for continuously preparing graphene

InactiveCN109704314AWith technical effectEasy to operateGrapheneElectrochemical responsePeristaltic pump

The invention discloses a method for continuously preparing graphene and belongs to the technical field of preparation of the graphene. The method for continuously preparing the graphene comprises thesteps: a graphite electrode serves as a sacrificial anode, a sheet metal or graphite electrode serves as a cathode, the sacrificial anode and the cathode are placed into an electrolyte of an oblique-placed electrolysis tank, and a DC regulated power supply is applied for electrochemical reaction stripping so as to form the graphene; during electrochemical reaction, the graphene containing electrolyte flows in a solid-liquid separator located below the electrolysis tank under the action of own gravity and is subjected to solid-liquid separation so as to obtain the graphene and the electrolyte;and the separated electrolyte is recycled and flows back into the electrolysis tank for the electrochemical reaction through being driven by a peristaltic pump. According to the method, the effect ofrapidly recycling the electrolyte is achieved by adopting a liquid flow recycling technology, the continuous production of the graphene is achieved, the continuous stripping production cycle is short, the product structure is excellent, and thus, the method is applicable to large-batch rapid continuous production. Meanwhile, no waste gas is generated, no strong acid is used, the electrolyte can be recycled and reused, and thus, the method has an obvious environment-friendly value.

Owner:JIAXING UNIV

Lithium iron phosphate flexible packed lithium ionic cell

InactiveCN101504993AImproved capacity and safety performanceLarge capacityElectrode manufacturing processesFinal product manufactureCarbon blackLithium electrode

The invention relates to a lithium ion battery flexibly packaged by lithium iron phosphate; a formula of an electrolyte comprises the following compositions: LiBOB, PS, BS, EC, PC, EMC, LiPF6 and VC; an anode material comprises the following compositions: LiFePO4, carbon black, an adhesive and a conduction agent; and a cathode material comprises the following compositions: graphite, carbon black and an adhesive. The lithium ion battery optimizes the electrolyte, improves the capacity and the safety performance of the battery on the basis of ensuring the electrochemical performance of the battery; the improvement of the anode material and the cathode material solves the problems of poor self conduction of the lithium iron phosphate, environmental protection and cost; in a preparation process, the preparation of an anode slurry and a cathode slurry, the anode coating environment and a process of the electrode rolling course are improved; and the lithium ion battery flexibly packaged by the lithium iron phosphate has the advantages of large capacity, high safety, high cost performance, environment-friendliness and the like.

Owner:GREAT POWER BATTRY ZHUHAI

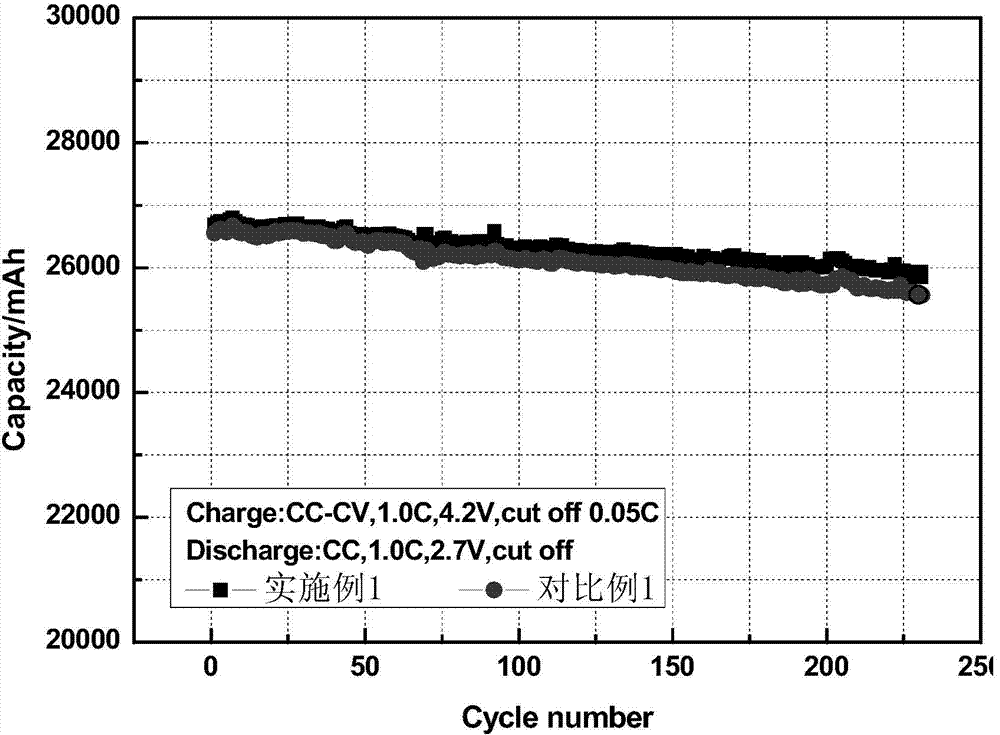

Lithium-ion battery and preparation method for same

ActiveCN102800889AGuaranteed electrochemical performanceReduce leakageFinal product manufactureNon-aqueous electrolyte accumulator electrodesElectrolytic agentLiquid state

The invention provides a lithium-ion battery, comprising a shell and a pole core contained in the shell, wherein the pole core comprises a positive pole, a negative pole, and a diaphragm located between the positive pole and the negative pole; and a liquid-state electrolyte is contained in the pole core, and a gel is filled between the pole core and the shell. The invention further provides a preparation method for the lithium-ion battery, comprising the following steps of: step 1, covering a rubberized fabric on the pole core, so as to form a sealed space in the pole core; and step 2, filling the liquid-state electrolyte in the sealed space of the pole core and performing pre-charge formation at first, and then filling second solution between the shell and the pore core, and heating to initiate a polymerization reaction, so as to form a gel between the pole core and the shell; or, filling second solution between the shell and the pore core, and heating to initiate a polymerization reaction, so as to form a gel between the pole core and the shell at first, and then filling the liquid-state electrolyte in the sealed space of the pole core and performing pre-charge formation. According to the invention, a problem of the leakage of the electrolyte is overcome, and the SEI (solid electrolyte interface) film of the negative pole cannot be influenced.

Owner:BYD CO LTD

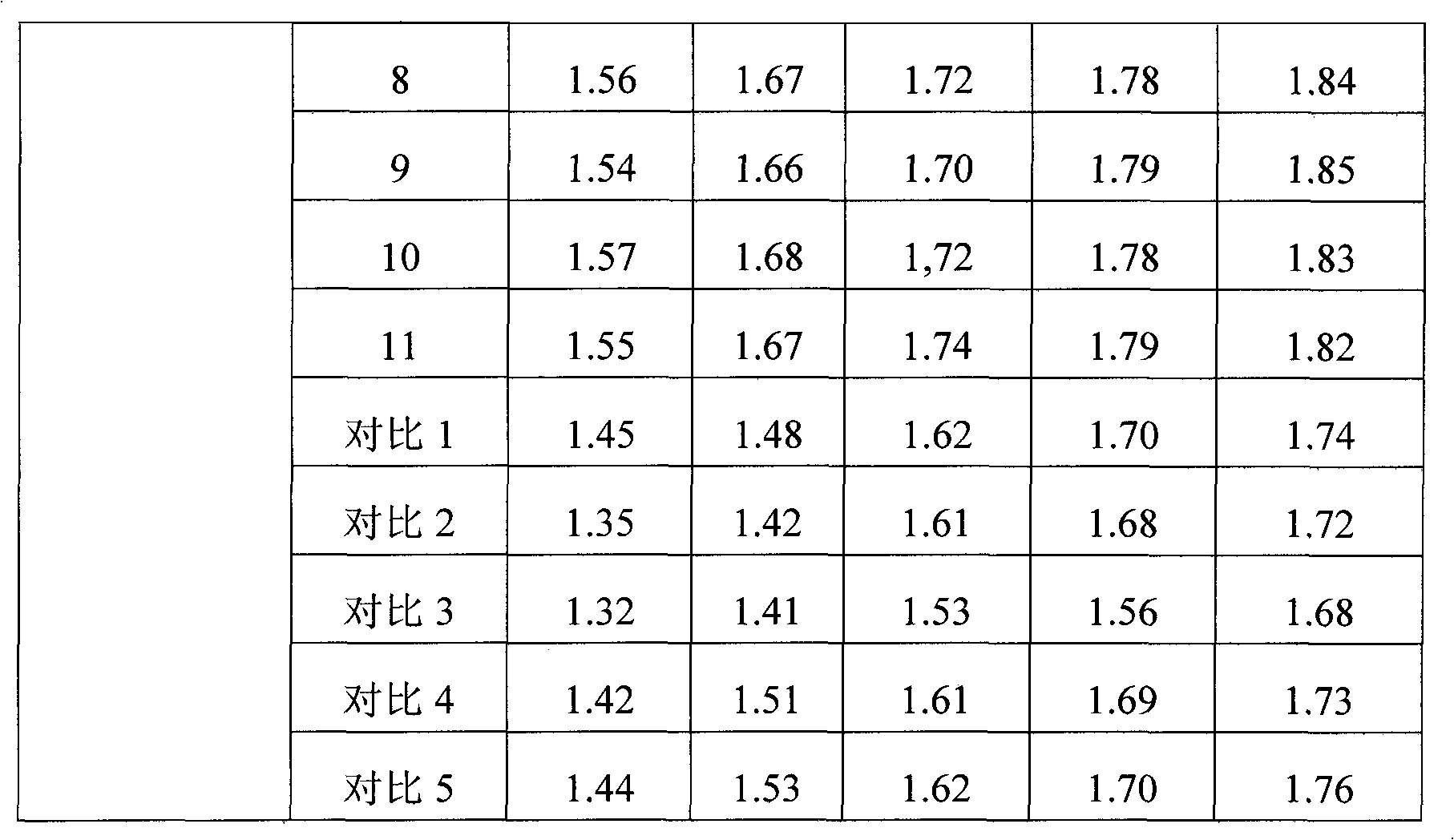

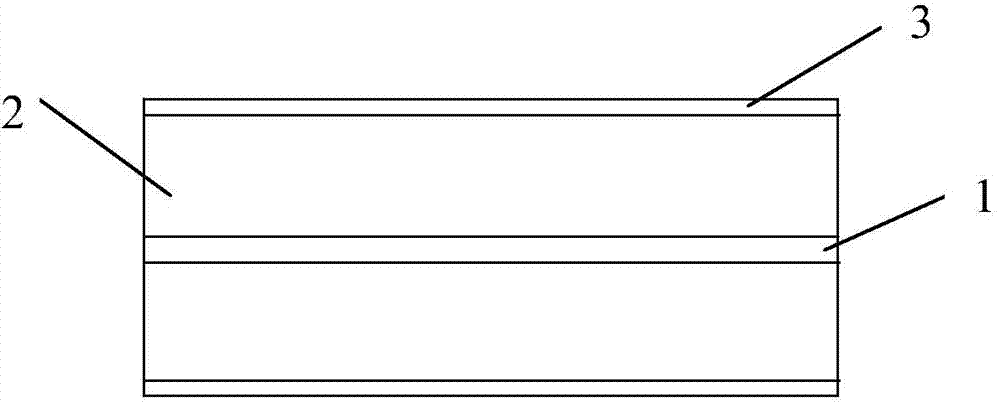

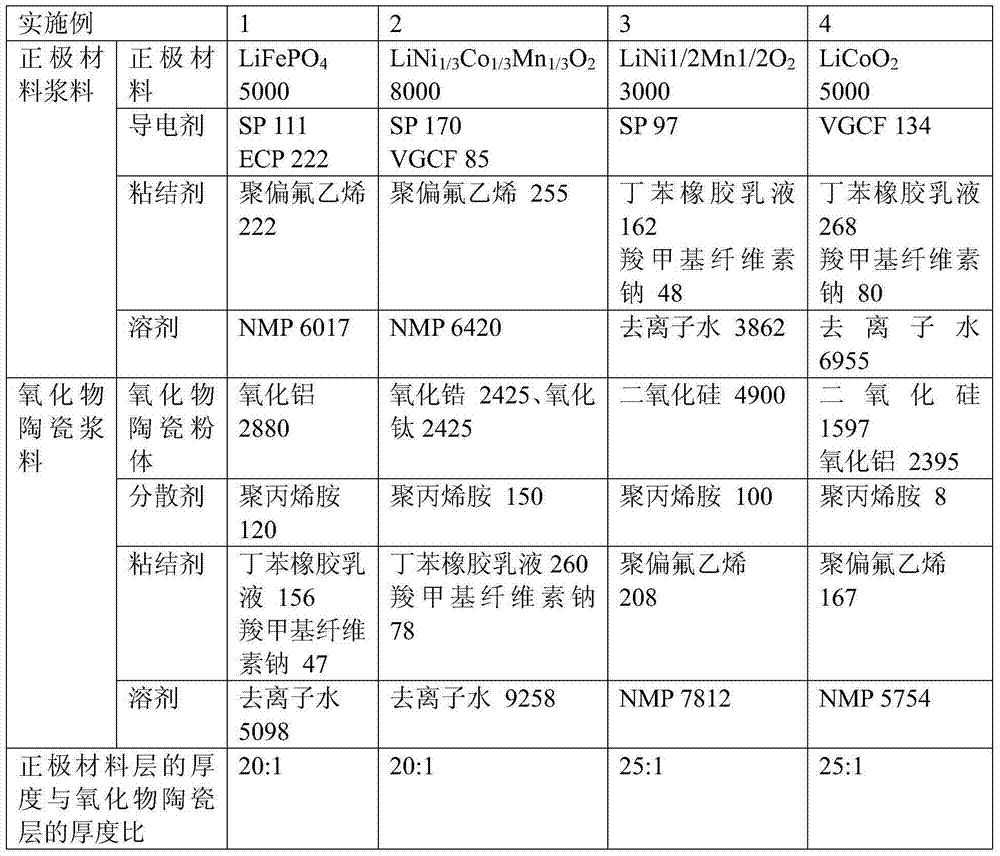

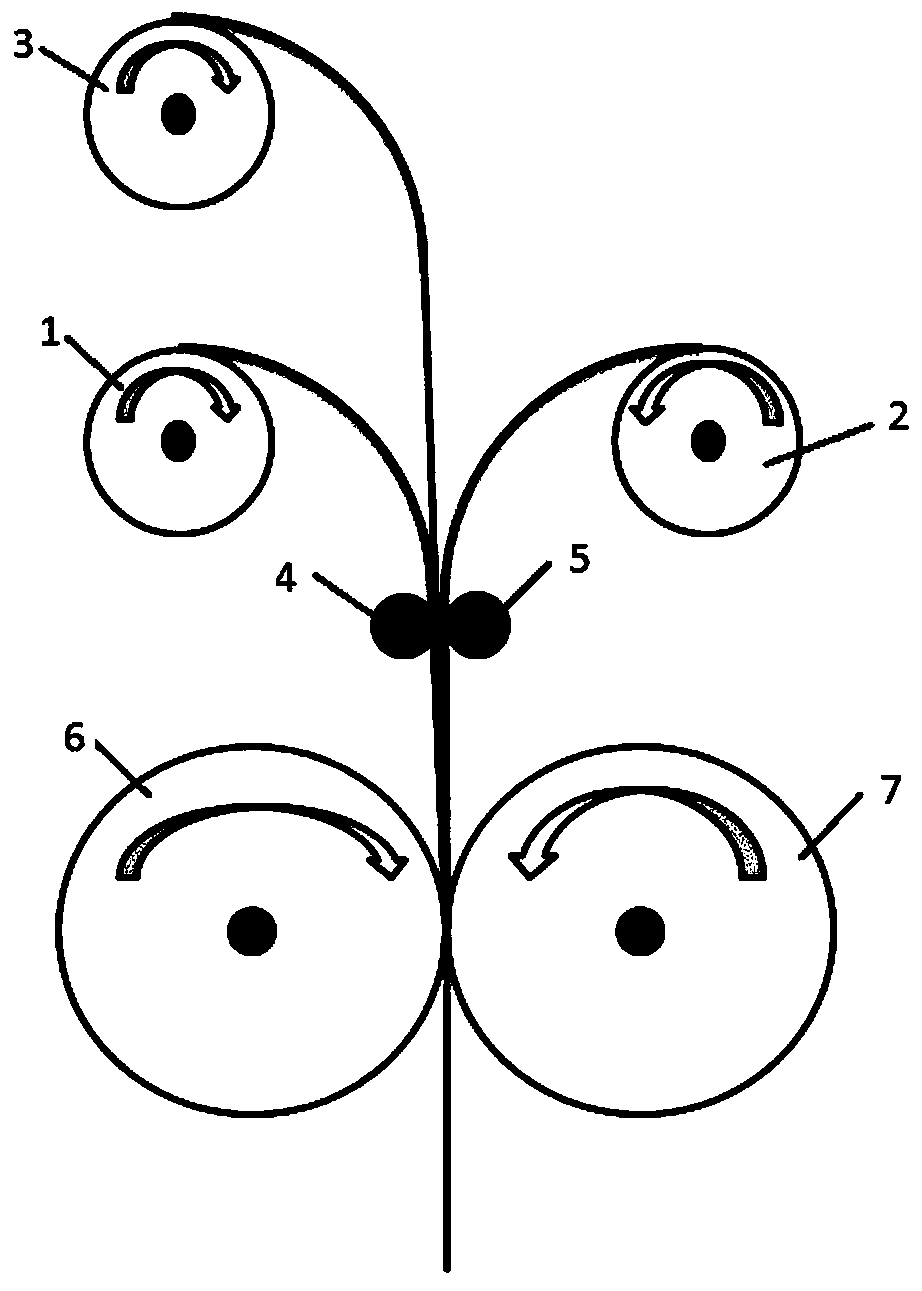

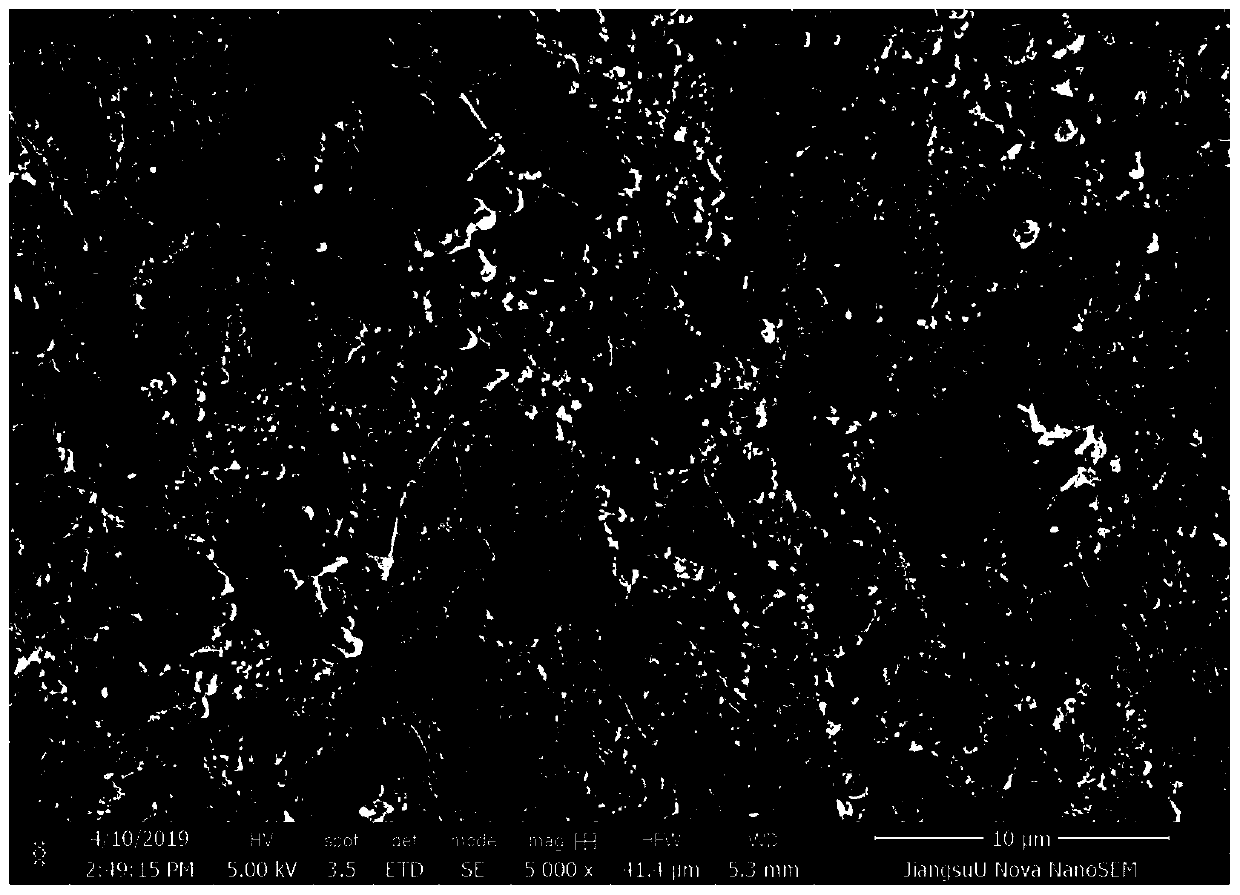

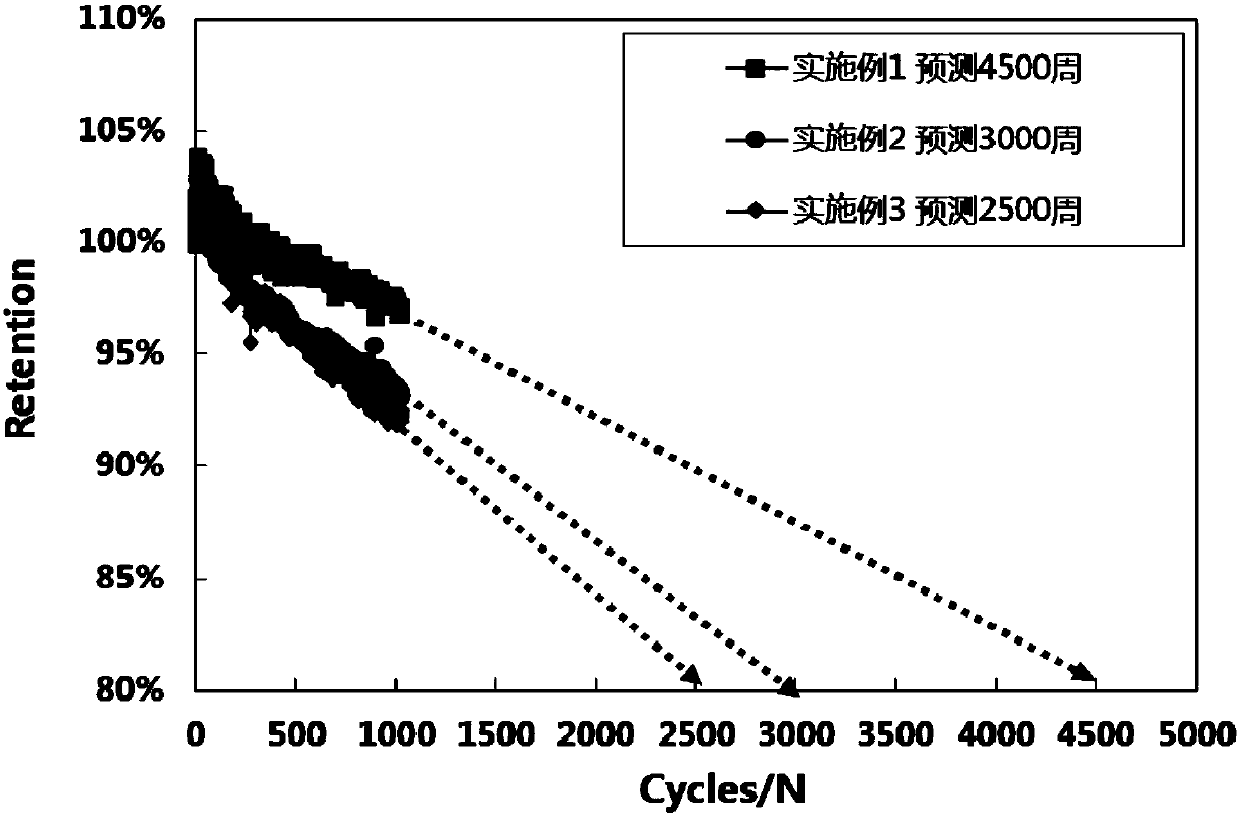

Positive plate of lithium-ion battery with high safety performance and fabrication method of positive plate

ActiveCN105449159APrevent micro sheddingReduce short circuitElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesOxide ceramicEngineering

The invention relates to a positive plate of a battery, in particular to a positive plate of a lithium-ion battery with high safety performance and a fabrication method of the positive plate. The positive plate of the lithium-ion battery comprises a current collector, a positive material layer and an oxide ceramic layer, wherein the positive material layer evenly coats the current collector; the oxide ceramic layer evenly coats the positive material layer; the current collector is an aluminum foil; the positive material layer is a mixture of a conductive agent, a binder and one or more of LiFePO<4>, LiCoO<2>, LiMn<2>O<4>, LiNiO<2>, LiMnO<2>, LiNi<x>Co<y>Mn<1-x-y>O<2> (x is smaller than 1 and greater than or equal to 0, and y is smaller than 1 and greater than or equal to 0) and xLi(Li<1 / 3>Mn<2 / 3>)O2.(1-x)LiNi<y>Co<z>Mn<1-y-z>O2 (x is smaller than 1 and greater than 0, y is smaller than 1 and greater than or equal to 0 and z is smaller than 1 and greater than or equal to 0); and the oxide ceramic layer is a mixture of oxide ceramic powder, a dispersing agent and the binder.

Owner:WANXIANG 123 CO LTD

Ion sieve cathode for electrolytic cell used for extracting lithium from lithium-containing aqueous solution and method for producing same

ActiveCN111018061AIncrease loadUniform and controllable thicknessWater/sewage treatmentProcess efficiency improvementAlkaline earth metalSulfide

The invention provides an ion sieve cathode for an electrolytic cell used for extracting lithium from a lithium-containing aqueous solution and a manufacturing method of the same. The manufacturing method comprises the following steps: uniformly mixing a conductive agent, lithium-intercalatable oxide and pre-lithiated polyphenylene sulfide or a pre-lithiated polyphenylene sulfide derivative in a mixer to obtain powder A; mixing polytetrafluoroethylene powder and the powder A in the mixer to obtain powder B; then carrying out grinding by using supersonic dry gas to extend and open a polytetrafluoroethylene molecular chain in the powder B and to allow the polytetrafluoroethylene molecular chain to form physical adhesion with carbon-based powder, thereby obtaining powder C; and preparing a cathode film D under high-temperature hot pressing, and thermally compounding the cathode film D on the two sides of a corrosion-resistant current collector by adopting a hot-pressing compounding process to prepare the ion sieve cathode. The prepared ion sieve cathode is large in active substance loading capacity, uniform and controllable in thickness, high in strength, good in corrosion resistance,high in conductivity and high in current efficiency; and a pre-lithiated polyphenylene sulfide-based ion sieve is introduced, so other alkali metals and alkaline-earth metals can be effectively prevented from entering crystal lattices of lithium-embedded oxide.

Owner:东莞奥创能源科技有限公司

Formation and validation method capable of improving cycle performance of lithium iron phosphate battery

InactiveCN108054436AImprove cycle performanceImpact capacityFinal product manufactureElectrolyte accumulators manufactureLithium iron phosphateInternal resistance

The invention provides a formation and validation method capable of improving the cycle performance of a lithium iron phosphate battery. The method comprises the steps of preparing a square soft package battery; carrying out normal-temperature staged preformation; completing a preformation stage and then carrying out secondary packaging on the battery; and finally carrying out battery capacity grading and validation. A matched formation and validation method capable of improving the cycle performance of the lithium iron phosphate battery is established for a specific square soft package powerbattery system; and in the process of the method, the factors, such as corresponding internal resistance change, fluid loss change, charge-discharge efficiency and scanning interface of the battery are analyzed to form the formation and validation method capable of improving the cycle performance of the lithium iron phosphate battery, which is optimal in SEI film, optimal in battery performance and longest in cycle life.

Owner:桑顿新能源科技(长沙)有限公司

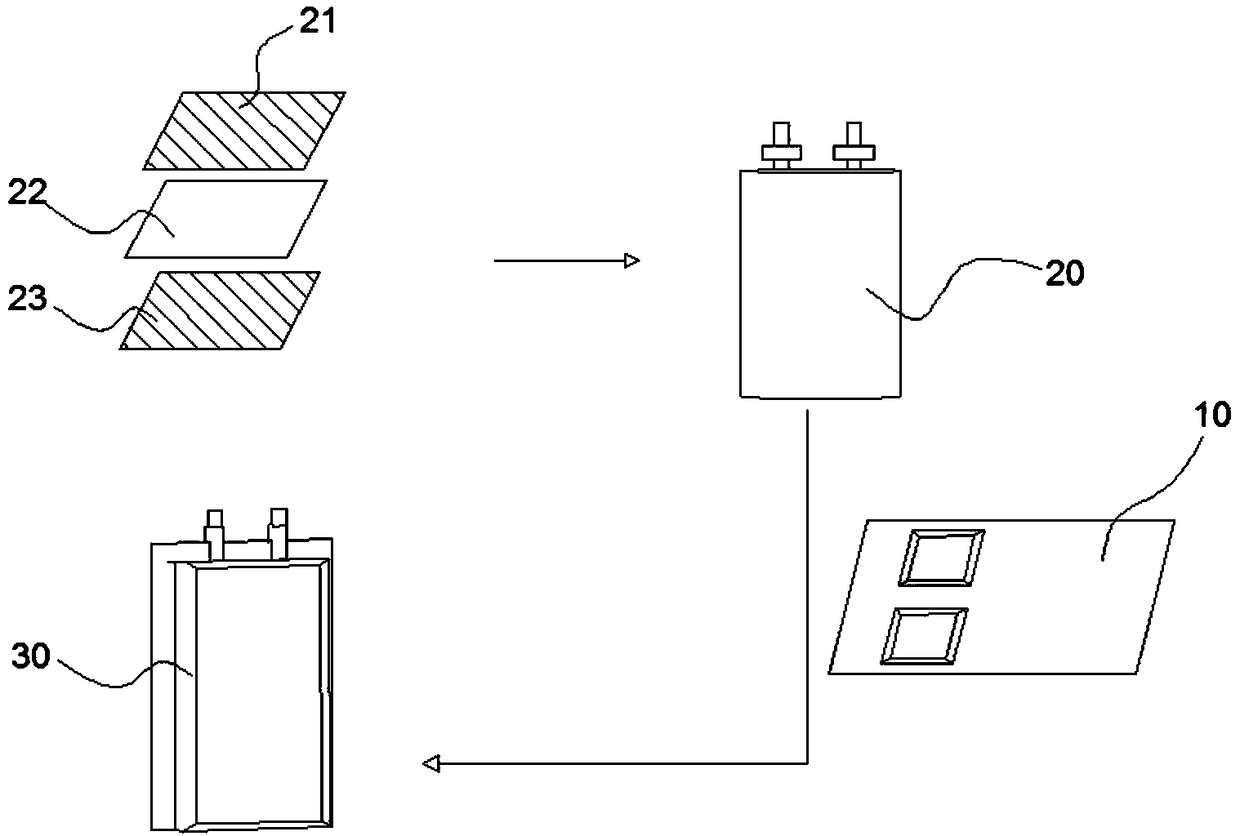

Three-dimensional lithium battery preparation method based on direct writing forming 3D printing technology

ActiveCN112186257AImprove plasticityImprove electrochemical performanceAdditive manufacturing apparatusFinal product manufacturePhysicsElectrical battery

The invention discloses a three-dimensional lithium battery preparation method based on a direct writing forming 3D printing technology. The three-dimensional lithium battery preparation method comprises the following steps: step 1, designing an electrolyte block and introducing the electrolyte block into a direct writing forming machine; 2, preparing gel electrolyte ink, and supplying the gel electrolyte ink to a charging barrel of a direct writing forming machine; 3, extruding the electrolyte ink in the charging barrel under pressure; 4, controlling a printing head to move on a working platform by a program according to the current section data to form a section; 5, completing the front section, and lowering the working platform by a layered thickness; 6, repeating the third step to thefifth step, and completing the printing of the electrolyte block; 7, performing laser drilling on the electrolyte block to obtain an electrode reserved through hole; 8, preparing positive electrode ink and negative electrode ink, and respectively pouring the positive electrode ink and the negative electrode ink into the reserved through holes to obtain a battery prefabricated body; 9, removing moisture through vacuum freeze drying; 10, carrying out heat treatment on the battery prefabricated body to realize solidification of the electrode and the electrolyte block; and 11, packaging to complete the preparation of the three-dimensional lithium battery.

Owner:XI AN JIAOTONG UNIV

Sodium cobalt pyrophosphate/carbon/graphene positive electrode composite material, preparation and application

InactiveCN107017394AUniform particle sizeGood lookingCell electrodesSecondary cellsWater bathsSodium-ion battery

The invention discloses a sodium cobalt pyrophosphate / carbon / graphene positive electrode composite material, and a preparation method thereof. The preparation method comprises the following steps: dissolving a cobalt source, a sodium source and a phosphorus source into deionized water separately according to a stoichiometric ratio, adding an acidic metal complexing agent to adjust the pH, stirring uniformly, and adding a certain amount of prepared graphene solution into the solution; mixing uniformly, heating in a water bath pot to form gel, evaporating to dryness under a vacuum drying box to obtain a precursor, grinding the precursor, and sintering under protective gas to obtain a sodium ion battery positive electrode composite material Na2CoP2O7@C which is embellished on graphene. The preparation method provided by the invention is simple and mild in condition. The prepared sodium ion battery positive electrode material has uniform granularity and good appearance, and has high specific capacity and high voltage and shows excellent circulating stability when being applied to a sodium ion battery.

Owner:CENT SOUTH UNIV

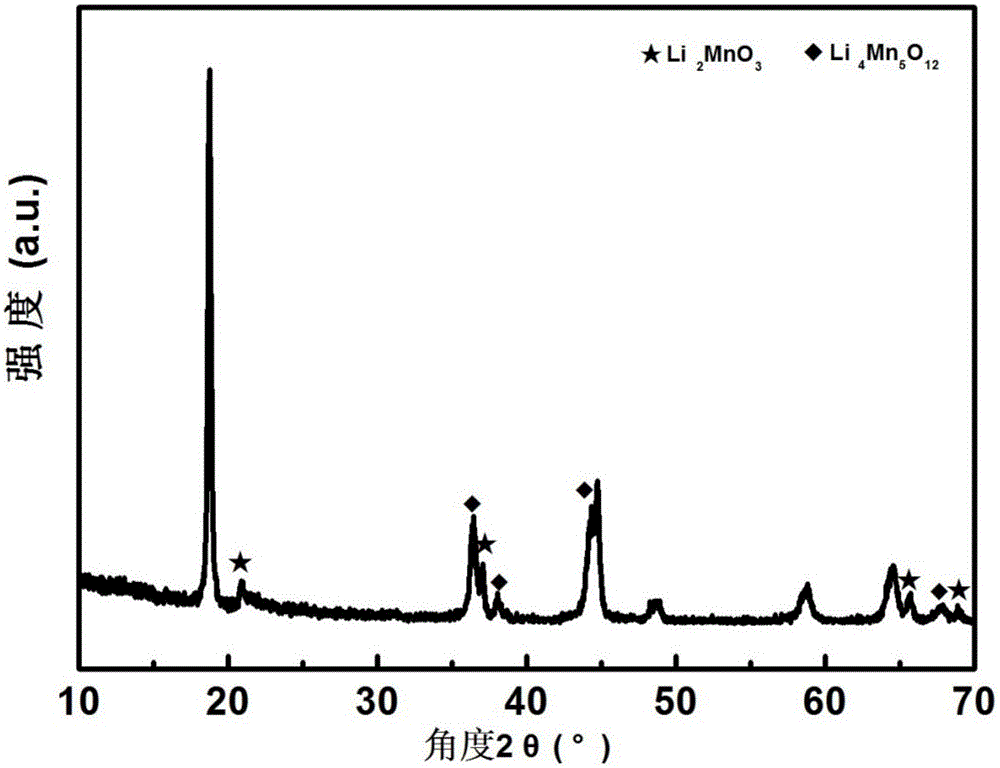

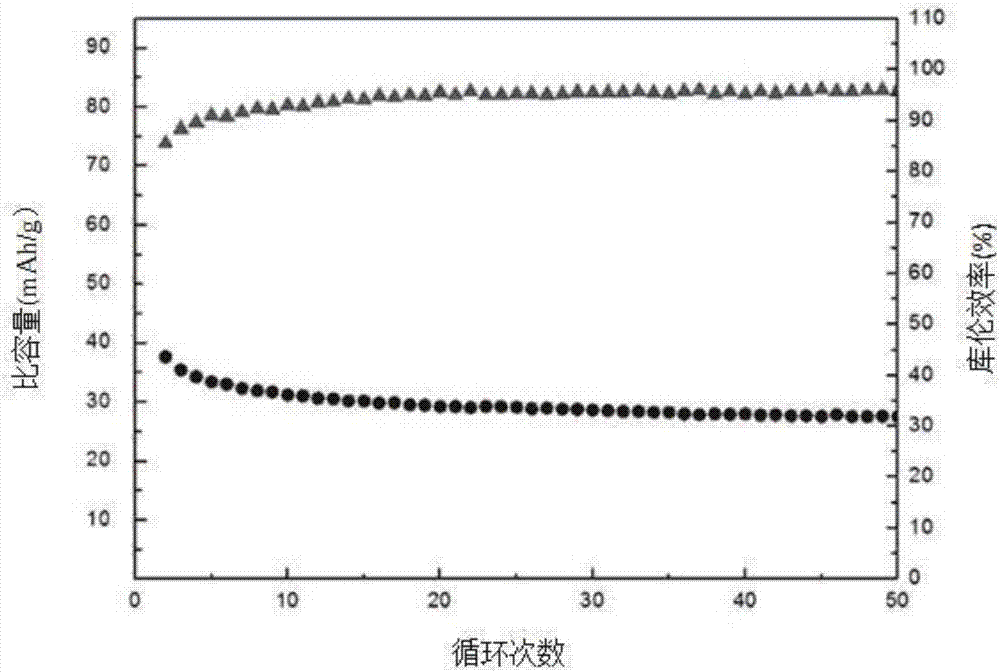

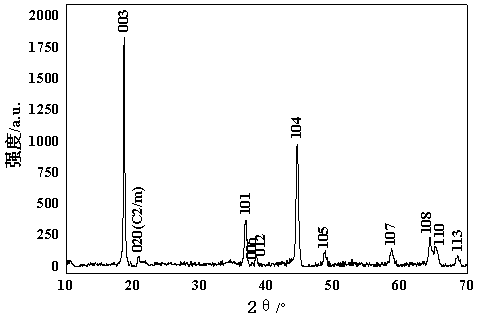

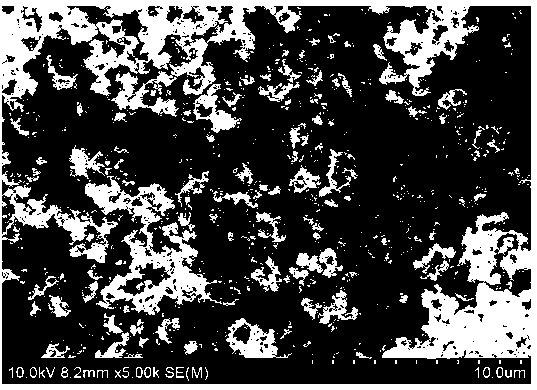

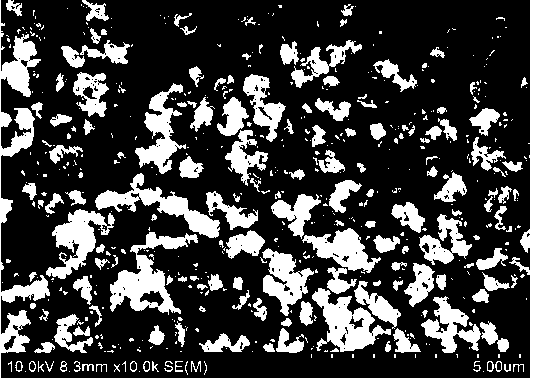

Multi-component lithium ion battery anode material rich in lithium and preparation method thereof

InactiveCN103066264ASimple preparation processReduce manufacturing costCell electrodesLithium acetateMaterials science

The invention discloses a multi-component lithium ion battery anode material rich in lithium and a preparation method thereof. The molecular formula of the multi-component lithium ion battery anode material rich in lithium is Li1.17Ni0.17Co0.17Mn0.50O2. The preparation method comprises the steps of firstly adopting an alcoholysis solid phase method, utilizing ethanol to dissolve cobalt acetate, nickel acetate, manganese acetate and lithium acetate, drying the mixture of dissolved cobalt acetate, nickel acetate, manganese acetate and lithium acetate by controlling the temperature at 120 DEG C so as to obtain transition metal acetate presoma solid powder; and finally, carrying out two times of sintering on the obtained transition metal acetate presoma powder in a high temperature pipe furnace system, and then carrying out sufficient ball milling until the particle diameter of a grain is less than 1 mum, thus obtaining the multi-component lithium ion battery anode material rich in lithium, with good morphological structure, small particle size distribution and better battery property; and the preparation method has the characteristics of being simple in preparation process, low in production cost, suitable for scale production and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

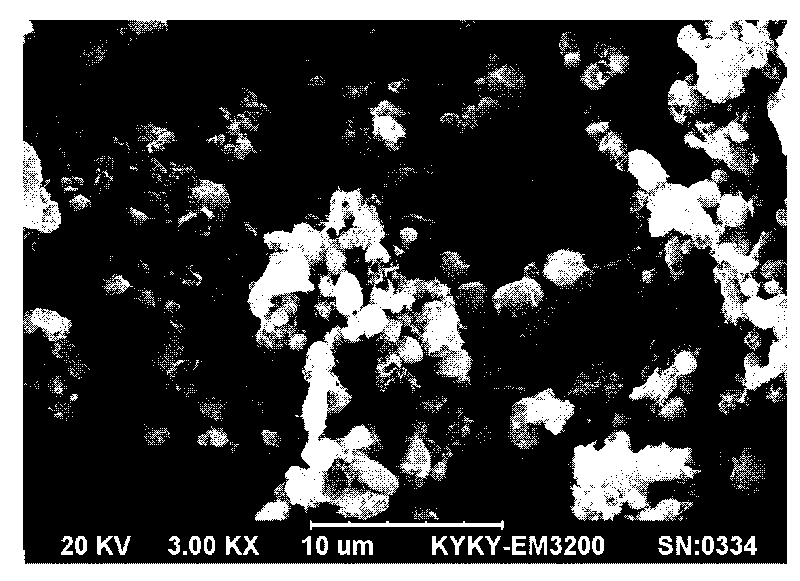

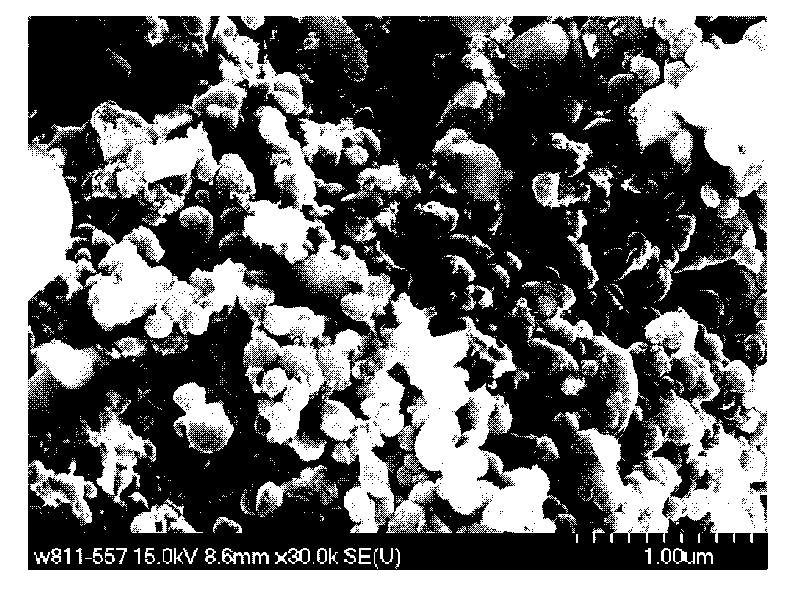

Preparation method of ferrous lithium phosphate cathode composite material

ActiveCN101527354ACoated evenlyGuaranteed tap densityElectrode manufacturing processesPhosphorus compoundsCarbon coatingPhosphate

The invention relates to a preparation method of a ferrous lithium phosphate cathode composite material. The method comprises the following steps: stocking a ferric iron-source compound, a lithium-source compound, phosphate, doped tantalum compounds and carbon black according to a certain proportion; firstly adding the ferric iron-source compound into an ultrafine ball mill so as to have the grain diameter of 100 nm to 500 nm by ball milling; then, adding other raw materials and using acetone as a dispersant for ball milling and mixing, drying in vacuum and sintering at a low temperature in an inert protective atmosphere oven to deacidize ferric iron; afterwards, adding a certain amount of conductive agent material to obtain ferrous lithium phosphate, ball milling, mixing and drying and sintering at a high temperature in the inert protective atmosphere oven; and finally, shattering, crushing and elutriating to obtain the ferrous lithium phosphate cathode composite material. The invention has the advantages that the materials ensure the tap density and can achieve favorable capacity and magnification performance, and secondary sintering enables the carbon coating to be more even and the granular magnification to be better.

Owner:JIANGXI SHENGHUA NEW MATERIAL CO LTD

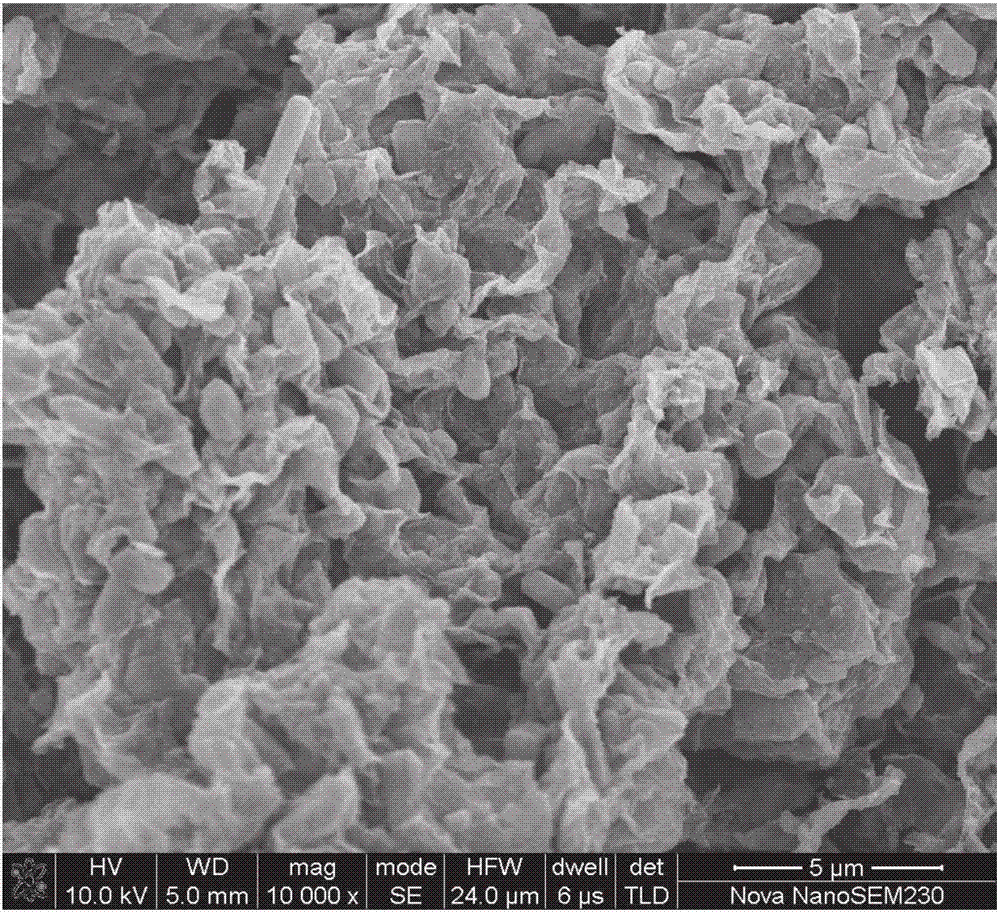

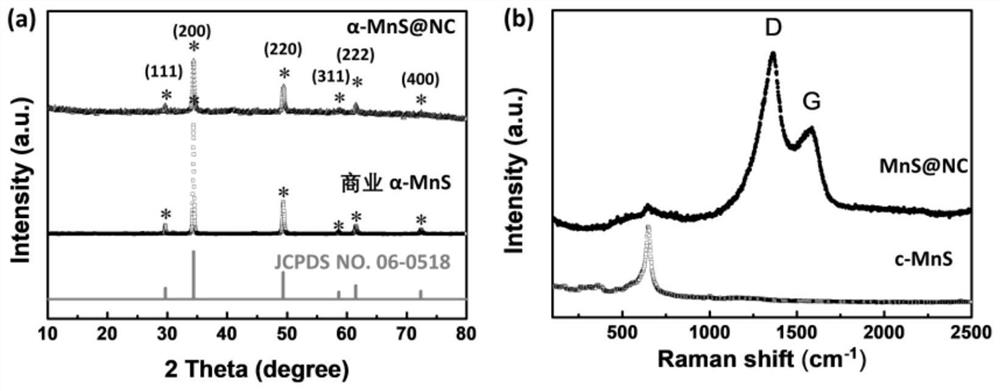

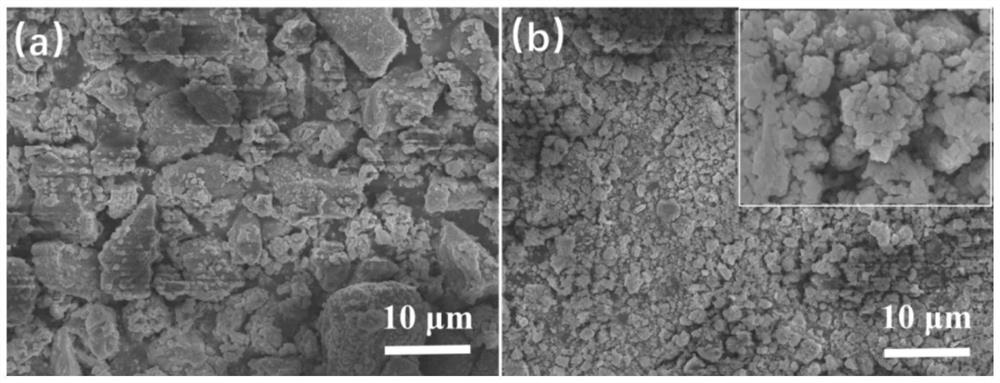

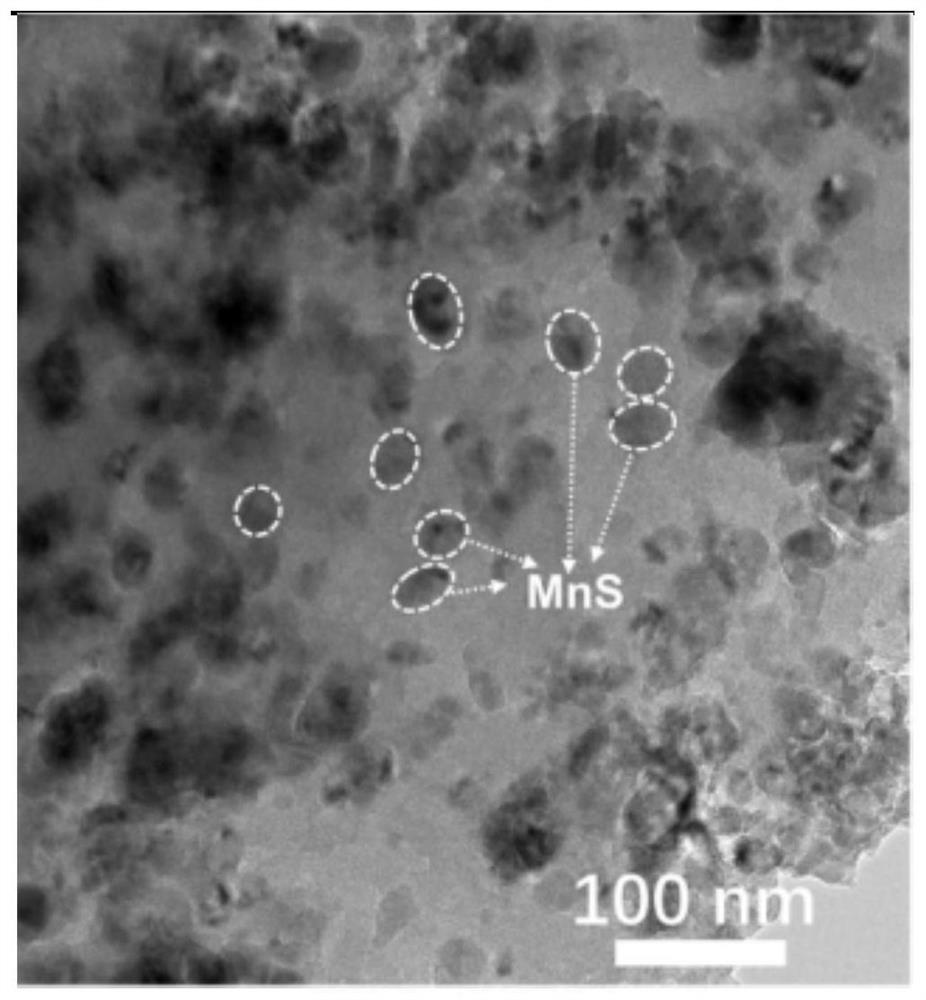

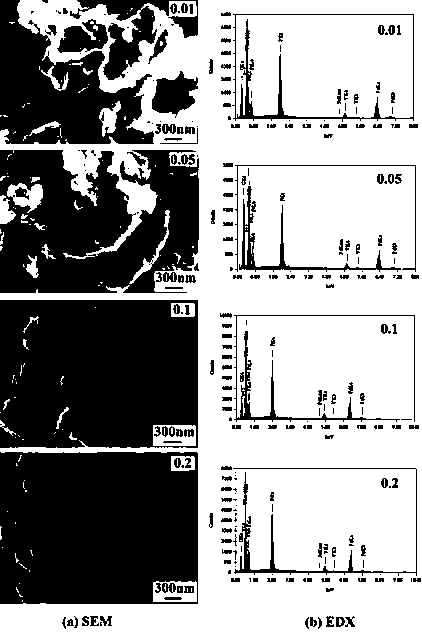

Nitrogen-doped carbon-coated manganese sulfide composite negative electrode material and preparation method and application thereof

ActiveCN114014368AImprove conductivityImprove structural stabilityMaterial nanotechnologyCell electrodesMicro nanoNano structuring

The invention provides a nitrogen-doped carbon-coated manganese sulfide composite negative electrode material and a preparation method and application thereof, and belongs to the technical field of negative electrode materials, and the preparation method comprises the following steps: ball-milling micron manganese sulfide, mixing the micron manganese sulfide with a nitrogen-containing polymer and a solvent, drying, and roasting to obtain the nitrogen-doped carbon-coated manganese sulfide composite negative electrode material. Nanometer manganese sulfide can be obtained by adopting micron manganese sulfide through one-step ball milling, then the nanometer manganese sulfide and a nitrogen-containing polymer solution are mixed, dried and then subjected to high-temperature roasting, the nitrogen-containing polymer is pyrolyzed to form a nitrogen-doped carbon matrix material in the high-temperature roasting process, the ion diffusion path is shortened through nanometer manganese sulfide particles, the nitrogen-doped carbon substrate material improves the electronic conductivity and the structural stability of the negative electrode material, and the negative electrode material is of a micro-nano structure, so that the specific surface area of the material is reduced, and the first efficiency and the tap density are improved, thereby ensuring the electrochemical performance of the material, especially the cycling stability under high magnification; the preparation process is simple, and no other harmful by-products are generated.

Owner:DONGGUAN UNIV OF TECH

Storage battery and storage battery pack

InactiveCN108091782AWith self-flame retardant effectImprove securityBattery isolationSecondary cellsPlastic filmElectrochemistry

The invention provides a storage battery and a storage battery pack, and relates to the technical field of battery. The storage battery includes an electric core and an aluminum plastic film for encapsulating the electric core, and a flame retardant microcapsule is embedded in the aluminum plastic film. With use of the storage battery, the technical problem of poor electrochemical performance of astorage battery caused when a flame retardant is added in an electrolyte solution of the storage battery to improve the flame retardancy in the prior art can be solved, and the effect of improving the flame retardancy of the storage battery without reduction of the electrochemical performance of the battery can be achieved.

Owner:桑德新能源技术开发有限公司 +1

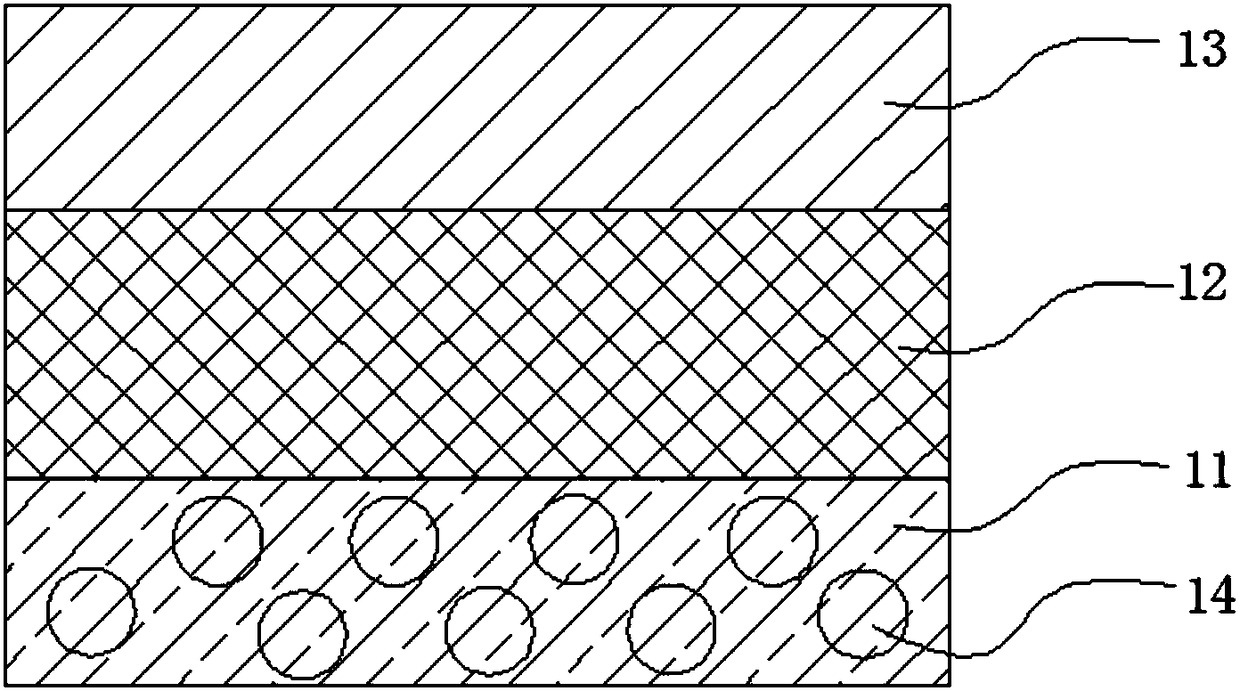

Method for manufacturing super-thick high-energy-density polymer lithium ion battery cell

InactiveCN103887565ACoping with Stress EpisodesMaintain electrochemical performanceFinal product manufactureSecondary cellsHigh energyEngineering

The invention relates to a method for manufacturing a super-thick high-energy-density polymer lithium ion battery cell. The method comprises the following steps: preparing a positive plate, an isolating membrane and a negative plate; winding the isolating membrane for a half layer, inserting the negative plate, winding the isolating membrane and the negative plate for a layer, inserting the positive plate, and winding the isolating membrane, the negative plate and the positive plate together, wherein the total number of winding layers of the battery cell is 12-76; when the number of the winding layers is 12-36, inserting a plastic hose between the isolating membrane and the positive plate or between the isolating membrane and the negative plate; when the total number of the winding layers is larger than 36, entering a step D; when the total number of the winding layers is less than or equal to 36, entering a step E; when the number of the winding layers of the battery cell is increased to 12-36 in the step D, inserting the plastic hose between the isolating membrane and the positive plate or between the isolating membrane and the negative plate; continuously winding in the step E until the number of the winding layers reaches a preset number; and detaching the plastic hose from the battery cell to obtain the finished product. According to the battery cell produced by the method, the problem that the battery cell is deformed can be solved.

Owner:DONGGUAN LIWINON ENERGY TECH

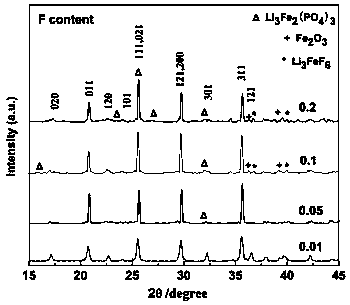

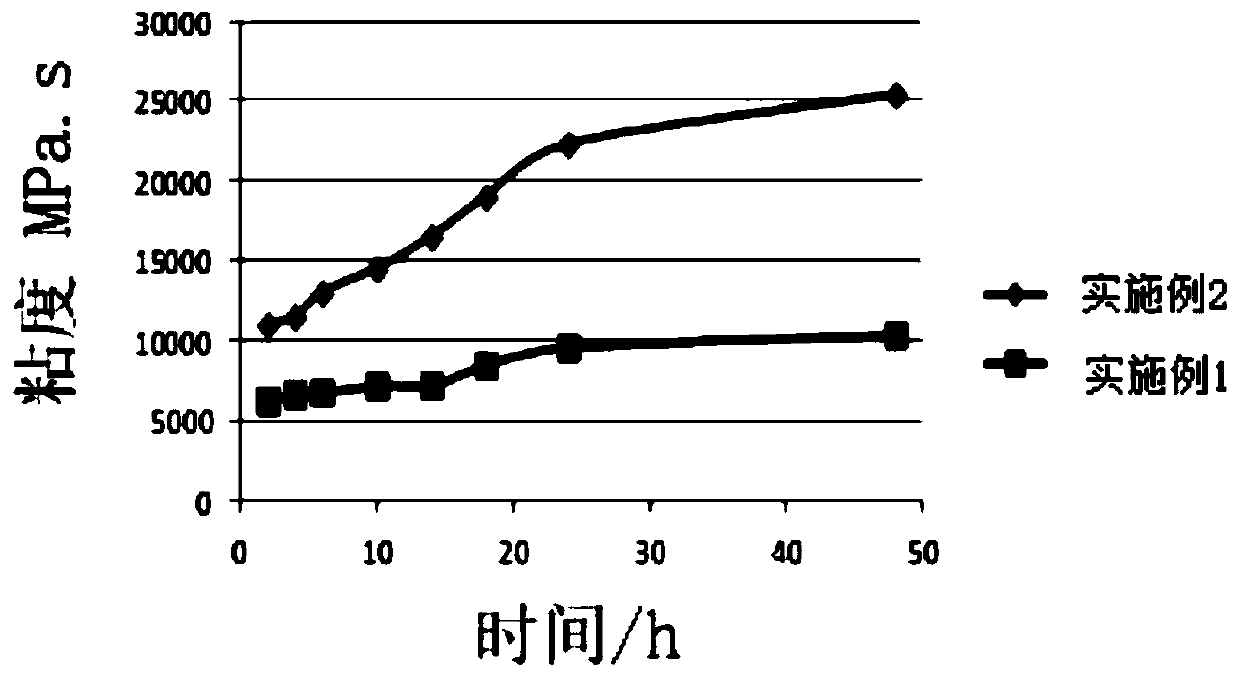

Preparation method of fluorine ion doped lithium iron phosphate material

InactiveCN110957491AReduce energy consumptionGuaranteed electrochemical performanceMaterial nanotechnologySecondary cellsPhosphoric acidCarbon source

The present invention discloses a preparation method of a fluorine ion doped lithium iron phosphate material. The method comprises the following steps of: S1, preparing of a precursor mixed solution,namely dissolving a soluble lithium source, an iron source, a phosphorus source and fluoride in deionized water, and adding a water-soluble carbon source and a water-soluble auxiliary agent for dissolving to obtain the precursor mixed solution; S2, gelation treatment: carrying out oil bath heating on the precursor mixed solution obtained in the step S1 to obtain viscous precursor gel; S3, self-propagating combustion treatment: heating the precursor gel obtained in the step S2 to carry out self-propagating combustion decomposition to obtain a combustion product; S4, ball-milling treatment: transferring the combustion product obtained by combustion decomposition in the step S3 into a ball-milling tank, and carrying out high-speed ball-milling mixing to obtain mixed slurry; and S5, low-temperature sintering treatment: and cooling the mixed slurry to room temperature to obtain a final product. The preparation method of the fluorine ion doped lithium iron phosphate material has the characteristics of low energy consumption, high tap density, uniform mixing, the good modification effect and the excellent electrochemical performance.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

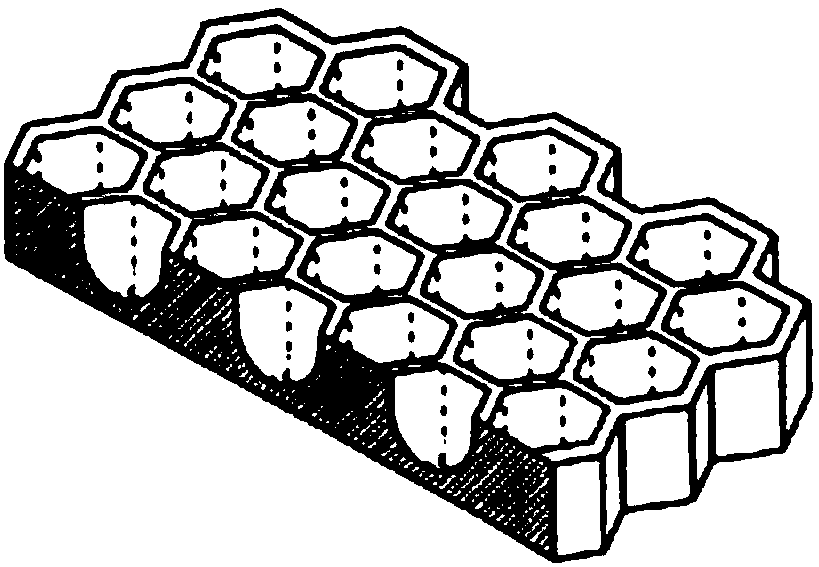

Current collector and manufacturing method thereof

ActiveCN110676463AGuaranteed electrochemical performanceIncrease contact areaElectrode carriers/collectorsConductive coatingEngineering

The invention provides a current collector and a manufacturing method thereof, and relates to the chemical power supply technology field. The current collector comprises a conductive substrate layer and at least one conductive coating with a regular three-dimensional grid structure. The conductive coating is coated on the substrate layer. By using the current collector, the at least one layer of conductive coating with the regular three-dimensional grid structure is coated on the conductive substrate layer so that a contact area between an electrode material and the conductive coating can be increased. Bonding strength of the current collector and the electrode material is improved, and simultaneously an electron conduction capability between the current collector and the electrode material is increased so that a usage amount of a binder is reduced while electrochemical performance of the current collector is ensured.

Owner:宁波铵特姆新能源科技有限公司

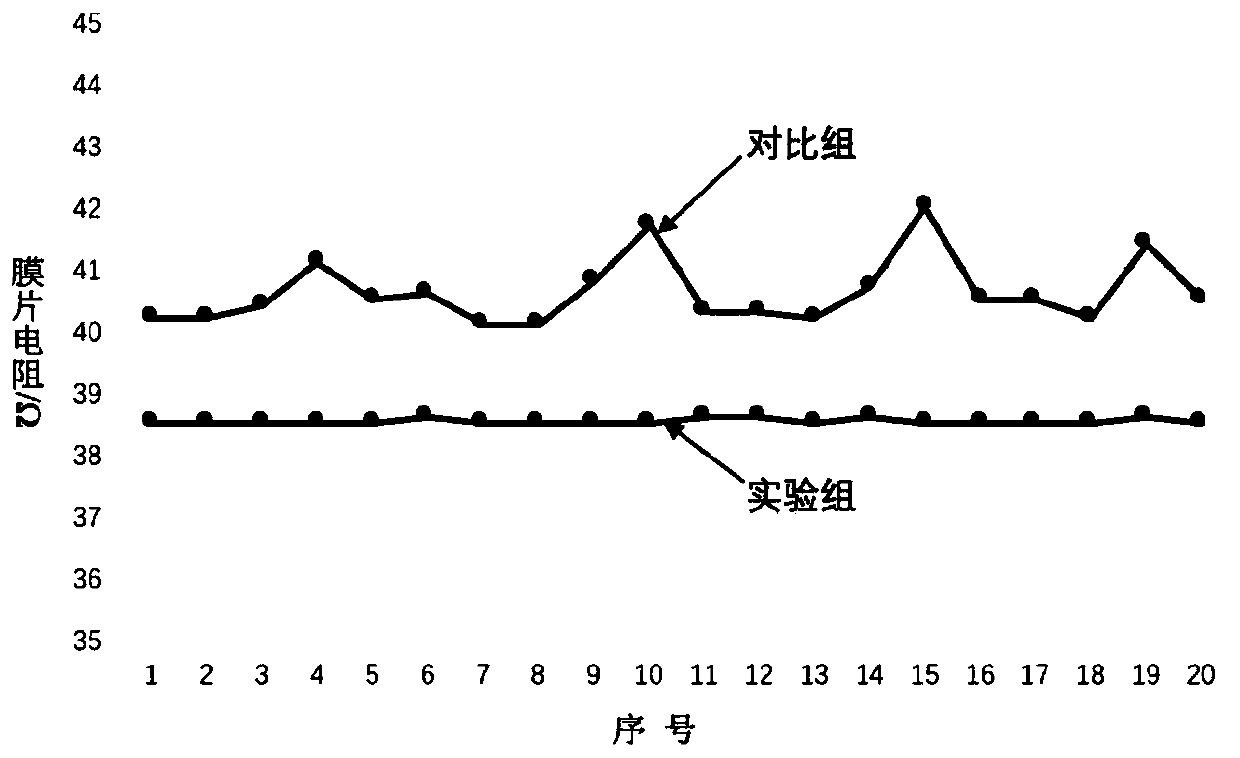

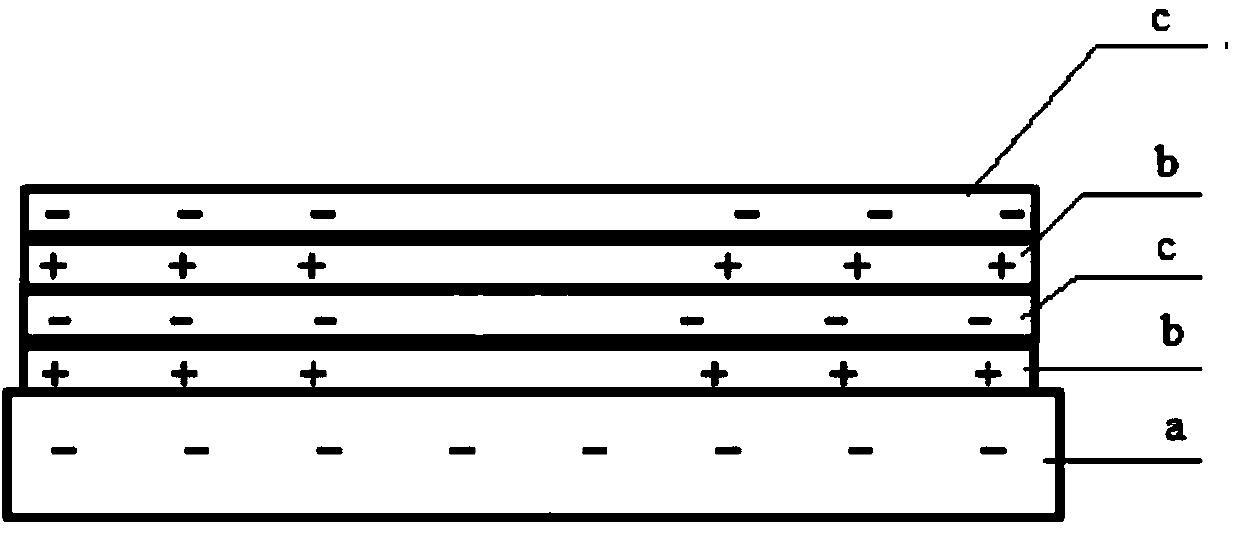

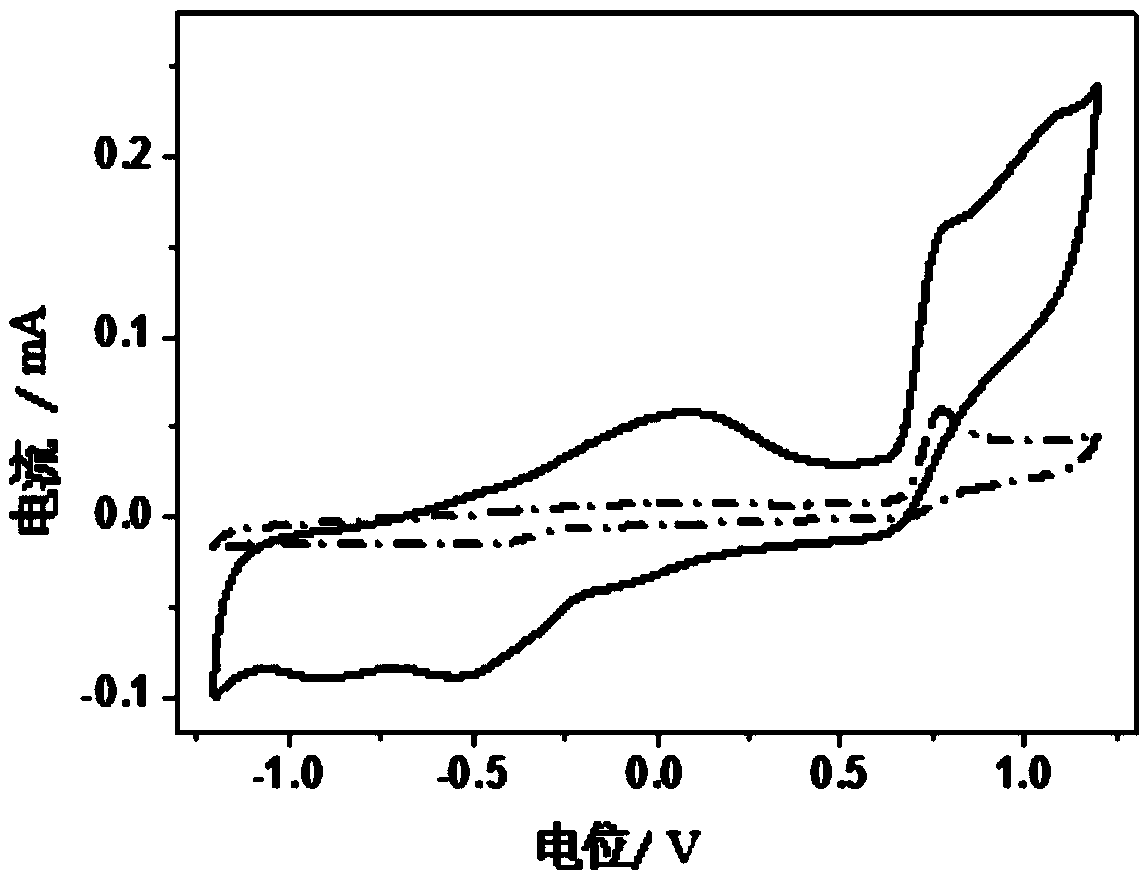

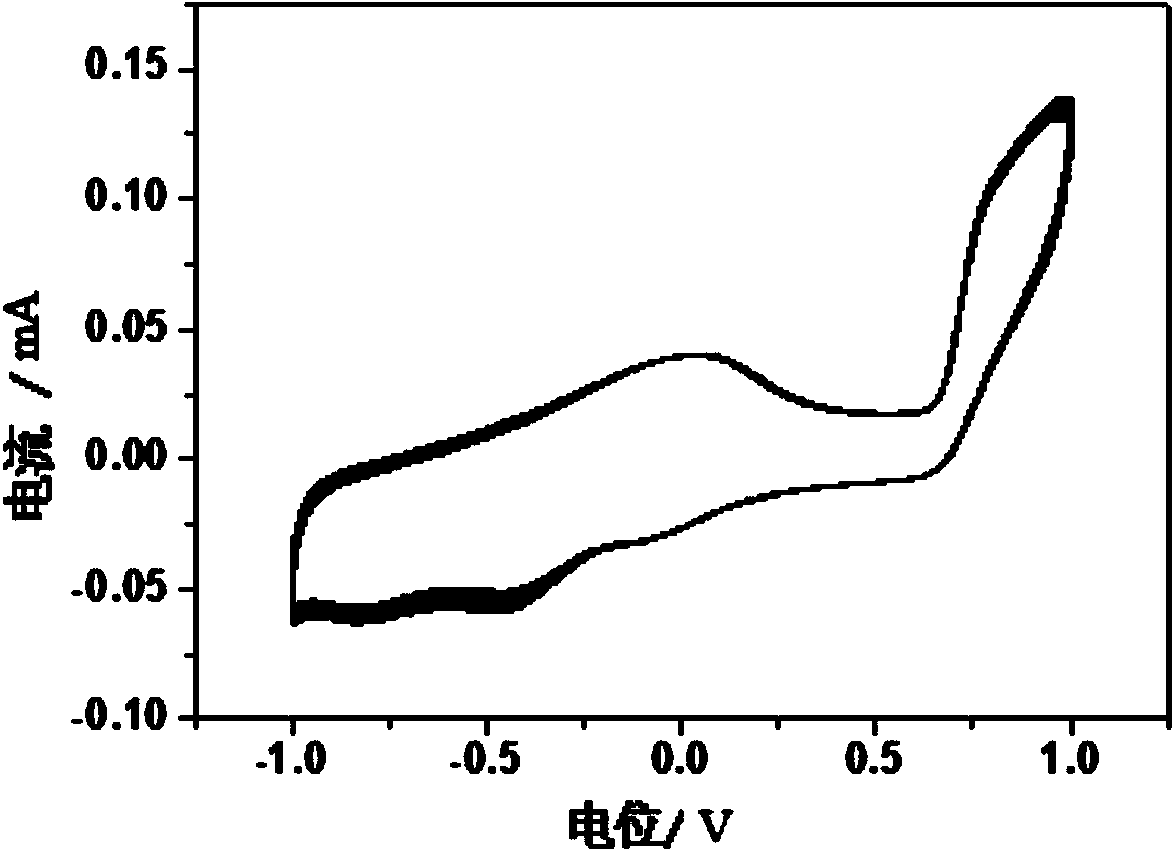

Cationic metal phthalocyanine/carbon nano-tube self-assembled membrane electrode and preparation method thereof

InactiveCN104198561AExcellent electrocatalytic performanceExcellent stabilityMaterial analysis by electric/magnetic meansCarbon nanotubeElectrochemistry

The invention belongs to the field of electrochemical / biological sensors, and in particular relates to a cationic metal phthalocyanine / carbon nano-tube self-assembled membrane electrode and a preparation method thereof, aiming to solve the problems that an existing membrane electrode is non-uniform in surface coverage, low in surface coverage rate and non-steady in electrochemical property, and an existing preparation method is complex in process and high in cost and pollutes the environment. The cationic metal phthalocyanine / carbon nano-tube self-assembled membrane electrode is obtained by alternatively assembling a cationic metal phthalocyanine layer with positive charge and a carbon nano-tube layer with negative charge on a substrate with negative charge and forming a multi-layer membrane electrode with the cationic metal phthalocyanine layer and the carbon nano-tube layer which are alternative. The preparation method disclosed by the invention comprises the following steps: (1), preparing a cationic metal phthalocyanine aqueous solution; (2), preparing carbon nano-tube dispersion liquid; (3), pre-processing the substrate; and (4), preparing the cationic metal phthalocyanine / carbon nano-tube self-assembled membrane electrode.

Owner:HEILONGJIANG UNIV

Preparation method of lithium ion battery formed at normal pressure and sealed at negative pressure

InactiveCN106848411AReduce internal pressureGuaranteed electrochemical performanceFinal product manufactureElectrolyte accumulators manufactureDew pointEngineering

The invention discloses a preparation method of a lithium ion battery formed at normal pressure and sealed at negative pressure. The preparation method comprises the following specific steps: a liquid-injected lithium ion battery is put into a battery formation cabinet, and the formation cabinet is in a dew point environment of minus 25 DEG C to minus 45 DEG C; battery formation is then carried out while forming current is 0.05-0.15 C and charging time is 60-360 min; after completion of battery formation, the battery is put into a vacuum chamber for exhausting and the process is maintained at minus 50 to minus 90 Kpa for 5-15 min; and after battery exhausting, steel balls are beaten for sealing under the condition of minus 50 to minus 90 Kpa, and preparation of the battery is finished. By the mode of controlling the dew point of the environment, the influence of moisture on the battery during formation is reduced; and after formation, by exhausting and negative-pressure sealing of the battery, gas inside the battery is discharged to reduce pressure inside the battery and electrochemical performance of the battery is guaranteed. There is no need to increase investment in equipment; battery cost is not raised; and market competitiveness of the battery is improved.

Owner:ZHONGTIAN ENERGY STORAGE TECH

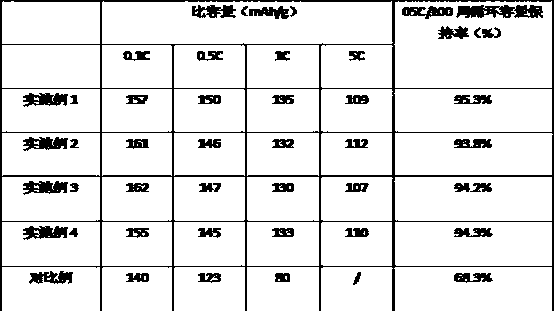

Coated modified positive electrode material and preparation method thereof

ActiveCN113830846ASimple processEasy to industrializeSecondary cellsPositive electrodesLithium electrodeNickel base

The invention belongs to the technical field of lithium ion battery materials, and particularly relates to a coated modified positive electrode material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing a high-nickel matrix material with zinc borate and other compound solid phases of coating elements to obtain a mixture A; and sintering the mixture A in an atmosphere furnace to obtain the coated and modified high-nickel positive electrode material. The zinc borate can be well fused with a high-nickel base material, meanwhile, zinc borate is decomposed into boron oxide and zinc oxide in the sintering reaction process, the boron oxide and the zinc oxide can be well combined with surface residual alkali, soluble lithium of the high-nickel material is reduced, meanwhile, uniform coating of B and Zn is formed on the surface of the material, and the material structure is stabilized. Compared with the prior art, the preparation method provided by the invention is simple in process and easy to industrialize, the positive electrode material can achieve a good alkali reduction effect without water washing, and the electrochemical performance of the positive electrode material is ensured while the synthesis process is simplified.

Owner:HUNAN CHANGYUAN LICO CO LTD +2

Positive electrode slurry, preparation method thereof, positive electrode sheet and lithium ion battery

InactiveCN109888174AImprove electrochemical performanceHigh capability densityMaterial nanotechnologyElectrode manufacturing processesOrganic solventAdhesive

The invention relates to a positive electrode slurry, a preparation method thereof, a positive electrode sheet and a lithium ion battery. The preparation method of the positive electrode slurry comprises the following steps: uniformly mixing an adhesive, carbon nanotubes and an active material to obtain the mixed dry powder; and adding an organic solvent into the mixed dry powder in batches, and stirring the organic solvent after each addition. After the first batch of organic solvent is added, the solid content of the slurry is 72% 80%, the stirring process between the addition of the first batch of organic solvent and the addition of the second batch of organic solvent is a knead process. The preparation method of the positive electrode slurry can uniformly disperse the carbon nanotubeswithout adopting a gluing process, thereby ensuring the electrochemical performance of the battery and reducing the production cost.

Owner:SOUNDON NEW ENERGY TECH CO LTD

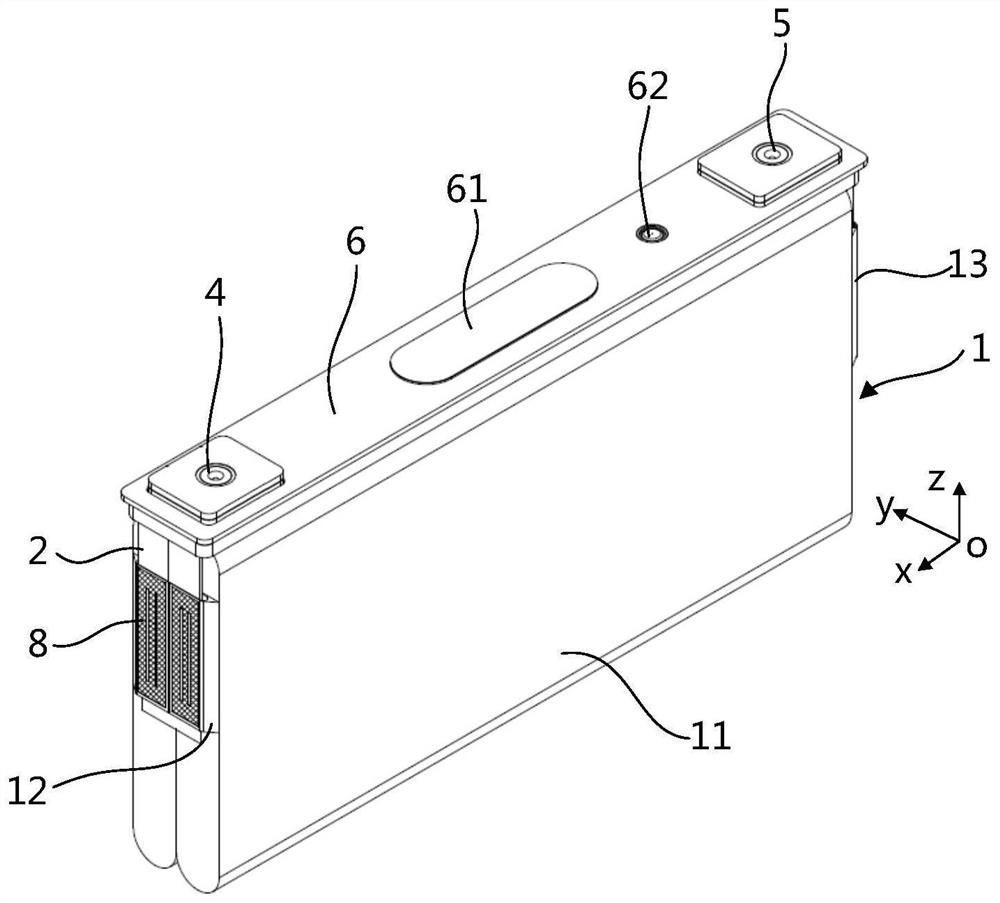

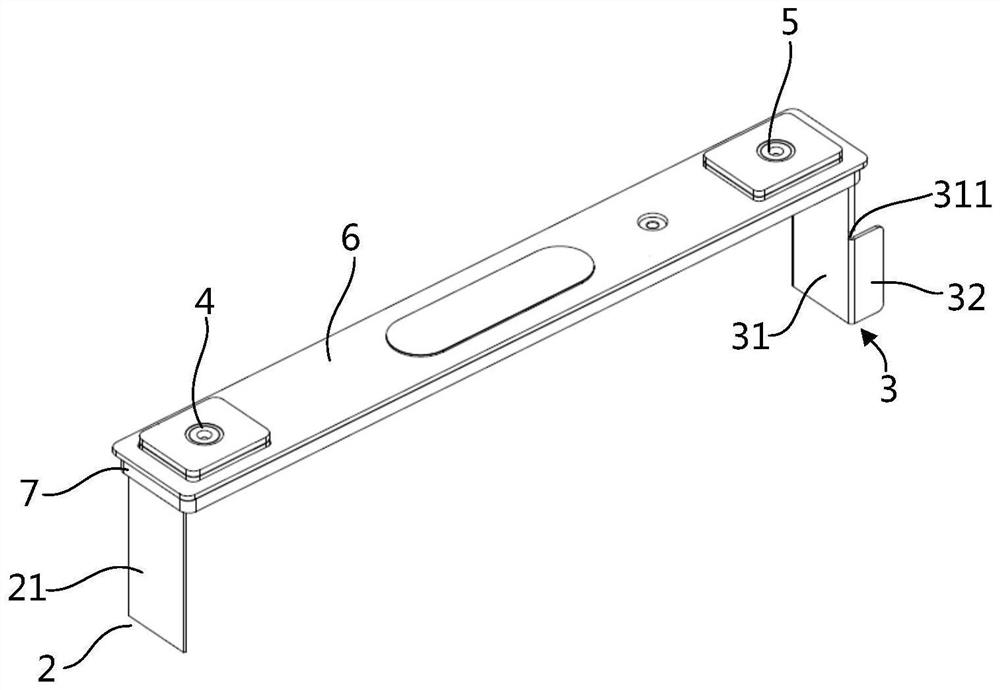

Battery unit and manufacturing method thereof and battery module

PendingCN111987340AIncrease winding spaceIncrease energy densityFinal product manufactureElectrode carriers/collectorsPhysicsEngineering

Owner:CONTEMPORARY AMPEREX TECH CO

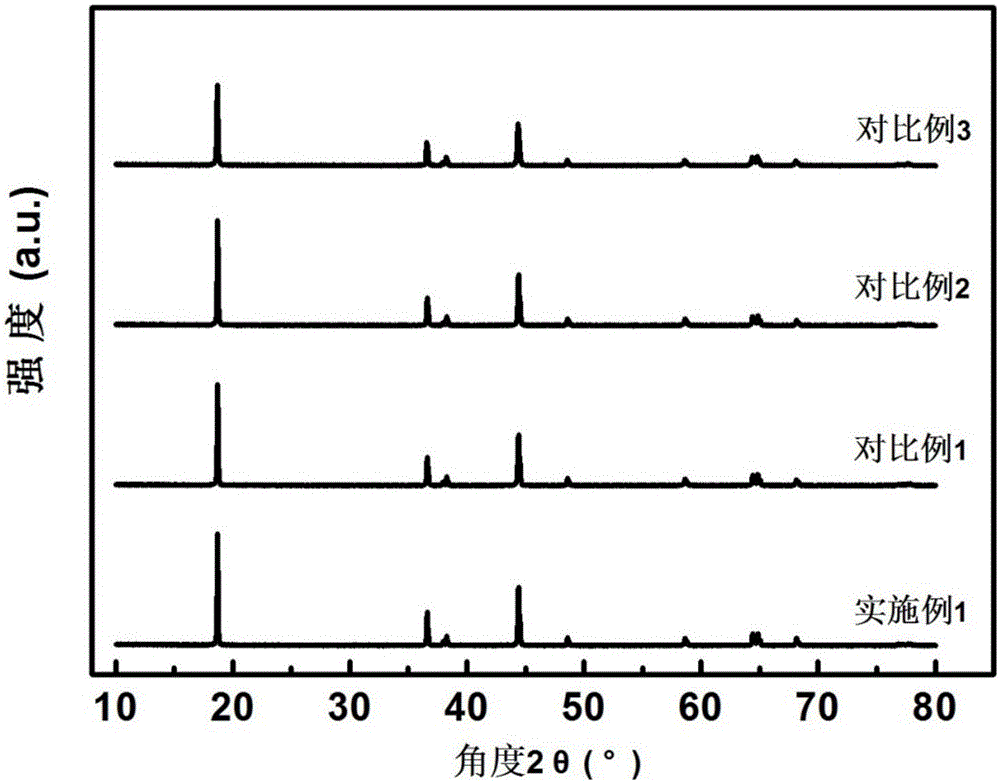

Lithium-rich multi-element positive electrode material, preparation method thereof, positive electrode and lithium ion power battery

ActiveCN111082041ALower firing temperatureGuaranteed electrochemical performanceCell electrodesSecondary cellsPower batteryLithium oxide

The invention provides a preparation method of a lithium-rich multi-element positive electrode material, which comprises the following steps: A) mixing a nickel-containing multi-element precursor witha primary lithium source, and presintering a mixture to obtain an intermediate; and the primary lithium source including one or more selected from lithium carbonate, lithium hydroxide, lithium fluoride and lithium nitrate; and B) mixing the intermediate, a secondary lithium source and an additive, and carrying out secondary sintering to obtain the lithium-rich multi-element positive electrode material, and the secondary lithium source including one or more selected from lithium carbonate, lithium hydroxide, lithium fluoride and lithium nitrate. The ratio of the total amount of substance of the primary lithium source and the secondary lithium source to the amount of substance of the nickel-containing multi-component precursor is (1-2): 1; wherein the molar ratio of the primary lithium source to the secondary lithium source is (1-9): (9-1); the lithium-rich multi-element positive electrode material has a chemical formula shown as a formula I: Li < 1 + x > Ni Co Mn < c > M <d > O < 2 >. The invention also provides the lithium-rich multi-element positive electrode material, a positive electrode and a lithium ion power battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com