Coated modified positive electrode material and preparation method thereof

A positive electrode material and coating technology, applied in the field of coating modified positive electrode material and its preparation, can solve the problems of deterioration of electrochemical performance, decreased stability, destruction of crystal structure of materials, etc., and achieves easy industrialization, simple process, Good alkali-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention also provides a method for preparing the above-mentioned coated and modified positive electrode material, comprising the following steps:

[0022] Mix the high-nickel base material with zinc borate and other compounds of coated elements in solid state, and mix them uniformly to obtain mixture A;

[0023] The mixture A is sintered in an atmosphere furnace to obtain a coated and modified high-nickel positive electrode material.

[0024] Wherein, the addition amount of the zinc borate is calculated according to the coating amount of B, and the coating amount of B is 0.05-0.5wt% of the high-nickel base material, preferably 0.1-0.3wt%. Other coating elements are at least one of Al, Co, W, Y, Ti, and the corresponding compounds are oxides, oxyhydroxides or hydroxides of coating elements.

[0025] Further, the amount of other coating elements is 0.01-1.0wt% of the high-nickel base material, preferably 0.1-0.5wt%.

[0026] Further, the sintering atmosphe...

Embodiment 1

[0032] Take 500g of LiNi 0.90 co 0.05 mn 0.045 Zr 0.005 o 2 Matrix matrix, add 7.16g of 2ZnO·3B 2 o 3 , which is equivalent to adding 0.25% of B, then adding 5.42g of Al(OH) 3 , equivalent to the addition of Al element is 0.15%.

[0033] Mix well in a blender to obtain a mixture.

[0034] The mixture was placed in an atmosphere furnace, sintered in an oxygen atmosphere, and heated to 300°C for 18 hours; after cooling, it was sieved to obtain LiNi coated with B, Zn and Al 0.90 co 0.05 mn 0.045 Zr 0.005 o 2 Ternary material.

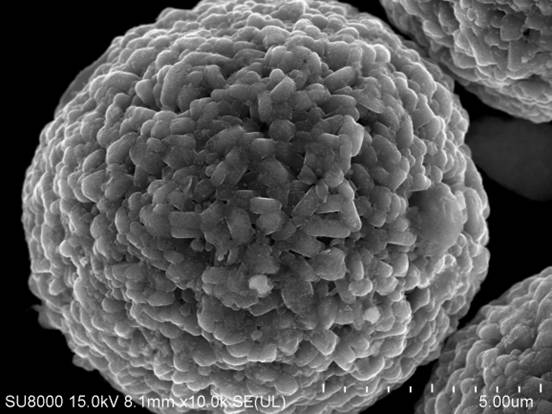

[0035] figure 1 The SEM image of the positive electrode material prepared in Example 1, it can be seen from the figure that the surface of the positive electrode material has a uniform coating layer.

Embodiment 2

[0041] Take 500g of LiNi 0.96 co 0.02 mn 0.01 Mg 0.005 Ti 0.005 o 2 matrix, adding 5.73g of 2ZnO·3B 2 o 3 , which is equivalent to adding 0.2% of B, then adding 2.52g of WO 3 , which is equivalent to adding 0.4% of the W element.

[0042] Mix well in a blender to obtain a mixture.

[0043]The mixture was sintered in an oxygen atmosphere, heated to 400°C for 15 hours at a constant temperature; after cooling, it was sieved to obtain LiNi coated with B, Zn and W 0.96 co 0.02 mn 0.01 Mg 0.005 Ti 0.005 o 2 Ternary material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com