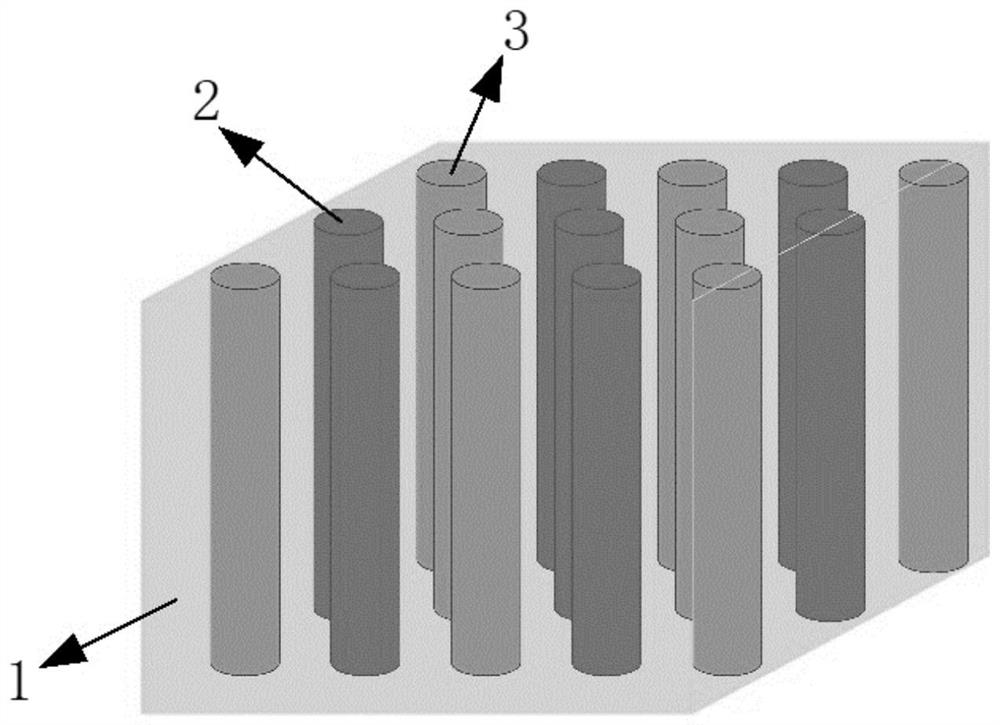

Three-dimensional lithium battery preparation method based on direct writing forming 3D printing technology

A technology of direct writing molding and 3D printing, which is applied in the manufacture of lithium batteries, electrolyte batteries, secondary batteries, etc. It can solve the problems of large-scale and batch manufacturing, industrialization restrictions, and high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of positive and negative electrode inks and gel electrolyte inks for lithium batteries

[0045] Positive electrode ink: Weigh LiMn2O4, sodium carboxymethylcellulose, carbon black, deionized water and 1,4-dioxane respectively according to the mass percentage of 30:7:8:20:35, fully mechanically stir, and prepare a Positive ink with shear thinning rheology;

[0046] Negative electrode ink: Weigh Li4Ti5O12, sodium carboxymethylcellulose, carbon black, deionized water and 1,4-dioxane respectively according to the mass percentage of 30:7:8:20:35, fully mechanically stir, and prepare to have Negative ink with shear thinning rheology;

[0047] Gel electrolyte ink: mix 10 μm boron nitride particles with polyvinylidene fluoride-hexafluoropropylene, dimethylformamide and 1,4 dioxane in a mass ratio of 6:1:1.5:1, and Sufficient mechanical agitation configures the electrolyte ink with shear-thinning rheology.

[0048] Print Gel Electrolyte Blocks

[0049] Use the 3D ...

Embodiment 2

[0059] Preparation of positive and negative electrode inks and gel electrolyte inks for lithium batteries

[0060] Positive electrode ink: Weigh LiCoMnO4, polyvinyl alcohol, carbon black, deionized water and 1,4 dioxane respectively according to the mass percentage of 35:3:2:35:25, fully mechanically stir, and prepare to have a shear strain Positive ink with dilute rheology;

[0061] Negative electrode ink: Weigh Nb2O5, polyvinyl alcohol, carbon black, deionized water and 1,4 dioxane respectively according to the mass percentage of 35:3:2:35:25, fully mechanically stir, and prepare to have a shear deformation Negative ink with dilute rheology;

[0062] Gel electrolyte ink: mix 10μm boron nitride particles with polyvinylidene fluoride-hexafluoropropylene, dimethylformamide and 1,4 dioxane at a mass ratio of 5:1:1:1, and configure into electrolyte inks with shear-thinning rheology.

[0063] Print Gel Electrolyte Blocks

[0064] Use the 3D printing layering software Simplify3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com